Professional Documents

Culture Documents

DataSheetSpec YVFA0259

DataSheetSpec YVFA0259

Uploaded by

Jorge Antonio Díaz NambrardOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DataSheetSpec YVFA0259

DataSheetSpec YVFA0259

Uploaded by

Jorge Antonio Díaz NambrardCopyright:

Available Formats

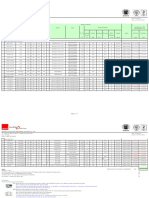

Design Conditions Datasheet

Net Cooling Nominal Refrigerant

Unit Tag Qty Model No

Capacity (kW) Voltage Type

CH-2 2 YVFA0259-OL-50 800.0 380-415/3/50.0 R-134a

PIN:

YVFA0259CS X50AAVBXXX SAKGXXXX41 54XDFXXV17 3W1SXSG2BT XCXRNOXXXX XXXFX

....5...10 ....5...20 ....5...30 ....5...40 ....5...50 ....5...60 ....5...70 ....5...80 ....5...90

Evaporator Data Free Cooling Data Performance Data

EWT (°C) 18.50 Free Cooling Type Open Loop EER (kW/kW) 3.384

LWT (°C) 12.00 Fluid Concentration N/A IPLV.IP (kW/kW) 5.390

Design Flow Rate (L/s) 31.37 NPLV.IP (kW/kW) 6.280

Total Press. Drop (kPa) 66.5

Mechanical Mode Press.

Drop (kPa)

29.4 Condenser Data Physical Data

Ethylene

Fluid 20 Ambient Temp. Design (°C) 36.2 Rigging Wt. (kg) 9820

Glycol (%)

Fouling Factor (m²K/kW) 0.0176 Altitude (m) 490 Operating Wt. (kg) 10667

VSD Screw - Semi

Fluid Volume (L) 269.0 Compressor Type Refrigerant Charge (kg) 216

Hermetic

Min. Flow Rate (L/s) 18.93

Max. Flow Rate (L/s) 51.10

Electrical Data

Circuit 1 2 3 4

Compressor kW 118.5 98

Compressor RLA 210 176

Fan QTY/FLA (each) 8 / 3.7 6 / 3.7

Single Point

Min. Circuit Ampacity 495

Max. Fuse / CB Rating (A) 700

Unit Short Circuit Withstand (STD) 65 [kA]

Wires Per Phase 3

Wire Range (Lug Size) 3/0 - 400 kcmil

Operating Condition Electrical Data

Compressor kW 216.5

Total kW 236.4

Notes:

Certified in accordance with the AHRI Air-Cooled Water-Chilling Packages Certification

Program, which is based on AHRI Standard 550/590 (I-P) and AHRI Standard 551/591 (SI).

Certified units may be found in the AHRI Directory at www.ahridirectory.org.

Unit contains freeze protection fluids in the evaporator with a leaving chilled fluid temperature

above 32 DEG F [0 DEG C] and is certified when rated per the Standard with water. Auxiliary

components included in total KW - Oil heaters, Chiller controls. Auxiliary power is already

included in the compressor and fan power

Min DSD (Factory Purpose/Use only): 91 psig

Displacement Power Factor refers to compressor only. Unit Power Factor depends on fan

option selected. Calculated value is available by request.

* 100% Free Cooling Ambient Temperature is provided for comparison purposes only. For maximum efficiency, energy optimization controls may

utilize mechanical cooling below this temperature.

Minimum and maximum evaporator flow information are for full load ratings with Ethylene Glycol.

Evaporator Passes: 2, Condenser Type: T, Fan Type: C

Total Pressure Drop includes evaporator and free cooling heat exchangers and is to be used for pump sizing.

Mechanical mode pressure drop includes the evaporator and factory provided pipework inside the chiller frame.

ASHRAE Standard 90.1-2010 and ASHRAE Standard 90.1-2013 & 2016 Compliant.

IECC 2012 and IECC 2015/2018 Compliant.

MLP Effective Date:15/11/2021 O Data STC2

Generated on2022-01-05 E.21.4.27286.0-D.93.0007(REV. v8_29.idd) Datasheet Spec

Unit Folder: CH-2 Software Version: YW21.04a Page_1_of_2

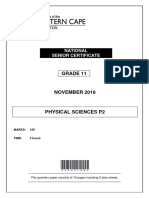

Design Conditions Datasheet

Part Load Rating Data

Unit Efficiency

Load % Ambient (°C) Capacity (kW) Total kW

(kW/kW)

100 36.2 800.0 236.4 3.384

75 27.5 600.0 125.7 4.772

50 18.7 400.0 55.28 7.237

25 12.8 200.0 * 25.04 * 7.989 *

* Values are time-averaged and include the effect of compressor cycling

Sound Power Levels (In Accordance with AHRI 370)

Ambient 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

Load % LWA

(°C) (dB) (dB) (dB) (dB) (dB) (dB) (dB) (dB)

100 36.2 93 91 90 89 86 82 76 70 91

75 27.5 89 88 88 88 85 79 74 69 89

50 18.7 86 87 84 87 84 75 70 64 88

25 12.8 86 86 85 86 81 74 69 63 87

Note: Unit is equipped with Low Sound Kit (Level 1 Reduction) and Low Profile High Efficiency Fans with Variable Speed EC motor NOTE: SQ and

Additional Lead Time Required.

Measurement of sound pressure used to obtain the sound power data presented is based on AHRI-370.

Air-cooled chillers are rated in terms of sound power not sound pressure. Johnson Controls provides estimates of sound pressure, but this is not the

rating metric.

For an air-cooled chiller, sound pressure calculated from sound power varies depending on how the chiller is assumed to behave, i.e. the radiation

model. In other words, determining sound pressure from sound power requires making assumptions that result in different answers at a given

distance from the chiller. The environment also influences sound pressure in the field installation. Sound pressure estimation radiation models

pertaining to air-cooled chillers include the ‘traditional’ hemispherical model, parallelepiped model and equivalent hemispherical model.

Regarding sound power, Johnson Controls references tolerance limits based on ASHRAE guidelines. These are +/- 6dB in the 63Hz octave band,

+/- 4dB in all other octave bands and +/- 3dB for the overall dBA.

Tolerance limits are based on uncertainties associated with:

1. Measurement Test Procedure

2. Repeatability

3. Production / Manufacturing Variability

Standard deviation associated with air-cooled chiller sound data is a measure of spread i.e. it indicates the range of probability of sound levels.

Note that for operating conditions other than AHRI’s Standard Rating Condition, higher levels of uncertainty can be expected.

Lead times for factory performance testing depend on test laboratory availability. Please confirm with Johnson Controls Customer Service.

Performance at AHRI Conditions

Evaporator Data Condenser Data Performance Data

EWT (°C) 12.22 Ambient Temp. (°C) 35.0 EER (kW/kW) 3.079

LWT (°C) 6.67 Altitude (m) 0.000 IPLV.IP (kW/kW) 5.390

Net Cooling Capacity

Flow Rate (L/s) 34.35 800.0

(kW)

Pressure Drop (kPa) 32.2

Fluid Water

Fouling Factor (m²K/kW) 0.0176

Fluid Volume (L) 269.0

Note: Unit rated at design condition capacity.

Note: YVFA with open loop requires use of glycol for freeze protection. IPLV information is provided for comparison purposes only.

MLP Effective Date:15/11/2021 O Data STC2

Generated on2022-01-05 E.21.4.27286.0-D.93.0007(REV. v8_29.idd) Datasheet Spec

Unit Folder: CH-2 Software Version: YW21.04a Page_2_of_2

You might also like

- Laws of Thermodynamics Lesson PlanDocument4 pagesLaws of Thermodynamics Lesson PlanDANDY DUMAYAONo ratings yet

- Vam DaikinDocument146 pagesVam Daikinntt_1219870% (1)

- Rcuf250wzpy (7-12, 37-32)Document2 pagesRcuf250wzpy (7-12, 37-32)Đức Anh NguyễnNo ratings yet

- Performance Chiller HG QueretaroDocument2 pagesPerformance Chiller HG QueretaroAntonio Chavez GarciaNo ratings yet

- 158TR Chiller Selection PDFDocument2 pages158TR Chiller Selection PDFabdullah amanullahNo ratings yet

- YVAA0233 (MTY) at 95 F - DataSheetSpecDocument2 pagesYVAA0233 (MTY) at 95 F - DataSheetSpecMohammed EmamNo ratings yet

- Folha de Dados Do Chiller YVAA0270DUF28BAVBXXDocument3 pagesFolha de Dados Do Chiller YVAA0270DUF28BAVBXXAdler LinharesNo ratings yet

- PERFORMANCEDocument3 pagesPERFORMANCEDanielNo ratings yet

- Screw Chiller Report: Unit InformationDocument8 pagesScrew Chiller Report: Unit InformationYosephanderNo ratings yet

- Aquaforce: Detailed Performance Summary For Untitled1Document3 pagesAquaforce: Detailed Performance Summary For Untitled1RikiNo ratings yet

- Chiller Tornilo - 205TR MIDEADocument5 pagesChiller Tornilo - 205TR MIDEAKatherine León ValverdeNo ratings yet

- Selection Sheet - 100Document1 pageSelection Sheet - 100SAI HVAC SYSTEMNo ratings yet

- Euroklimat Centrifugal Chiller Ekdc750b3Document3 pagesEuroklimat Centrifugal Chiller Ekdc750b3EddieNo ratings yet

- DCLCDV850EDocument3 pagesDCLCDV850EzordicksNo ratings yet

- Chiller Giai Nhiet Nuoc PDFDocument8 pagesChiller Giai Nhiet Nuoc PDFHa CongNo ratings yet

- Selection of Water Cooled Chiller - 221 TR PDFDocument2 pagesSelection of Water Cooled Chiller - 221 TR PDFcalvin.bloodaxe4478No ratings yet

- 200RT - Hxev400dsttg (10PK) PDFDocument2 pages200RT - Hxev400dsttg (10PK) PDFSiva NyanamNo ratings yet

- YVAA0178CAV50 - Performance ChartDocument2 pagesYVAA0178CAV50 - Performance Chartmoejamal80No ratings yet

- Detailed Performance Summary: Input DataDocument3 pagesDetailed Performance Summary: Input DataSebastian Muñoz GonzalezNo ratings yet

- AVX-B Performance (Vertical Compressor)Document4 pagesAVX-B Performance (Vertical Compressor)Inzamam ShithilNo ratings yet

- 370RT Heat RecoveryDocument2 pages370RT Heat Recoveryasl91No ratings yet

- KINGSUN CTI Certified (HKD) Cross-Flow Cooling Tower CatalogueDocument9 pagesKINGSUN CTI Certified (HKD) Cross-Flow Cooling Tower CataloguehyperchandikaNo ratings yet

- 350RT - Hxev490tstgg - 14-7.5 29.5-34.6C VPF60Document3 pages350RT - Hxev490tstgg - 14-7.5 29.5-34.6C VPF60muhammad saqib IlyasNo ratings yet

- Sierra02-0716y3 Data SheetDocument6 pagesSierra02-0716y3 Data SheetjonathanNo ratings yet

- Air Cooled Scroll Chiller Performance Specification: EFR 28 1 YCAL0028EE28 28.2 230/3/60 R410ADocument2 pagesAir Cooled Scroll Chiller Performance Specification: EFR 28 1 YCAL0028EE28 28.2 230/3/60 R410ACesar CamachoNo ratings yet

- 30RB0262 Partload Chiller DataDocument3 pages30RB0262 Partload Chiller Datacalvin.bloodaxe4478No ratings yet

- Chiller Data SheetDocument1 pageChiller Data SheetDevendra DhumalNo ratings yet

- 500TR Serie Contra Fluxo - Maquina de Saida - XW4004HC3BD12SO FL IPLV NPLV e LL - 380VDocument3 pages500TR Serie Contra Fluxo - Maquina de Saida - XW4004HC3BD12SO FL IPLV NPLV e LL - 380VSergio AlvarezNo ratings yet

- Chiller Tonillo Daikin WGS190A - Technical Data SheetDocument2 pagesChiller Tonillo Daikin WGS190A - Technical Data SheetMatthew OlsenNo ratings yet

- 1Document3 pages1ntt_121987No ratings yet

- Water Cooled Centrifugal Chiller: Technical Data SheetDocument2 pagesWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiNo ratings yet

- Sample For Heat Load CalculationDocument6 pagesSample For Heat Load CalculationKannan VivekNo ratings yet

- Blower Selection For PharmaDocument1 pageBlower Selection For PharmaKasturirangan NarayananNo ratings yet

- 1.ChillerTechnicalData 1 1Document2 pages1.ChillerTechnicalData 1 1Nguyên Trịnh CaoNo ratings yet

- Air Handling Unit / Pre-Cool Air Handling Unit: Field Test ReportDocument1 pageAir Handling Unit / Pre-Cool Air Handling Unit: Field Test ReportNaynyi MinNo ratings yet

- CCTV - CVHG780-CN123 - Product ReportDocument2 pagesCCTV - CVHG780-CN123 - Product ReportTân NguyễnNo ratings yet

- Mockup T510Document5 pagesMockup T510ardiansyah marwanNo ratings yet

- Ahu-1, 1500CFMDocument1 pageAhu-1, 1500CFMChandra SekharNo ratings yet

- Arzel Zoning Bypass CalculatorDocument6 pagesArzel Zoning Bypass CalculatorVíctor RojasNo ratings yet

- Ahu 6 Alternate ArrangementDocument4 pagesAhu 6 Alternate Arrangementnaresh100% (1)

- Infrared Sensor Controller: AHU Control BoxDocument1 pageInfrared Sensor Controller: AHU Control Boxmarco demonteNo ratings yet

- AHU SizingDocument8 pagesAHU Sizingmohammad hamdanNo ratings yet

- Ah HVAC System 04Document41 pagesAh HVAC System 04A OmairaNo ratings yet

- Cooling Load Estimation TableDocument2 pagesCooling Load Estimation TableeimanNo ratings yet

- Air To Air Heat Transfer TypesDocument20 pagesAir To Air Heat Transfer TypesSantosh TamangNo ratings yet

- 1.0) Design Flow: Rectangle R.C.Open DrainDocument1 page1.0) Design Flow: Rectangle R.C.Open DrainjjdavidNo ratings yet

- Design & Analysis of Exhaust Heat Recovery SystemDocument9 pagesDesign & Analysis of Exhaust Heat Recovery SystemGRD JournalsNo ratings yet

- Process Specification Heat Exchanger CpeccDocument2 pagesProcess Specification Heat Exchanger CpeccroyNo ratings yet

- Hvac Tds StatusDocument2 pagesHvac Tds StatusRavi VermaNo ratings yet

- Site Comments Datasheets-DG SetDocument14 pagesSite Comments Datasheets-DG Setavinashpratap100% (1)

- Chiller Selection Building A+j Cooling Only Rev 2Document7 pagesChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedNo ratings yet

- Selection Output 30XW0902PDocument1 pageSelection Output 30XW0902PLuffyVeraAghestyNo ratings yet

- Coil Selection For 38 TR Ahu r0 18.12.2006Document2 pagesCoil Selection For 38 TR Ahu r0 18.12.2006Mohsin ShaikhNo ratings yet

- Load Calculation Sheet - 071 Dve - Cw3 - 001Document16 pagesLoad Calculation Sheet - 071 Dve - Cw3 - 001jeerashetNo ratings yet

- Final Design Values of PHE C-510 CoolersDocument4 pagesFinal Design Values of PHE C-510 CoolersRamji MishraNo ratings yet

- Heatload Summary Sheet - Standard Sgu Adp 54Document5 pagesHeatload Summary Sheet - Standard Sgu Adp 54Mihir SaveNo ratings yet

- Sweety Home T&C Form PDFDocument4 pagesSweety Home T&C Form PDFHtin Aung KyawNo ratings yet

- Data Sheet 30HP MVN-90 03TR, TCV 1 PUMPSETDocument3 pagesData Sheet 30HP MVN-90 03TR, TCV 1 PUMPSETAnggara PangestuNo ratings yet

- Relief Valve SizingDocument3 pagesRelief Valve SizingcutefrenzyNo ratings yet

- Water Cooled Reciprocating Chiller Data - 30HRC070Document1 pageWater Cooled Reciprocating Chiller Data - 30HRC070calvin.bloodaxe4478No ratings yet

- Yvaa0490 Performance SheetDocument2 pagesYvaa0490 Performance Sheetkdpmansi0% (1)

- FanWall Manual InstalacionDocument53 pagesFanWall Manual InstalacionJorge Antonio Díaz NambrardNo ratings yet

- P2100SU-182 Technical Data SheetDocument4 pagesP2100SU-182 Technical Data SheetJorge Antonio Díaz NambrardNo ratings yet

- Master in Integrated Building SystemsDocument4 pagesMaster in Integrated Building SystemsJorge Antonio Díaz NambrardNo ratings yet

- P2100SU-182 Technical Data SheetDocument4 pagesP2100SU-182 Technical Data SheetJorge Antonio Díaz NambrardNo ratings yet

- For Revit MEPDocument28 pagesFor Revit MEPJorge Antonio Díaz NambrardNo ratings yet

- Ansi Ashrae 62Document11 pagesAnsi Ashrae 62Jorge Antonio Díaz NambrardNo ratings yet

- Lemonade: Amy GibsonDocument2 pagesLemonade: Amy GibsonJorge Antonio Díaz NambrardNo ratings yet

- AF Daikin PL - B 60 HZ - EN WebDocument2 pagesAF Daikin PL - B 60 HZ - EN WebTatiana DiazNo ratings yet

- DryerFT Fox Thermal Spec Bulletin FT4X DatasheetDocument8 pagesDryerFT Fox Thermal Spec Bulletin FT4X DatasheetAllisonNo ratings yet

- Studies On Drying Kinetics of Solids in A Rotary DryerDocument6 pagesStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhNo ratings yet

- Thermodynamics Vol. LLDocument673 pagesThermodynamics Vol. LLJoshua McDonaldNo ratings yet

- Chapter 2 - Steady Heat Conduction PDFDocument62 pagesChapter 2 - Steady Heat Conduction PDFAroon KumarNo ratings yet

- Transport Properties of Foods - G. D. Sanauacos & Z. B. MaroulisDocument427 pagesTransport Properties of Foods - G. D. Sanauacos & Z. B. MaroulisElí Leiton100% (1)

- 11 Sci P2 Nov 16Document15 pages11 Sci P2 Nov 16Levi JohnsonNo ratings yet

- Kinetic TheoryDocument20 pagesKinetic Theorykishorkumarn8212No ratings yet

- Manual Termobalanza ShimadzuDocument61 pagesManual Termobalanza ShimadzuRoger Dominguez vi no no ijlñNo ratings yet

- Condensers Control and Reclaim VOCsDocument3 pagesCondensers Control and Reclaim VOCsgpcshfNo ratings yet

- Student Support MaterialDocument333 pagesStudent Support MaterialRohit KumarNo ratings yet

- Lecture 06Document8 pagesLecture 06محمد حسينNo ratings yet

- Eldom Fisa TehnicaDocument1 pageEldom Fisa TehnicadoggovyNo ratings yet

- Chapter 3-Thermodynamics FinalDocument20 pagesChapter 3-Thermodynamics FinalMURALIGOCAM_29070605No ratings yet

- 033 BOD IncubatorDocument4 pages033 BOD Incubatorbhavna sharmaNo ratings yet

- Thermal Stress MonitoringDocument78 pagesThermal Stress MonitoringSIVA KAVYANo ratings yet

- Daikin VRV IV-i Installation and Operation Manual EngDocument44 pagesDaikin VRV IV-i Installation and Operation Manual EngRayhan SayeedNo ratings yet

- Class 12 - Physics (Complete Notes)Document281 pagesClass 12 - Physics (Complete Notes)Sadiq HameedNo ratings yet

- Refrigerating, Ventilating and Air Conditioning, SI Edition. AtlantaDocument3 pagesRefrigerating, Ventilating and Air Conditioning, SI Edition. Atlantaibnu hajarNo ratings yet

- Bsc. Csit Entrance Mock Test - Ii: Saral Notes Presents in Association With Iit NepalDocument4 pagesBsc. Csit Entrance Mock Test - Ii: Saral Notes Presents in Association With Iit NepalPravat PokharelNo ratings yet

- Heat Transfer: Physical Origins and Rate EquationsDocument29 pagesHeat Transfer: Physical Origins and Rate EquationsAllyth AlqhtaniNo ratings yet

- Sunbeam Generator Internship ReportDocument16 pagesSunbeam Generator Internship ReportChibi Raja100% (2)

- Wollo University Kombolcha Institute of Technology Chemical Engineering DepartmentDocument39 pagesWollo University Kombolcha Institute of Technology Chemical Engineering Departmentየነበር ነበር በነበርNo ratings yet

- DSP High PDFDocument41 pagesDSP High PDFsahidudin100% (2)

- Samsung Refrigerator RF263BEAESR-AA Service ManualDocument105 pagesSamsung Refrigerator RF263BEAESR-AA Service ManualTheodore Avdursekz100% (2)

- ASTM D 36-95-Softening Point of Bitumen (Ring-and-Ball Apparatus) E (Document4 pagesASTM D 36-95-Softening Point of Bitumen (Ring-and-Ball Apparatus) E (anjanaNo ratings yet

- Hcu 40Document12 pagesHcu 40Alex Railean0% (1)

- BOSCH B20CS50 (Geladeira) PDFDocument71 pagesBOSCH B20CS50 (Geladeira) PDFatomo33No ratings yet

- Chapter 2Document29 pagesChapter 2Bilal shahzadNo ratings yet