Professional Documents

Culture Documents

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

Uploaded by

Daniel IonasCopyright:

Available Formats

You might also like

- A07-Za-E-7002757 BGH A SGB ApprovedDocument107 pagesA07-Za-E-7002757 BGH A SGB ApprovedRAMIL50% (2)

- Our House Is On FireDocument45 pagesOur House Is On FireKatharina J. MuhrNo ratings yet

- Standard Operating Procedure For (MAINTENANCE SM)Document6 pagesStandard Operating Procedure For (MAINTENANCE SM)JCSNo ratings yet

- Hazards and Operability (Hazop) Review: Dps Document No.Document143 pagesHazards and Operability (Hazop) Review: Dps Document No.Immanuel100% (1)

- Cruise PerformanceDocument23 pagesCruise PerformanceÁlvaro Arroyo ParejoNo ratings yet

- ElastisiteDocument2 pagesElastisiteEray KoçNo ratings yet

- 4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDocument9 pages4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument11 pages4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument9 pages4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDocument9 pages4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDocument10 pages4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDocument6 pages4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDaniel IonasNo ratings yet

- Comments Response Sheet (CRS) : Page 1 of 5Document27 pagesComments Response Sheet (CRS) : Page 1 of 5Idris SiddiquiNo ratings yet

- 4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDocument8 pages4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- R-07-046 Flaktwoods GSK R&D InstBal 110907Document9 pagesR-07-046 Flaktwoods GSK R&D InstBal 110907SarafianNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- 页面提取自-toaz.info itp fw for civil amp building works 2Document3 pages页面提取自-toaz.info itp fw for civil amp building works 2Kevin TangNo ratings yet

- CSU Findings Recommendation and Closure Log (17 Dec 2020) THRDocument19 pagesCSU Findings Recommendation and Closure Log (17 Dec 2020) THRREHAN IQBALNo ratings yet

- 4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDocument7 pages4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- PM - Usermanul - Shutdown MaintenanceDocument23 pagesPM - Usermanul - Shutdown MaintenanceHarshvardhan RajawatNo ratings yet

- DSV ALVIN LARS FEA Tech AssistDocument6 pagesDSV ALVIN LARS FEA Tech AssistJulio Andrés Casal RamosNo ratings yet

- Was Alb Aeb MST Ar 0009 2 PDFDocument66 pagesWas Alb Aeb MST Ar 0009 2 PDFChris EnyinnayaNo ratings yet

- N-G-HE 250: Relief Device Design Basis and Verification RequirementsDocument7 pagesN-G-HE 250: Relief Device Design Basis and Verification RequirementsMEGAN ASBROCKNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- 04 - 03 - Annex C - Maintenance Plan - Ver03Document2 pages04 - 03 - Annex C - Maintenance Plan - Ver03ELILTANo ratings yet

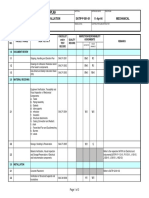

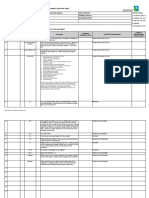

- Working Procedure: Trial Compaction Subbase & Base Course Lampunut North Road (Haju Junction To Beriwit River)Document10 pagesWorking Procedure: Trial Compaction Subbase & Base Course Lampunut North Road (Haju Junction To Beriwit River)Gilang Naufal AlipandieNo ratings yet

- ABC-SFOP-36 Fall Protection PlanDocument25 pagesABC-SFOP-36 Fall Protection PlanShafie ZubierNo ratings yet

- DNV RP-H102 (2004)Document22 pagesDNV RP-H102 (2004)m nur egaNo ratings yet

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabDocument19 pagesMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaNo ratings yet

- Punch List ProcedureDocument18 pagesPunch List ProcedureAnu Jose50% (2)

- Distribution Boards Method Statement Approval - SubmissionDocument20 pagesDistribution Boards Method Statement Approval - SubmissionKalesha Vali ShaikNo ratings yet

- MPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantDocument1 pageMPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantMaria Geraldine Zervoulakos100% (1)

- Satip D 100 01Document11 pagesSatip D 100 01Mirza BaigNo ratings yet

- A285mel1 Na1 L DWG 0001 01 A4 Code 1Document3 pagesA285mel1 Na1 L DWG 0001 01 A4 Code 1Gajendra KumarNo ratings yet

- SATIP-F-001-01 Fired Heaters Field InstallationDocument3 pagesSATIP-F-001-01 Fired Heaters Field InstallationhossamalsherbinyNo ratings yet

- 5691 Gen Sa RPT 0016 0Document8 pages5691 Gen Sa RPT 0016 0ĐiệnBiênNhâmNo ratings yet

- Technical Appendix A - The A-Vdgs System Requirements DefinitionDocument26 pagesTechnical Appendix A - The A-Vdgs System Requirements DefinitionRahul RanaNo ratings yet

- Facilities Required by Ats: Air Traffic Services Planning ManualDocument47 pagesFacilities Required by Ats: Air Traffic Services Planning ManualKhauhelo LesekeleNo ratings yet

- CRS - MSJSA For Lube Oil Flushing 43Document3 pagesCRS - MSJSA For Lube Oil Flushing 43Riaz Ali Khan BangashNo ratings yet

- Subject Comments: A、 ReferencesDocument6 pagesSubject Comments: A、 ReferencesSuman BajracharyaNo ratings yet

- Method Statement - Excavation, Bracing & Backfilling WorksDocument10 pagesMethod Statement - Excavation, Bracing & Backfilling WorksKamal Deo ShahNo ratings yet

- SOF June 2021Document4 pagesSOF June 2021Syed ZabiullahNo ratings yet

- 05 - Zonal & L-HIRF PrinciplesDocument64 pages05 - Zonal & L-HIRF PrinciplesAsaadNo ratings yet

- VP Groundforce Technical BrochureDocument146 pagesVP Groundforce Technical BrochureAhsan MushtaqNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- Subject Comments: A、 ReferencesDocument6 pagesSubject Comments: A、 ReferencesSuman BajracharyaNo ratings yet

- DRC - Installation of Fire Dampers-Me-0008Document3 pagesDRC - Installation of Fire Dampers-Me-0008Altaf KhanNo ratings yet

- MS002 ST Rep 076 00016Document78 pagesMS002 ST Rep 076 00016DavisTranNo ratings yet

- Grund ForceDocument150 pagesGrund ForceFabrizio MansuetoNo ratings yet

- EN-769-PL-1828 - Rev A - Short Service Employees ProgramDocument14 pagesEN-769-PL-1828 - Rev A - Short Service Employees ProgramSkinhead TvNo ratings yet

- Titan Series Operatin Manual PDFDocument87 pagesTitan Series Operatin Manual PDFAnonymous rI9kkru5No ratings yet

- Electrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Document40 pagesElectrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Alif Rahmat FebriantoNo ratings yet

- AA5373.09-MS002 Rev 0 PDFDocument41 pagesAA5373.09-MS002 Rev 0 PDFanisaan100% (2)

- SOW BMS Rectification - Upgradation - AJRE-REV1Document7 pagesSOW BMS Rectification - Upgradation - AJRE-REV1Hariharan NatarajanNo ratings yet

- SN-7537-MA-Technical ReportDocument86 pagesSN-7537-MA-Technical Reportomar cisséNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- First PageDocument1 pageFirst PageDaniel IonasNo ratings yet

- 4763.420.0006 Rev.01 - Land Transportations - Client Aiding Documentary Guidelines - UnlockedDocument8 pages4763.420.0006 Rev.01 - Land Transportations - Client Aiding Documentary Guidelines - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDocument7 pages4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDocument9 pages4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDocument10 pages4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0004.F&WTG Rev.01 - Self Elevating Units Operations - UnlockedDocument7 pages4763.420.0004.F&WTG Rev.01 - Self Elevating Units Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDocument9 pages4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument9 pages4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDocument8 pages4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0008.C Rev.01 - Cables Installation Operations - UnlockedDocument9 pages4763.420.0008.C Rev.01 - Cables Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDocument6 pages4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- Technical Policy BoardDocument15 pagesTechnical Policy BoardDaniel IonasNo ratings yet

- 4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument11 pages4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- Aire Premium Delta 8 Vape - 1000mg - Everything 420Document1 pageAire Premium Delta 8 Vape - 1000mg - Everything 4206hsphckmf8No ratings yet

- Research Paper Example in Citation Guide PDFDocument6 pagesResearch Paper Example in Citation Guide PDFDm Wivinny JesonNo ratings yet

- PEH Pre-Finals ReviewerDocument1 pagePEH Pre-Finals ReviewerMaribeth Alyssa GoNo ratings yet

- Graded Quesions Complete Book0Document344 pagesGraded Quesions Complete Book0Irimia Mihai Adrian100% (1)

- Loans and MortgagesDocument26 pagesLoans and Mortgagesparkerroach21No ratings yet

- Policy For Take-Back ProgramDocument16 pagesPolicy For Take-Back ProgramShaswat SrivastavaNo ratings yet

- IoT LAB #2Document8 pagesIoT LAB #2HALIMANo ratings yet

- All Pass Comb FiltersDocument13 pagesAll Pass Comb Filterspho144No ratings yet

- Catalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ADocument36 pagesCatalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ALuis Eugenio Hernandez QuijaiteNo ratings yet

- Media Preparation and Uses in Medical MicrobiologyDocument20 pagesMedia Preparation and Uses in Medical MicrobiologyPrincewill SeiyefaNo ratings yet

- Manual Leroy Somer Generator Lsa 50 l8Document28 pagesManual Leroy Somer Generator Lsa 50 l8Carlos Andre Sante MancillaNo ratings yet

- AVCN1 Full BDocument395 pagesAVCN1 Full BPhương TrungNo ratings yet

- Wallenberg's BlizzBaller - Diablo 2 at Diablo2Document9 pagesWallenberg's BlizzBaller - Diablo 2 at Diablo2kuntokinteNo ratings yet

- CIV2037F Additional QuestionsDocument3 pagesCIV2037F Additional QuestionsquikgoldNo ratings yet

- Chalno Meaning v2Document1 pageChalno Meaning v2Roldan WilfridoNo ratings yet

- Halliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsDocument51 pagesHalliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsOlimpiade InfoNo ratings yet

- Plum CalculationDocument33 pagesPlum CalculationMido MagicNo ratings yet

- Cash Flow StatementDocument16 pagesCash Flow Statementrajesh337masssNo ratings yet

- Geothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowDocument1 pageGeothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowImmanuel Lumban GaolNo ratings yet

- Part 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportDocument52 pagesPart 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportToby ChessonNo ratings yet

- Love Marriage Vs Arranged Marriage EssayDocument8 pagesLove Marriage Vs Arranged Marriage Essayezmt6r5c100% (1)

- Python Interview QuestionsDocument2 pagesPython Interview Questionsriyaz husainNo ratings yet

- Saep 358Document17 pagesSaep 358Adel SulimanNo ratings yet

- CS Form No. 4 Certification of Assumption To Duty (Enteria)Document5 pagesCS Form No. 4 Certification of Assumption To Duty (Enteria)Concepcion MpsNo ratings yet

- Wealth Management AssignmentDocument2 pagesWealth Management AssignmentHimanshu BajajNo ratings yet

- Health: Quarter 3 - Module 1Document18 pagesHealth: Quarter 3 - Module 1Kimran C. De JesusNo ratings yet

- The 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, CODocument17 pagesThe 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, COzhikNo ratings yet

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

Uploaded by

Daniel IonasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

4763.420.0003.OSS Rev.01 - Off-Shore Installation Operations - Unlocked

Uploaded by

Daniel IonasCopyright:

Available Formats

Page | 1 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance

Document Number: 4763.420.Doc.0003.OSS

Revision Date Prepared by Approved by

01 05.November.2013 Mircea Lucian PAVEL Thomas HOFFMANN

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 2 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Below Items are meant to offer Guidance in preparing Off-shore Installation

Operations related documents to be presented to GL-Noble Denton for acceptance.

In order to facilitate document issuing, review and acceptance process, documents shall be submitted in

Coherent Manuals, Analyses or Calculation Reports. This means, when information is directly connected to a

certain topics it shall be included in the related Manual or Report.

For Off-shore Installation Operations, the following documents shall be put together by the Client and be

presented for review / acceptance:

B.5.1a) Installation Manual / Procedure 1

B.5.2a) Cargo Structural Analysis during Temporary Condition (i.e. Installation) 2

Advis-

To be able to

de- be also

Ref. Class / Sub-Class Description tailed shortly

within refer-

… enced

in…

A General Operational Considerations

A.1 Weather forecast 48 hrs + 12 hrs or as per Operation Bar-Chart (and also 1

taking into account a reasonable contingency)

A.2 Detailed Method Statement of the Operation 1

A.3 Each stage of the operation must be identifiable by a sequential drawing or 1

properly detailed so as to take into account the variable parameters

throughout the installation operation

A.4 Installation Sequential Operational Check-List 1

A.5 Installation Operational Risk Assessment (in relation to the cargo, including 1

preparatory work)

A.6 Operational limitations of the equipment being used (temperature limits, 1

humidity, break requirements, etc) and of the operation (maximum

inclinations, minimum metacentric height, etc)

A.7 Particulars for the mooring lines to be used 1

A.8 Particulars of all wires, mooring equipment to be used 1

A.9 Statement / report regarding deck loading capacity of the barge / vessel 1

A.10 Emergency Response Plan - Communications / Reports (Including

1

Emergency notification flowchart)

A.11 Lighting arrangements in case the operation is to be carried out by night 1

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 3 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advis-

To be able to

de- be also

Ref. Class / Sub-Class Description tailed shortly

within refer-

… enced

in…

B Structure

B.1 Structural analysis report during installation phases, including: 2

B.1.1 Structural drawings including additional loadout / off-loading steelwork (if the 2

case)

B.1.2 Reference of used software in this respect 2

B.1.3 Structural model 2 1

B.1.4 Description of cargo support conditions during temporary conditions 2

B.1.5 Load cases including derivation of weights and contingencies 2 1

B.1.6 Unity checks 2

B.1.7 Justification of over-stressed members 2

B.1.8 Detailed checks on structure support points, pad-eyes, winch connection 2 1

points, trunnions, etc (if applicable)

B.1.9 Proposals for structural reinforcements if required 2

B.2 Weight Control Report or Weighing Report results 1, 2

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 4 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

C Off-shore Site

C.1 Site plan, showing installation location / spread, position of structure(s), 1

position of the vessels / units, vessel positioning options

C.2 Details of under-keel clearance 1

C.3 Drawing(s) showing heights above datum during installation, structure support 1

points, barge and water levels

C.4 Maximum allowable out of verticality for the item(s) to be installed 1

C.5 UXO survey / seabed survey for the locations where anchors are to be 1

dropped or objects to be installed in contact with the seabed.

C.6 Method of fendering between the vessels / units if they are to be in contact 1

during installation, showing sliding or rolling surfaces

D Barge / Vessel

D.1 General arrangement and compartmentation drawings 1

D.2 Hydrostatic tables and tank tables 1

D.3 Details of class 1

D.4 Static stability at critical stages of installation 1

D.5 Static stability of the barge / vessel the cargo is lifted from will have to be 1

assessed after each lift and the compensating methods must be indicated (if

the feeding concept is applied)

D.6 Self positioning systems details for the units participating to the installation 1

operation (Dynamic Positioning systems details, anchoring systems, etc).

There should also be carried out a station keeping analysis / mooring

analysis.

D.7 In case two units are to be coupled (moored together) during the installation 1

process, details of the mooring systems of the participating units, the mooring

procedure (backed up by calculations for the design environmental criteria)

and equipment specification / identification drawing

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 5 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

E Pumps

E.1 Specification and layout of pumps, including back-up pumps 1

E.2 Pipe schematic and details of manifolds and valves where applicable 1

E.3 Pump performance curves 1

E.4 Pump functional limitations: 1

- environmental range

- other possible critical issues that might affect pump functionality

F Vessel / Barge

F.1 Planned date, time and duration of the installation, with alternative dates, 1

limitations and weather windows

F.2 Ballast calculations for each critical stage showing: 1

F.2.1 Time 1

F.2.2 Tidal level 1

F.2.3 Structure position 1

F.2.4 Weight on barge 1

F.2.5 Ballast distribution 1

F.2.6 Barge draft, trim and heel 1

F.2.7 Pumps in use, and pump rates required 1

F.2.8 Moment to change heel and trim. 1

F.3 Stages to be considered should include as a minimum: 1

F.3.1 Start condition with structure entirely onboard 1 2

F.3.2 At least 3 intermediate critical load cases considered 1 2

F.3.3 100% & 0% of weight off the vessel / barge 1 2

F.3.4 Subsequent movements on barge up to the final position. 1 2

F.4 Stages requiring movement or reconnection of pumps shall be defined. 1

F.5 Should more items installed, critical operations will be divided as per F.3 item 1

(above)

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 6 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

G Piling

G.1 Pile movements description during installation phases (upending) 1

G.2 Pile structural analysis during temporary conditions (i.e. upending and lifting) 2

G.3 Pile Drivability Study / Analysis 1 2

G.3.1 Piling location(s) soil profile(s) – geotechnical investigation / data and soil 1

conditions

G.3.2 Pile penetrations required to be reached 1

G.3.3 Pile driving equations used in the study (e.g. wave equation) 1

G.3.4 Soil conditions assessment – case by case – identification of the worst 1

expected scenario

G.3.5 Assessment: can the hammer-pile-soil system overcome the soil resistance? 1

G.4 Pile stability under different conditions (if there are piling operations during 1

installation)

G.5 Pile refusal criteria / identification / hammering limitations – corrective actions 1

(if there are piling operations during installation)

G.6 Pile and Jacket recovery / abandonment options (if there are piling operations 1

during installation)

H Lifted Installations

H.1 Justification of Weight and COG by referencing the Weight Control Report or 1

Weighing Report

H.2 Crane details, including load-radius curve with lift superimposed and details of 1

vertical and horizontal clearances

H.3 Mooring / anchoring / DP / other arrangements and thruster specification for 1

floating cranes.

H.4 For mobile cranes, position of crane at pick-up and set-down, travel route if 1

applicable, actual and allowable ground bearing pressures at installation

locations

H.5 NDT procedure of lifting attachments and connections to structure 1

H.6 If the lift points are re-used offshore, proposals for post-use inspection / NDT 1

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 7 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

H.7 Calculations and Checks:

H.7.1 Component lift points (padears, padeyes, trunnions etc.), rigging (slings, 1

shackles, spreader bars, beams, frames, etc.) should be analyzed or

reviewed to demonstrate that each component and its attachment to the

structure is adequate according to the set out loads and factors

H.7.2 Positioning Guides and Bumpers should be assessed in accordance with the 1

set out loads and factors

H.7.3 Centre of lift and centre of gravity should be vertically aligned closely enough 1

to give a tilt that will not cause overloading of any item, or clash with adjacent

modules or structures

H.7.4 Derived hook loads should be within the capacity of crane load-radius curves 1

with sufficient reserve

H.7.5 Any abnormal operational behaviour or deviation from the MWS accepted 1

procedure should be noticed – define the ways to manage the abnormality /

circuit of messages (key persons who will have to be informed / agree on the

procedural alternative deviation before resuming the installation)

H.7.6 When analyzing the lifting behaviour of submerged items, suitable 1

calculations, eventually aided by software shall be used

H.8 Structural analysis report for structure to be lifted, including lift points and any 1

spreaders. If the lifting attachments are not orientated to the centre of the lift

then misalignment must be allowed for in the structural analysis / review

H.9 Copy of crane load chart and limitations 1

H.10 Rigging arrangement package showing sling geometry, computed sling loads, 1

required breaking loads, tabulation of slings and shackles.

I Moorings - Anchoring / Positioning

I.1 Limiting design and operational weather conditions for installation / 1

Environmental criteria for the installation (including visibility and time of the

day)

I.2 Mooring - Anchoring / Positioning arrangements for installation operation and 1

post-installation / termination sequence

I.3 Calculations showing environmental loads, line tensions and attachment point 1

loads for limiting weather condition for installation, and for post-installation

moorings.

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 8 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

I.4 Specification of anchors, wires, ropes , chains and other equipment that 1

needs to be certified in order to be used

I.5 Specification equipment used for positioning and position keeping (i.e. 1

winches, anchors, securing arrangements, thrusters, etc.)

I.6 Estimated position keeping capabilities under different scenarios, including 1

redundancy arrangements for position keeping and different failure scenarios

I.7 Details of fendering including lubrication arrangements as appropriate if two 1

units are to come together during installation

I.8 Specification of any aiding thrusters to be used during the operation, when 1

and at what capacity they would function

I.9 Mooring mounting and dismantling / Winching policy and monitoring 1

I.9.1 Equalising peak tensions in upwind lines (survival conditions) 1

I.9.2 Minimising peak tensions in downwind lines 1

I.9.3 Locking off all winches / eventual self-tensioning systems details 1

I.9.4 Equalising peak tensions in upwind lines 1

I.9.5 Maintaining original position within + m 1

I.9.6 Keeping minimum tensions in certain lines to prevent contact if other lines 1

break

I.10 Minimum and maximum tensions in the mooring lines 1

I.11 Motion Excursion (in case such motion is expected considering the particulars 1

of limiting weather conditions, location configuration / exposure)

J Supporting Tugs / Vessels (if applicable)

J.1 Details / Full Particulars of any supporting tugs including bollard pull and 1

mooring / towing equipment

J.2 Arrangements and tug positions during installation 1

J.3 Means of communication with tug master(s) 1

K Management

K.1 Organogram showing management structure and responsibilities 1

K.2 Location of key personnel 1

K.3 Details of manning levels, showing adequate coverage for all operations and 1

emergency procedures

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

Page | 9 / 9

List of Information Required for

Off-shore Installation Operations Procedural Acceptance –

OSS

Advisa

To be ble to

detaile be also

Ref. Class / Sub-Class Description d shortly

within referen

… ced

in…

K.4 Times of shift changes, if applicable 1

K.5 Weather forecast arrangements 1

K.6 Communications during the operation: VHF channels, common language and 1

translators if needed

K.7 Operation bar-chart showing time and duration of all critical activities (e.g. 1

Unit movements, Initial ballasting, Structure movements, Installation

operation, Seafastening, Re-positioning, Decision points, Contingency time)

K.8 Methods of monitoring unit level and trim, and ballast quantities, including 1

consideration of hang-up between unit s or unit/off-shore pre-installed

structure

L Contingencies

L.1 Contingency plans shall be presented for all eventualities, including as 1

appropriate:

L.1.1 Pump failure 1

L.1.2 Main power supply failure 1

L.1.3 Jack-winch failure 1

L.1.8 Failure of any computerized control or monitoring system 1

L.1.9 Mooring System failure 1

L.1.10 Anchoring / Positioning System failure 1

L.1.11 Structural failure 1

L.1.12 Deteriorating weather 1

L.1.13 Crane structural or machinery failure with weight suspended 1

L.1.14 Failed installation / recovery or abort measures 1

L.1.15 Power failure for the systems taking part in the installation process or that 1

could affect it

Managing Directors: Lutz Wittenberg (Spokesman) • Andreas Schröter

Germanischer Lloyd Industrial Services GmbH, Registered Office Hamburg No. HR B 86804, VAT Reg. No. DE 228 282 604

Place of performance and jurisdiction is Hamburg. The latest edition of the General Terms and Conditions of Germanischer Lloyd Industrial Services GmbH is applicable. German law applies.

You might also like

- A07-Za-E-7002757 BGH A SGB ApprovedDocument107 pagesA07-Za-E-7002757 BGH A SGB ApprovedRAMIL50% (2)

- Our House Is On FireDocument45 pagesOur House Is On FireKatharina J. MuhrNo ratings yet

- Standard Operating Procedure For (MAINTENANCE SM)Document6 pagesStandard Operating Procedure For (MAINTENANCE SM)JCSNo ratings yet

- Hazards and Operability (Hazop) Review: Dps Document No.Document143 pagesHazards and Operability (Hazop) Review: Dps Document No.Immanuel100% (1)

- Cruise PerformanceDocument23 pagesCruise PerformanceÁlvaro Arroyo ParejoNo ratings yet

- ElastisiteDocument2 pagesElastisiteEray KoçNo ratings yet

- 4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDocument9 pages4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument11 pages4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument9 pages4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDocument9 pages4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDocument10 pages4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDocument6 pages4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDaniel IonasNo ratings yet

- Comments Response Sheet (CRS) : Page 1 of 5Document27 pagesComments Response Sheet (CRS) : Page 1 of 5Idris SiddiquiNo ratings yet

- 4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDocument8 pages4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- GT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsDocument14 pagesGT-1065 - Disconnection and Removal, #2 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- R-07-046 Flaktwoods GSK R&D InstBal 110907Document9 pagesR-07-046 Flaktwoods GSK R&D InstBal 110907SarafianNo ratings yet

- GT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsDocument20 pagesGT-1064-Disconnection and Removal, #1 Bearing Area Probes and TCPLsMadih ElghannamNo ratings yet

- 页面提取自-toaz.info itp fw for civil amp building works 2Document3 pages页面提取自-toaz.info itp fw for civil amp building works 2Kevin TangNo ratings yet

- CSU Findings Recommendation and Closure Log (17 Dec 2020) THRDocument19 pagesCSU Findings Recommendation and Closure Log (17 Dec 2020) THRREHAN IQBALNo ratings yet

- 4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDocument7 pages4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- PM - Usermanul - Shutdown MaintenanceDocument23 pagesPM - Usermanul - Shutdown MaintenanceHarshvardhan RajawatNo ratings yet

- DSV ALVIN LARS FEA Tech AssistDocument6 pagesDSV ALVIN LARS FEA Tech AssistJulio Andrés Casal RamosNo ratings yet

- Was Alb Aeb MST Ar 0009 2 PDFDocument66 pagesWas Alb Aeb MST Ar 0009 2 PDFChris EnyinnayaNo ratings yet

- N-G-HE 250: Relief Device Design Basis and Verification RequirementsDocument7 pagesN-G-HE 250: Relief Device Design Basis and Verification RequirementsMEGAN ASBROCKNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- 04 - 03 - Annex C - Maintenance Plan - Ver03Document2 pages04 - 03 - Annex C - Maintenance Plan - Ver03ELILTANo ratings yet

- Working Procedure: Trial Compaction Subbase & Base Course Lampunut North Road (Haju Junction To Beriwit River)Document10 pagesWorking Procedure: Trial Compaction Subbase & Base Course Lampunut North Road (Haju Junction To Beriwit River)Gilang Naufal AlipandieNo ratings yet

- ABC-SFOP-36 Fall Protection PlanDocument25 pagesABC-SFOP-36 Fall Protection PlanShafie ZubierNo ratings yet

- DNV RP-H102 (2004)Document22 pagesDNV RP-H102 (2004)m nur egaNo ratings yet

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabDocument19 pagesMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaNo ratings yet

- Punch List ProcedureDocument18 pagesPunch List ProcedureAnu Jose50% (2)

- Distribution Boards Method Statement Approval - SubmissionDocument20 pagesDistribution Boards Method Statement Approval - SubmissionKalesha Vali ShaikNo ratings yet

- MPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantDocument1 pageMPL - 027 Permit To Work Form - 11.02.2022 Umingan Crushing PlantMaria Geraldine Zervoulakos100% (1)

- Satip D 100 01Document11 pagesSatip D 100 01Mirza BaigNo ratings yet

- A285mel1 Na1 L DWG 0001 01 A4 Code 1Document3 pagesA285mel1 Na1 L DWG 0001 01 A4 Code 1Gajendra KumarNo ratings yet

- SATIP-F-001-01 Fired Heaters Field InstallationDocument3 pagesSATIP-F-001-01 Fired Heaters Field InstallationhossamalsherbinyNo ratings yet

- 5691 Gen Sa RPT 0016 0Document8 pages5691 Gen Sa RPT 0016 0ĐiệnBiênNhâmNo ratings yet

- Technical Appendix A - The A-Vdgs System Requirements DefinitionDocument26 pagesTechnical Appendix A - The A-Vdgs System Requirements DefinitionRahul RanaNo ratings yet

- Facilities Required by Ats: Air Traffic Services Planning ManualDocument47 pagesFacilities Required by Ats: Air Traffic Services Planning ManualKhauhelo LesekeleNo ratings yet

- CRS - MSJSA For Lube Oil Flushing 43Document3 pagesCRS - MSJSA For Lube Oil Flushing 43Riaz Ali Khan BangashNo ratings yet

- Subject Comments: A、 ReferencesDocument6 pagesSubject Comments: A、 ReferencesSuman BajracharyaNo ratings yet

- Method Statement - Excavation, Bracing & Backfilling WorksDocument10 pagesMethod Statement - Excavation, Bracing & Backfilling WorksKamal Deo ShahNo ratings yet

- SOF June 2021Document4 pagesSOF June 2021Syed ZabiullahNo ratings yet

- 05 - Zonal & L-HIRF PrinciplesDocument64 pages05 - Zonal & L-HIRF PrinciplesAsaadNo ratings yet

- VP Groundforce Technical BrochureDocument146 pagesVP Groundforce Technical BrochureAhsan MushtaqNo ratings yet

- SB 30-3143 Engine Inlet Anti-Ice Line InspectionDocument6 pagesSB 30-3143 Engine Inlet Anti-Ice Line InspectionGarrett ReeveNo ratings yet

- Subject Comments: A、 ReferencesDocument6 pagesSubject Comments: A、 ReferencesSuman BajracharyaNo ratings yet

- DRC - Installation of Fire Dampers-Me-0008Document3 pagesDRC - Installation of Fire Dampers-Me-0008Altaf KhanNo ratings yet

- MS002 ST Rep 076 00016Document78 pagesMS002 ST Rep 076 00016DavisTranNo ratings yet

- Grund ForceDocument150 pagesGrund ForceFabrizio MansuetoNo ratings yet

- EN-769-PL-1828 - Rev A - Short Service Employees ProgramDocument14 pagesEN-769-PL-1828 - Rev A - Short Service Employees ProgramSkinhead TvNo ratings yet

- Titan Series Operatin Manual PDFDocument87 pagesTitan Series Operatin Manual PDFAnonymous rI9kkru5No ratings yet

- Electrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Document40 pagesElectrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Alif Rahmat FebriantoNo ratings yet

- AA5373.09-MS002 Rev 0 PDFDocument41 pagesAA5373.09-MS002 Rev 0 PDFanisaan100% (2)

- SOW BMS Rectification - Upgradation - AJRE-REV1Document7 pagesSOW BMS Rectification - Upgradation - AJRE-REV1Hariharan NatarajanNo ratings yet

- SN-7537-MA-Technical ReportDocument86 pagesSN-7537-MA-Technical Reportomar cisséNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- 4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0007 Rev.01 - Weight Determinations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0004 Rev.02 - Self Elevating Units Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- First PageDocument1 pageFirst PageDaniel IonasNo ratings yet

- 4763.420.0006 Rev.01 - Land Transportations - Client Aiding Documentary Guidelines - UnlockedDocument8 pages4763.420.0006 Rev.01 - Land Transportations - Client Aiding Documentary Guidelines - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDocument7 pages4763.420.doc.0008 Rev.01 - Cables Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDocument9 pages4763.420.doc.0001 Rev.03 - Loadout and Off-Loading Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDocument10 pages4763.420.doc.0003 Rev.03 - Off-Shore Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0004.F&WTG Rev.01 - Self Elevating Units Operations - UnlockedDocument7 pages4763.420.0004.F&WTG Rev.01 - Self Elevating Units Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDocument6 pages4763.420.doc.0005 Rev.02 - Flexibles Installation Operations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDocument9 pages4763.420.0003.F&WTG Rev.01 - Off-Shore Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument9 pages4763.420.0001.OSS Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.OSS Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDocument8 pages4763.420.doc.0002 Rev.02 - Marine Transportations - Client Aiding Documentary GuidelinesDaniel IonasNo ratings yet

- 4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.C Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0008.C Rev.01 - Cables Installation Operations - UnlockedDocument9 pages4763.420.0008.C Rev.01 - Cables Installation Operations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDocument6 pages4763.420.0007.OSS Rev.01 - Weight Determinations - UnlockedDaniel IonasNo ratings yet

- 4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDocument9 pages4763.420.0002.F&WTG Rev.01 - Marine Transportations - UnlockedDaniel IonasNo ratings yet

- Technical Policy BoardDocument15 pagesTechnical Policy BoardDaniel IonasNo ratings yet

- 4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDocument11 pages4763.420.0001.C Rev.01 - Loadout and Off-Loading Operations - UnlockedDaniel IonasNo ratings yet

- Aire Premium Delta 8 Vape - 1000mg - Everything 420Document1 pageAire Premium Delta 8 Vape - 1000mg - Everything 4206hsphckmf8No ratings yet

- Research Paper Example in Citation Guide PDFDocument6 pagesResearch Paper Example in Citation Guide PDFDm Wivinny JesonNo ratings yet

- PEH Pre-Finals ReviewerDocument1 pagePEH Pre-Finals ReviewerMaribeth Alyssa GoNo ratings yet

- Graded Quesions Complete Book0Document344 pagesGraded Quesions Complete Book0Irimia Mihai Adrian100% (1)

- Loans and MortgagesDocument26 pagesLoans and Mortgagesparkerroach21No ratings yet

- Policy For Take-Back ProgramDocument16 pagesPolicy For Take-Back ProgramShaswat SrivastavaNo ratings yet

- IoT LAB #2Document8 pagesIoT LAB #2HALIMANo ratings yet

- All Pass Comb FiltersDocument13 pagesAll Pass Comb Filterspho144No ratings yet

- Catalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ADocument36 pagesCatalogo de Maquina de Soldar Marca Miller XMT 304 CC CV MA410427ALuis Eugenio Hernandez QuijaiteNo ratings yet

- Media Preparation and Uses in Medical MicrobiologyDocument20 pagesMedia Preparation and Uses in Medical MicrobiologyPrincewill SeiyefaNo ratings yet

- Manual Leroy Somer Generator Lsa 50 l8Document28 pagesManual Leroy Somer Generator Lsa 50 l8Carlos Andre Sante MancillaNo ratings yet

- AVCN1 Full BDocument395 pagesAVCN1 Full BPhương TrungNo ratings yet

- Wallenberg's BlizzBaller - Diablo 2 at Diablo2Document9 pagesWallenberg's BlizzBaller - Diablo 2 at Diablo2kuntokinteNo ratings yet

- CIV2037F Additional QuestionsDocument3 pagesCIV2037F Additional QuestionsquikgoldNo ratings yet

- Chalno Meaning v2Document1 pageChalno Meaning v2Roldan WilfridoNo ratings yet

- Halliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsDocument51 pagesHalliday/Resnick/Walker Fundamentals of Physics: Classroom Response System QuestionsOlimpiade InfoNo ratings yet

- Plum CalculationDocument33 pagesPlum CalculationMido MagicNo ratings yet

- Cash Flow StatementDocument16 pagesCash Flow Statementrajesh337masssNo ratings yet

- Geothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowDocument1 pageGeothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowImmanuel Lumban GaolNo ratings yet

- Part 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportDocument52 pagesPart 2 Twentieth Century Naval Dockyards Devonport and Portsmouth Characterisation ReportToby ChessonNo ratings yet

- Love Marriage Vs Arranged Marriage EssayDocument8 pagesLove Marriage Vs Arranged Marriage Essayezmt6r5c100% (1)

- Python Interview QuestionsDocument2 pagesPython Interview Questionsriyaz husainNo ratings yet

- Saep 358Document17 pagesSaep 358Adel SulimanNo ratings yet

- CS Form No. 4 Certification of Assumption To Duty (Enteria)Document5 pagesCS Form No. 4 Certification of Assumption To Duty (Enteria)Concepcion MpsNo ratings yet

- Wealth Management AssignmentDocument2 pagesWealth Management AssignmentHimanshu BajajNo ratings yet

- Health: Quarter 3 - Module 1Document18 pagesHealth: Quarter 3 - Module 1Kimran C. De JesusNo ratings yet

- The 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, CODocument17 pagesThe 3-Level Acupuncture Balance - Part 3 - More On The Eight Extraordinary Channel Balance - Dr. Jake Fratkin - Boulder, COzhikNo ratings yet