Professional Documents

Culture Documents

BTH Incremental Encoders BI-58-S10

BTH Incremental Encoders BI-58-S10

Uploaded by

kanhav joshiCopyright:

Available Formats

You might also like

- Current Best Practices For Training LLMs From Scratch - FinalDocument23 pagesCurrent Best Practices For Training LLMs From Scratch - FinalHasala MarakkalageNo ratings yet

- Introduction To ERPDocument3 pagesIntroduction To ERPmaheshNo ratings yet

- Merlin Service Ops Ap1590 66-88 PDFDocument231 pagesMerlin Service Ops Ap1590 66-88 PDFPaolo Fontanazzi100% (2)

- VSB SeriesDocument3 pagesVSB SeriesCubix AutomationNo ratings yet

- Sdurf2040cta N1636 Rev.a PDFDocument4 pagesSdurf2040cta N1636 Rev.a PDFcesarNo ratings yet

- Specifications - 700-HB Relays: Attribute 700-HB Electrical RatingsDocument1 pageSpecifications - 700-HB Relays: Attribute 700-HB Electrical RatingsArif KhanNo ratings yet

- Data Sheet For Angle Sensors: Optical Encoders Series MHL40Document6 pagesData Sheet For Angle Sensors: Optical Encoders Series MHL40bokic88No ratings yet

- EAC58EA Sensor VelocidadDocument3 pagesEAC58EA Sensor VelocidadrajalingamNo ratings yet

- Electronic Over Current Relay (EOCR)Document2 pagesElectronic Over Current Relay (EOCR)BambangsNo ratings yet

- Rotary Measuring Technology: Incremental EncodersDocument5 pagesRotary Measuring Technology: Incremental Encodersalgoga27No ratings yet

- Single Phase Short Circuit Protected Solid State Relay DatasheetDocument2 pagesSingle Phase Short Circuit Protected Solid State Relay DatasheetjbhupiNo ratings yet

- Sk26a N0153 Rev.aDocument4 pagesSk26a N0153 Rev.avainillaycajetaNo ratings yet

- Specifications - 700-HD RelaysDocument1 pageSpecifications - 700-HD RelaysArif KhanNo ratings yet

- Vert-X 5151736281602Document2 pagesVert-X 5151736281602Mohammad SholichudinNo ratings yet

- MADP 000907 14020xDocument5 pagesMADP 000907 14020xShanu SeherNo ratings yet

- Ekinglux-E6c0606rgbc3uda C375569Document8 pagesEkinglux-E6c0606rgbc3uda C375569Aritra DasguptaNo ratings yet

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbNo ratings yet

- Cat. No. 700-HLT (Relay Output)Document1 pageCat. No. 700-HLT (Relay Output)Arif KhanNo ratings yet

- SUrge Arrester Specification For LoW Voltage SwitchegarDocument1 pageSUrge Arrester Specification For LoW Voltage SwitchegarpeeramohamedNo ratings yet

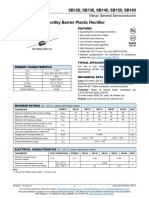

- SB120 Thru SB160: Vishay General SemiconductorDocument4 pagesSB120 Thru SB160: Vishay General SemiconductorrezaNo ratings yet

- Wra-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document6 pagesWra-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Gopal HegdeNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- Ld20 Series: 20W, Ac-Dc ConverterDocument5 pagesLd20 Series: 20W, Ac-Dc ConverterAnonymous QqyLDoW1No ratings yet

- Champtig 400PDocument3 pagesChamptig 400Pvasantha kumarNo ratings yet

- Universal Circuit BreakerDocument3 pagesUniversal Circuit BreakerMalith DeemanthaNo ratings yet

- Relay Test Set: MOT - RTS: FeaturesDocument2 pagesRelay Test Set: MOT - RTS: Featuresamiya_driemsNo ratings yet

- Catalog SA-N Series (Watt)Document1 pageCatalog SA-N Series (Watt)Chanya JetsukontornNo ratings yet

- SK320 Diode SchottkyDocument4 pagesSK320 Diode SchottkyangelsantanamoreiraNo ratings yet

- Interruptor 1A ABB InglésDocument4 pagesInterruptor 1A ABB Inglésanderson pisconteNo ratings yet

- Miniature Circuit Breaker - SH200 - 1P - C - 10 Ampere: Product-DetailsDocument4 pagesMiniature Circuit Breaker - SH200 - 1P - C - 10 Ampere: Product-DetailsSapto NurshendiNo ratings yet

- Marathon Gen-744RSL4058 480V 60hzDocument2 pagesMarathon Gen-744RSL4058 480V 60hzjesus_rs01No ratings yet

- AlldocumentsDocument3 pagesAlldocumentsArthur JOUVENo ratings yet

- AlldocumentsDocument3 pagesAlldocumentsArthur JOUVENo ratings yet

- SMC-3 Specs PDFDocument3 pagesSMC-3 Specs PDFManuelNo ratings yet

- SMB-141N-SMB-901M: Surface Mount Glass TubeDocument2 pagesSMB-141N-SMB-901M: Surface Mount Glass TubeSebastian ChaileNo ratings yet

- Pressure Sensor With DisplayDocument5 pagesPressure Sensor With DisplayEslam YehiaNo ratings yet

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Document3 pagesCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNo ratings yet

- 1N5817/1N5818/1N5819 Siyu: Plastic Schottky Barrier RectifierDocument2 pages1N5817/1N5818/1N5819 Siyu: Plastic Schottky Barrier RectifierJosé Joaquim Braga BragaNo ratings yet

- KS0835FDocument9 pagesKS0835FDaniel Fernando Sotelo LagosNo ratings yet

- Champtig 400 PDocument4 pagesChamptig 400 PAbuhurairah MunshiNo ratings yet

- Champtig 400 P PDFDocument4 pagesChamptig 400 P PDFAbuhurairah MunshiNo ratings yet

- Finder-70 11 8 230 2022-Datasheet PDFDocument10 pagesFinder-70 11 8 230 2022-Datasheet PDFovidiuNo ratings yet

- Relay Sanyou SFK PDFDocument3 pagesRelay Sanyou SFK PDFMaartin FoxNo ratings yet

- HK4100F HuikeDocument3 pagesHK4100F HuikeamshahidNo ratings yet

- H H H HK K K K 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 FDocument3 pagesH H H HK K K K 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 Fzakaria alhosinyNo ratings yet

- Miniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-Detailsliron2312396No ratings yet

- Datasheet 000 008 PDFDocument2 pagesDatasheet 000 008 PDFBill NyeNo ratings yet

- Low Input Current Photodarlington Coupler: Features DescriptionDocument15 pagesLow Input Current Photodarlington Coupler: Features DescriptionStuxnetNo ratings yet

- BES M12MI-PSC40B-S04G-M02 Order Code: BES05F9: Inductive SensorsDocument2 pagesBES M12MI-PSC40B-S04G-M02 Order Code: BES05F9: Inductive SensorsTomas Vargas RamirezNo ratings yet

- 2CDS213001R0104 sh203 c10Document4 pages2CDS213001R0104 sh203 c10BilalNo ratings yet

- SB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorDocument4 pagesSB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorYaraNo ratings yet

- 1N34ADocument1 page1N34AfreddyNo ratings yet

- Sanyou Relays: Miniature High Power RelayDocument3 pagesSanyou Relays: Miniature High Power RelayTV Cinaqui ContiNo ratings yet

- Alldatasheet: Z Ibo Seno Electronic Engineering Co., LTDDocument2 pagesAlldatasheet: Z Ibo Seno Electronic Engineering Co., LTDEhab omarNo ratings yet

- Diodo A8 PhilcoDocument5 pagesDiodo A8 PhilcoFelipe StevanNo ratings yet

- Hall Effect Current Sensor L05Z800S15: SpecificationsDocument2 pagesHall Effect Current Sensor L05Z800S15: Specificationsalllim88No ratings yet

- Elexia FP2 RELAY Axicom D3016Document4 pagesElexia FP2 RELAY Axicom D3016Коресендович ЮрийNo ratings yet

- Miniature Circuit Breaker - SH200 - 3P - C - 16 Ampere: Product-DetailsDocument4 pagesMiniature Circuit Breaker - SH200 - 3P - C - 16 Ampere: Product-DetailsCesar Augusto Navarro SalasNo ratings yet

- 1101-808-1 Datasheets USDocument4 pages1101-808-1 Datasheets USJOSE BNo ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- 2CDS213001R0204 sh203 c20Document4 pages2CDS213001R0204 sh203 c20BilalNo ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- BTH Incremental Encoders BI-58-HDocument2 pagesBTH Incremental Encoders BI-58-Hkanhav joshiNo ratings yet

- BTH Incremental Encoders BI-38-S6Document2 pagesBTH Incremental Encoders BI-38-S6kanhav joshiNo ratings yet

- BTH Block Design 50x20x10mm, 3 Wire DC Capacitive ProximityDocument1 pageBTH Block Design 50x20x10mm, 3 Wire DC Capacitive Proximitykanhav joshiNo ratings yet

- BTH Incremental Encoders BI-38-HDocument2 pagesBTH Incremental Encoders BI-38-Hkanhav joshiNo ratings yet

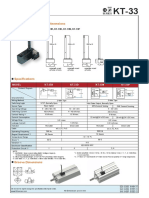

- BTH Magnetic Sensor KT33Document1 pageBTH Magnetic Sensor KT33kanhav joshiNo ratings yet

- BTH BPR12-Series Diffuse Photo SensorDocument1 pageBTH BPR12-Series Diffuse Photo Sensorkanhav joshiNo ratings yet

- Galileo 616 Ds PDFDocument4 pagesGalileo 616 Ds PDFCodinasound CaNo ratings yet

- TransactionSummary 920020060866153 051023033316Document3 pagesTransactionSummary 920020060866153 051023033316gaurav sondhiNo ratings yet

- Sony Z7 BrochureDocument20 pagesSony Z7 BrochureTodorNo ratings yet

- RMMV Script Calls PDFDocument7 pagesRMMV Script Calls PDFMiguel OmangayNo ratings yet

- Warehouse For Storing Aluminum Castings Report 2018-04-01 10-20-58 Am Audit QuestionDocument68 pagesWarehouse For Storing Aluminum Castings Report 2018-04-01 10-20-58 Am Audit QuestionMuhammad Younis KhanNo ratings yet

- Lecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingDocument71 pagesLecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingUnsharp DevNo ratings yet

- Innovations in Maruti SuzukiDocument17 pagesInnovations in Maruti SuzukiNitin MadhuNo ratings yet

- MAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Document4 pagesMAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Alejandro Lopez CuquerellaNo ratings yet

- WWW Techomsystems Com Au Mobile-Device-management-melbourneDocument9 pagesWWW Techomsystems Com Au Mobile-Device-management-melbournetechomsystems stemsNo ratings yet

- Transmittal: Design Document Transmittal Document No Rev Titles StatusDocument2 pagesTransmittal: Design Document Transmittal Document No Rev Titles Statushasan shahriarNo ratings yet

- IngurubeDocument42 pagesIngurubeEmmanuel ConsolationNo ratings yet

- Tendernotice 1Document7 pagesTendernotice 1Shree ConstructionNo ratings yet

- Bibliometric Insights Into The Evolution of DigitaDocument15 pagesBibliometric Insights Into The Evolution of Digitavinubharath.testerNo ratings yet

- Basic Korean GrammarDocument2 pagesBasic Korean GrammarKenneth John RaotraotNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument162 pagesService Manual: Downloaded From Manuals Search EngineFenomenos TransporteNo ratings yet

- EE552 Power Electronics Project ReportDocument17 pagesEE552 Power Electronics Project ReportMashood NasirNo ratings yet

- Beats PILL User ManualDocument40 pagesBeats PILL User ManualJohn M. RoyNo ratings yet

- Captura de Pantalla 2021-07-02 A La(s) 1.48.27 P. M.Document255 pagesCaptura de Pantalla 2021-07-02 A La(s) 1.48.27 P. M.Laura CardozoNo ratings yet

- Site SelectionDocument22 pagesSite Selectionswapnil kotwalNo ratings yet

- Service Description CB DRIVE HMB4-8 1HC0082505 E01 AADocument2 pagesService Description CB DRIVE HMB4-8 1HC0082505 E01 AAaalbaki1No ratings yet

- Mini SportDocument116 pagesMini Sportapi-3732333No ratings yet

- Dairy Project AnalysisDocument16 pagesDairy Project AnalysisSalmanNo ratings yet

- Truck-Mounted Concrete Pump BSF 20-4.09 HDocument2 pagesTruck-Mounted Concrete Pump BSF 20-4.09 HJeff Neurauter100% (1)

- Oracle Developer CVDocument2 pagesOracle Developer CVwaibhavNo ratings yet

- Nokia Operations in BangladeshDocument38 pagesNokia Operations in Bangladeshmmnaim90No ratings yet

- Perception Towards Social Media Marketing Project PDFDocument49 pagesPerception Towards Social Media Marketing Project PDFalifahadmz04No ratings yet

- PC Diagnostic, Testing, Maintenance and Tools - Prashant SeraiDocument30 pagesPC Diagnostic, Testing, Maintenance and Tools - Prashant SeraiprashantseraiNo ratings yet

BTH Incremental Encoders BI-58-S10

BTH Incremental Encoders BI-58-S10

Uploaded by

kanhav joshiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTH Incremental Encoders BI-58-S10

BTH Incremental Encoders BI-58-S10

Uploaded by

kanhav joshiCopyright:

Available Formats

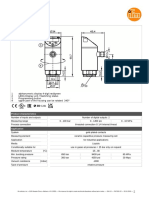

BI-58-S10

58mm dia Shaft Type

Incremental

Rotary

Encoder

● Ø58 mm European Industrial standard encoder

● Robustness and excellent resistance to shocks / vibrations

● High resolutions available : up to 5000 PPR

● Low price contributes to cost reduction of system

● High protection level IP64

● Wide range of power sources : 5~24VDC, 5VDC ±5%

● Various output types

Order code Shaft version

Series Incremental Outer Dia Shaft Dia 10mm Pulse Per Revolution (PPR) Output Power Supply

30, 50, 60, 100, 200, 250, 360,

B I 58 S10

PPDG Push Pull Differential 5~24VDC

400, 500, 600, 720, 1000, 1024,

1800, 2000, 2048, 2500, 3600,

4096, 5000 L Line Driver 5 5VDC

(other PPR are available on request)

A simple way of sensing rotary movements -20º + 85º

High rotational Temperature Shock/vibration Magnetic field Short-circuit Optical sensor

speed resistant proof proof

Electrical Characteristics

Output Circuit Push Pull Differential Line Driver

Supply Voltage 5-30 VDC 5 V ±5%

Power Consumption with Inverted Signal (no load) typ. 50mA / max. 100mA typ. 40 mA / max. 90mA

Permissible Load / Channel ±20mA

Pulse Frequency Max. 300 kHz

Signal Level High Min. UB - 1V Min. 2.5V

Signal Level Low Max. 0.5V Max. 0.5V

Rising Edge Time Max. 1µs Max. 200ns

Falling Edge Time Max. 1µs Max. 200ns

Short Circuit Proof Outputs Yes

Reverse Polarity Protection of the Power Supply Yes No

Over Current Protection Yes

Mechanical Characteristics

Max. Speed 6000RPM

Max. Speed Continuous Max. Response Frequency / Resolution

Rotor Moment of Inertia approx. 1.8 x 10-6 kgm2

Shock Resistance 50G/11ms

Vibration Resistance 100 m/s2 , 10...2000Hz

Starting Torque <0.05 Nm

Shaft Material SS

Body Material Aluminum alloy 2A12

Outer Case Material Al-alloy

Disk Material Glass

Cable 2 Mtr. Black shield cable, side entry

Degree of Protection IP 64

Weight 350g

Position Deflection of Allowable Shaft Radial : Less than 0.05mm, Axial : Less than 0.2mm

Allowable Shaft Load Radial : 2.5kg Max. Axial : 1.3kg Max.

Operating Temperature Range -30ºC ~ +85ºC (No freezing) at 30% ~ 85% RH

Connection Table

Wire Colour Black Red Green White Yellow Brown Grey Orange Shield

Push Pull / NPN Open Collector 0V +V A B Z A B Z Ground

Line Driver 0V +V A B Z A B Z Ground

The specifications are subject to change without prior notice. BTH BI-58-S10 Version 1.0

BI-58-S10

58mm dia Shaft Type

Incremental

Rotary

Encoder

Caution: Avoid damage to your BTH Encoder. The following

Dimension Drawing actions may cause damage, and void product warranty.

72 ± 0.2

20 8 2

15

φ 31.75g6 (-0.025)

-0.009)

-0.009)

φ 36g6 (-0.025)

φ 10h7 (-0.015)

0

φ 58-0.1

0

Do not shock or strike Do not subject shaft to excessive

axial or radial shaft stresses

53.3 ± 0.2

3-M3

φ 48 ± 0.1 Do not disassemble Do not use a rigid coupling

Incremental Encoder is the direct use of the principle

9.5 of photoelectric conversion output. Incremental output phases are

A phase, B phase which have phase difference at 90º and

Z phase one pulse per revolution for benchmarking point positioning.

The advantage is that the principle of simple structure,

the average life span of the machine can be in the tens of

thousands of hours, anti-interference ability, high reliability,

suitable for long distance transmission. Ensures highest safety against

field breakdowns and is thus suitable also for outside use thanks to its

resistant die-cast housing

(5/8 Core Cable φ 6 x Lmm)

Output Waveform

Push Pull output / NPN open collector output Line driver output

H

A phase

L

H H

A phase

A phase L

L

H B phase H

L

B phase

L H

B phase

L

H Rotating Toward Clockwise

Z phase

CW Z phase H

Viewed from an Arrow

L L

H

Z phase

CW (Clock wise) L

Inverse type of Z phase is optional. CW (Clock wise)

CW : In a view of shaft

Industries Applications

● Automotive Assembly ● Drive and conveyor technology ● Conveying systems in day-mining

● Chemical, Petrochemical ● Ship construction

● Lift construction

● Drive Technology

● Electronic Production ● Processing machines ● Gear test stands

● Food, Beverage, Semi-luxury Goods ● Handling Control ● Packaging machines

● Graphical Machinery

● Handling and Robotics ● Robotics ● Blister and carton box packaging

● Injection Molding, Die Casting ● Metal sheet processing ● Labelling machines

● Machine Tools

● Profile milling machines ● Foil-winding machines

● Medical Industry

● Pharmaceutical, Bio Technology ● Machinery for plastics and semiconductor industry ● High racks

● Semiconductor Industry ● Wood processing machines ● Chipboard production plants

● Textile Machinery

● Transportation ● Spindle positioning at profile milling machines ● Warehouse and logistics

● Water, Energy, Mining ● Graphical machinery (printing machines) ● Metal sheet processing machines

● Warehouse and Logistics

● Wood Machinery ● Environment plant engineering and textile machinery ● Mobile conveyor plants (concrete pumps)

The specifications are subject to change without prior notice. All Dimension are in mm BTH BI-58-S10 Version 1.0

You might also like

- Current Best Practices For Training LLMs From Scratch - FinalDocument23 pagesCurrent Best Practices For Training LLMs From Scratch - FinalHasala MarakkalageNo ratings yet

- Introduction To ERPDocument3 pagesIntroduction To ERPmaheshNo ratings yet

- Merlin Service Ops Ap1590 66-88 PDFDocument231 pagesMerlin Service Ops Ap1590 66-88 PDFPaolo Fontanazzi100% (2)

- VSB SeriesDocument3 pagesVSB SeriesCubix AutomationNo ratings yet

- Sdurf2040cta N1636 Rev.a PDFDocument4 pagesSdurf2040cta N1636 Rev.a PDFcesarNo ratings yet

- Specifications - 700-HB Relays: Attribute 700-HB Electrical RatingsDocument1 pageSpecifications - 700-HB Relays: Attribute 700-HB Electrical RatingsArif KhanNo ratings yet

- Data Sheet For Angle Sensors: Optical Encoders Series MHL40Document6 pagesData Sheet For Angle Sensors: Optical Encoders Series MHL40bokic88No ratings yet

- EAC58EA Sensor VelocidadDocument3 pagesEAC58EA Sensor VelocidadrajalingamNo ratings yet

- Electronic Over Current Relay (EOCR)Document2 pagesElectronic Over Current Relay (EOCR)BambangsNo ratings yet

- Rotary Measuring Technology: Incremental EncodersDocument5 pagesRotary Measuring Technology: Incremental Encodersalgoga27No ratings yet

- Single Phase Short Circuit Protected Solid State Relay DatasheetDocument2 pagesSingle Phase Short Circuit Protected Solid State Relay DatasheetjbhupiNo ratings yet

- Sk26a N0153 Rev.aDocument4 pagesSk26a N0153 Rev.avainillaycajetaNo ratings yet

- Specifications - 700-HD RelaysDocument1 pageSpecifications - 700-HD RelaysArif KhanNo ratings yet

- Vert-X 5151736281602Document2 pagesVert-X 5151736281602Mohammad SholichudinNo ratings yet

- MADP 000907 14020xDocument5 pagesMADP 000907 14020xShanu SeherNo ratings yet

- Ekinglux-E6c0606rgbc3uda C375569Document8 pagesEkinglux-E6c0606rgbc3uda C375569Aritra DasguptaNo ratings yet

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbNo ratings yet

- Cat. No. 700-HLT (Relay Output)Document1 pageCat. No. 700-HLT (Relay Output)Arif KhanNo ratings yet

- SUrge Arrester Specification For LoW Voltage SwitchegarDocument1 pageSUrge Arrester Specification For LoW Voltage SwitchegarpeeramohamedNo ratings yet

- SB120 Thru SB160: Vishay General SemiconductorDocument4 pagesSB120 Thru SB160: Vishay General SemiconductorrezaNo ratings yet

- Wra-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Document6 pagesWra-A: Contactless Magnetostrictive Linear Position Transducer (Analog Output)Gopal HegdeNo ratings yet

- General Purpose Relay: TA, TR Series Part Number DescriptionDocument17 pagesGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENo ratings yet

- Ld20 Series: 20W, Ac-Dc ConverterDocument5 pagesLd20 Series: 20W, Ac-Dc ConverterAnonymous QqyLDoW1No ratings yet

- Champtig 400PDocument3 pagesChamptig 400Pvasantha kumarNo ratings yet

- Universal Circuit BreakerDocument3 pagesUniversal Circuit BreakerMalith DeemanthaNo ratings yet

- Relay Test Set: MOT - RTS: FeaturesDocument2 pagesRelay Test Set: MOT - RTS: Featuresamiya_driemsNo ratings yet

- Catalog SA-N Series (Watt)Document1 pageCatalog SA-N Series (Watt)Chanya JetsukontornNo ratings yet

- SK320 Diode SchottkyDocument4 pagesSK320 Diode SchottkyangelsantanamoreiraNo ratings yet

- Interruptor 1A ABB InglésDocument4 pagesInterruptor 1A ABB Inglésanderson pisconteNo ratings yet

- Miniature Circuit Breaker - SH200 - 1P - C - 10 Ampere: Product-DetailsDocument4 pagesMiniature Circuit Breaker - SH200 - 1P - C - 10 Ampere: Product-DetailsSapto NurshendiNo ratings yet

- Marathon Gen-744RSL4058 480V 60hzDocument2 pagesMarathon Gen-744RSL4058 480V 60hzjesus_rs01No ratings yet

- AlldocumentsDocument3 pagesAlldocumentsArthur JOUVENo ratings yet

- AlldocumentsDocument3 pagesAlldocumentsArthur JOUVENo ratings yet

- SMC-3 Specs PDFDocument3 pagesSMC-3 Specs PDFManuelNo ratings yet

- SMB-141N-SMB-901M: Surface Mount Glass TubeDocument2 pagesSMB-141N-SMB-901M: Surface Mount Glass TubeSebastian ChaileNo ratings yet

- Pressure Sensor With DisplayDocument5 pagesPressure Sensor With DisplayEslam YehiaNo ratings yet

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Document3 pagesCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanNo ratings yet

- 1N5817/1N5818/1N5819 Siyu: Plastic Schottky Barrier RectifierDocument2 pages1N5817/1N5818/1N5819 Siyu: Plastic Schottky Barrier RectifierJosé Joaquim Braga BragaNo ratings yet

- KS0835FDocument9 pagesKS0835FDaniel Fernando Sotelo LagosNo ratings yet

- Champtig 400 PDocument4 pagesChamptig 400 PAbuhurairah MunshiNo ratings yet

- Champtig 400 P PDFDocument4 pagesChamptig 400 P PDFAbuhurairah MunshiNo ratings yet

- Finder-70 11 8 230 2022-Datasheet PDFDocument10 pagesFinder-70 11 8 230 2022-Datasheet PDFovidiuNo ratings yet

- Relay Sanyou SFK PDFDocument3 pagesRelay Sanyou SFK PDFMaartin FoxNo ratings yet

- HK4100F HuikeDocument3 pagesHK4100F HuikeamshahidNo ratings yet

- H H H HK K K K 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 FDocument3 pagesH H H HK K K K 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 F 41 0 0 F / 4 1 0 1 Fzakaria alhosinyNo ratings yet

- Miniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200M - 4P - C - 16 Ampere: Product-Detailsliron2312396No ratings yet

- Datasheet 000 008 PDFDocument2 pagesDatasheet 000 008 PDFBill NyeNo ratings yet

- Low Input Current Photodarlington Coupler: Features DescriptionDocument15 pagesLow Input Current Photodarlington Coupler: Features DescriptionStuxnetNo ratings yet

- BES M12MI-PSC40B-S04G-M02 Order Code: BES05F9: Inductive SensorsDocument2 pagesBES M12MI-PSC40B-S04G-M02 Order Code: BES05F9: Inductive SensorsTomas Vargas RamirezNo ratings yet

- 2CDS213001R0104 sh203 c10Document4 pages2CDS213001R0104 sh203 c10BilalNo ratings yet

- SB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorDocument4 pagesSB120, SB130, SB140, SB150, SB160: Vishay General SemiconductorYaraNo ratings yet

- 1N34ADocument1 page1N34AfreddyNo ratings yet

- Sanyou Relays: Miniature High Power RelayDocument3 pagesSanyou Relays: Miniature High Power RelayTV Cinaqui ContiNo ratings yet

- Alldatasheet: Z Ibo Seno Electronic Engineering Co., LTDDocument2 pagesAlldatasheet: Z Ibo Seno Electronic Engineering Co., LTDEhab omarNo ratings yet

- Diodo A8 PhilcoDocument5 pagesDiodo A8 PhilcoFelipe StevanNo ratings yet

- Hall Effect Current Sensor L05Z800S15: SpecificationsDocument2 pagesHall Effect Current Sensor L05Z800S15: Specificationsalllim88No ratings yet

- Elexia FP2 RELAY Axicom D3016Document4 pagesElexia FP2 RELAY Axicom D3016Коресендович ЮрийNo ratings yet

- Miniature Circuit Breaker - SH200 - 3P - C - 16 Ampere: Product-DetailsDocument4 pagesMiniature Circuit Breaker - SH200 - 3P - C - 16 Ampere: Product-DetailsCesar Augusto Navarro SalasNo ratings yet

- 1101-808-1 Datasheets USDocument4 pages1101-808-1 Datasheets USJOSE BNo ratings yet

- DatasheetDocument2 pagesDatasheetStuxnetNo ratings yet

- 2CDS213001R0204 sh203 c20Document4 pages2CDS213001R0204 sh203 c20BilalNo ratings yet

- RTS DC Servo DriveDocument4 pagesRTS DC Servo DriveJunaid YNo ratings yet

- BTH Incremental Encoders BI-58-HDocument2 pagesBTH Incremental Encoders BI-58-Hkanhav joshiNo ratings yet

- BTH Incremental Encoders BI-38-S6Document2 pagesBTH Incremental Encoders BI-38-S6kanhav joshiNo ratings yet

- BTH Block Design 50x20x10mm, 3 Wire DC Capacitive ProximityDocument1 pageBTH Block Design 50x20x10mm, 3 Wire DC Capacitive Proximitykanhav joshiNo ratings yet

- BTH Incremental Encoders BI-38-HDocument2 pagesBTH Incremental Encoders BI-38-Hkanhav joshiNo ratings yet

- BTH Magnetic Sensor KT33Document1 pageBTH Magnetic Sensor KT33kanhav joshiNo ratings yet

- BTH BPR12-Series Diffuse Photo SensorDocument1 pageBTH BPR12-Series Diffuse Photo Sensorkanhav joshiNo ratings yet

- Galileo 616 Ds PDFDocument4 pagesGalileo 616 Ds PDFCodinasound CaNo ratings yet

- TransactionSummary 920020060866153 051023033316Document3 pagesTransactionSummary 920020060866153 051023033316gaurav sondhiNo ratings yet

- Sony Z7 BrochureDocument20 pagesSony Z7 BrochureTodorNo ratings yet

- RMMV Script Calls PDFDocument7 pagesRMMV Script Calls PDFMiguel OmangayNo ratings yet

- Warehouse For Storing Aluminum Castings Report 2018-04-01 10-20-58 Am Audit QuestionDocument68 pagesWarehouse For Storing Aluminum Castings Report 2018-04-01 10-20-58 Am Audit QuestionMuhammad Younis KhanNo ratings yet

- Lecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingDocument71 pagesLecture 23: Port and Vulnerability Scanning, Packet Sniffing, Intrusion Detection, and Penetration TestingUnsharp DevNo ratings yet

- Innovations in Maruti SuzukiDocument17 pagesInnovations in Maruti SuzukiNitin MadhuNo ratings yet

- MAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Document4 pagesMAN-MAQ012.2 Microscopio Leica LMD6 (LOC-MIC1)Alejandro Lopez CuquerellaNo ratings yet

- WWW Techomsystems Com Au Mobile-Device-management-melbourneDocument9 pagesWWW Techomsystems Com Au Mobile-Device-management-melbournetechomsystems stemsNo ratings yet

- Transmittal: Design Document Transmittal Document No Rev Titles StatusDocument2 pagesTransmittal: Design Document Transmittal Document No Rev Titles Statushasan shahriarNo ratings yet

- IngurubeDocument42 pagesIngurubeEmmanuel ConsolationNo ratings yet

- Tendernotice 1Document7 pagesTendernotice 1Shree ConstructionNo ratings yet

- Bibliometric Insights Into The Evolution of DigitaDocument15 pagesBibliometric Insights Into The Evolution of Digitavinubharath.testerNo ratings yet

- Basic Korean GrammarDocument2 pagesBasic Korean GrammarKenneth John RaotraotNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument162 pagesService Manual: Downloaded From Manuals Search EngineFenomenos TransporteNo ratings yet

- EE552 Power Electronics Project ReportDocument17 pagesEE552 Power Electronics Project ReportMashood NasirNo ratings yet

- Beats PILL User ManualDocument40 pagesBeats PILL User ManualJohn M. RoyNo ratings yet

- Captura de Pantalla 2021-07-02 A La(s) 1.48.27 P. M.Document255 pagesCaptura de Pantalla 2021-07-02 A La(s) 1.48.27 P. M.Laura CardozoNo ratings yet

- Site SelectionDocument22 pagesSite Selectionswapnil kotwalNo ratings yet

- Service Description CB DRIVE HMB4-8 1HC0082505 E01 AADocument2 pagesService Description CB DRIVE HMB4-8 1HC0082505 E01 AAaalbaki1No ratings yet

- Mini SportDocument116 pagesMini Sportapi-3732333No ratings yet

- Dairy Project AnalysisDocument16 pagesDairy Project AnalysisSalmanNo ratings yet

- Truck-Mounted Concrete Pump BSF 20-4.09 HDocument2 pagesTruck-Mounted Concrete Pump BSF 20-4.09 HJeff Neurauter100% (1)

- Oracle Developer CVDocument2 pagesOracle Developer CVwaibhavNo ratings yet

- Nokia Operations in BangladeshDocument38 pagesNokia Operations in Bangladeshmmnaim90No ratings yet

- Perception Towards Social Media Marketing Project PDFDocument49 pagesPerception Towards Social Media Marketing Project PDFalifahadmz04No ratings yet

- PC Diagnostic, Testing, Maintenance and Tools - Prashant SeraiDocument30 pagesPC Diagnostic, Testing, Maintenance and Tools - Prashant SeraiprashantseraiNo ratings yet