Professional Documents

Culture Documents

Painting Procedure Rev.A

Painting Procedure Rev.A

Uploaded by

คุณพ่อน้อง บิ๊กบอสOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Painting Procedure Rev.A

Painting Procedure Rev.A

Uploaded by

คุณพ่อน้อง บิ๊กบอสCopyright:

Available Formats

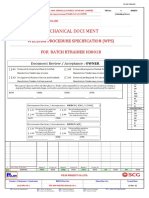

EP-CM-F-0004-003

CLIENT NAME : THAI PLASTIC AND CHEMICALS PUBLIC COMPANY LIMITED TOTAL: 12 SHEETS

PROJECT NAME : TPR Productivity improvement PG680,740 130 MTPD ( Including Cover )

PROJECT NO. : C-22-1092

LOCATION : RAYONG THAILAND

MECHANICAL DOCUMENT

PAINTING PROCEDURE

FOR BATCH STRAINER H3001B

DISTRIBUTION

Master File

Client

Maintenance

Procurement

ENG. DESIGN

EM

PR

PIP

IE

MSE

MRE

EE

CVE

IC

] IA

CONSTRUCTION

PM

CM

CVE

ME

PIP

IE

EE

B IFR = Issue for Review Khanis Y. 6-Dec-22 Khanis Y. 6-Dec-22 Khanis Y. 6-Dec-22

A IFR = Issue for Review Khanis Y. 8-Dec-22 Khanis Y. 8-Dec-22 Khanis Y. 8-Dec-22

REV. PURPOSE PRED. DATE CHKD. DATE APPD. DATE EM DATE PM DATE

PILIN PROJECT CO.,LTD.

Vendor / Fabricator / Contractor REPCO Doc. No. Client Doc. No. Issued Date

6518-PRO-08-A TPC-000-MSE-PRO-H3001B-08-A - 8-Dec-22

IFS = Issue for Squadcheck IFR = Issue for Review IFE = Issue for Enquiry IFD = Issue for Design IFC = Issue for Construction

IFI = Issue for Information IFP = Issue for Purchase IFF = Issue for Final

EP-CM-F-0004-003

PILIN PROJECT CO.,LTD.

REPCO Doc. No. Rev. Sheet No.

REVISION LIST

TPC-000-MSE-PRO-H3001B-08-A A 2 OF 12

REV. DATE ITEM No. REFERENCE DOCUMENT DESCRIPTION

A 8-Dec-22 - - IFR = Issue for Review

B 6-Dec-22 - - IFR = Issue for Review

FOR BATCH STRAINER H3001B

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 Surface pretreatment and requirement 3

2.0 Surface preparation 3

3.0 Material Safety Data Sheet (MSDS) 3

4.0 Painting Application 4

5.0 Paint Filer thickness 5

6.0 Inspection 6

7.0 Painting Area and painting system 7

Attachment 8

PILIN PROJECT CO., LTD. Page 3

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

This painting procedure will provide for TPR Productivity improvement PG680,740

130 MTPD Project of THAI PLASTIC AND CHEMICALS PUBLIC COMPANY LIMITED The

activity shall be follow as below.

1. Surface pretreatment and requirement

1.1. The product shall remove slag, Spatter, heavy rust scale and flux residues from

surface, prior to blasting.

1.2. The preparation for paint at corners, edges, weldment shall carefully perform to

ensure specified nominal dry film thickness is achieved.

1.3. The blast cleaning and painting shall be always applied after acceptable visual /

dimension and inspection.

1.4. The item below shall not be paint

a) Stainless steel

b) Machine surface and raised face of flange

c) Name plate

1.5. All grease and oil shall remove by rago or brush with solvent and clean dry cloths

before blasting

2. Surface preparation

2.1. The surface preparation shall be blast clean by abrasive grit with degree specified in

standard.

2.2. The primer shall apply immediately after blasting and inspection accept.

2.3. All blast cleaned surfaces shall be primed before visible re-rusting occurs or within

two hours of the commencement of blasting. If visible re-rusting occurs after more

than two hours have elapsed then the metal surfaces shall be lightly re-blasted.

3. Material Safety Data Sheet (MSDS)

3.1. MSDS shall be provided to SCG.

PILIN PROJECT CO., LTD. Page 4

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

4. Painting Application

4.1. The weather and surface condition as below not be paint

a) Conventional solvent based paints shall not be applied to exterior surfaces in

damp, humid weather when air temperature is below 5C or when the metal

surface temperature is less than 3C above the dew-point temperature.

b) Chemically cured paints shall not be applied at air or metal surface temperature

below 10C or when relative humidity is above 85%.

c) Paint materials shall not be applied over metal surfaces having temperatures in

excess of 38C

d) Paint materials shall not be applied in rain, snow, fog or mist, nor to wet or damp

surfaces. Paint shall not be applied to frosted or ice coated surfaces.

4.2. Paint material shall be thoroughly mixed to give uniform mixture immediately prior to

apply. Mixing shall be by mechanical stirrer, can vibrator or can shaker.

4.3. Constant mechanical agitation shall be maintained is the paint reservoir during paint

spraying operation.

4.4. Thinner shall only add during mixing process and strictly in accordance with the paint

manufacturer’s inspection.

4.5. Spray gun shall be hold perpendicular to the surface being coated a maximum

distance of 300 mm. and not closer than 200 mm. from the surface.

4.6. Air pressure on the spray gun shall be regulated to achieve optimum atomization of

the paint with the lowest possible pressure to avoid spray ricochet from the surface

being paint.

4.7. Overlapping pusses shall make for each spray coat to obtain uniform application.

Particular care shall be exercised to ensure that a uniform, complete wet coat is

applied. Semidry spraying result in poor “Flow Out” with excessive pin hole and shall

be avoided.

PILIN PROJECT CO., LTD. Page 5

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

4.8. Coat of paint shall be uniformly applied without sage , runs , spots , damage or

contamination such irregularity shall remove and the affect area re-coat

4.9. Each coat of paint shall be in a proper state of dryness before apply of the succeeding

coat

4.10. To minimize intercoat contamination, succeeding coat shall be applied with a

minimum time lapoc consistent with proper drying time, production schedule.

4.11. Brush application may apply under the following circumstances.

a) Area cannot be properly coated by spraying for any reason

b) Touch-up or repairs to localized paint or area of incorrectly apply paint

c) The coating material suitable by brush

d) Apply the initial coat of paint to comers , edges , hole weld or other irregular surface

prior to spray application

e) Primer on mechanical clean surface.

The brushing shall be done, so that a smooth area, as nearly uniform in thickness as

possible is obtained. There shall be not deep or detrimental brush mark.

5. Paint Filer thickness

5.1. Measurement of thickness of individual paint coating and the total system shall be

accordance with procedure.

5.2. The dry film thickness of each applied coating shall be check and record.

5.3. References to film thickness throughout this Standard shall be taken to indicate the

nominal dry film thickness acceptable. The applied dry film thickness over any square

meter shall have average readings that are not less than nominal and 75 per cent of

the readings taken are not less than nominal. No readings shall be less than 75 per

cent of the nominal.

5.4. Maximum thickness for each system

a) Primer coat : Should not be more than 120 per cent of the nominal.

b) Intermediate coat : Should not be more than 150 per cent of the nominal.

c) Top coat : Should not be more than 150 per cent of the nominal.

PILIN PROJECT CO., LTD. Page 6

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

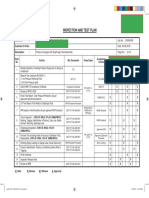

6. Inspection

6.1. The painting supervisor shall required to keep an accurate daily record, temperature,

humidity and the time of commencement and cessation of all phase of cleaning,

surface preparation and painting operation.

6.2. The frequency to check the surface profile should be a minimum of once per 100 m2

per shift.

6.3. The surface profile (peak-to-valley roughness) shall be range: 1.5 to 2.55 mils (38 to

164 μm). Inspection by Press-O-Film HT .

6.4. The painting inspection record shall be submitted with production data bock.

6.5. Acceptance criteria follow the manufacturer.

6.6. Inspection item.

Item Description Inspection and response

1 Cleaning before blast Visual by painting supervisor

Visual by representation of painting manufacturing

2 Sandblast

(CHOGOKU supervisor)

3 Painting Visual & DFT by representation of manufacturing

PILIN PROJECT CO., LTD. Page 7

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

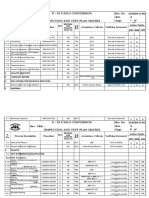

7. Painting Area and painting system

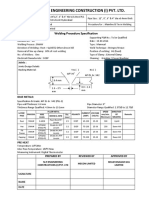

7.1 Painting system

New Construction

Surface preparation : Near White Blast SSPC SP10 ( A Sa2.5)

Primer coat : GALBON S-HB D.F.T. 75 micron

Intermediate coat : EPICON F-HS D.F.T. 125 micron

Top coat : UNY MARINE HS D.F.T. 50 micron

Total D.F.T. 250 micron

Area to be apply by class “C1” (0-80°C)

- Leg Support color code : Reseda Green RAL6011

Note : D.F.T. = Dry Film Thickness (um)

*** Touch up means weld area in new fabricate project.

St 2 for spot repair, St 3 for area repair

PILIN PROJECT CO., LTD. Page 8

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

Attachment

PILIN PROJECT CO., LTD. Page 9

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

PILIN PROJECT CO., LTD. Page 10

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

PILIN PROJECT CO., LTD. Page 11

Doc. No. : 6518-PRO-07-B

Painting Procedure

Pilin Project Co,Ltd. Rev. No. :

PILIN PROJECT CO., LTD. Page 12

You might also like

- Method Statement For Rotating Equipment InstallationDocument10 pagesMethod Statement For Rotating Equipment Installationคุณพ่อน้อง บิ๊กบอส100% (4)

- Method Statement For Piping InstallationDocument9 pagesMethod Statement For Piping Installationคุณพ่อน้อง บิ๊กบอส100% (12)

- Alignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / DateDocument6 pagesAlignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / Dateคุณพ่อน้อง บิ๊กบอส100% (1)

- ITP-NMFOC - Type TestDocument6 pagesITP-NMFOC - Type TestPrabhakar SvNo ratings yet

- Dots in ASME B36.10 Under Schedule TableDocument5 pagesDots in ASME B36.10 Under Schedule TableIbrahim BashaNo ratings yet

- Procedure Qualification Records (PQR)Document13 pagesProcedure Qualification Records (PQR)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Scope of Supply T60Document25 pagesScope of Supply T60cmaduroheNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- SR - No Description QtyDocument12 pagesSR - No Description QtyBoyzannazNo ratings yet

- 6.1 Data Sheet For Pipeline Ball ValveDocument3 pages6.1 Data Sheet For Pipeline Ball ValveDeepak PalNo ratings yet

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocument1 pageProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNiel100% (1)

- ITPDocument1 pageITPVenkatesh PethurajNo ratings yet

- StandardsDocument4 pagesStandardsrania hammamiNo ratings yet

- 48 Sweet Corrosion Rate in Oil and Gas PipelinesDocument4 pages48 Sweet Corrosion Rate in Oil and Gas PipelinesuktaindraNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Wps 06Document2 pagesWps 06eldobie3No ratings yet

- Project Handover Checklist & Client Acceptance DocumentDocument8 pagesProject Handover Checklist & Client Acceptance DocumentParamjeet KalraNo ratings yet

- Field Test Form Metal Enclosed Busway: Section 1: Mechanical Check and Visual InspectionDocument5 pagesField Test Form Metal Enclosed Busway: Section 1: Mechanical Check and Visual Inspectionehtesham100% (1)

- I.E.M.S.A.: Welding Procedure SpecificationDocument2 pagesI.E.M.S.A.: Welding Procedure Specificationeldobie3No ratings yet

- Wrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PDocument2 pagesWrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PSimbu ArasanNo ratings yet

- Alignment Methods in Rotating EquipmentDocument6 pagesAlignment Methods in Rotating EquipmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- ITP For Piping WorksDocument44 pagesITP For Piping WorksSyafril Akbar100% (3)

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Contoh ItpDocument3 pagesContoh Itphafiz elektroNo ratings yet

- COOLING TOWER FAN Erection Quality ChecklistsDocument1 pageCOOLING TOWER FAN Erection Quality ChecklistsBudoy SmithNo ratings yet

- Method Statement of Sprinkler System Without LogoDocument9 pagesMethod Statement of Sprinkler System Without LogokiranramNo ratings yet

- TMG Hold & Check Points 16.11.17Document54 pagesTMG Hold & Check Points 16.11.17anjnaNo ratings yet

- An Overview of Cathodic Protection Potential MeasurementDocument7 pagesAn Overview of Cathodic Protection Potential MeasurementKhanh DTNo ratings yet

- QCF316 Cold Insulation Inspection Report For Vessel / MachineryDocument1 pageQCF316 Cold Insulation Inspection Report For Vessel / MachineryminhnnNo ratings yet

- ASME CheckDocument14 pagesASME Checkfuransu777No ratings yet

- Lighting Poles Installation ReportDocument5 pagesLighting Poles Installation ReportsidharthNo ratings yet

- Slope CheckDocument2 pagesSlope Checkคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Pre Comm FormatDocument75 pagesPre Comm FormatHaleem Ur Rashid Bangash100% (1)

- Inspection Plan For Tank With No Floating Part Needs To Be ImprovedDocument6 pagesInspection Plan For Tank With No Floating Part Needs To Be ImprovedHussain M.SukarNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- Deliverable ListDocument2 pagesDeliverable Listanu radhaNo ratings yet

- Vendor Punch List: M/s. Aquatech / Sulzer PumpsDocument1 pageVendor Punch List: M/s. Aquatech / Sulzer PumpsSantosh Narayan IngoleNo ratings yet

- KP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksDocument3 pagesKP-00+++-CQ712-B7357-Rev 0-ITP For CB Installation WorksUtku Can KılıçNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- Presentation - Method Statement For Fire Fighting System 20.04.22Document21 pagesPresentation - Method Statement For Fire Fighting System 20.04.22TranDungNo ratings yet

- Step 7 De-Watering & DryingDocument1 pageStep 7 De-Watering & Dryingmansih457No ratings yet

- Detailed Project Construction MethodologyDocument27 pagesDetailed Project Construction MethodologyElxao XanNo ratings yet

- Tata A2239 Qap Rev.00Document4 pagesTata A2239 Qap Rev.00PRASHANTNo ratings yet

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFZaheedManooNo ratings yet

- Nde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTDocument2 pagesNde Plan: Joint Number / Parts Before PWHT After PWHT RT Paut UT MT PT PMI RT MTfizanlaminNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Foam Chamber DatasheetDocument4 pagesFoam Chamber DatasheetMoorthy MuruganNo ratings yet

- ITP ElectricalDocument7 pagesITP Electricalcherif yahyaouiNo ratings yet

- Std-Ze-Itp-000001-Is00 - C.S. Shell and Tube Heat ExchangersDocument16 pagesStd-Ze-Itp-000001-Is00 - C.S. Shell and Tube Heat ExchangersAlexandru AsmarandeiNo ratings yet

- PSV CertificateDocument1 pagePSV CertificatePrashanth MandalNo ratings yet

- A2001-0003 - Rev.f - Condensate Filter GA DrawingDocument4 pagesA2001-0003 - Rev.f - Condensate Filter GA DrawingvamcodongNo ratings yet

- Fabrication and Control ProcedureDocument19 pagesFabrication and Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welder Qualification Records (WQT)Document17 pagesWelder Qualification Records (WQT)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- PL-6220-1-ITP-001 Inspection and Test Plan (A)Document5 pagesPL-6220-1-ITP-001 Inspection and Test Plan (A)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Shell DimensionDocument1 pageShell Dimensionคุณพ่อน้อง บิ๊กบอสNo ratings yet

- CC F 01102557Document1 pageCC F 01102557คุณพ่อน้อง บิ๊กบอสNo ratings yet

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- ITP Equipment1Document9 pagesITP Equipment1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- MDR lNDEXDocument35 pagesMDR lNDEXคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Att-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSDocument22 pagesAtt-6 - 077QS0101 - B - INSPECTION INSTRUCTION TO VENDORSคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test 3D-3711Document3 pagesHydrostatic Test 3D-3711คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Weld Location MapDocument1 pageWeld Location Mapคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Cleaning Inspection ReportDocument2 pagesCleaning Inspection Reportคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Slope CheckDocument2 pagesSlope Checkคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Inspection & Test PlansDocument3 pagesInspection & Test Plansคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Hydrostatic Test ProcedureDocument11 pagesHydrostatic Test Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Fabrication and Control ProcedureDocument19 pagesFabrication and Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Inspection Report TK3200Document100 pagesInspection Report TK3200คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Welder Qualification Records (WQT)Document17 pagesWelder Qualification Records (WQT)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Procedure Qualification Records (PQR)Document13 pagesProcedure Qualification Records (PQR)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- PL 6507 Pul 01Document1 pagePL 6507 Pul 01คุณพ่อน้อง บิ๊กบอสNo ratings yet

- CAST - WP0 - Deliverable 0.3Document34 pagesCAST - WP0 - Deliverable 0.3คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Field Schedule Control ProcedureDocument37 pagesField Schedule Control Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- 7) - Procedure FRP Tank InstallationDocument34 pages7) - Procedure FRP Tank Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Polishing Procedure For PipesDocument4 pagesPolishing Procedure For Pipesคุณพ่อน้อง บิ๊กบอส0% (1)

- S-A3-125f-01 - Specification For Painting Work - Rev.b - CDocument35 pagesS-A3-125f-01 - Specification For Painting Work - Rev.b - Cคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Material Inspection Report 6426-1Document5 pagesMaterial Inspection Report 6426-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Method Statement For Static Equipment InstallationDocument20 pagesMethod Statement For Static Equipment Installationคุณพ่อน้อง บิ๊กบอสNo ratings yet

- ISBL ISO Joint DB 14-9-16Document35 pagesISBL ISO Joint DB 14-9-16คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Exotic PlantsDocument164 pagesExotic PlantsKenneth100% (9)

- 2 Lecture in Adultery and ConcubinageDocument6 pages2 Lecture in Adultery and ConcubinageJerick OrtegaNo ratings yet

- Project For LMSDocument7 pagesProject For LMSTHUY PHAM NGOCNo ratings yet

- Change of Name Request FormDocument2 pagesChange of Name Request FormDinesh Rishi BhogaNo ratings yet

- Manual John Deere Gator XUV 850DDocument2 pagesManual John Deere Gator XUV 850Djoel blancoNo ratings yet

- Personal Development: Quarter 1-Module 3 Week 3&4Document12 pagesPersonal Development: Quarter 1-Module 3 Week 3&4Nikka Irah CamaristaNo ratings yet

- 03 Industrial RevolutionDocument103 pages03 Industrial Revolutioninfo12060% (1)

- Invoction: Bs English Iii Poetry-A (Invocation) Faraz AhmedDocument2 pagesInvoction: Bs English Iii Poetry-A (Invocation) Faraz AhmedaliNo ratings yet

- ResumeDocument2 pagesResumeSamm0% (1)

- Final Report SubmisionDocument53 pagesFinal Report SubmisionGaurav TrivediNo ratings yet

- Einstein Mirror and Fermat's Principle of Least TimeDocument3 pagesEinstein Mirror and Fermat's Principle of Least TimeHanan RosenthalNo ratings yet

- Briefhistoryof MyrespectedforefathersDocument11 pagesBriefhistoryof MyrespectedforefathersAli Zar GrafixNo ratings yet

- Conflict Management: Conflict Management Strategies Tips For Managing Conflict Conflict Prevention TechniquesDocument77 pagesConflict Management: Conflict Management Strategies Tips For Managing Conflict Conflict Prevention Techniquesgoldfish8No ratings yet

- Romeo and JulietDocument20 pagesRomeo and JulietSher Elliott100% (1)

- Anito Elementary SchoolDocument4 pagesAnito Elementary SchoolKristina CalvoNo ratings yet

- Course Modules - IT Systems Management 1 HISM100-1Document8 pagesCourse Modules - IT Systems Management 1 HISM100-1Bonginkosi0% (1)

- Financial Accounting Chapter 13Document59 pagesFinancial Accounting Chapter 13Waqas MazharNo ratings yet

- 2019 CLC 211Document6 pages2019 CLC 211Asif NawazNo ratings yet

- 1ST DYNAMIC Questionnaire and Background CheckingDocument2 pages1ST DYNAMIC Questionnaire and Background CheckingGregory RabulanNo ratings yet

- MRTS71Document15 pagesMRTS71bradrimmNo ratings yet

- Paternity and Filiation Study Guide CivRevDocument12 pagesPaternity and Filiation Study Guide CivRevOL VRNo ratings yet

- Kyc Form - Corporate - MotorDocument2 pagesKyc Form - Corporate - Motorjoseph hoffarthNo ratings yet

- 10B 1Document8 pages10B 1Nazar RachmawanNo ratings yet

- Corrosion of Steel in Concrete Understanding Investigation and Repair-51-100Document50 pagesCorrosion of Steel in Concrete Understanding Investigation and Repair-51-100Sumit Singh ThakurNo ratings yet

- "Building Information Modeling": Cadd Ii Cadd For Architecture 2Document8 pages"Building Information Modeling": Cadd Ii Cadd For Architecture 2Darlene FernandezNo ratings yet

- Lesson2 ShsDocument4 pagesLesson2 ShsCristy Balubayan NazarenoNo ratings yet

- Chromium and DiabetesDocument29 pagesChromium and DiabetesTri Kusuma Agung PuruhitaNo ratings yet

- Mathematics Achievement Test (MAT)Document18 pagesMathematics Achievement Test (MAT)Rustico Y Jerusalem0% (1)

- 5/ What Is The Relationship Between Structure of The Small Intestine and Its Function?Document3 pages5/ What Is The Relationship Between Structure of The Small Intestine and Its Function?just kimbooNo ratings yet

- GFH 44Document9 pagesGFH 44Marie MedinaNo ratings yet