Professional Documents

Culture Documents

IMG - 0053 PSME Code 2008 42

IMG - 0053 PSME Code 2008 42

Uploaded by

Arwyn BermasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0053 PSME Code 2008 42

IMG - 0053 PSME Code 2008 42

Uploaded by

Arwyn BermasCopyright:

Available Formats

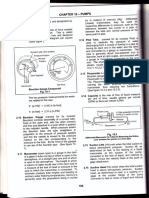

CHAPTER 4 - MACHTNERY DANGER ZONE AND POINTS OF OPERATION

a slot or hopper or a rod located directly in front

7.17 Starching Machine (Cylinder or Box Type)

(Class Aj. Eacn starching machine shall have of the feed'and extending the full length of the

roll.

ihe rolls or cylinders guarded so as to prevent

contact by the employees while the machine is

in motion. 7.21 lroner (Flatwork Type) (Class A):

?"{8 Drying Tumbler (Horizontal Conventional a. Each flat-work and collar ironer shall

Type) (Class A):

equipped with a guard across the enti(

froni of the feed or first pressure roles, so

arranged that when struck, the machine will

a. Each dryirrg tumbler shall be equipped with

immediatelY stoP'

an interiocking device that will prevent the

inside cylinder from moving when the door

on the case or shell is open' Such device b. The pressure rolls shall be guarded be

or

shall also prevent the door from being covered so that an ernployee cannot

caught or Pulled into the rolls.

opened while the inside cylinders is in

motion'

7.22 lroner (Body Type) (Class A)' Each body

Nofe: Ihis should not prevent the movement ironer, sfratt Ue equipped with a guard across

of the inner cylinder under the action of a the entire length of the feed roll or' shoe, so

hand-operated mechanism or under the arranged that when struck, the machine will

oPeration of an "inching" deviae' immediatelY stoP.

b. Each drying tumbler shall be provided with 7.23 lroner (Rotary'body Type) (Glass A)' Each

adequate means for holding open the doors combined rotary bosom and coat-ironer shall be

or covers of inner and outer cylinders or equipped with a guard across the entire length

shells while being loaded or unloaded' of'the feed roll or shoe, so arranged that when

struck, the machine will immediately stop'

c. Each drying tumbler shall be equipped with

7.24 lroner (Press TYPe) (Class A)

br"akes or other positive lockinE devices to

prevent tl"re inner cylinder from moving

during loading and unloading' "lnching a. Each ironing press (excluding hand or foot

power presses) shall be equipped with a two

devices" are Permitted.

hand device which require the simultaneous

Exception: Shakeout or canditioning action of both hands to operate the press'

tumblers where the clothes are loaded into

the open end of the revolving cylinder and b. Every power-driven ironing press of the type

'in

are automaticatly discharged out of the used the dry cleaning or garment

oPPosite end-

manufacturing industry shall be equipped

with two hand controls which will require the

simultaneous use of both hands to apply

7.19 Shaker (Clothes Tumbler, Batch Type) (CIass

heavy pressure or to look the press'

A):

a. Each shaker or clothes tumbler shall be 7.25 Laundry Machine. Working areas around the

equipped with a device that will prevent the Laundry Machine shall be provided with non

tumbler from moving while the door is open' skid or sliP-resistant flooring.

The tumbler shall be enclosed or guarded

so as to prevent accidental contact' Section 8.0 Leather and Gomposition

Good Machines

b. Each shaker or clothes tumbler shall be

equipped with brakes or other positivt' 8.1 Dinking and Glicking Machlnes (Glass A)'

locking devices to prevent the insidt" Every dinking machine shall be guarded by at

cylinder from moving when the machine t:; least one of the following methods:

loaded or unloaded. "lnching devices" are 8.3 I

Permitted' a. "safety type" dies shall be used throughout'

Dies of t-fris type shall be at least 75 mm in

7.20 Dampening Machine (Class A)' The rolls on height provided with safety grooves or

dampening machines shall be guarded by either flanges. This safety flanges reduce the

42

You might also like

- Jake Bernstein's Seasonal Trader's Bible - The Best of The Best in Seasonal Trades - Jake Bernstein (1996) PDFDocument561 pagesJake Bernstein's Seasonal Trader's Bible - The Best of The Best in Seasonal Trades - Jake Bernstein (1996) PDF林耀明100% (4)

- Service Manual Winch Models Pa55 & Pa56: SENR5358-04Document62 pagesService Manual Winch Models Pa55 & Pa56: SENR5358-04Gabriel Paredes E.No ratings yet

- 205 V358%20CompleteOperationManual PDFDocument182 pages205 V358%20CompleteOperationManual PDFLê Thanh NgọcNo ratings yet

- исходикDocument498 pagesисходикДмитрий Лобзов100% (4)

- Long Three Point Hitch Backhoes Owners ManualDocument33 pagesLong Three Point Hitch Backhoes Owners ManualBric Baker100% (1)

- The Market EconomyDocument298 pagesThe Market Economylg50% (2)

- IMG - 0052 PSME Code 2008 41Document1 pageIMG - 0052 PSME Code 2008 41Arwyn BermasNo ratings yet

- IMG - 0050 PSME Code 2008 39Document1 pageIMG - 0050 PSME Code 2008 39Arwyn BermasNo ratings yet

- IMG - 0051 PSME Code 2008 40Document1 pageIMG - 0051 PSME Code 2008 40Arwyn BermasNo ratings yet

- 1205Document2 pages1205jemuelNo ratings yet

- Article 4.6: Paper and Printing MachinesDocument54 pagesArticle 4.6: Paper and Printing MachinesCharlyn FloresNo ratings yet

- IMG - 0044 PSME Code 2008 33Document1 pageIMG - 0044 PSME Code 2008 33Bugoy2023No ratings yet

- IMG - 0061 PSME Code 2008 50Document1 pageIMG - 0061 PSME Code 2008 50Master JaguarNo ratings yet

- Pacific Brake OperationDocument67 pagesPacific Brake OperationNathan RittenhouseNo ratings yet

- Machine Guards and SafetiesDocument20 pagesMachine Guards and SafetiesJabber Reyes Ambor100% (1)

- Provisional For SafetyDocument4 pagesProvisional For SafetyrammalsamNo ratings yet

- IMG - 0043 PSME Code 2008 32Document1 pageIMG - 0043 PSME Code 2008 32Bugoy2023No ratings yet

- Ppis 9Document5 pagesPpis 9Fadilah Bint AbdulakeemNo ratings yet

- Machine Guarding.163121034Document53 pagesMachine Guarding.163121034Anonymous iI88LtNo ratings yet

- IMG - 0055 PSME Code 2008 44Document1 pageIMG - 0055 PSME Code 2008 44Arwyn BermasNo ratings yet

- IMG - 0057 PSME Code 2008 46Document1 pageIMG - 0057 PSME Code 2008 46Master JaguarNo ratings yet

- IMG - 0067 PSME Code 2008 56Document1 pageIMG - 0067 PSME Code 2008 56Arwyn BermasNo ratings yet

- h2 PDFDocument11 pagesh2 PDFSubhash Kumar KNo ratings yet

- Hazardous Activities AgriDocument1 pageHazardous Activities AgriRodrigo SuarezNo ratings yet

- Chapter 12 Machine SafeguardingDocument30 pagesChapter 12 Machine SafeguardingShah FahadNo ratings yet

- z14 171225105333 PDFDocument32 pagesz14 171225105333 PDFVương HoàngNo ratings yet

- dp60 PDFDocument31 pagesdp60 PDFDanilominaNo ratings yet

- We Will Cover:: Machine Guarding PrinciplesDocument32 pagesWe Will Cover:: Machine Guarding PrinciplesChaitanya MyneniNo ratings yet

- Rewinding Paper Safely: Safe Use of Reeling and Slitting MachinesDocument25 pagesRewinding Paper Safely: Safe Use of Reeling and Slitting MachinesRiandrika Iman SetyonoNo ratings yet

- IMG - 0029 PSME Code 2008 18Document1 pageIMG - 0029 PSME Code 2008 18Hnqr584hNo ratings yet

- Labour Laws - SafetyDocument29 pagesLabour Laws - Safetypriyanka pinkyNo ratings yet

- PM 66Document15 pagesPM 66Erdinc SenmanNo ratings yet

- Summit: Intuitive 16-Channel 8-Bus Digital Mixing ConsoleDocument44 pagesSummit: Intuitive 16-Channel 8-Bus Digital Mixing ConsoleJunior GodoiNo ratings yet

- Safety, Factories ActDocument49 pagesSafety, Factories ActHarshvardhan KambleNo ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet

- LSA Code Chapter IV 4-4-7-6 Amended by Res 320Document3 pagesLSA Code Chapter IV 4-4-7-6 Amended by Res 320rojoubeda63100% (1)

- Mitsubishi Crane Operational GuideDocument5 pagesMitsubishi Crane Operational GuideAlex Vie100% (1)

- Poseidon 1200Document22 pagesPoseidon 1200AndreAPLNo ratings yet

- Towing Winch Emergency Release Systems-Cu Aplicare Din 2020Document4 pagesTowing Winch Emergency Release Systems-Cu Aplicare Din 2020tonyNo ratings yet

- Material HseDocument6 pagesMaterial HseOsmar JrNo ratings yet

- Butterfly 5000 Sewing Machine InstructionsDocument48 pagesButterfly 5000 Sewing Machine InstructionsiliiexpugnansNo ratings yet

- Power Transmission Equipment Prime Movers MachinesDocument62 pagesPower Transmission Equipment Prime Movers MachinesLurking RogueNo ratings yet

- Wasscomat Junior - W - 75 - 105Document50 pagesWasscomat Junior - W - 75 - 105AdrianaMtzRNo ratings yet

- Need For Safety MeasuresDocument8 pagesNeed For Safety MeasuresSharad AgrawalNo ratings yet

- MANUAL Auto Coating.Document28 pagesMANUAL Auto Coating.Hernando Galindo PintoNo ratings yet

- Operation and Maintanance of Conveyor Belt Final 04-10-16Document11 pagesOperation and Maintanance of Conveyor Belt Final 04-10-16Guru Raja Ragavendran NagarajanNo ratings yet

- Los Angeles Abrasion Machine HM-70A & HM-70AF: Operating ManualDocument16 pagesLos Angeles Abrasion Machine HM-70A & HM-70AF: Operating ManualSalvatore LombardoNo ratings yet

- Plant MachineryDocument100 pagesPlant MachinerySahil GouthamNo ratings yet

- Manual Za Freeman Big Baler 1592D PDFDocument85 pagesManual Za Freeman Big Baler 1592D PDFcatalin9494No ratings yet

- Electric Pressure Washers: Offering A Wide Selection of Products at Competitive PricesDocument34 pagesElectric Pressure Washers: Offering A Wide Selection of Products at Competitive PricesSergiu Silviu SfetcuNo ratings yet

- Manual Singer Tradition 2282Document64 pagesManual Singer Tradition 2282Eva Muñoz RosúaNo ratings yet

- New Holland E70BSR Mini Excavator Service Repair ManualDocument21 pagesNew Holland E70BSR Mini Excavator Service Repair ManualggjjjjotonesNo ratings yet

- KRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902Document152 pagesKRESS MISSION KR172EKR173EKR174EOwnersmanual-20220902dakar3No ratings yet

- Carding MachinesDocument30 pagesCarding MachinessalmanarssNo ratings yet

- Manual p5000 Servicio CatDocument349 pagesManual p5000 Servicio CatSimón100% (1)

- Cangilones MARTIN - Catalogo 3000Document20 pagesCangilones MARTIN - Catalogo 3000MatiasBarretoNo ratings yet

- Ti Hse Ppis 10Document4 pagesTi Hse Ppis 10ayari med aliNo ratings yet

- Roller Circle - Remove and InstallDocument5 pagesRoller Circle - Remove and InstallGilney FreitasNo ratings yet

- Compacting and Baling EquipmentDocument2 pagesCompacting and Baling EquipmentYexiong YIALENGNo ratings yet

- Instruction Manual En: Please Read This User Manual Carefully Before Using The Appliance!Document24 pagesInstruction Manual En: Please Read This User Manual Carefully Before Using The Appliance!marc0No ratings yet

- IMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Document1 pageIMG - 0094 MCQ Bank For Computer Fundamentals MRC 19Arwyn BermasNo ratings yet

- IMG - 0313 MCQ Industrial Plant Engg 209Document1 pageIMG - 0313 MCQ Industrial Plant Engg 209Arwyn BermasNo ratings yet

- IMG - 0320 MCQ Industrial Plant Engg 223Document1 pageIMG - 0320 MCQ Industrial Plant Engg 223Arwyn BermasNo ratings yet

- IMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Document1 pageIMG - 0092 MCQ Bank For Computer Fundamentals MRC 17Arwyn BermasNo ratings yet

- IMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Document1 pageIMG - 0096 MCQ Bank For Computer Fundamentals MRC 21Arwyn BermasNo ratings yet

- IMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Document1 pageIMG - 0091 MCQ Bank For Computer Fundamentals MRC 16Arwyn BermasNo ratings yet

- IMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Document1 pageIMG - 0100 MCQ Bank For Computer Fundamentals MRC 25Arwyn BermasNo ratings yet

- IMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Document1 pageIMG - 0095 MCQ Bank For Computer Fundamentals MRC 20Arwyn BermasNo ratings yet

- IMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Document1 pageIMG - 0093 MCQ Bank For Computer Fundamentals MRC 18Arwyn BermasNo ratings yet

- IMG - 0292 MCQ Industrial Plant Engg 169Document1 pageIMG - 0292 MCQ Industrial Plant Engg 169Arwyn BermasNo ratings yet

- IMG - 0291 MCQ Industrial Plant Engg 167Document1 pageIMG - 0291 MCQ Industrial Plant Engg 167Arwyn BermasNo ratings yet

- IMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Document1 pageIMG - 0097 MCQ Bank For Computer Fundamentals MRC 22Arwyn BermasNo ratings yet

- IMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Document1 pageIMG - 0099 MCQ Bank For Computer Fundamentals MRC 24Arwyn BermasNo ratings yet

- IMG - 0076 MCQ EE Board Problem 2012 33Document1 pageIMG - 0076 MCQ EE Board Problem 2012 33Arwyn BermasNo ratings yet

- IMG - 0295 MCQ Industrial Plant Engg 175Document1 pageIMG - 0295 MCQ Industrial Plant Engg 175Arwyn BermasNo ratings yet

- IMG - 0208 PSME Code 2008 197Document1 pageIMG - 0208 PSME Code 2008 197Arwyn BermasNo ratings yet

- IMG - 0209 PSME Code 2008 198Document1 pageIMG - 0209 PSME Code 2008 198Arwyn BermasNo ratings yet

- IMG - 0201 PSME Code 2008 190Document1 pageIMG - 0201 PSME Code 2008 190Arwyn BermasNo ratings yet

- IMG - 0210 PSME Code 2008 199Document1 pageIMG - 0210 PSME Code 2008 199Arwyn BermasNo ratings yet

- IMG - 0207 PSME Code 2008 196Document1 pageIMG - 0207 PSME Code 2008 196Arwyn BermasNo ratings yet

- IMG - 0077 MCQ EE Board Problem 2012 34Document1 pageIMG - 0077 MCQ EE Board Problem 2012 34Arwyn BermasNo ratings yet

- IMG - 0073 MCQ EE Board Problem 2012 30Document1 pageIMG - 0073 MCQ EE Board Problem 2012 30Arwyn BermasNo ratings yet

- IMG - 0075 MCQ EE Board Problem 2012 32Document1 pageIMG - 0075 MCQ EE Board Problem 2012 32Arwyn BermasNo ratings yet

- IMG - 0205 PSME Code 2008 194Document1 pageIMG - 0205 PSME Code 2008 194Arwyn BermasNo ratings yet

- IMG - 0203 PSME Code 2008 192Document1 pageIMG - 0203 PSME Code 2008 192Arwyn BermasNo ratings yet

- IMG - 0078 MCQ EE Board Problem 2012 35Document1 pageIMG - 0078 MCQ EE Board Problem 2012 35Arwyn BermasNo ratings yet

- IMG - 0079 MCQ EE Board Problem 2012 36Document1 pageIMG - 0079 MCQ EE Board Problem 2012 36Arwyn BermasNo ratings yet

- IMG - 0074 MCQ EE Board Problem 2012 31Document1 pageIMG - 0074 MCQ EE Board Problem 2012 31Arwyn BermasNo ratings yet

- IMG - 0072 MCQ EE Board Problem 2012 29Document1 pageIMG - 0072 MCQ EE Board Problem 2012 29Arwyn BermasNo ratings yet

- IMG - 0071 MCQ EE Board Problem 2012 28Document1 pageIMG - 0071 MCQ EE Board Problem 2012 28Arwyn BermasNo ratings yet

- Jyske BankDocument7 pagesJyske BankRashed Rony100% (1)

- Operators Manual (Extruder) PDFDocument2 pagesOperators Manual (Extruder) PDFAthulya PallipurathNo ratings yet

- Bank Reconciliation StatementDocument2 pagesBank Reconciliation Statementvihanjangid223No ratings yet

- MCQs Chapters 156 - The Monetary PolicyDocument40 pagesMCQs Chapters 156 - The Monetary PolicyLộc TrầnNo ratings yet

- Detail Syllabus - Elective StatisticsDocument2 pagesDetail Syllabus - Elective StatisticsSut MouNo ratings yet

- Master INV SpecificationDocument171 pagesMaster INV Specificationsensor_versionNo ratings yet

- IAS 16 Property Plant EquipmentDocument4 pagesIAS 16 Property Plant EquipmentMD Hafizul Islam HafizNo ratings yet

- Managerial Ecnomics Subject Outline - StudentversionDocument10 pagesManagerial Ecnomics Subject Outline - StudentversionAhmed MunawarNo ratings yet

- ZF Test-CompressedDocument33 pagesZF Test-CompressedegadydqmdctlfzhnkbNo ratings yet

- Borang Utc 2022-New - 220314 - 071606Document16 pagesBorang Utc 2022-New - 220314 - 071606macanNo ratings yet

- Journal Entries and Ledger Accounts - FinalDocument6 pagesJournal Entries and Ledger Accounts - FinalMukul SinhaNo ratings yet

- Normal and Inferior GoodsDocument8 pagesNormal and Inferior GoodsVandana DubeyNo ratings yet

- Warehouses and Headquarters Addresses and Price List TemplateDocument22 pagesWarehouses and Headquarters Addresses and Price List TemplateTudor FlorinNo ratings yet

- LACROIX v. CANADA (1954) 4 D.L.R. 470: Presented byDocument3 pagesLACROIX v. CANADA (1954) 4 D.L.R. 470: Presented byLina KhalidaNo ratings yet

- Test Bank For Microeconomics 15th Canadian Edition Campbell R Mcconnell Stanley L Brue Sean Masaki Flynn Tom BarbieroDocument36 pagesTest Bank For Microeconomics 15th Canadian Edition Campbell R Mcconnell Stanley L Brue Sean Masaki Flynn Tom Barbieroovercloydop.qpio7p100% (45)

- Bio Sketch Jiban K. Mukhopadhyay Is at Present Consultant, Corporate Economics &Document5 pagesBio Sketch Jiban K. Mukhopadhyay Is at Present Consultant, Corporate Economics &shadab0123No ratings yet

- CSE Catalog - IndiaDocument67 pagesCSE Catalog - IndiaDheeraj SivadasNo ratings yet

- Cost - Handwritten Notes - (Aarambh 2024)Document14 pagesCost - Handwritten Notes - (Aarambh 2024)Vandana KatariaNo ratings yet

- Hidrolik Kirici Sarf Malzeme KataloguDocument132 pagesHidrolik Kirici Sarf Malzeme KataloguÇkta FıfiNo ratings yet

- Mindstone-Creating Change That Matters - HyperRevelanceDocument9 pagesMindstone-Creating Change That Matters - HyperRevelanceMoksh SharmaNo ratings yet

- Tabix 1-50 ENDocument1 pageTabix 1-50 ENuğur alparslanNo ratings yet

- Lion Air ETicket (LSGVFS) - SupriyadiDocument5 pagesLion Air ETicket (LSGVFS) - SupriyadiAfif sbyNo ratings yet

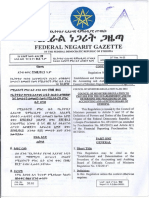

- Regulation No 332 2014 Establishment and Determination of The Procedure of The Accounting and Auditing Board of EthiopiaDocument20 pagesRegulation No 332 2014 Establishment and Determination of The Procedure of The Accounting and Auditing Board of EthiopiajemalNo ratings yet

- Economics For Investment Decision Makers Workbook Micro Macro and International Economics 1st Edition Christopher D. Piros CfaDocument43 pagesEconomics For Investment Decision Makers Workbook Micro Macro and International Economics 1st Edition Christopher D. Piros Cfabenjamin.johnson786100% (11)

- Terex RT780Document20 pagesTerex RT780Pelican PelcomNo ratings yet

- Cost AccountingDocument16 pagesCost AccountingDennis LacsonNo ratings yet

- Sample Requistion For Jay Vijay LLP Godrej Site DATED 23 JAN 2024Document4 pagesSample Requistion For Jay Vijay LLP Godrej Site DATED 23 JAN 2024kiranmisale7No ratings yet

- CSS 2018 Past PaperDocument7 pagesCSS 2018 Past PaperPrinxess ParasNo ratings yet