Professional Documents

Culture Documents

DA SRVP-Hygienic EN 060420

DA SRVP-Hygienic EN 060420

Uploaded by

Fernando RuedaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DA SRVP-Hygienic EN 060420

DA SRVP-Hygienic EN 060420

Uploaded by

Fernando RuedaCopyright:

Available Formats

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

Operating conditions:

Maximum pressure: 0,9 bar absolute up to <1,5 bar g.

Product temperature from -20°C up to 120°C with corresponding clearance for constant operating

temperature.

Bulk solid data:

Powder form, up to medium hardness.

Free flowing up to limited flowing products.

Referencia Entrada / Salida Altura V / vuelta Peso

SRVP1504Y01B Ø 150 mm 320 mm 5 dm3 130 kg

SRVP2007Y01B Ø 200 mm 375 mm 9,5 dm3 165 kg

SRVP2515Y01C Ø 250 mm 450 mm 19 dm3 220 kg

*) Flange-outside-Ø and holes acc. to PN10 DIN2576

Basical version:

According to EHEDG-guidelines type EL-Class II, machinery

directive 2006/42/EC, DIN EN ISO 14159 (hygienic

requirements), DIN EN 1672-2 (food machinery) and GMP/FDA-

requirements.

Housing: casted stainless steel 1.4408 (DIN) / CF-8M (AISI).

Rotor: welding construction – stainless steel 1.4307 (DIN) / 304L

(AISI). 8 rounded pockets, rotor extensible without leading rails. Shown with

options 1 and 3

Outside bearings.

Shaft seal: radial shaft sealing rings FDA-approved with

sealing/purge air connection.

Pneumatic installation for sealing / purge air, consisting of 2/2-

way solenoid valve, pressure regulator and nozzles.

Hygienic design for food, pharma, cosmetics and chemistry.

Easy to dismantle, easy to clean, free of dead zones and free of

gaps, possibility to CIP.

In contact with product (inside) surface quality Ra < 0,8 µm.

Weldings free of gaps. High-quality automatical weldings Ra~3

Rotor with rounded pockets:

µm and not grinded.

Corners and edges with wide radius.

Gapfree connection between housing and bearing shield.

Shock pressure proof 10 bar, flame propagation proof

Drive: direct.

Motor: three-phase gearboxmotor, manufacturer: SEW,

Separately specified.

Form: slip on gear with torque arm.

approval: MIGSA SST Preliminary

Date: Sign: Date: Sign: Modifications reserved

06.04.20 Ru

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 1 of 6

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

Bearing of the rotor in the shield with bearing

bushings (1) 1 2

Advantage:

When pulling the rotor out the sealings

remain intact, because the bearing bushing

stay in the shield

Double bearing (2) of the rotor shaft in the

bearing bushing

Advantage:

Exact radial fixing and absorbing of high

bending moments due to pressure

differences

Sealing of the bearing and the rotor shaft

against the product zone by use of a co-

rotating seal disc (3) and a circular flushing

chamber (4) with purge air / gas

Advantage:

The area of the bearing need not to be cleaned 4

during CIP-cleaning the purge air / gas prevents 3

the entry of the cleaning fluid into the area of the

bearing

5 6

Axial centering device with adjustable screw

socket and fixed stop (5)

Axial free of clearance rotor bearing by use of

suitable ball bearings (6) and axial fixing of the

bearing bushing

Fixing of the rotor with only one bolt (7)

Advantage:

Simple and time saving disassembly and

assembly of the rotor without adjustment of the

gap between rotor and housing

7

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 2 of 6

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

Wet cleaning CIP

1. Rotor remains assembled

2. Washing the valve with cleaning liquid when the rotor is rotating

and purge of the shaft throughput with compressed air

3. Drying, analog washing

4. If necessary after the CIP-cleaning the rotor will be pulled out and

the cleanness of the critical points will be checked and secondary

cleaned. During validation of the CIP-cleaning the additional

actions (inspection, cleaning) will be defined.

5. Rotor push in again

Protective system:

Shock pressure proof 10 bar, flame propagation proof.

Suitable for zone 20 inside and protective system category 1

acc. ATEX 2014/34/EU.

Without sensoric and control.

For dust explosions grade St1 and St2, Kst value from 0 to

300 bar x m x s-1.

With type examination test by a notified body. Certificate

number FTZÚ 18 ATEX 0126X.

With water pressure test for housing with bearing shields.

Maximum 20 turn/min. due to type examination.

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 3 of 6

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

Options:

1. Pull out device with leading rails. 5. Leakage air collector

with granule inlet

made of stainless

steel 1.4307 (DIN) /

304L (AISI).

Pressure shock resistant. Hygienic-

design. In contact with product, inside,

surface quality Ra < 0,8 µm, outside <

3,0 µm. Incl. connection parts for

assembling.

6. Leakage air collector

for powders made of

2. Electropolished, incl. leakage air collector / stainless steel

granule inlet / blowing shoe. 1.4307 (DIN) / 304L

3. Inlet and outlet with centering flange and (AISI).

connection pipe plain. Pressure shock Pressure shock resistant. Hygienic-

resistant. Hygienic-design. In contact with design. In contact with product, inside,

product, inside, surface quality Ra < 0,8 µm, surface quality Ra < 0,8 µm, outside <

outside < 3,0 µm. Incl. connection parts for 3,0 µm. Incl. connection parts for

assembling. assembling.

7. Blowing shoe for

pneumatic conveying

made of stainless

steel 1.4307 (DIN) /

304L (AISI).

Pressure shock resistant. Hygienic-design.

In contact with product, inside, surface

4. Granule inlet for

quality Ra < 0,8 µm, outside < 3,0 µm.

grain size > 500 µm Pipeline connection without flange. Incl.

cubic up to 10 mm, connection parts for assembling.

made of stainless

steel 1.4307 (DIN) / 8. Casted parts made of 1,4408 (DIN) / CF-

304L (AISI). 8M (AIS), rest 1.4404 (DIN) / 316L (AISI),

Pressure shock resistant. Hygienic-design. incl. leakage air collector / granule inlet /

In contact with product, inside, surface blowing shoe.

quality Ra < 0,8 µm, outside < 3,0 µm. 9. Casted parts made of 1,4408 (DIN) / CF-

Incl. connection parts for assembling. 8M (AIS), rest 1.4571 (DIN) / 316Ti (AISI),

incl. leakage air collector / granule inlet /

blowing shoe.

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 4 of 6

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

10. Standstill monitoring with star and sensor 13. Blowing shoe for pneumatic conveying

made of stainless steel 1.4307 (DIN) /

304L (AISI). Pressure shock resistant.

Hygienic-design. In contact with

product, inside, surface quality Ra < 0,8

µm, outside < 3,0 µm. Pipeline

connection with clamp. Incl. connection

parts assembled.

14. Pneumatic discharge of the pockets for

cohesive products, incl. pneumatic

11. Protective system, shock pressure

installation.

proof 13 bar for dust explosion class

St 1 and St 2, Kst-value 0 up to 300

bar x m x s-1, maximum explosion

pressure 13 bar, rotor with 10 rounded

pockets made of stainless steel

1.4307 (DIN) / 304L (AISI), reinforced

design. Certificate number BVS 10

ATEX H 014 X N1.

Type V / turn

SRVP1504Y01B 3,6 dm3

SRVP2007Y01B 6,7 dm3

15. Dosing-stop by switching-off-positioning of

SRVP2515Y01C 15,5 dm3

the rotor with 8 or 10-finger-star

(depending on the selected rotor) and

12. Protective system, shock pressure sensor.

proof 10 bar for dust explosion class

St 3, Kst-value >300 bar x m x s-1,

maximum explosion pressure 10 bar,

rotor with 10 rounded pockets made

of stainless steel 1.4307 (DIN) / 304L

(AISI), reinforced design. Certificate

number BVS 10 ATEX H 014 X N1.

Type V / turn

SRVP1504Y01B 3,6 dm3

SRVP2007Y01B 6,7 dm3 16. Electrical parts outside, suitable for zone

SRVP2515Y01C 15,5 dm3 2/22.

17. Electrical parts outside, suitable, for zone

1/21.

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 5 of 6

Datasheet

solids - Rotary Valve / Protective System

SRVP - Hygienic-Wet

18. Nitriding thermic treatment by absortion

for wear protection in housing, caps and

rotor. Penetrates until 50 µm. Obtained

hardness: between 600 and 1000 HV.

Related documents:

3D-Part: Type.step (example : SRVP15005Y01. Step)

2D-planning drawing: Type.dxf (example: SRVP15005Y01. dxf)

Selection criteria: SG- ZRS-SRV-DBS

Pricelist: PL-SRVP-Hygienic

List of drawing numbers: Draw-No-List_SRVP-Hygienic

solids solutions group

www.solids.eu

\\SERVIDOR\Documentacion\01 Datasheet\7. solids Zellenradschleusen_Válvulas rotativas\06_SRVP-Hygienic\DA_SRVP-Hygienic_EN_060420.doc Page 6 of 6

You might also like

- Dormakaba Ro Price List 2020Document220 pagesDormakaba Ro Price List 2020The DarkNo ratings yet

- Logan Standard Releasing Spear ManualDocument37 pagesLogan Standard Releasing Spear ManualSamuel Arévalo GNo ratings yet

- Catalog WiperDocument24 pagesCatalog WiperRicardo RivasNo ratings yet

- Topworx DXP - Installation and ConfigurationDocument52 pagesTopworx DXP - Installation and ConfigurationJames Dawe100% (1)

- Lit Fta156 TechDocument12 pagesLit Fta156 TechNaser JahangiriNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- Non-return-Valves M2010 Sudmo LeafletDocument2 pagesNon-return-Valves M2010 Sudmo Leafletwili_ab8040No ratings yet

- Manometre Fise Tehnice 2000.i PDFDocument2 pagesManometre Fise Tehnice 2000.i PDFGaina IOnutNo ratings yet

- Non-Return Valve enDocument2 pagesNon-Return Valve enMilagritos Sánchez De OroNo ratings yet

- Mechanical Seals in AgitatorsDocument6 pagesMechanical Seals in AgitatorsLy Ca TieuNo ratings yet

- Flowserve Kämmer 191000Document8 pagesFlowserve Kämmer 191000ALFREDO SANTANANo ratings yet

- 3SU15500AA100AA0_datasheet_enDocument3 pages3SU15500AA100AA0_datasheet_enYgor BarretoNo ratings yet

- Kayttoohje - SSG600 A DCDocument34 pagesKayttoohje - SSG600 A DCuripssgmailNo ratings yet

- Shaffer ShpericalDocument11 pagesShaffer Shpericaljeinerdt100% (1)

- VZAV 202303 enDocument32 pagesVZAV 202303 enMafe CastilloNo ratings yet

- Tech 1440 ManDocument23 pagesTech 1440 ManRiski Kurniawan67% (3)

- Datasheet n5500 Low Pressure Capsule GaugeDocument5 pagesDatasheet n5500 Low Pressure Capsule GaugeLuis AliagaNo ratings yet

- Catalogo de Presion ReotempDocument48 pagesCatalogo de Presion Reotempdiuska13No ratings yet

- Butterfly Valve ConcentricDocument6 pagesButterfly Valve ConcentricpramodtryNo ratings yet

- Archivos 1387 A 0Document11 pagesArchivos 1387 A 0Anonymous K3FaYFlNo ratings yet

- ISC2 Series Broch A4Document6 pagesISC2 Series Broch A4isosicaNo ratings yet

- High Pressure Quick Release CouplingsDocument43 pagesHigh Pressure Quick Release Couplingssushant0261100% (1)

- Erreesse SRL - BrochureDocument32 pagesErreesse SRL - BrochureEduardo VasquezNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- Bar Pneumatic Actuators GT ENG BET O BW GT EnglischDocument28 pagesBar Pneumatic Actuators GT ENG BET O BW GT EnglischMỹ Anh 3B-PhạmNo ratings yet

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet

- OverpressureDocument2 pagesOverpressureampowersidNo ratings yet

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujNo ratings yet

- DA PIP-Hygienic-Dry PIV PIS PIVS EN 110418Document9 pagesDA PIP-Hygienic-Dry PIV PIS PIVS EN 110418Fernando RuedaNo ratings yet

- Schneider Electric Harmony-XB6 XB6ETN521PDocument7 pagesSchneider Electric Harmony-XB6 XB6ETN521Pktsaprazis2No ratings yet

- Dichta CatalogueDocument62 pagesDichta CataloguemaxatadesignNo ratings yet

- Guth Non-Return Valve: A Good ChoiceDocument4 pagesGuth Non-Return Valve: A Good ChoiceВалентин КовальчукNo ratings yet

- 3SU15000AA100AA0 Datasheet enDocument3 pages3SU15000AA100AA0 Datasheet ensuadNo ratings yet

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- WG OrbinoxDocument11 pagesWG Orbinoxsam alfajayaenergyNo ratings yet

- Kammer Series 191000 PDFDocument8 pagesKammer Series 191000 PDFyg89No ratings yet

- Type 1227: Installation, Operation and Maintenance InstructionsDocument11 pagesType 1227: Installation, Operation and Maintenance InstructionsgffNo ratings yet

- Single Seat Valves SVP Select Sudmo Leaflet v2110 enDocument2 pagesSingle Seat Valves SVP Select Sudmo Leaflet v2110 enMark JonesNo ratings yet

- Dossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Document212 pagesDossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Bureau VeritasNo ratings yet

- Pump DatasheetDocument15 pagesPump DatasheetHedi Ben MohamedNo ratings yet

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- MeasureMaster Dual Chamber Orifice FittingDocument6 pagesMeasureMaster Dual Chamber Orifice FittingirfanNo ratings yet

- Differential Pressure Recorder Data SheetDocument8 pagesDifferential Pressure Recorder Data SheetEdmund LimNo ratings yet

- DS2300 2300 8802 Yg Eu enDocument16 pagesDS2300 2300 8802 Yg Eu enLucas Vinícius CostaNo ratings yet

- O Ring BrochureDocument36 pagesO Ring BrochureJesus N RodriguezNo ratings yet

- What Is A Flushing RingDocument6 pagesWhat Is A Flushing RingFarooqNo ratings yet

- Swivel Joint 229-244Document16 pagesSwivel Joint 229-244Gregory StewartNo ratings yet

- Omml 7 201 300 B enDocument7 pagesOmml 7 201 300 B enEngr Mohammed UsmaniaNo ratings yet

- RCS Staubli A100eDocument8 pagesRCS Staubli A100eFlávio leme da SilvaNo ratings yet

- AVT Ball & Butterfly Brochure 05 Latest 12 PageDocument12 pagesAVT Ball & Butterfly Brochure 05 Latest 12 PageshalbyNo ratings yet

- B-971 LGT MBE Mixer 04 2018Document8 pagesB-971 LGT MBE Mixer 04 2018lsisniegasNo ratings yet

- CSTR Oring Catalog Or2009Document48 pagesCSTR Oring Catalog Or2009roccandradoNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Oring With Back Up For High PressureDocument33 pagesOring With Back Up For High PressureGaurav MahajanNo ratings yet

- Multi-Port Flow Selector Valve: KitsnetDocument14 pagesMulti-Port Flow Selector Valve: KitsnetNigin ParambathNo ratings yet

- Alfa Laval Sru Rotary Lobe Pump Product LeafletDocument5 pagesAlfa Laval Sru Rotary Lobe Pump Product Leafletمصطفى محمدNo ratings yet

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDocument8 pagesW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999No ratings yet

- Namur Solenoid Valves BFD27-2Document12 pagesNamur Solenoid Valves BFD27-2tungbk9No ratings yet

- Loss in Weight - ScalesDocument4 pagesLoss in Weight - ScalesFernando RuedaNo ratings yet

- DA SRVS-Hygienic EN 060420Document5 pagesDA SRVS-Hygienic EN 060420Fernando RuedaNo ratings yet

- DA DKA-Basic EN 080221Document6 pagesDA DKA-Basic EN 080221Fernando RuedaNo ratings yet

- Da Srvs-Clean en 060420Document4 pagesDa Srvs-Clean en 060420Fernando RuedaNo ratings yet

- Solids - Big-Bag-Discharger: Datasheet BBD-V-CleanDocument5 pagesSolids - Big-Bag-Discharger: Datasheet BBD-V-CleanFernando RuedaNo ratings yet

- DA EVK-Basic EN 050121Document5 pagesDA EVK-Basic EN 050121Fernando RuedaNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Datasheet DR2-06 Ha0026 ENDocument2 pagesDatasheet DR2-06 Ha0026 ENBryan AlexisNo ratings yet

- FALSE CeilingDocument1 pageFALSE CeilingNidhi KauravNo ratings yet

- Alcaldia Mixed Rendering PlantDocument1 pageAlcaldia Mixed Rendering Plantgrovertarqui77No ratings yet

- Tecline Regulator V1 - V2 - CATALOGDocument12 pagesTecline Regulator V1 - V2 - CATALOGMTNo ratings yet

- CP100 STD Pump Build & Service Manual Revision 2 01-Sep-09Document11 pagesCP100 STD Pump Build & Service Manual Revision 2 01-Sep-09ISRAEL GONZALESNo ratings yet

- SsovgasvalvesDocument12 pagesSsovgasvalvesTin Aung KyiNo ratings yet

- Item 3 - GA10010211 PN 400824Document1 pageItem 3 - GA10010211 PN 400824Pablo GarcíaNo ratings yet

- SC Bulk Hose Handling Guidance DocumentDocument24 pagesSC Bulk Hose Handling Guidance DocumentLeonardo AlvarezNo ratings yet

- Seat Cordoba 1.4 16v 2002-2010: Timing Belt: Removal/installationDocument11 pagesSeat Cordoba 1.4 16v 2002-2010: Timing Belt: Removal/installationMihaiCapraruNo ratings yet

- Siemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesDocument88 pagesSiemens Steam Turbine Portfolio Steam Turbines From 10 KW To 1,900 MW Siemens - Com - SteamturbinesaminardakaniNo ratings yet

- Hh7 CatalogDocument1 pageHh7 Catalogjitender kumarNo ratings yet

- 2K20S3R236A-6B: Panasonic Industrial CompanyDocument22 pages2K20S3R236A-6B: Panasonic Industrial CompanyGeiler Benitez PiñaNo ratings yet

- Lowprofile DTI HolderDocument4 pagesLowprofile DTI HolderArniNo ratings yet

- Bop, Pressure Test Skid, Shopfloor, Tam 410Document5 pagesBop, Pressure Test Skid, Shopfloor, Tam 410Śąmįř BęłğcęmNo ratings yet

- Robak v2.2 InfoDocument26 pagesRobak v2.2 InfoozhanaNo ratings yet

- Manual de TritonDocument28 pagesManual de Tritonperla_canto_1No ratings yet

- Tensile Load and Tightening Torque: Bolt Class, Coarse PitchDocument2 pagesTensile Load and Tightening Torque: Bolt Class, Coarse Pitchfater esmandarNo ratings yet

- PCM 2.0l 3 de 5Document2 pagesPCM 2.0l 3 de 5Felix VelasquezNo ratings yet

- 110 Series Solution Tanks: Low-Cost Chemical Storage Tanks Made For Years of Dependable ServiceDocument2 pages110 Series Solution Tanks: Low-Cost Chemical Storage Tanks Made For Years of Dependable ServiceFer PabNo ratings yet

- MR372J8420A000Document7 pagesMR372J8420A000Ilhami DemirNo ratings yet

- Girth Gears - More Than Just Metal and Teeth: Steve LovellDocument8 pagesGirth Gears - More Than Just Metal and Teeth: Steve LovellFurqan ShabbirNo ratings yet

- LG Refrigerator Compressor CatalogueDocument11 pagesLG Refrigerator Compressor CatalogueMilos Lazovic73% (11)

- Marine Railway Site InstallationDocument14 pagesMarine Railway Site Installationtapumonisha.navalNo ratings yet

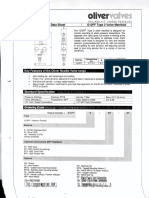

- Drawing Oliver ValveDocument1 pageDrawing Oliver ValveANTONIUS TRIMARTANTONo ratings yet

- CW 630 PJDocument1 pageCW 630 PJSuryacendra PuramegahNo ratings yet

- Door LocksetDocument11 pagesDoor LocksetJustine PadillaNo ratings yet

- Inspection and Test Plan (ITP) / Quality Control ProcedureDocument3 pagesInspection and Test Plan (ITP) / Quality Control Proceduremanunited unitedNo ratings yet