Professional Documents

Culture Documents

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

Uploaded by

JOSUE FERNANDO FERNANDEZCopyright:

Available Formats

You might also like

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- Permit To Work: Construction & Commissioning Procedures ManualDocument16 pagesPermit To Work: Construction & Commissioning Procedures ManualALADINHENo ratings yet

- Manual Docs-200Document134 pagesManual Docs-200Javier Rizo50% (2)

- SW200i Install Manual Rev 3.0 PDFDocument82 pagesSW200i Install Manual Rev 3.0 PDFSyed iliyasNo ratings yet

- Interference of Light & It's Applications (Interferometry)Document24 pagesInterference of Light & It's Applications (Interferometry)Pranav Marathe100% (11)

- Hobart Handler 175 220 VAC MIG Welder User Manual O944 - HobDocument48 pagesHobart Handler 175 220 VAC MIG Welder User Manual O944 - HobrbastaNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- Aa39 SeriesDocument28 pagesAa39 Seriesjoel alvaradoNo ratings yet

- MC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1Document10 pagesMC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1nguyenmainamNo ratings yet

- Method Statement: American University-Small Cost Renovation ProjectDocument7 pagesMethod Statement: American University-Small Cost Renovation ProjectAnonymous X37L15QznoNo ratings yet

- 00etb Manual en v1.0Document16 pages00etb Manual en v1.0lachgarboutaina07No ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- TES-ELEC-FACGND Facility General Grounding Specification (CDN-US-MEX)Document14 pagesTES-ELEC-FACGND Facility General Grounding Specification (CDN-US-MEX)Vladimir Javier Aleman AndradeNo ratings yet

- OPS-EnG-3-005-00 Electrostatic Discharge (ESD) Control Procedure Rev DDocument42 pagesOPS-EnG-3-005-00 Electrostatic Discharge (ESD) Control Procedure Rev Dmanuel100% (1)

- PDR 5 Ems 002 R00Document110 pagesPDR 5 Ems 002 R00wan haffizNo ratings yet

- Norme EchangeurDocument85 pagesNorme EchangeurBilalNo ratings yet

- Sprinklers Fire ProtectionDocument30 pagesSprinklers Fire Protectionsmarika.tamrakar32No ratings yet

- 150 67-NM1Document228 pages150 67-NM1mariaNo ratings yet

- Cooling Gas Compressor: DP07J1-FE21-E3020-RS504Document5 pagesCooling Gas Compressor: DP07J1-FE21-E3020-RS504Haitham AbdEl-TawabNo ratings yet

- Attachment A: Engineering Standards Manual STD-342-100Document29 pagesAttachment A: Engineering Standards Manual STD-342-100SAURABH SINGHNo ratings yet

- MC20005 WHP WI P 0115 - Stand Pipe Datasheet Work Instruction - RevD1Document7 pagesMC20005 WHP WI P 0115 - Stand Pipe Datasheet Work Instruction - RevD1nguyenmainamNo ratings yet

- MOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseDocument25 pagesMOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseKingston RivingtonNo ratings yet

- SP-1131Hand Over & As-Built DocsDocument22 pagesSP-1131Hand Over & As-Built DocskattabommanNo ratings yet

- 1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00Document12 pages1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00jaffrinNo ratings yet

- 03 150000 4100001496 SPM Ele MST 000005 - 01Document32 pages03 150000 4100001496 SPM Ele MST 000005 - 01ImthiyazAliAhamedHNo ratings yet

- M040 Operator ManualDocument12 pagesM040 Operator Manualingener.giza2582No ratings yet

- MC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1Document8 pagesMC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1nguyenmainamNo ratings yet

- Oil Seal DesignDocument10 pagesOil Seal DesignRavindra PawarNo ratings yet

- 1126-MIG-SDS-105-B1 (FDS - AI - Family - B1)Document98 pages1126-MIG-SDS-105-B1 (FDS - AI - Family - B1)makramNo ratings yet

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- EDS 07-4110 Grid and Primary Transformer Retrospective Oil ContainmentDocument16 pagesEDS 07-4110 Grid and Primary Transformer Retrospective Oil ContainmentNgoni MafondokotoNo ratings yet

- Specification For Sprinkler DesignDocument14 pagesSpecification For Sprinkler DesignFarhan AhmedNo ratings yet

- 667 Ds 20664 000Document19 pages667 Ds 20664 000ALDONSANo ratings yet

- Mcs - Method StatementsDocument179 pagesMcs - Method StatementsMitendra Kumar ChauhanNo ratings yet

- Nonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsDocument46 pagesNonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsMahdy MazinyNo ratings yet

- Specification For Instrumentation ControlDocument68 pagesSpecification For Instrumentation ControlSorinNo ratings yet

- 150.72-RP1 Ylaa 2Document54 pages150.72-RP1 Ylaa 2José RamosNo ratings yet

- Mots-76 - Mog-Ep-Plr-Std-0076Document7 pagesMots-76 - Mog-Ep-Plr-Std-0076botmaxNo ratings yet

- MQ SP I 7024 PDFDocument33 pagesMQ SP I 7024 PDFJaseelKanhirathinkalNo ratings yet

- MOS For Electrical Board Turn OnDocument8 pagesMOS For Electrical Board Turn OnYuz FiNo ratings yet

- Infineon-MOSFET OptiMOS Datasheet explanation-AN-v01 00-EN PDFDocument30 pagesInfineon-MOSFET OptiMOS Datasheet explanation-AN-v01 00-EN PDFrajeshNo ratings yet

- Vol1 12Document41 pagesVol1 12keerthi dayarathnaNo ratings yet

- Installation and Calibration of Instruments GuidanceDocument17 pagesInstallation and Calibration of Instruments GuidanceCarlos SalazarNo ratings yet

- Solving The Current Challenges Requires A Multidimensional View of Engineering SimulationDocument12 pagesSolving The Current Challenges Requires A Multidimensional View of Engineering SimulationKyon EsdelleNo ratings yet

- Air Transport Association: E-Business Specification For Materiels ManagementDocument132 pagesAir Transport Association: E-Business Specification For Materiels ManagementRiadh BelaizNo ratings yet

- Spec 2000 S2K - Ch12 - 2004.1Document150 pagesSpec 2000 S2K - Ch12 - 2004.1deardevenNo ratings yet

- CER Example Registry: Professional Development ProgramDocument13 pagesCER Example Registry: Professional Development ProgramPradyut TiwariNo ratings yet

- Specification For Nickel Base Alloy 625 Plus (UNS N07716) AND ALLOY 725 (UNS N07725) FOR OIL and Gas Drilling and Production EquipmentDocument20 pagesSpecification For Nickel Base Alloy 625 Plus (UNS N07716) AND ALLOY 725 (UNS N07725) FOR OIL and Gas Drilling and Production EquipmentakintundeakinboladeNo ratings yet

- Southwest Association ESD: February MeetingDocument3 pagesSouthwest Association ESD: February MeetingNilesh NarkhedeNo ratings yet

- Piping and Equipment InsulationDocument22 pagesPiping and Equipment InsulationRampal Rahul Rampal RahulNo ratings yet

- COP0010 Iss 3Document4 pagesCOP0010 Iss 3nigelNo ratings yet

- Ylaa0070 - Ylaa0120Document108 pagesYlaa0070 - Ylaa0120Juan David Hurtado CuencaNo ratings yet

- ESR - Rev 5.0 HSE-OC-01-05Document105 pagesESR - Rev 5.0 HSE-OC-01-05balajiNo ratings yet

- Saes J 902Document32 pagesSaes J 902Mudabbir HussainNo ratings yet

- Comment Resolution Sheet (CRS) : Document No. REV E1121-240-PS-DS-101437 - 7 0Document6 pagesComment Resolution Sheet (CRS) : Document No. REV E1121-240-PS-DS-101437 - 7 0sumit kumarNo ratings yet

- Siemens Service Report AVR Adjustment September 2012 Report-2712 PDFDocument4 pagesSiemens Service Report AVR Adjustment September 2012 Report-2712 PDFJurekNo ratings yet

- Special Notice: Anodyne Electronics Manufacturing CorpDocument24 pagesSpecial Notice: Anodyne Electronics Manufacturing CorpLin FengNo ratings yet

- AHS 3000+Attitude+Heading+Reference+SystemDocument121 pagesAHS 3000+Attitude+Heading+Reference+Systemgilgamesh riponziNo ratings yet

- Sow 1000483 TW 834 15 75 006Document38 pagesSow 1000483 TW 834 15 75 006Sayed AhammadNo ratings yet

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- Dep 31.10.03.10 - Symbols and Identification System - MechanicalDocument15 pagesDep 31.10.03.10 - Symbols and Identification System - Mechanicalsudeep9666No ratings yet

- 2013-06 - June Monthly ReportDocument74 pages2013-06 - June Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- Siemens Confirmation of NTP - Santo Domingo - January 27 2012Document1 pageSiemens Confirmation of NTP - Santo Domingo - January 27 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- Siemens NTP Offshore Invoice - Santo Domingo - January 27 2012Document1 pageSiemens NTP Offshore Invoice - Santo Domingo - January 27 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- Pe1007-Ds00-000-0391-10 - Acoustical Test ProcedureDocument19 pagesPe1007-Ds00-000-0391-10 - Acoustical Test ProcedureJOSUE FERNANDO FERNANDEZNo ratings yet

- 2013-05 - May Monthly ReportDocument69 pages2013-05 - May Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- 2013-09 - September Monthly ReportDocument76 pages2013-09 - September Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- SD R TCH Sei NNNNDocument1 pageSD R TCH Sei NNNNJOSUE FERNANDO FERNANDEZNo ratings yet

- TIR PRE-ING Siemens 006 - ResponseDocument2 pagesTIR PRE-ING Siemens 006 - ResponseJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-FINAL REPORT-Final Seismic Hazard Analysis and Geotechnical EvaluationDocument149 pagesPE1007-FINAL REPORT-Final Seismic Hazard Analysis and Geotechnical EvaluationJOSUE FERNANDO FERNANDEZNo ratings yet

- Energy, Inc.: Attached Document(s) Are Provided For Design/ConstructionDocument1 pageEnergy, Inc.: Attached Document(s) Are Provided For Design/ConstructionJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0006 - Monthly Progess Report For Ending Period FebruaryDocument1 pageSD-L-SEI-TCH-0006 - Monthly Progess Report For Ending Period FebruaryJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalDocument2 pagesSD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0011 - Certification of Completion-Offshore Work Payment Milestone 2Document5 pagesSD-L-SEI-TCH-0011 - Certification of Completion-Offshore Work Payment Milestone 2JOSUE FERNANDO FERNANDEZNo ratings yet

- Irvine Insurance Cert 2012Document1 pageIrvine Insurance Cert 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)Document3 pagesSD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)JOSUE FERNANDO FERNANDEZNo ratings yet

- SD L SEI TCH 0002 Communication ProcessesDocument2 pagesSD L SEI TCH 0002 Communication ProcessesJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0003 - Certification of Milestone Completion and Payment Request For Milestone 1Document3 pagesSD-L-SEI-TCH-0003 - Certification of Milestone Completion and Payment Request For Milestone 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundDocument2 pagesPE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0008 - Offshore Work Payment Milestone 1Document2 pagesSD-L-SEI-TCH-0008 - Offshore Work Payment Milestone 1JOSUE FERNANDO FERNANDEZNo ratings yet

- SD L SEI TCH 0005 - Introduction Meeting On March 15Document1 pageSD L SEI TCH 0005 - Introduction Meeting On March 15JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorDocument1 pageSD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorJOSUE FERNANDO FERNANDEZNo ratings yet

- Form 10-KDocument100 pagesForm 10-KJOSUE FERNANDO FERNANDEZNo ratings yet

- 1-A) BIS-711 Form - PRELLENADO POR FIRMARDocument1 page1-A) BIS-711 Form - PRELLENADO POR FIRMARJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationDocument2 pagesSD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012Document7 pagesSD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012JOSUE FERNANDO FERNANDEZNo ratings yet

- 130 M 20026 - 0Document1 page130 M 20026 - 0JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1Document2 pagesPE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- How To Download by Upload CheatDocument2 pagesHow To Download by Upload Cheatng chee yongNo ratings yet

- Alcatel 1660 SMDocument8 pagesAlcatel 1660 SMILiketobWithuNo ratings yet

- 4.2.6 Lab - Working With Text Files in The CLIDocument10 pages4.2.6 Lab - Working With Text Files in The CLITran Truong Giang (K16HCM)No ratings yet

- MCQ Artificial Intelligence Class 10 Computer VisionDocument41 pagesMCQ Artificial Intelligence Class 10 Computer VisionpratheeshNo ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Advanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution SystemsDocument15 pagesAdvanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution Systemsndaryanto 92No ratings yet

- s2s VPN User GuideDocument57 pagess2s VPN User GuidealozieNo ratings yet

- Big Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemDocument31 pagesBig Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemShushanth munna100% (1)

- RTU QuestionnaireDocument7 pagesRTU Questionnaireimadz853No ratings yet

- GOMO Complete Document February 2020 2 242Document1 pageGOMO Complete Document February 2020 2 242RICROD71No ratings yet

- Zain Asif Allied-Data ScientistDocument3 pagesZain Asif Allied-Data ScientistZain AsifNo ratings yet

- Aab-e-Kausar by Mufti Ameen PDFDocument306 pagesAab-e-Kausar by Mufti Ameen PDFSamina Kosar96% (26)

- 5.FM-ENG-05 Part Submission WarrantDocument1 page5.FM-ENG-05 Part Submission WarrantUttrakhand Vibes- OriginalNo ratings yet

- 11.inheritance and PolymorphismDocument47 pages11.inheritance and PolymorphismVivek BhardwajNo ratings yet

- 2A Introduction EDP AuditDocument98 pages2A Introduction EDP AuditnasrciaNo ratings yet

- Wiley - Nonlinear Finite Elements For Continua and Structures - Ted Belytschko, Wing Kam Liu, Brian Moran PDFDocument2 pagesWiley - Nonlinear Finite Elements For Continua and Structures - Ted Belytschko, Wing Kam Liu, Brian Moran PDFnikunjkavadiaNo ratings yet

- Ug 146 PDFDocument36 pagesUg 146 PDFTrần LinhNo ratings yet

- CIT212Document255 pagesCIT212CharlesNo ratings yet

- HDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsDocument44 pagesHDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsVy TungNo ratings yet

- User Manual: Model M834 SeriesDocument21 pagesUser Manual: Model M834 SeriesMarcelo WillyNo ratings yet

- Violence in Digital Communication Social Media Through TH - 2023 - MeasurementDocument7 pagesViolence in Digital Communication Social Media Through TH - 2023 - MeasurementFelix PhilipNo ratings yet

- Developing Thermoplastic Composites For Use in Commercial Aircraft - Aerospace & Defense TechnologyDocument9 pagesDeveloping Thermoplastic Composites For Use in Commercial Aircraft - Aerospace & Defense TechnologyБердик БайсерикNo ratings yet

- Welcome To Atmel-Wincupl V5.30.3Document8 pagesWelcome To Atmel-Wincupl V5.30.3imenenouvelleNo ratings yet

- TAM Final LASDocument4 pagesTAM Final LASprintsbyarishaNo ratings yet

- PGL - Online 101.1 DraftDocument4 pagesPGL - Online 101.1 DraftZaeni AhmadNo ratings yet

- Service Manual - Canon Ir2422 - 2420 - 2320 - 2318Document286 pagesService Manual - Canon Ir2422 - 2420 - 2320 - 2318Nonon Raingam79% (14)

- Advanced Linux: Exercises: 0 Download and Unpack The Exercise Files (Do That First Time Only)Document6 pagesAdvanced Linux: Exercises: 0 Download and Unpack The Exercise Files (Do That First Time Only)Niran SpiritNo ratings yet

- Tensores Van GorpDocument17 pagesTensores Van GorpsalematadorNo ratings yet

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

Uploaded by

JOSUE FERNANDO FERNANDEZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

PE1007-XK01-MB-013100 - Customer Piping Connection Process Information

Uploaded by

JOSUE FERNANDO FERNANDEZCopyright:

Available Formats

Siemens Energy, Inc.

ENGINEERING SPECIFICATION

Title CUSTOMER PIPING CONNECTION PROCESS INFORMATION

Titel

UNID

PE1007 XK01 MB 013100

478161777

Proj. Code/Proj.-Kennz. Doc./UA Contents Code/Inhaltskennzeichen Count no./Zähl-nr.

Confidential Vertraulich

Original / Ursprung Module Coordinator / Modulverantwortlicher Handling Handhabung

See Section 2.0 APPLICABLE DOCUMENTS 4

Related Documents/Zugehörige Dokumente Review Level

Department Dept. Code Name Signature Date

Prepared Mechanical Engineering, PRSIENMEA Douglas Carlson Douglas Carlson Apr. 24, 2012

by 60 Hz Engineering Technician

Reviewed Mechanical Engineering, PRSIENMEA Paul Blankenship Paul Blankenship Apr. 24, 2012

by 60 Hz 2D Engineer

Approved Mechanical Engineering, PRSIENMEA Martin Howell Martin Howell Apr. 25, 2012

by 60 Hz Piping Engineer

Approved Mechanical Engineering, PRSIENMEA Anthony Deininger Anthony Deininger Apr. 25, 2012

by 60 Hz Engineer

Approved Systems Auxiliaries, America PRGTENESCS Eric Sola Eric Sola Apr. 26, 2012

by SYST1 Systems Lead

Approved Mechanical Engineering, PRSIENMEA Marco Fuentes Marco Fuentes Apr. 25, 2012

by 60 Hz Lead Engineer

Approved Mechanical Engineering, PRSIENMEA Jack D. Moore Jack D. Moore Apr. 26, 2012

by 60 Hz 2D Group Leader

Approved Mechanical Engineering, PRSIENMEA Ashok Vyas Ashok Vyas Apr. 26, 2012

by 60 Hz Manager

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 1 of 11

FILE: PE1007-XK01-MB-013100.DOC

REVISION SHEET

Revision Revision Date Section Description of Change

001 Apr. 27, 2012 All Original issue

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 2 of 11

FILE: PE1007-XK01-MB-013100.DOC

TABLE OF CONTENTS

SECTION PAGE

REVISION SHEET ........................................................................................................................... 2

1.0 SCOPE ................................................................................................................................. 4

2.0 APPLICABLE DOCUMENTS ................................................................................................ 4

3.0 CUSTOMER CONNECTION TABLE .................................................................................... 4

4.0 NOTES: ................................................................................................................................ 8

FIGURE 1 COMBUSTOR DRAIN SCHEMATIC ............................................................................ 10

FIGURE 2 P-TRAP DETAILS FOR INLET MANIFOLD/DUCT DRAIN .......................................... 11

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 3 of 11

FILE: PE1007-XK01-MB-013100.DOC

1.0 SCOPE

The purpose of this document is to define the process conditions for the SANTO DOMINGO

DE LOS OLLEROS SGT-PAC customer piping connections. The parameters given in the

Customer Connection Table shall be considered operating conditions and not design

conditions. The information given in this specification shall be limited to design of Balance of

Plant (BOP) piping systems. For sizing equipment and other system design components,

this specification can be used in addition to other requirements. In case of conflict between

this document and the project contract, contact Siemens Energy, Inc. in writing for

clarification.

2.0 APPLICABLE DOCUMENTS

The following documents shall be referred to for locations and details of Customer

connections:

Siemens Energy, Inc. Spec. No. PE1007- SANTO DOMINGO DE LOS OLLEROS

XK01-MB-013000 SGT6-5000F Customer Piping Connections

– Physical Locations

Siemens Energy, Inc. Dwg. No. PE1007- SANTO DOMINGO DE LOS OLLEROS Gas

XG02-MB-011200 Turbine and Auxiliaries P&ID

3.0 CUSTOMER CONNECTION TABLE

The table below in conjunction with the documents listed in Section 2 fully define all SGT-

PAC piping interface points for the SANTO DOMINGO DE LOS OLLEROS project.

Customer connection points shown in the attached table correspond to customer interfaces

identified on Siemens Energy, Inc. P&ID Drawing. No. PE1007-XG02-MB-011200 as

hexagons with the connection number listed therein.

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 4 of 11

FILE: PE1007-XK01-MB-013100.DOC

CONN NUM DESCRIPTION SIZE FLUID PRESS MIN PRESS MAX TEMP MIN TEMP MAX FLOW PROCESS P&ID

(IN) NOTES PAGE#

EKG-020 FUEL GAS FLOWMETER 8 Natural Gas 394 PSIG 424 PSIG 60 Deg. F Ambient 89,095 LB/HR 106, 109, 112, 34

INLET (27.2 bar) (29.2 bar) (15.6 Deg. C) (40413 kg/hr) 140, 161, 165

EKG-021 FUEL GAS FLOWMETER 8 Natural Gas 394 PSIG 424 PSIG 60 Deg. F Ambient 89,095 LB/HR 106, 109, 112, 34

OUTLET (27.2 bar) (29.2 bar) (15.6 Deg. C) (40413 kg/hr) 161, 165

MBA-001 WASTE DRAIN 2 Water ATM ATM Ambient 550.4 Deg. F See Notes 103, 116, 141, 7

(228 Deg. C) 149

MBA-004 EXHAUST CYLINDER DRAIN 0.75 Water ATM ATM Ambient 149 Deg. F Not Specified 7

(65 Deg. C)

MBA-005 EXHAUST TRANSITION 2 Water ATM ATM Ambient 149 Deg. F Not Specified 113 7

DRAIN (65 Deg. C)

MBA-006 EXHAUST STACK DRAIN Water ATM ATM Ambient Ambient Not Specified 111 7

MBA-007 INLET MANIFOLD DRAIN 2 Demin Water / 10" H2O (Vac) ATM Ambient Ambient 3.96 GPM 125, 149, 152, 7

Chemical (24.9 mbar (Vac)) (15 LPM) 157

MBA-015 PORTABLE COMPRESSOR Water ATM ATM Ambient Ambient Not Specified 6

WASH WATER TANK FILL

MBA-016 PORTABLE COMPRESSOR Chemical ATM ATM Ambient Ambient Not Specified 6

WASH DETERGENT TANK

FILL

MBA-017 COMPRESSOR WASH 0.75 Water / Chemical ATM 14.5 PSIG Ambient Ambient 2 GPM 6

INTERCONNECT PIPING (1 bar) (7.6 LPM)

DRAIN

MBA-018 PORTABLE COMPRESSOR 0.5 Water / Chemical ATM ATM Ambient Ambient Not Specified 6

WASH SKID DRAIN

MBA-019 PORTABLE COMPRESSOR 1.5 Water / Chemical ATM 200 PSIG Ambient Ambient 35 GPM 6

WASH SKID OUTLET (13.8 bar) (132 LPM)

MBA-020 COMPRESSOR WASH 1.5 Water / Chemical ATM 200 PSIG Ambient Ambient 35 GPM 6

INTERCONNECT PIPING (13.8 bar) (132 LPM)

CONNECTION

MBH-005 COMPRESSOR AIR TO 2 Air ATM 305 PSIG Ambient 450 Deg. F 230 SCFM 110 11

PLANT AIR SYSTEM (21 bar) (232.2 Deg. C) (108.5 L/s at

STP)

MBP-001 MAIN FUEL GAS SUPPLY 10 Natural Gas 384 PSIG 424 PSIG 60 Deg. F 105 Deg. F 89,095 LB/HR 106, 109, 139, 16

(26.5 bar) (29.2 bar) (15.6 Deg. C) (40.6 Deg. C) (40413 kg/hr) 140, 153

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted in confidence and is to be used solely for the purpose for which it is

furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 5 of 11

FILE: PE1007-XK01-MB-013100.DOC

CONN NUM DESCRIPTION SIZE FLUID PRESS MIN PRESS MAX TEMP MIN TEMP MAX FLOW PROCESS P&ID

(IN) NOTES PAGE#

MBP-002 FUEL GAS VENT 0.75 Natural Gas 384 PSIG 424 PSIG 60 Deg. F 105 Deg. F Not Specified 104, 107, 116, 17

(26.5 bar) (29.2 bar) (15.6 Deg. C) (40.6 Deg. C) 122

MBP-004 MAIN F/G SEPARATOR 1 Water / ATM 424 PSIG 60 Deg. F 105 Deg. F 33 GPM 111, 118 16

DRAIN Hydrocarbons (29.2 bar) (15.6 Deg. C) (40.6 Deg. C) (125 LPM)

MAX

MBP-006 MAIN F/G SEPARATOR 1 Natural Gas ATM 424 PSIG 60 Deg. F 105 Deg. F Not Specified 107, 111, 122 16

VENT (29.2 bar) (15.6 Deg. C) (40.6 Deg. C)

MBP-010 MAIN F/G SEP THERMAL 1 Natural Gas 384 PSIG 424 PSIG 60 Deg. F 105 Deg. F 1600 SCFM 107, 111, 116, 16

RELIEF VLV (26.5 bar) (29.2 bar) (15.6 Deg. C) (40.6 Deg. C) (755 L/s at STP) 122

MBV-001 LUBE OIL TANK 1.5 Lube Oil Not Specified ATM 69.8 Deg. F 158 Deg. F Not Specified 102 18

FILL/EXTERNAL PURIFIER (21 Deg. C) (70 Deg. C)

RETURN

MBV-002 LUBE OIL TANK 2 Lube Oil Not Specified 17.4 PSIG 69.8 Deg. F 158 Deg. F Not Specified 148 18

DRAIN/EXTERNAL (1.2 bar) (21 Deg. C) (70 Deg. C)

PURIFIER SUPPLY

MBV-003 VAPOR EXTRACTOR 6 Oily Mist Not Specified 0.15 PSIG 69.8 Deg. F 158 Deg. F 899.94 SCFM 114, 115, 122 18

DISCHARGE (10.3 mbar) (21 Deg. C) (70 Deg. C) (424.8 L/s at

STP)

MBV-012 LUBE OIL RESERVOIR 2 Lube Oil Not Specified 17.4 PSIG 69.8 Deg. F 158 Deg. F Not Specified 18

DRAIN (1.2 bar) (21 Deg. C) (70 Deg. C)

MBX-002 INSTRUMENT AIR FROM 0.5 Air 95 PSIG 250 PSIG -20 Deg. F 130 Deg. F 25 SCFM 105 26

PLANT AIR SYSTEM (6.6 bar) (17.2 bar) (-28.9 Deg. C) (54.4 Deg. C) (11.8 L/s at STP)

MBX-010 CONTROL OIL RESERVOIR 1 Hydraulic Oil ATM ATM 40 Deg. F 140 Deg. F 5 GPM 23

TANK FILL (4.4 Deg. C) (60 Deg. C) (19 LPM)

MBX-011 CONTROL OIL RESERVOIR 0.75 Hydraulic Oil ATM ATM Ambient 194 Deg. F 5 GPM 23

TANK DRAIN (90 Deg. C) (19 LPM)

MBX-012 INSTRUMENT AIR 0.5 Oily Water ATM 250 PSIG Ambient 130 Deg. F Not Specified 27

COALESCING FILTER (17.2 bar) (54.4 Deg. C)

DRAIN

MBX-014 INSTRUMENT AIR 0.5 Oily Water ATM 250 PSIG Ambient 130 Deg. F Not Specified 26

RECEIVER TANK DRAIN (17.2 bar) (54.4 Deg. C)

MBX-015 INSTRUMENT AIR TRAP 0.5 Water ATM 305 PSIG Ambient 130 Deg. F Not Specified 26

DRAIN (21 bar) (54.4 Deg. C)

SAM-001 ELECTRICAL PACKAGE AIR Water ATM ATM Ambient Ambient N/A 118 32

CONDITIONING DRAIN

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted in confidence and is to be used solely for the purpose for which it is

furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 6 of 11

FILE: PE1007-XK01-MB-013100.DOC

CONN NUM DESCRIPTION SIZE FLUID PRESS MIN PRESS MAX TEMP MIN TEMP MAX FLOW PROCESS P&ID

(IN) NOTES PAGE#

SAM-002 ELECTRICAL PACKAGE AIR Water ATM ATM Ambient Ambient N/A 118 32

CONDITIONING DRAIN

SAM-003 STATIC EXCITATION SKID Water ATM ATM Ambient Ambient N/A 118 32

AIR CONDITIONING #1

DRAIN

SAM-004 STATIC EXCITATION SKID Water ATM ATM Ambient Ambient N/A 118 32

AIR CONDITIONING #2

DRAIN

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted in confidence and is to be used solely for the purpose for which it is

furnished and returned upon request. This document and such information is not to be reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 7 of 11

FILE: PE1007-XK01-MB-013100.DOC

4.0 NOTES:

101 Not Used

102 Lube Oil System initial fill is approximately 4750 gallons (17981 liters).

103 Approximately 550 gallons (2082 liters) of water/detergent for each compressor wash cycle.

A/E and/or Customer to route this piping to waste tank. Drain(s) from connection numbers

MBA-004 and MBA-005 can be combined with this connection (see Figure 1), as long as

they are indirect (bell-up) drains, that is, an air gap must be provided to prevent hot gases

from traveling through the drain pipe to the waste tank. All indirect (bell-up) drains shall be

located outside the enclosed building. An indirect (bell-up) drain between drain connection

and waste tank shall be always provided, regardless if these drains are combined or not.

104 Maximum pressure and temperature do not occur simultaneously.

105 Instrument air quality must meet the following criteria:

Maximum dew point: -40 Deg F at 100 psig (-40 Deg C at 6.9 bar)

Removal of greater than or equal to 99.9% of the particulate greater than or equal to 0.1

micron

Maximum oil content: 0.5 ppm

106 See Gas Fuel specification ZDX555-DC01-MBP-2500-01 for additional requirements.

107 Do not locate any isolation devices downstream of the connections.

108 Not Used

109 Minimum total fuel gas flow (at ignition) is 4000 lb/hr (1814.4 kg/hr).

110 Siemens Energy, Inc. does not have the responsibility to provide aftercoolers to cool this air

to make suitable for plant air usage.

111 Refer to approved vendor print for this equipment to confirm connection size, number of

connections, and design parameters such as pressure, temperature, and flow.

112 To preserve meter tube integrity and calibration the meter tube shall not be installed until

time of performance test, and shall not be disassembled. The customer shall provide

temporary pipe spool, equal in length to the meter tube, to support commissioning

activities.

113 An insignificant amount of water is expected during off line compressor water wash. A/E

and/or Customer may route drains downstream of manual shut off valves per local codes

and as shown in Figure 1, if desired. Drain(s) can be combined with combustor shell drain

connection MBA-001, as long as they are indirect (bell-up) drains, that is, an air gap must

be provided to prevent hot gases from traveling through the drain pipe to the waste tank.

These indirect (bell-up) drains shall be located outside the enclosed building. An indirect

(bell-up) drain between drain connection and waste tank shall always be provided,

regardless if these drains are combined or not.

114 Maximum allowable pressure drop in the customer piping to be 10.00 inches of water (24.9

mbar). No piping loads shall be transmitted to this connection

115 Rain cap supplied by Siemens Energy, Inc. must be located at the discharge end of the

customer piping, if provided.

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 8 of 11

FILE: PE1007-XK01-MB-013100.DOC

116 The indicated conditions exist only momentarily when the system is vented or drained. In

all cases, the values provided are the system operating conditions upstream of the vent or

drain valve.

117 Not Used

118 Provided as an equipment drain. No additional piping is required, except as required by

local codes and/or A/E or Customer standards.

119-121 Not Used

122 Route to atmosphere, away from ignition sources, as per local code requirements.

123-124 Not Used

125 Flow rate during Compressor Water Wash only.

126-138 Not Used

139 Supply pressure must be maintained within the minimum/maximum values specified in

order to ensure proper system operation.

140 The Customer must provide upstream over-pressure protection that will not allow the Fuel

Gas system pressure to exceed 580 psig (40 bar) under any circumstance in order to

preserve system integrity.

141 Maximum temperature shown at this drain connection may be seen as a transient condition

immediately following a turbine trip.

142-147 Not Used

148 Provided as an equipment drain and external purifier supply connections as applicable. No

additional piping is required, except as required by local codes and/or A/E or Customer

standards, unless an external purifier is needed.

149 The customer drain system should be designed with a minimum downward slope of 1/8"

per foot (10.4mm per meter), to drain the indicated quantity of demineralized water.

150-151 Not Used

152 Inlet manifold drain can realize a vacuum of up to 10 inches of water with operation of gas

turbine. Gas Turbine operation should not be initiated if Siemens or Customer 's P trap and

check valve are not installed.

153 Max pressure condition is calculated with the max flow at 60 deg F (16 deg C).

154-156 Not Used

157 To insure proper operation, customer is to provide a P-Trap and check valve arrangement

as shown on Figure 2. This may require the installation of a pit.

158-160 Not Used

161 Minimum and maximum pressures shall be calculated by the customer based on the

pressure requirements of MBP-001, equipment losses, and customer pipe losses. In any

event the maximum pressure must not exceed the design pressure of an ANSI 300 pound

class flange at the maximum temperature.

162-164 Not Used

165 Pressure losses are as follows: EKG-020 to EKG-021 = 10 psid (0.69 bar)

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 9 of 11

FILE: PE1007-XK01-MB-013100.DOC

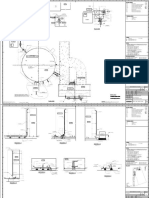

FIGURE 1

COMBUSTOR DRAIN SCHEMATIC

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 10 of 11

FILE: PE1007-XK01-MB-013100.DOC

M BA

007

2" PIPE CAP FOR CLEANOUT

2" DIA. SWING

5" CHECK VALVE *

5"

SLOPE 1/8" PER

FT. (M IN.)

5" 5"

P-TRAP DETAIL FOR

2" DIA. INLET M ANIFOLD DRAIN

NOTE:

1. SITE CONDITIONS M AY REQUIRE A PIT TO FACILITATE

THE P-TRAP AND CHECK VALVE. ALLOW FOR FUTURE

M AINTENANCE IN PIT DESIGN.

2. ALWAYS INSTALL CHECK VALVE IN HORIZONTAL RUN

OF PIPE DOWNSTREAM OF P-TRAP.

* SWING CHECK VALVE-LADISH NO 5274 OR EQUIVALENT

FIGURE 2

P-TRAP DETAILS FOR INLET

MANIFOLD DRAIN

© Siemens Energy, Inc. 2008. All Rights Reserved. This document contains information confidential and proprietary to Siemens Energy, Inc. It is submitted

in confidence and is to be used solely for the purpose for which it is furnished and returned upon request. This document and such information is not to be

reproduced, transmitted, disclosed or used otherwise in whole or in part without the written authorization of Siemens Energy, Inc. Confidential

Title: CUSTOMER PIPING CONNECTION PROCESS INFORMATION PE1007-XK01-MB-013100

Project: SANTO DOMINGO DE LOS OLLEROS Issued: Apr. 27, 2012

Siemens Energy, Inc., Orlando, FL Rev. 001 Type: ESP Page 11 of 11

FILE: PE1007-XK01-MB-013100.DOC

You might also like

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- Permit To Work: Construction & Commissioning Procedures ManualDocument16 pagesPermit To Work: Construction & Commissioning Procedures ManualALADINHENo ratings yet

- Manual Docs-200Document134 pagesManual Docs-200Javier Rizo50% (2)

- SW200i Install Manual Rev 3.0 PDFDocument82 pagesSW200i Install Manual Rev 3.0 PDFSyed iliyasNo ratings yet

- Interference of Light & It's Applications (Interferometry)Document24 pagesInterference of Light & It's Applications (Interferometry)Pranav Marathe100% (11)

- Hobart Handler 175 220 VAC MIG Welder User Manual O944 - HobDocument48 pagesHobart Handler 175 220 VAC MIG Welder User Manual O944 - HobrbastaNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- Aa39 SeriesDocument28 pagesAa39 Seriesjoel alvaradoNo ratings yet

- MC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1Document10 pagesMC20005-WHP-WI-P-0117 Chemical Injection Datasheet WI - Rev D1nguyenmainamNo ratings yet

- Method Statement: American University-Small Cost Renovation ProjectDocument7 pagesMethod Statement: American University-Small Cost Renovation ProjectAnonymous X37L15QznoNo ratings yet

- 00etb Manual en v1.0Document16 pages00etb Manual en v1.0lachgarboutaina07No ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- TES-ELEC-FACGND Facility General Grounding Specification (CDN-US-MEX)Document14 pagesTES-ELEC-FACGND Facility General Grounding Specification (CDN-US-MEX)Vladimir Javier Aleman AndradeNo ratings yet

- OPS-EnG-3-005-00 Electrostatic Discharge (ESD) Control Procedure Rev DDocument42 pagesOPS-EnG-3-005-00 Electrostatic Discharge (ESD) Control Procedure Rev Dmanuel100% (1)

- PDR 5 Ems 002 R00Document110 pagesPDR 5 Ems 002 R00wan haffizNo ratings yet

- Norme EchangeurDocument85 pagesNorme EchangeurBilalNo ratings yet

- Sprinklers Fire ProtectionDocument30 pagesSprinklers Fire Protectionsmarika.tamrakar32No ratings yet

- 150 67-NM1Document228 pages150 67-NM1mariaNo ratings yet

- Cooling Gas Compressor: DP07J1-FE21-E3020-RS504Document5 pagesCooling Gas Compressor: DP07J1-FE21-E3020-RS504Haitham AbdEl-TawabNo ratings yet

- Attachment A: Engineering Standards Manual STD-342-100Document29 pagesAttachment A: Engineering Standards Manual STD-342-100SAURABH SINGHNo ratings yet

- MC20005 WHP WI P 0115 - Stand Pipe Datasheet Work Instruction - RevD1Document7 pagesMC20005 WHP WI P 0115 - Stand Pipe Datasheet Work Instruction - RevD1nguyenmainamNo ratings yet

- MOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseDocument25 pagesMOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseKingston RivingtonNo ratings yet

- SP-1131Hand Over & As-Built DocsDocument22 pagesSP-1131Hand Over & As-Built DocskattabommanNo ratings yet

- 1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00Document12 pages1.MST 48 - DX Split System, AC Unit and Refrigerant Pipe Rev.00jaffrinNo ratings yet

- 03 150000 4100001496 SPM Ele MST 000005 - 01Document32 pages03 150000 4100001496 SPM Ele MST 000005 - 01ImthiyazAliAhamedHNo ratings yet

- M040 Operator ManualDocument12 pagesM040 Operator Manualingener.giza2582No ratings yet

- MC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1Document8 pagesMC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1nguyenmainamNo ratings yet

- Oil Seal DesignDocument10 pagesOil Seal DesignRavindra PawarNo ratings yet

- 1126-MIG-SDS-105-B1 (FDS - AI - Family - B1)Document98 pages1126-MIG-SDS-105-B1 (FDS - AI - Family - B1)makramNo ratings yet

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- EDS 07-4110 Grid and Primary Transformer Retrospective Oil ContainmentDocument16 pagesEDS 07-4110 Grid and Primary Transformer Retrospective Oil ContainmentNgoni MafondokotoNo ratings yet

- Specification For Sprinkler DesignDocument14 pagesSpecification For Sprinkler DesignFarhan AhmedNo ratings yet

- 667 Ds 20664 000Document19 pages667 Ds 20664 000ALDONSANo ratings yet

- Mcs - Method StatementsDocument179 pagesMcs - Method StatementsMitendra Kumar ChauhanNo ratings yet

- Nonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsDocument46 pagesNonincendive Electrical Equipment For Use in Class I and II, Division 2 and Class III, Divisions 1 and 2 Hazardous (Classified) LocationsMahdy MazinyNo ratings yet

- Specification For Instrumentation ControlDocument68 pagesSpecification For Instrumentation ControlSorinNo ratings yet

- 150.72-RP1 Ylaa 2Document54 pages150.72-RP1 Ylaa 2José RamosNo ratings yet

- Mots-76 - Mog-Ep-Plr-Std-0076Document7 pagesMots-76 - Mog-Ep-Plr-Std-0076botmaxNo ratings yet

- MQ SP I 7024 PDFDocument33 pagesMQ SP I 7024 PDFJaseelKanhirathinkalNo ratings yet

- MOS For Electrical Board Turn OnDocument8 pagesMOS For Electrical Board Turn OnYuz FiNo ratings yet

- Infineon-MOSFET OptiMOS Datasheet explanation-AN-v01 00-EN PDFDocument30 pagesInfineon-MOSFET OptiMOS Datasheet explanation-AN-v01 00-EN PDFrajeshNo ratings yet

- Vol1 12Document41 pagesVol1 12keerthi dayarathnaNo ratings yet

- Installation and Calibration of Instruments GuidanceDocument17 pagesInstallation and Calibration of Instruments GuidanceCarlos SalazarNo ratings yet

- Solving The Current Challenges Requires A Multidimensional View of Engineering SimulationDocument12 pagesSolving The Current Challenges Requires A Multidimensional View of Engineering SimulationKyon EsdelleNo ratings yet

- Air Transport Association: E-Business Specification For Materiels ManagementDocument132 pagesAir Transport Association: E-Business Specification For Materiels ManagementRiadh BelaizNo ratings yet

- Spec 2000 S2K - Ch12 - 2004.1Document150 pagesSpec 2000 S2K - Ch12 - 2004.1deardevenNo ratings yet

- CER Example Registry: Professional Development ProgramDocument13 pagesCER Example Registry: Professional Development ProgramPradyut TiwariNo ratings yet

- Specification For Nickel Base Alloy 625 Plus (UNS N07716) AND ALLOY 725 (UNS N07725) FOR OIL and Gas Drilling and Production EquipmentDocument20 pagesSpecification For Nickel Base Alloy 625 Plus (UNS N07716) AND ALLOY 725 (UNS N07725) FOR OIL and Gas Drilling and Production EquipmentakintundeakinboladeNo ratings yet

- Southwest Association ESD: February MeetingDocument3 pagesSouthwest Association ESD: February MeetingNilesh NarkhedeNo ratings yet

- Piping and Equipment InsulationDocument22 pagesPiping and Equipment InsulationRampal Rahul Rampal RahulNo ratings yet

- COP0010 Iss 3Document4 pagesCOP0010 Iss 3nigelNo ratings yet

- Ylaa0070 - Ylaa0120Document108 pagesYlaa0070 - Ylaa0120Juan David Hurtado CuencaNo ratings yet

- ESR - Rev 5.0 HSE-OC-01-05Document105 pagesESR - Rev 5.0 HSE-OC-01-05balajiNo ratings yet

- Saes J 902Document32 pagesSaes J 902Mudabbir HussainNo ratings yet

- Comment Resolution Sheet (CRS) : Document No. REV E1121-240-PS-DS-101437 - 7 0Document6 pagesComment Resolution Sheet (CRS) : Document No. REV E1121-240-PS-DS-101437 - 7 0sumit kumarNo ratings yet

- Siemens Service Report AVR Adjustment September 2012 Report-2712 PDFDocument4 pagesSiemens Service Report AVR Adjustment September 2012 Report-2712 PDFJurekNo ratings yet

- Special Notice: Anodyne Electronics Manufacturing CorpDocument24 pagesSpecial Notice: Anodyne Electronics Manufacturing CorpLin FengNo ratings yet

- AHS 3000+Attitude+Heading+Reference+SystemDocument121 pagesAHS 3000+Attitude+Heading+Reference+Systemgilgamesh riponziNo ratings yet

- Sow 1000483 TW 834 15 75 006Document38 pagesSow 1000483 TW 834 15 75 006Sayed AhammadNo ratings yet

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- Dep 31.10.03.10 - Symbols and Identification System - MechanicalDocument15 pagesDep 31.10.03.10 - Symbols and Identification System - Mechanicalsudeep9666No ratings yet

- 2013-06 - June Monthly ReportDocument74 pages2013-06 - June Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- Siemens Confirmation of NTP - Santo Domingo - January 27 2012Document1 pageSiemens Confirmation of NTP - Santo Domingo - January 27 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- Siemens NTP Offshore Invoice - Santo Domingo - January 27 2012Document1 pageSiemens NTP Offshore Invoice - Santo Domingo - January 27 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- Pe1007-Ds00-000-0391-10 - Acoustical Test ProcedureDocument19 pagesPe1007-Ds00-000-0391-10 - Acoustical Test ProcedureJOSUE FERNANDO FERNANDEZNo ratings yet

- 2013-05 - May Monthly ReportDocument69 pages2013-05 - May Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- 2013-09 - September Monthly ReportDocument76 pages2013-09 - September Monthly ReportJOSUE FERNANDO FERNANDEZNo ratings yet

- SD R TCH Sei NNNNDocument1 pageSD R TCH Sei NNNNJOSUE FERNANDO FERNANDEZNo ratings yet

- TIR PRE-ING Siemens 006 - ResponseDocument2 pagesTIR PRE-ING Siemens 006 - ResponseJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-FINAL REPORT-Final Seismic Hazard Analysis and Geotechnical EvaluationDocument149 pagesPE1007-FINAL REPORT-Final Seismic Hazard Analysis and Geotechnical EvaluationJOSUE FERNANDO FERNANDEZNo ratings yet

- Energy, Inc.: Attached Document(s) Are Provided For Design/ConstructionDocument1 pageEnergy, Inc.: Attached Document(s) Are Provided For Design/ConstructionJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0006 - Monthly Progess Report For Ending Period FebruaryDocument1 pageSD-L-SEI-TCH-0006 - Monthly Progess Report For Ending Period FebruaryJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalDocument2 pagesSD-L-SEI-TCH-0086 - Option Proposal For The Santo Domingo Project Top Soil Waste Material RemovalJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0011 - Certification of Completion-Offshore Work Payment Milestone 2Document5 pagesSD-L-SEI-TCH-0011 - Certification of Completion-Offshore Work Payment Milestone 2JOSUE FERNANDO FERNANDEZNo ratings yet

- Irvine Insurance Cert 2012Document1 pageIrvine Insurance Cert 2012JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)Document3 pagesSD-L-SEI-TCH-0087 - Customer Witness Point (Third Notice)JOSUE FERNANDO FERNANDEZNo ratings yet

- SD L SEI TCH 0002 Communication ProcessesDocument2 pagesSD L SEI TCH 0002 Communication ProcessesJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0003 - Certification of Milestone Completion and Payment Request For Milestone 1Document3 pagesSD-L-SEI-TCH-0003 - Certification of Milestone Completion and Payment Request For Milestone 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundDocument2 pagesPE1007-XH01-00UZ-470003 Piping GA Drawing - Above GroundJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0008 - Offshore Work Payment Milestone 1Document2 pagesSD-L-SEI-TCH-0008 - Offshore Work Payment Milestone 1JOSUE FERNANDO FERNANDEZNo ratings yet

- SD L SEI TCH 0005 - Introduction Meeting On March 15Document1 pageSD L SEI TCH 0005 - Introduction Meeting On March 15JOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorDocument1 pageSD-L-SEI-TCH-0089 - Site Access For Grading SubcontractorJOSUE FERNANDO FERNANDEZNo ratings yet

- Form 10-KDocument100 pagesForm 10-KJOSUE FERNANDO FERNANDEZNo ratings yet

- 1-A) BIS-711 Form - PRELLENADO POR FIRMARDocument1 page1-A) BIS-711 Form - PRELLENADO POR FIRMARJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationDocument2 pagesSD-L-SEI-TCH-0090 - Certificate of Completion Offshore Work Payment Milestone 7, Site MobilizationJOSUE FERNANDO FERNANDEZNo ratings yet

- SD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012Document7 pagesSD-L-SEI-TCH-0088 - Certificates of Insurane-Letter GG-SEI-061-2012JOSUE FERNANDO FERNANDEZNo ratings yet

- 130 M 20026 - 0Document1 page130 M 20026 - 0JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsDocument12 pagesPE1007-DC01-MB-839700 - SGT-PAC Piping Insulation RequirementsJOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1Document2 pagesPE1007-XH01-00UZ-470001 Piping GA Drawing - Fire Hydrant Loop - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- How To Download by Upload CheatDocument2 pagesHow To Download by Upload Cheatng chee yongNo ratings yet

- Alcatel 1660 SMDocument8 pagesAlcatel 1660 SMILiketobWithuNo ratings yet

- 4.2.6 Lab - Working With Text Files in The CLIDocument10 pages4.2.6 Lab - Working With Text Files in The CLITran Truong Giang (K16HCM)No ratings yet

- MCQ Artificial Intelligence Class 10 Computer VisionDocument41 pagesMCQ Artificial Intelligence Class 10 Computer VisionpratheeshNo ratings yet

- Unit 6 PII MACHINE LEARNINGDocument43 pagesUnit 6 PII MACHINE LEARNINGSakshi ChoudharyNo ratings yet

- Advanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution SystemsDocument15 pagesAdvanced Control Solutions For Enhanced Resilience of Modern Power-Electronic-Interfaced Distribution Systemsndaryanto 92No ratings yet

- s2s VPN User GuideDocument57 pagess2s VPN User GuidealozieNo ratings yet

- Big Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemDocument31 pagesBig Data Analytics: By: Syed Nawaz Pasha at SR Univeristy Professional Elective-5 B.Tech Iv-Ii SemShushanth munna100% (1)

- RTU QuestionnaireDocument7 pagesRTU Questionnaireimadz853No ratings yet

- GOMO Complete Document February 2020 2 242Document1 pageGOMO Complete Document February 2020 2 242RICROD71No ratings yet

- Zain Asif Allied-Data ScientistDocument3 pagesZain Asif Allied-Data ScientistZain AsifNo ratings yet

- Aab-e-Kausar by Mufti Ameen PDFDocument306 pagesAab-e-Kausar by Mufti Ameen PDFSamina Kosar96% (26)

- 5.FM-ENG-05 Part Submission WarrantDocument1 page5.FM-ENG-05 Part Submission WarrantUttrakhand Vibes- OriginalNo ratings yet

- 11.inheritance and PolymorphismDocument47 pages11.inheritance and PolymorphismVivek BhardwajNo ratings yet

- 2A Introduction EDP AuditDocument98 pages2A Introduction EDP AuditnasrciaNo ratings yet

- Wiley - Nonlinear Finite Elements For Continua and Structures - Ted Belytschko, Wing Kam Liu, Brian Moran PDFDocument2 pagesWiley - Nonlinear Finite Elements For Continua and Structures - Ted Belytschko, Wing Kam Liu, Brian Moran PDFnikunjkavadiaNo ratings yet

- Ug 146 PDFDocument36 pagesUg 146 PDFTrần LinhNo ratings yet

- CIT212Document255 pagesCIT212CharlesNo ratings yet

- HDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsDocument44 pagesHDL and FPGA Ch05 HVT 2024 RTL Combinational CircuitsVy TungNo ratings yet

- User Manual: Model M834 SeriesDocument21 pagesUser Manual: Model M834 SeriesMarcelo WillyNo ratings yet

- Violence in Digital Communication Social Media Through TH - 2023 - MeasurementDocument7 pagesViolence in Digital Communication Social Media Through TH - 2023 - MeasurementFelix PhilipNo ratings yet

- Developing Thermoplastic Composites For Use in Commercial Aircraft - Aerospace & Defense TechnologyDocument9 pagesDeveloping Thermoplastic Composites For Use in Commercial Aircraft - Aerospace & Defense TechnologyБердик БайсерикNo ratings yet

- Welcome To Atmel-Wincupl V5.30.3Document8 pagesWelcome To Atmel-Wincupl V5.30.3imenenouvelleNo ratings yet

- TAM Final LASDocument4 pagesTAM Final LASprintsbyarishaNo ratings yet

- PGL - Online 101.1 DraftDocument4 pagesPGL - Online 101.1 DraftZaeni AhmadNo ratings yet

- Service Manual - Canon Ir2422 - 2420 - 2320 - 2318Document286 pagesService Manual - Canon Ir2422 - 2420 - 2320 - 2318Nonon Raingam79% (14)

- Advanced Linux: Exercises: 0 Download and Unpack The Exercise Files (Do That First Time Only)Document6 pagesAdvanced Linux: Exercises: 0 Download and Unpack The Exercise Files (Do That First Time Only)Niran SpiritNo ratings yet

- Tensores Van GorpDocument17 pagesTensores Van GorpsalematadorNo ratings yet