Professional Documents

Culture Documents

SB 10054469 8890

SB 10054469 8890

Uploaded by

Youssef MoutaouadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB 10054469 8890

SB 10054469 8890

Uploaded by

Youssef MoutaouadiCopyright:

Available Formats

SB-10054469-8890

9 11-13

1 9 11-13

SUBJECT DATE

EPA10/GHG14 SPN 652/FMI 3, 4, 5, 6, 7 September 2013

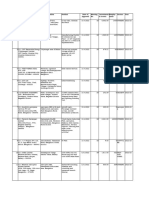

Additions, Revisions, or Updates

Publication Number / Title Platform Section Title Change

SPN 652/FMI 3 –

EPA10/GHG14

SPN 652/FMI 4 –

EPA10/GHG14

EPA10/

SPN 652/FMI 6 – Graphics have been added, two new steps are added, two new

DDC-SVC-MAN-0084 GHG14 DD

EPA10/GHG14 notes are added.

Platform

SPN 652/FMI 5 –

GHG14

SPN 652/FMI 7 –

GHG14

All information subject to change without notice. 3

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

2 SPN 652/FMI 3 - EPA10 - GHG14

2 SPN 652/FMI 3 - EPA10 - GHG14

This diagnostic is typically Injector Cylinder #2 Needle Control Valve Abnormal Operation (MAX).

Table 1.

SPN 652/FMI 3

Description Injector Cylinder #2 Needle Control Valve Abnormal Operation

(MAX)

Monitored Parameter Injector Cylinder #2 Needle Control Valve

Typical Enabling Conditions Engine rpm = idle or higher

Monitor Sequence None

Execution Frequency Continuous when enabling conditions met

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

1. Check for multiple codes. Using DDDL/DDRS 7.10 or newer retain log file of active fault and clear codes (code active

for one key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

4 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

2. Check the warranty claim history. Check with driver. Is this the first occurrence of this fault within the last 30 days?

a. Yes; Go to step 3.

b. No; complete diagnostics, retain a log file of active fault and the measured resistance values recorded in this

procedure and contact the Customer Support Center at 800-445-1980.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

3. Start and warm the engine until the coolant temperature is above 71°C (160°F).

4. Turn the engine OFF.

5. Disconnect the front fuel injector harness 14-pin injector connector.

6. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion).

a. If water or oil intrusion, bent or spread pins are found, repair as necessary.

b. If the connector shows no signs of damage, Go to step 7.

NOTE: Do NOT touch the metal ohmmeter leads with your hands when the measurements are made.

7. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

All information subject to change without notice. 5

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

2 SPN 652/FMI 3 - EPA10 - GHG14

Table 2.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

Table 3.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 11.

b. No; Go to step 8.

8. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

9. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

10. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistance values within range?

6 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

Table 4.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater than Greater than Greater than

Needle

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System"

Refer to section "Removal of the Fuel Injector - Two-Filter System"

11. Disconnect the Motor Control Module (MCM) 120-pin connector.

12. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

All information subject to change without notice. 7

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

2 SPN 652/FMI 3 - EPA10 - GHG14

b. If no signs of damage, Go to step 13.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

13. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 5.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Front Engine Side

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Valve Cover 14-pin Valve Cover 14 pin

Connector 1Ω or less 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 14.

b. No; repair the engine side harness. Verify repairs.

NOTE: The use of extension harness J-49120 will ease installation of test MCM.

14. Install a test MCM.

15. Reconnect all connections and start engine. Bring to operating temperature of 71°C (160°F). Road test the vehicle for

30 minutes. Does fault become active?

a. Yes; repeat all steps. If results are the same, retain a log file of active fault and the measured resistance values

recorded in this procedure and contact the Customer Support Center at 800-445-1980 for further instructions.

b. No; Go to step 16.

16. Install original MCM. Bring to operating temperature of 71°C (160°F). Road test the vehicle for 30 minutes. Does fault

become active?

a. Yes; retain log file of active fault. Replace the MCM. Refer to section "Removal of the Motor Control Module".

b. No; release vehicle.

8 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

3 SPN 652/FMI 4 - EPA10 - GHG14

This diagnostic is typically Injector Cylinder #2 Needle Control Valve Abnormal Operation (MIN).

Table 6.

SPN 652/FMI 4

Description Injector Cylinder #2 Needle Control Valve Abnormal Operation (MIN)

Monitored Parameter Injector Cylinder #2 Needle Control Valve

Typical Enabling Conditions Engine rpm = idle or higher

Monitor Sequence None

Execution Frequency Continuous when enabling conditions met

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

1. Check for multiple codes. Using DDDL/DDRS 7.10 or newer, retain log file of active fault and clear codes (code active

for one key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

All information subject to change without notice. 9

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

3 SPN 652/FMI 4 - EPA10 - GHG14

2. Check the warranty claim history. Check with driver. Is this the first occurrence of this fault within the last 30 days?

a. Yes; Go to step 3.

b. No; complete diagnostics, retain a log file of active fault and the measured resistance values recorded in this

procedure and contact the Customer Support Center at 800-445-1980.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

3. Start and warm the engine until the coolant temperature is above 71°C (160°F).

4. Turn the engine OFF.

5. Disconnect the front fuel injector harness 14-pin injector connector.

6. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion).

a. If water or oil intrusion, bent or spread pins are found, repair as necessary.

b. If the connector shows no signs of damage, Go to step 7.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

7. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

Table 7.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater Greater Greater

Needle 1.3 to 2.5Ω*

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater Greater Greater

Needle 1.3 to 2.5Ω*

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater Greater

Needle 1.3 to 2.5Ω*

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

10 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

Table 8.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 11.

b. No; Go to step 8.

8. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

9. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

10. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

All information subject to change without notice. 11

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

3 SPN 652/FMI 4 - EPA10 - GHG14

Table 9.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System"

Refer to section "Removal of the Fuel Injector - Two-Filter System"

11. Disconnect the Motor Control Module (MCM) 120-pin connector.

12. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

12 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

b. b. If no signs of damage, Go to step 13.

NOTE: DO NOT touch the metal ohmmeter leads with your hands whilen the measurements are being taken.

13. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM 120-pin connector. Are the resistances within range?

Table 10.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Front Engine Side

MCM 120-Pin Harness Acceptable Resistance Acceptable Resistance

Valve Cover 14-pin Valve Cover 14 pin

Connector 1Ω or less 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 14.

b. No; repair the engine side harness. Verify repairs.

NOTE: The use of extension harness J-49120 will ease installation of test MCM.

14. Install a test MCM.

15. Reconnect all connections and start engine. Bring to operating temperature of 71°C (160°F). Road test the vehicle for

30 minutes. Does fault become active?

a. Yes; repeat all steps. If results are the same, retain a log file of active fault and the measured resistance values

recorded in this procedure and contact the Customer Support Center at 800-445-1980 for further instructions.

b. No; Go to step 16.

16. Install original MCM. Bring to operating temperature of 71°C (160°F). Road test the vehicle for 30 minutes. Does fault

become active?

a. Yes; retain log file of active fault. Replace the MCM. Refer to section "Removal of the Motor Control Module".

b. No; release vehicle.

All information subject to change without notice. 13

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

4 SPN 652/FMI 6 - EPA10 - GHG14

4 SPN 652/FMI 6 - EPA10 - GHG14

This diagnostic is typically Injector Cylinder #2 Needle Control Valve Shorted Circuit.

Table 11.

SPN 652/FMI 6

Description Injector Cylinder #2 Needle Control Valve, Valve Shorted Circuit

Monitored Parameter Injector Cylinder #2 Needle Control Valve

Typical Enabling Conditions Engine rpm = idle or higher

Monitor Sequence None

Execution Frequency Continuous when enabling conditions met

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

1. Check for multiple codes. Using DDDL/DDRS 7.10 or newer, retain log file of active fault and clear codes (code active

for one key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

14 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

2. Check the warranty claim history. Check with driver. Is this the first occurrence of this fault within the last 30 days?

a. Yes; Go to step 3.

b. No; complete diagnostics, retain a log file of active fault and the measured resistance values recorded in this

procedure and contact the Customer Support Center at 800-445-1980.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

3. Start and warm the engine until the coolant temperature is above 71°C (160°F).

4. Turn the engine OFF.

5. Disconnect the front rocker cover 14–pin injector harness connector.

6. Inspect the front injector harness 14–pin injector connectors for bent or spread pins. Inspect the connector seal for

damage (signs of water or oil intrusion).

a. If water or oil intrusion, bent or spread pins are found, repair as necessary.

b. If the connector shows no signs of damage, Go to step 7.

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

7. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front injector harness listed below. Are the resistances within range?

Table 12.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Valve Cover Side)

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater Greater Greater

Needle 1.3 to 2.5Ω*

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater Greater Greater

Needle 1.3 to 2.5Ω*

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater Greater

Needle 1.3 to 2.5Ω*

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

All information subject to change without notice. 15

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

4 SPN 652/FMI 6 - EPA10 - GHG14

Table 13.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #1

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #2

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 2 and 3 Pin 2 and Pin 3 and

ground ground

Injector #3

1.3 to 2.5Ω* Greater Greater Greater

Needle

than100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 11.

b. No; Go to step 8.

8. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

9. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

10. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistances within range?

16 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

Table 14.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #1

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #2

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

Pins 3 and 4 Pins 3 and 2 Pin 2 and Pin 3 and

ground ground

Injector #3

2.0Ω or less* Greater than Greater Greater

Needle

100kΩ* than100kΩ* than100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System".

Refer to section "Removal of the Fuel Injector - Two-Filter System".

11. Disconnect the Motor Control Module (MCM) 120-pin connector.

12. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

All information subject to change without notice. 17

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

4 SPN 652/FMI 6 - EPA10 - GHG14

b. b. If no signs of damage, Go to step 13.

NOTE: DO NOT touch the metal ohmmeter leads with your hands whilen the measurements are being taken.

13. Using the chart below, measure and record the resistance values between the engine harness side of the front valve

cover 14-pin connector and the MCM 120-pin harness connector. Are the resistances within range?

Table 15.

Engine Harness Injector Circuit Resistance Table

Front Engine Side MCM 120-Pin Harness Acceptable Resistance Front Engine Side Acceptable Resistance

Valve Cover 14-pin Connector 1Ω or less Valve Cover 14 pin 1KΩ or greater

connector # connector #

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 14.

b. No; repair the engine side harness. Verify repairs.

NOTE: The use of extension harness J-49120 will ease installation of test MCM.

14. Install a test MCM.

15. Reconnect all connections and start engine. Bring to operating temperature of 71°C (160°F). Road test the vehicle for

30 minutes. Does fault become active?

a. Yes; repeat all steps. If results are the same, retain a log file of active fault and the measured resistance values

recorded in this procedure and contact the Customer Support Center at 800-445-1980 for further instructions.

b. No; Go to step 16.

16. Install original MCM. Bring to operating temperature of 71°C (160°F). Road test the vehicle for 30 minutes. Does fault

become active?

a. Yes; retain log file of active fault. Replace the MCM. Refer to section "Removal of the Motor Control Module".

b. No; release vehicle.

18 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

5 SPN 652/FMI 5 - GHG14

This diagnostic is typically Injector Cylinder #2 Needle Control Valve Circuit Open.

Table 16.

SPN 652/FMI 5

Description Injector Cylinder #2 Needle Control Valve Abnormal Operation

(MAX)

Monitored Parameter Injector Cylinder #2 Needle Control Valve

Typical Enabling Conditions Engine rpm = idle or higher

Monitor Sequence None

Execution Frequency Continuous when enabling conditions met

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

1. Check for multiple codes. Using DDDL/DDRS 7.10 or newer, retain log file of active fault and clear codes (code active

for one key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

All information subject to change without notice. 19

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

5 SPN 652/FMI 5 - GHG14

b. If SPN fault code 168 or 723 / FMI any is NOT present, Go to step 2.

2. Check the warranty claim history. Check with driver. Is this the first occurrence of this fault within the last 30 days?

a. Yes; Go to step 3.

b. No; complete diagnostics, retain a log file of active fault and the measured resistance values recorded in this

procedure and contact the Customer Support Center at 800-445-1980.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

3. Start and warm the engine until the coolant temperature is above 71°C (160°F).

4. Turn the engine OFF.

5. Disconnect the front fuel injector harness 14-pin injector connector.

6. Inspect the front fuel injector harness 14-pin injector connector for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion).

a. If water or oil intrusion, bent or spread pins are found, repair as necessary.

b. If the connector shows no signs of damage, Go to step 7.

NOTE: Do NOT touch the metal ohmmeter leads with your hands when the measurements are made.

7. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

20 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

Table 17.

Front Fuel Injector Harness 14-Pin Connector (Valve Cover Side) Resistance Chart

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

Table 18.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #1

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #2

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #3

Needle 1.3 - 2.5Ω* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 11.

b. No; Go to step 8.

8. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

9. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

10. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistance values within range?

All information subject to change without notice. 21

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

5 SPN 652/FMI 5 - GHG14

Table 19.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #1

Needle 2.0Ω or less* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #2

Needle 2.0Ω or less* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #3

Needle 2.0Ω or less* >100kΩ* >100kΩ* >100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System"

Refer to section "Removal of the Fuel Injector - Two-Filter System"

11. Disconnect the MCM2.1 120-pin connector.

12. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 13.

22 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

13. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM2.1 120-pin connector. Are the resistances within range?

Table 20.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Valve

MCM2.1 120-Pin Acceptable Resistance Front Engine Side Valve Acceptable Resistance

Cover 14-pin connector

Harness Connector 1Ω or less Cover 14 pin connector # 1KΩ or greater

#

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 14.

b. No; repair the engine side harness. Verify repairs.

NOTE: The use of extension harness J-49120 will ease installation of test MCM2.1.

14. Install a test MCM2.1.

15. Reconnect all connections and start engine. Bring to operating temperature of 71°C (160°F). Road test the vehicle for

30 minutes. Does fault become active?

a. Yes; repeat all steps. If results are the same, retain a log file of active fault and the measured resistance values

recorded in this procedure and contact the Customer Support Center at 800-445-1980 for further instructions.

b. No; Go to step 16.

16. Install original MCM. Bring to operating temperature of 71°C (160°F). Road test the vehicle for 30 minutes. Does fault

become active?

a. Yes; retain log file of active fault. Replace the MCM. Refer to section "Removal of the Motor Control Module".

b. No; release vehicle.

All information subject to change without notice. 23

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

6 SPN 652/FMI 7 - GHG14

6 SPN 652/FMI 7 - GHG14

This diagnostic is typically Injector Cylinder #2 Needle Control Valve Stuck Open.

Table 21.

SPN 652/FMI 7

Description Injector Cylinder #2 Needle Control Valve Abnormal Operation

(MAX)

Monitored Parameter Injector Cylinder #2 Needle Control Valve

Typical Enabling Conditions Engine rpm = idle or higher

Monitor Sequence None

Execution Frequency Continuous when enabling conditions met

Typical Duration 2 Seconds

Dash Lamps MIL, CEL

Engine Reaction Derate 25%

Verification Engine Idle (1 minute)

Check as follows:

NOTE: Submit completed diagnostics with warranty claim.

NOTE: Injector chart PDF available on DDCSN/SUPPORT/SPECIALIZED SERVICE.

1. Check for multiple codes. Using DDDL/DDRS 7.10 or newer, retain log file of active fault and clear codes (code active

for one key cycle).

a. If SPN fault code 168 or 723/FMI any is present, service those faults first.

24 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

b. If SPN fault code 168 or 723/FMI any is NOT present, Go to step 2.

2. Check the warranty claim history. Check with driver. Is this the first occurrence of this fault within the last 30 days?

a. Yes; Go to step 3.

b. No; complete diagnostics, retain a log file of active fault and the measured resistance values recorded in this

procedure and contact the Customer Support Center at 800-445-1980.

WARNING: ENGINE EXHAUST

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level

surface, parking brake is set, and the wheels are blocked.

3. Start and warm the engine until the coolant temperature is above 71°C (160°F).

4. Turn the engine OFF.

5. Disconnect the front fuel injector harness 14-pin injector connector.

6. Inspect the front fuel injector harness 14-pin injector connectors for bent or spread pins; inspect the connector seal for

damage (signs of water or oil intrusion).

a. If water or oil intrusion, bent or spread pins are found, repair as necessary.

b. If the connector shows no signs of damage, Go to step 7.

NOTE: Do NOT touch the metal ohmmeter leads with your hands when the measurements are made.

7. Using the appropriate chart below, measure and record the resistance values between the corresponding pins on the

valve cover side of the front fuel injector harness listed below. Are the resistances within range?

All information subject to change without notice. 25

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

6 SPN 652/FMI 7 - GHG14

Table 22.

Front Fuel Injector Harness 14-Pin Connector (Valve Cover Side) Resistance Chart

Pin 2 and Pin 8 and

Pins 1 and 2 Pins 1 and 8

ground ground

Injector #1

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 3 and Pin 9 and

Pins 1 and 3 Pins 1 and 9

ground ground

Injector #2

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 4 and Pin 12 and

Pins 1 and 4 Pins 1 and 12

ground ground

Injector #3

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

Table 23.

Front Fuel Injector Harness 14-Pin Connector Resistance Chart (Using J-48671-10 Injector Breakout Box)

Note: Ensure J-48671-10 ground strap is connected to cylinder head.

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #1

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #2

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 2 and 3

ground ground

Injector #3

Greater than Greater than Greater than

Needle 1.3 to 2.5Ω*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; Go to step 11.

b. No; Go to step 8.

8. Remove the rocker cover. Refer to section "Removal of the Rocker Cover"

9. Remove the front fuel injector harness from the engine.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

10. Using the chart below, measure and record the resistance values between the injector pins listed below. Are the

resistance values within range?

26 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

Table 24.

Injector Needle Resistance Chart (Injector Harness must be removed from engine)

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #1

Greater than Greater than Greater than

Needle 2.0Ω or less*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #2

Greater than Greater than Greater than

Needle 2.0Ω or less*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

Pin 2 and Pin 3 and

Pins 3 and 4 Pins 3 and 2

ground ground

Injector #3

Greater than Greater than Greater than

Needle 2.0Ω or less*

100kΩ* 100kΩ* 100kΩ*

Ω Ω Ω Ω

* = acceptable resistance

a. Yes; replace the front fuel injector harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

b. No; replace the injector with the out-of-range resistance.

Refer to section "Removal of the Fuel Injector - Three-Filter System"

Refer to section "Removal of the Fuel Injector - Two-Filter System"

11. Disconnect the Motor Control Module (MCM2.1) 120-pin connector.

12. Inspect the MCM 120-pin connector and 120-pin harness connector for signs of corrosion, spread, unseated (pushed

out) or damaged pins, connector seal for damage (signs of water or oil intrusion) or signs of wire damage.

a. If signs of damage are found, repair as necessary. Verify repairs.

b. If no signs of damage, Go to step 13.

All information subject to change without notice. 27

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

6 SPN 652/FMI 7 - GHG14

NOTE: DO NOT touch the metal ohmmeter leads with your hands when the measurements are made.

13. Using the chart below, measure and record the resistance values between the engine side of the front valve cover 14-pin

connector and the MCM2.1 120-pin connector. Are the resistances within range?

Table 25.

Engine Harness Injector Circuit Resistance Table

Front Engine Side Valve

MCM2.1 120-Pin Acceptable Resistance Front Engine Side Valve Acceptable Resistance

Cover 14-pin connector

Harness Connector 1Ω or less Cover 14 pin connector # 1KΩ or greater

#

1 25 Ω 1 and ground Ω

2 26 Ω 2 and ground Ω

3 22 Ω 3 and ground Ω

4 24 Ω 4 and ground Ω

a. Yes; Go to step 14.

b. No; repair the engine side harness. Verify repairs.

NOTE: The use of extension harness J-49120 will ease installation of test MCM2.1.

14. Install a test MCM2.1.

15. Reconnect all connections and start engine. Bring to operating temperature of 71°C (160°F). Road test the vehicle for

30 minutes. Does fault become active?

a. Yes; repeat all steps. If results are the same, retain a log file of active fault and the measured resistance values

recorded in this procedure and contact the Customer Support Center at 800-445-1980 for further instructions.

b. No; Go to step 16.

16. Install original MCM. Bring to operating temperature of 71°C (160°F). Road test the vehicle for 30 minutes. Does fault

become active?

a. Yes; retain log file of active fault. Replace the MCM. Refer to section "Removal of the Motor Control Module".

28 All information subject to change without notice.

Copyright © 2013 DETROIT DIESEL CORPORATION 9 11-13

9 11-13

b. No; release vehicle.

All information subject to change without notice. 29

9 11-13 Copyright © 2013 DETROIT DIESEL CORPORATION

You might also like

- P345 Relay Test ReportDocument18 pagesP345 Relay Test Reportratheeshkumard60% (5)

- Upc 1 2021Document495 pagesUpc 1 2021Alihassan100% (2)

- 808 10 PDFDocument74 pages808 10 PDFHamilton miranda100% (1)

- Bulletin 6l90 PDFDocument4 pagesBulletin 6l90 PDFAnonymous WzR5h9g8VNo ratings yet

- Codigo de Falla DdecDocument9 pagesCodigo de Falla DdecAnonymous nhF45CNo ratings yet

- 1218 10Document19 pages1218 10Hamilton mirandaNo ratings yet

- MC 10124184 9999 PDFDocument8 pagesMC 10124184 9999 PDFTracto Rescates de Occidente CtrlNo ratings yet

- DetruitDocument4 pagesDetruitfaiz aliNo ratings yet

- GHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Document17 pagesGHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Octavio Hernandez RodriguezNo ratings yet

- 1010 14 PDFDocument5 pages1010 14 PDFruddyNo ratings yet

- Sop Rebar Bending LintechDocument11 pagesSop Rebar Bending Lintechmahindra hardinataNo ratings yet

- Norgren Valve Pilot NC PDFDocument4 pagesNorgren Valve Pilot NC PDFLuis Eduardo Albarracin RugelesNo ratings yet

- SB 10054700 6991Document3 pagesSB 10054700 6991dhiraj586272No ratings yet

- SPN 4334 - Fmi 4 - GHG17Document5 pagesSPN 4334 - Fmi 4 - GHG17Francisco Javier TorresNo ratings yet

- Fabrication Pnuematic Trainer Kit For Educational PurposesDocument15 pagesFabrication Pnuematic Trainer Kit For Educational PurposesUday Bagade100% (1)

- Operating Instruction Manual FOR Optical Interferometic Gas Analyzer MODEL FI-800Document23 pagesOperating Instruction Manual FOR Optical Interferometic Gas Analyzer MODEL FI-800Hoàn NguyễnNo ratings yet

- IS132 - R8865 Digital Hourmeter RevbDocument2 pagesIS132 - R8865 Digital Hourmeter RevbHilman Adi LuhungNo ratings yet

- Dd15 FaultDocument19 pagesDd15 FaultSs100% (1)

- 706 15 PDFDocument25 pages706 15 PDFHelloNo ratings yet

- PVT831-E-10-34-Instrument and Alarm Point List (090116) - WorkingDocument34 pagesPVT831-E-10-34-Instrument and Alarm Point List (090116) - WorkingBui Duy ThanhNo ratings yet

- Hydrocarbon (HC) Doser Fuel Supply PressureDocument14 pagesHydrocarbon (HC) Doser Fuel Supply PressureJose AlanisNo ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- MC 10140985 9999Document4 pagesMC 10140985 9999speedtransport60No ratings yet

- Manual Cabezal 11-31338Document37 pagesManual Cabezal 11-31338producciontecnolaminasNo ratings yet

- Emanagebasicoperation PDFDocument23 pagesEmanagebasicoperation PDFanthony dizonNo ratings yet

- WS 2 - (Kawalan Motor Mara Songsang)Document10 pagesWS 2 - (Kawalan Motor Mara Songsang)ZULHILMINo ratings yet

- NEOPRSP001WI015 - Rev. 01 - Pages 06 - Shut Down of 2nd Pass RO System Work InstructionsDocument6 pagesNEOPRSP001WI015 - Rev. 01 - Pages 06 - Shut Down of 2nd Pass RO System Work Instructionsalialharbi021No ratings yet

- Additions, Revisions, or Updates: Subject DateDocument9 pagesAdditions, Revisions, or Updates: Subject DateDilroy seebalackNo ratings yet

- P643-T2 GregarDocument25 pagesP643-T2 Gregarcj.karthikNo ratings yet

- P74FA-9700 MergedDocument9 pagesP74FA-9700 MergedhazimNo ratings yet

- Final Inspection Report 12-E-101 ADocument4 pagesFinal Inspection Report 12-E-101 AYudi Ibnu ChannelNo ratings yet

- 3456 Wheel Speed Sensor CheckDocument4 pages3456 Wheel Speed Sensor CheckTun Tun Win KseNo ratings yet

- Httpsstatic - nhtsa.govoditsbs2017MC 10142121 9999 PDFDocument5 pagesHttpsstatic - nhtsa.govoditsbs2017MC 10142121 9999 PDFkqgy9s6sgvNo ratings yet

- Diff Micom P543 GT1 3 Line DiffDocument20 pagesDiff Micom P543 GT1 3 Line DiffPandrayar MaruthuNo ratings yet

- Cracked Gas CompressorDocument7 pagesCracked Gas CompressorfvaefaNo ratings yet

- Riello G750 ManuelDocument21 pagesRiello G750 Manuelmelvin hoferNo ratings yet

- Norgren Bombas de Vacio NORVACDocument18 pagesNorgren Bombas de Vacio NORVACECO Green and BlueNo ratings yet

- Silo - Tips Manual Revision August 2015 P NDocument62 pagesSilo - Tips Manual Revision August 2015 P NerikNo ratings yet

- Fluke 8026B Digital Multimeter Instruction ManualDocument101 pagesFluke 8026B Digital Multimeter Instruction ManualRade ČikarićNo ratings yet

- Rociador Rango Extendido EC5Document6 pagesRociador Rango Extendido EC5victorNo ratings yet

- GFDocument211 pagesGFCatalin StoicescuNo ratings yet

- Greenstar 12-14 Ri ErP Operating InstructionsDocument20 pagesGreenstar 12-14 Ri ErP Operating InstructionsKevin JordanNo ratings yet

- Product Information: Air Impact WrenchDocument12 pagesProduct Information: Air Impact WrenchkareemNo ratings yet

- CH3 Engine TroubleshootingDocument51 pagesCH3 Engine TroubleshootingMigue SalazarNo ratings yet

- Grasso Self-Limiting Automatic Purger Ce Ped: Installation and Maintenance Manual (IMM) 0089293Document28 pagesGrasso Self-Limiting Automatic Purger Ce Ped: Installation and Maintenance Manual (IMM) 0089293Paweł HejmowskiNo ratings yet

- EIPDocument12 pagesEIPKrishna Pardeshi100% (1)

- FakinasolDocument17 pagesFakinasolmasgontarNo ratings yet

- Manual BEST RIGHT DWDocument7 pagesManual BEST RIGHT DWJohann BrionesNo ratings yet

- Sls 35 Mec PR 022 - Fat Procedure RpaDocument16 pagesSls 35 Mec PR 022 - Fat Procedure Rparoronoa_zorro11100% (1)

- Updated Sales QTN - Upsc 2019 1814Document4 pagesUpdated Sales QTN - Upsc 2019 1814Oliver DsouzaNo ratings yet

- Riken-Keiki Monitors-Hydrogen ManualDocument101 pagesRiken-Keiki Monitors-Hydrogen Manualebin vargheseNo ratings yet

- Service Bulletin: Mil Comes On With One or More DTCS: P0301 Thru P0304, P3400, or P3497Document6 pagesService Bulletin: Mil Comes On With One or More DTCS: P0301 Thru P0304, P3400, or P3497Eduardo GonzálezNo ratings yet

- Nota Praktikal 5 (Inspect - Testing) - EditDocument11 pagesNota Praktikal 5 (Inspect - Testing) - EditMuhammad Ilyasak Abdul HalimNo ratings yet

- p345 Relay Test ReportDocument23 pagesp345 Relay Test Reportbig bad wolfNo ratings yet

- Instructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentDocument13 pagesInstructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentsorabhNo ratings yet

- Table (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)Document5 pagesTable (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)NaveenRajNo ratings yet

- Direy 6Document9 pagesDirey 6Yoseph TsegayeNo ratings yet

- For Execution Unit H45 To H48: GE Official GE OfficialDocument2 pagesFor Execution Unit H45 To H48: GE Official GE OfficialSulaiman JafferyNo ratings yet

- 4runner Limited 2009 2UZ FEDocument314 pages4runner Limited 2009 2UZ FEarmotrixmecNo ratings yet

- 3000 Liter Undergorund LPG TankDocument4 pages3000 Liter Undergorund LPG TankHarshana AtapattuNo ratings yet

- SHLCCapprovedprojectssince 58 TH SHLCCmeetingDocument7 pagesSHLCCapprovedprojectssince 58 TH SHLCCmeetingfelixfperiaNo ratings yet

- PMC / OWNER Reply To Pre-Bid Queries (SET-1 / PART-2) : Page 2 of 3Document2 pagesPMC / OWNER Reply To Pre-Bid Queries (SET-1 / PART-2) : Page 2 of 3Rohit GoelNo ratings yet

- Form Check List Maintenance: Activity 250 500 1000 2000 RemarksDocument1 pageForm Check List Maintenance: Activity 250 500 1000 2000 Remarksferry saputra100% (2)

- Danfoss PS KP Low PressureDocument20 pagesDanfoss PS KP Low PressureNikunjNo ratings yet

- Lesson Exemplar in Science 8 Week 3Document6 pagesLesson Exemplar in Science 8 Week 3Joyce PerezNo ratings yet

- Innovative Building MaterialsDocument11 pagesInnovative Building MaterialspriyaNo ratings yet

- Lecture - 6 EDocument33 pagesLecture - 6 ETung HoNo ratings yet

- Quest Es TermoDocument20 pagesQuest Es TermoSk1lzNo ratings yet

- KALMARDocument92 pagesKALMARSadik AloNo ratings yet

- B.1 - TH - Main Engine - STX Engine PDFDocument772 pagesB.1 - TH - Main Engine - STX Engine PDFnaya aninditaNo ratings yet

- Installation Manual 1 Way Cassette VRFDocument14 pagesInstallation Manual 1 Way Cassette VRF••ωłњアى••No ratings yet

- Sulfur Compound Extraction and Sweetening: P A R T 11Document14 pagesSulfur Compound Extraction and Sweetening: P A R T 11Ashraf SeragNo ratings yet

- PillsDocument3 pagesPillsAhmedMohsenNo ratings yet

- LAUDA-GFL Cross Reference List 20-12-15 EnglDocument4 pagesLAUDA-GFL Cross Reference List 20-12-15 EnglĐoàn HạnhNo ratings yet

- Static Electricity and Direct Current (DC) Circuit 1.1 Electric Current Voltage, and Resistance (1) Fundamentals of ElectricityDocument60 pagesStatic Electricity and Direct Current (DC) Circuit 1.1 Electric Current Voltage, and Resistance (1) Fundamentals of ElectricityEndraNo ratings yet

- Operation Manual - 74714763 - Injection - Power - Stage - HPI - 5Document20 pagesOperation Manual - 74714763 - Injection - Power - Stage - HPI - 5Aussi SidNo ratings yet

- Energy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesDocument12 pagesEnergy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesAshfaq Ali KhanNo ratings yet

- Neoen Equity ReportDocument11 pagesNeoen Equity ReportTiffany SandjongNo ratings yet

- Bme Lab Manual PDFDocument55 pagesBme Lab Manual PDFhemant rathodNo ratings yet

- JOCA CABLE - TDS SolarDocument2 pagesJOCA CABLE - TDS SolarSalmanAnjumNo ratings yet

- G2 - Math Word Problem 2Document3 pagesG2 - Math Word Problem 2Harris SuhardjaNo ratings yet

- Multiphysics Analysis of A Burning CandleDocument1 pageMultiphysics Analysis of A Burning CandleOlair RosaNo ratings yet

- 1LA6106-4AA90-Z B02+L2F Datasheet enDocument1 page1LA6106-4AA90-Z B02+L2F Datasheet enledamtmendoncaNo ratings yet

- How To Read PEFs DrawingDocument20 pagesHow To Read PEFs DrawingEmmanuel Ezekiel-Hart EdemNo ratings yet

- Catalogo Garrett Vol8Document86 pagesCatalogo Garrett Vol8Robson Adauto LicursiNo ratings yet

- Offshore ReferencesDocument32 pagesOffshore ReferencesKalaiYarasanNo ratings yet

- Tejas Bhandari Final ReportDocument77 pagesTejas Bhandari Final ReportPavan BarhateNo ratings yet

- BSK 46 & Other Grade Material SpecificationDocument6 pagesBSK 46 & Other Grade Material Specification4alamz100% (1)

- Acon (Radial Thru-Hole) GF SeriesDocument2 pagesAcon (Radial Thru-Hole) GF Seriesxyz99No ratings yet