Professional Documents

Culture Documents

IEC 61439-3-2012(压缩)

IEC 61439-3-2012(压缩)

Uploaded by

Srf Saharin0 ratings0% found this document useful (0 votes)

25 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

25 views4 pagesIEC 61439-3-2012(压缩)

IEC 61439-3-2012(压缩)

Uploaded by

Srf SaharinCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

61439.3 © IEC:2012 =o.

NOTE In Normay, protective devices in ovlgsing circuits wsed for wiring protection in building shall comply with

IEG 6898-1, IEC 81006, IEC 61009, IEC 60289-3 or IEC 60947-2 as long as the requirements in IEC S0BGE-1 or

HEC 61008 are met for’ all tests except tbe test for time-current characteristic 8. C and 0 as specified in

HEG 60898-1:2001, 9.10.1 or IEC 61009-12010, clause 9.9.2.1

8.6.1. Main circuits

Replacement of second paragraph:

Each of the conductors between the Incoming unit and outgoing unit as well as the

‘components included in these units may be rated on the basis of the reduced short-circuit

stresses occurring on the load side of the respective outgoing short-circuit protective device,

provided that these conductors are arranged so that under narmal operation an internal short

circuit between phases and/or between phases and earth is not to be expected (see 8.6.4 of

Part 1).

Addition:

NOTE UK Electricity, Safety and Quality Regulations §.!. 2002 No. 2965 require electricity suppliers to stato the:

‘maximum prospective short circu curreat at the supply terminals, In the UK the maximum prospective shert-cireuit

‘current at the supply terminals of household and similar electrical installations deciared by the supply authority in

accondance with the Electricity Association Publication P 25 is 16 KA for single-phase supalies up to and including

woo A,

8.8 Terminals for external conductors

Addition:

‘The number of neutral terminals of a DBO shall be not less than one outgoing terminal for

each outgoing circuit requiring a neutral terminal. These terminals shall be located or

identified in the same sequence as their respective phase conductor terminals.

OBOs shall have a minimum of two terminals for electrical installation protective bonding

‘conductors,

NOTE In the USA, the neutral conductor is identified by the colour white and the protective earth conductor may

bo either grooniyoliow or soli greon,

9 Performance requirements

This clause of Part 1 applies.

10 Design verification

Tr

clause of Part 1 applies except as follows.

10.

2 Severity test A

Addition:

The following is an alternative test.

All grease is removed from the parts or representative samples of the steel enclosures of the

DBO to be tested, by immersion in a cold chemical degreaser such as methylehloroform or

refined petrol for 10 min, The parts are then immersed for 10min in a 10 % solution of

ammonium chloride in water at a temperature of (20 +5) *C.

Without drying but after shaking off any drops, the parts are placed for 10 min in a box

‘containing air saturated with moisture at a temperature af (20 + 5) °C.

=10- 61439.3 © IEC:2012

‘After the parts have dried for 10 min in a heating cabinet at a temperature of (100 + 5) °C and

have been left at room temperature for 24h, their surfaces shall show no signs of iron

‘oxidization.

Traces of iron oxide on sharp edges and any yellowish film remavable by rubbing ar

ignored.

For small helical springs and the like, and for inaccessible parts exposed to abrasion, a layer

of grease may provide sufficient protection against iron oxidization. Such parts are subjected

to the test only if there is doubt about the effectiveness of the grease film, and the test is then

made without previous removal of the grease,

10.2.2.4 Results to be obtained

The first paragraph of Part 1 does not apply to the alternative test of this standard

10.2.3.2 Verification of resistance of insulating matorials to abnormal heat and fire due

to internal electric effects

‘The last paragraph of Part 1 does not apply.

Adzition:

NOTE 850°C does net apply to secestible parts of the enclosure after mounting in hollow walls 0.9. covers,

doors.

10.2.6 Mechanical impact

Replacement:

Verification of the degree of protection against mechanical impacts shall be carried out in

accordance with IEG 62262

The test shall be carried out by means of a hammer test apparatus as described in

IEC 60068-2-75, e.g. impact spring hammer. The test is made after the sample(s) has been

for 2h at a temperature of -8 'C + 1 K for indoor use and -25 °C + 1K for outdoor use,

‘Compliance is checked on those exposed parts of the DBO which may be subjected to

mechanical impact when mounted as in normal use

‘The sample with cover, or the enclosure,

against a rigid support

any, shail be fixed as in normal use or placed

Three blows shall be applied an separate places of each of the accessible faces and door (if

provided). The impacts shall be evenly distributed on the faces of the enclosure(s) under test.

in no 6886 shall the impacts be applied in the surroundings of the same point of the

nclosure. A new sample for each accessible face is used, unless the previous test has not

influenced the results of the subsequent test(s). then the sample may be reused. They shall

not be applied to knock-outs. built-in components complying with other standards, or other

fastening means which are recessed below the surface 80 as not to be subject to impact.

Cable entries which are not provided with knock-outs shall be left open. If they are provided

‘with knock-outs, two of them shall be opened,

Before applying the blows, fi jhtened with

a torque equal to that specified it

screws of bases, covers and the like shall be

Table 102

61439.3 © IEC:2012 =t-

‘After the test, visual inspection shall verify that the specified IP code and dielectric properties

have be maintained, Remavable covers can still be removed and reinstalled, doors opened

and elosed,

10.2.7 Marking

Addition of mew first paragraph:

‘This test only applies to OBO's intended for outdoor instal

10,10.2.3.1 General

Addition after the third paragraph:

In the absence of manufacturer's instructions, the tightening torque applied to terminals shall

be in accordance with those specified for the temperature rise test in the relevant device

product standard

10.10.2.3.6 Verification considering individual functional units separ

complete assenaLy

ly and the

Aggition to fourth paragraph:

‘One methad to determine the most onerous group, is for the rated current of the DBO (Faq), to

bbe distributed amongst the smallest possible number of outgoing circuits, so that each of

these circuits is loaded with its rated current multiplied by the assumed loading factor shown

in Table 101 of this standard or a diversity factor stated by the manufacturer. For an example

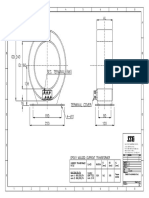

‘considering a complete DBO, see Figure 101

10.10.2.3.7 Verification considering individual functional units and the main and

distribution busbars separately as well as the complete ASSEMBLY

Addition to item d):

‘One methad to determine the most onerous group, is for the rated current of the DBO (/,a), to

bbe distributed amongst the smallest possible number of outgoing circuits. so that each of

these circuits is loaded with its rated current multiplied by the rated diversity factor shown in

Table 101 of this standard or a diversity factor stated by the manufacturer.

10.10.32 ASSEMBLIES

Addition:

(BOs with synthetic enclosures are considered representative of DBOs with metallic

enclosures, if the highest air temperature ‘on the inside surfaces of the synthetic

‘enclosure does not exceed the maximum surface temperature rise for the accessible external

metal surfaces according to Table 6 of Part 1,

10.10.4.2.3 Results to be obtained

Addition:

NOTE Guidance is in the form of a publication of the maximum raied current at a specified ambient air

jerperatu Immediate vicinity of the device.

Example:

8) yy = 200 A.at 40 °C local ambiont air tomperature, therefore 0.8 x 200.4 = 160A,

=12- 61439.3 © IEC:2012

'b) The calculated alc temperature within the enclosure is 60 °C. The manufacturer's information limits the device

Iy.to 150 A at 69 °C local ambient air temperature.

Conclusion: the lower value from a) and b) ie tho continuous permissible load, In this cage 150A at Ine.

alevlated local air temperature.

10.10.4.3.2 Results to be obtained

Addition:

NOTE Guidance is in the form of a publication of the maximum rated current at a specified ambient air

Tomporalure in the immediate vicinity of the device,

Example:

8) yy 200 A at 40 °C local ambient air temperature, therefore 0.8 200.4» 160.8,

) The calculated ac temperature within the enclosure is 60 °C. The manufacturer's information limits the device

Jy to 180 A at 60 °C local ambient air temperature

Genelusion: the lewer value trem a) and b) is the continuous permissible load, in this case 180. at the

calculated local air emperature.

10.11.8.3.3 Incoming circuit and main busbars

Addition:

A rated conditional short-circuit current can be assigned where the distance of the main and

distribution busbar between the load terminals of the incoming device connected ta the main

busbar and the supply terminals of the outgoing functional unit does not exceed 3m. The

‘main busbar, distribution busbar and incoming device may be tested and rated on the basis of

the reduced short-circuit stresses occurring on the load side of the respective short-circuit

protective device within each unit. Provided that these conductors are arranged $0 that an

internal short-circuit between phases and/or between phases and earth is not to be expected

(see 8.6.4 of Part 1).

NOTE Examples of conductor types. and installation requirements are given in Table of Part 1

410.13 Mechanical oper

ion

Replacement of second paragraph:

For parts, which need verification by test, satisfactory mechanical operation shall be verified

after installation in the 080. The number of operating cycles shall be 50.

11 Routine verification

This clause of Part 1 applies.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- CSCS Managers Professional Study Pack Rev ADocument108 pagesCSCS Managers Professional Study Pack Rev Anagen2005100% (2)

- CSCS Managers Professional Study Pack Rev ADocument108 pagesCSCS Managers Professional Study Pack Rev Anagen2005100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- THM0044014S6Document1 pageTHM0044014S6Srf Saharin100% (1)

- THM0082289S2Document1 pageTHM0082289S2Srf SaharinNo ratings yet

- 132 - 33KV RTCC Ref.1Document3 pages132 - 33KV RTCC Ref.1Srf SaharinNo ratings yet

- Schedule B4 - 33KV Underground Works - V1Document2 pagesSchedule B4 - 33KV Underground Works - V1Srf SaharinNo ratings yet

- En Principal DALI Equity Fund IRDocument52 pagesEn Principal DALI Equity Fund IRSrf SaharinNo ratings yet

- Schedule B1 - BQ G - P - V1Document2 pagesSchedule B1 - BQ G - P - V1Srf SaharinNo ratings yet

- Busbar Protection General Principles Application ExamplesDocument67 pagesBusbar Protection General Principles Application ExamplesSrf SaharinNo ratings yet

- MediSavers Prima Pass Pricing TableDocument4 pagesMediSavers Prima Pass Pricing TableSrf SaharinNo ratings yet

- Mandatory Pre Check (GIS Supervision) - 275kVDocument6 pagesMandatory Pre Check (GIS Supervision) - 275kVSrf SaharinNo ratings yet

- Shoto IntroductionDocument41 pagesShoto IntroductionSrf SaharinNo ratings yet

- SSE's Company ProfileDocument10 pagesSSE's Company ProfileSrf SaharinNo ratings yet

- Jean Muller Fuse and Fuse Bases SpecificationsDocument22 pagesJean Muller Fuse and Fuse Bases SpecificationsSrf SaharinNo ratings yet

- Warranty Letter For Fiamm Battery 240ah (05.02.2020)Document1 pageWarranty Letter For Fiamm Battery 240ah (05.02.2020)Srf SaharinNo ratings yet

- Shoto 6-GFM-250Document2 pagesShoto 6-GFM-250Srf SaharinNo ratings yet

- TLC 6-GFM (English)Document6 pagesTLC 6-GFM (English)Srf SaharinNo ratings yet

- Vkan Testing & Lab - Test ReportDocument13 pagesVkan Testing & Lab - Test ReportSrf SaharinNo ratings yet

- Sabre VRN6a: Installation, Operation and Maintenance ManualDocument48 pagesSabre VRN6a: Installation, Operation and Maintenance ManualSrf SaharinNo ratings yet

- Sabre VRN6a IOM LIOM01-059 - 1Document61 pagesSabre VRN6a IOM LIOM01-059 - 1Srf Saharin100% (2)

- 12Kv Ring Main Unit: Answer For Reliable and Efficient NetworkDocument12 pages12Kv Ring Main Unit: Answer For Reliable and Efficient NetworkSrf SaharinNo ratings yet

- Analogue Instruments: AC AmmeterDocument7 pagesAnalogue Instruments: AC AmmeterSrf SaharinNo ratings yet

- Borang Permohonan T1 A1m 2018Document202 pagesBorang Permohonan T1 A1m 2018Srf SaharinNo ratings yet

- Agilent U1210 Series Handheld Clamp Meters: Handle Big Currents - More SafelyDocument16 pagesAgilent U1210 Series Handheld Clamp Meters: Handle Big Currents - More SafelySrf SaharinNo ratings yet

- Sse Rmu 11KV Catalogue PDFDocument6 pagesSse Rmu 11KV Catalogue PDFSrf SaharinNo ratings yet

- 33KV GloveDocument1 page33KV GloveSrf SaharinNo ratings yet

- Current Transformer Details:: SS: SN: MS: Nil: 15-11-2013Document3 pagesCurrent Transformer Details:: SS: SN: MS: Nil: 15-11-2013Srf SaharinNo ratings yet

- CT Calculation P541Document1 pageCT Calculation P541Srf Saharin100% (1)