Professional Documents

Culture Documents

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

Uploaded by

PRASHANT KANTECopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Rotary Shouldered Connections HandBook Smith InternationalDocument212 pagesRotary Shouldered Connections HandBook Smith InternationalPRASHANT KANTE100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- G.R. No. 181455-56 Case DigestDocument2 pagesG.R. No. 181455-56 Case DigestKevin Jeason PerdidoNo ratings yet

- Ae 101963362 PDFDocument4 pagesAe 101963362 PDFPRASHANT KANTENo ratings yet

- Demand LetterDocument109 pagesDemand LetterLex Anne100% (1)

- G16 Chapter 7Document11 pagesG16 Chapter 7PRASHANT KANTENo ratings yet

- MHA ZENTGRAF 144-147 BKH Gas SteelDocument3 pagesMHA ZENTGRAF 144-147 BKH Gas SteelPRASHANT KANTENo ratings yet

- HES 340 UNIT Jack FrameDocument9 pagesHES 340 UNIT Jack FramePRASHANT KANTENo ratings yet

- $R4370IQDocument3 pages$R4370IQPRASHANT KANTENo ratings yet

- $R076ZVFDocument1 page$R076ZVFPRASHANT KANTENo ratings yet

- $RR55O0PDocument1 page$RR55O0PPRASHANT KANTENo ratings yet

- RP205Document1 pageRP205PRASHANT KANTENo ratings yet

- $R0AZ43FDocument1 page$R0AZ43FPRASHANT KANTENo ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- Ground Floor Plan - Rev 6Document1 pageGround Floor Plan - Rev 6PRASHANT KANTENo ratings yet

- Fluid Power Metric Catalogue 2018 780 WebDocument8 pagesFluid Power Metric Catalogue 2018 780 WebPRASHANT KANTENo ratings yet

- Aol / Bol / Oca Series: General Information MaintenanceDocument1 pageAol / Bol / Oca Series: General Information MaintenancePRASHANT KANTENo ratings yet

- Pipe ScheduleDocument20 pagesPipe SchedulePRASHANT KANTENo ratings yet

- Beam ColumnDocument6 pagesBeam ColumnPRASHANT KANTENo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Electronic Temperature Sensors: Technical DataDocument7 pagesElectronic Temperature Sensors: Technical DataPRASHANT KANTENo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Viswanath ResumeDocument3 pagesViswanath ResumePRASHANT KANTENo ratings yet

- Advanced Oilfield Technology Company: Member of Al Sulaimi GroupDocument1 pageAdvanced Oilfield Technology Company: Member of Al Sulaimi GroupPRASHANT KANTENo ratings yet

- Cenlub Dimensional CatalogueDocument34 pagesCenlub Dimensional CataloguePRASHANT KANTE100% (1)

- Taper Bushing Installation: IMPORTANT NOTE: Please Follow The Instructions On This Sheet in Order For TheDocument6 pagesTaper Bushing Installation: IMPORTANT NOTE: Please Follow The Instructions On This Sheet in Order For ThePRASHANT KANTENo ratings yet

- O RingDocument50 pagesO RingPRASHANT KANTE100% (1)

- Atlas Copco PDFDocument6 pagesAtlas Copco PDFPRASHANT KANTENo ratings yet

- 2023-2024 Competition Rules Price Media Law Moot CourtDocument23 pages2023-2024 Competition Rules Price Media Law Moot CourtSamridhi BajoriaNo ratings yet

- Touchstone LicenseDocument4 pagesTouchstone LicensenoblexoutNo ratings yet

- Alex Latimer Gordon Latimer Patrick LatimerDocument18 pagesAlex Latimer Gordon Latimer Patrick LatimerPriya KNo ratings yet

- The Silence of The Lambs 1991 1080p BluRay X264 YIFYDocument94 pagesThe Silence of The Lambs 1991 1080p BluRay X264 YIFYFernando Peña FloresNo ratings yet

- Purchase Agreement Template: Seller Name of BuyerDocument3 pagesPurchase Agreement Template: Seller Name of BuyerMochamad Bilal, SH.No ratings yet

- Accounts Practicle First YearDocument33 pagesAccounts Practicle First YearMITESHKADAKIANo ratings yet

- Current Issues Trends Psychology Applied To LawDocument18 pagesCurrent Issues Trends Psychology Applied To LawDimple GuiraNo ratings yet

- Oprita Marius FR 2024-04-08 2024-04-09Document1 pageOprita Marius FR 2024-04-08 2024-04-09Dumitru IftodeNo ratings yet

- Answers To ClarificationsDocument3 pagesAnswers To ClarificationskuhussNo ratings yet

- 153.CIR Vs La FlorDocument9 pages153.CIR Vs La FlorClyde KitongNo ratings yet

- Satyam 2040 Labour FinalDocument17 pagesSatyam 2040 Labour FinalSatyam SinghNo ratings yet

- Judge ScriptDocument9 pagesJudge ScriptLara Mae EnajeNo ratings yet

- Omega-Ventures WL Trading Corp.: Subject: Letter of Commitment and UndertakingDocument2 pagesOmega-Ventures WL Trading Corp.: Subject: Letter of Commitment and Undertakingrodel vallartaNo ratings yet

- Annexure 1 Self DeclarationDocument1 pageAnnexure 1 Self DeclarationnagaNo ratings yet

- The Human Rights Covenants at 50 Their Past Present and Future Daniel Moeckli Full ChapterDocument56 pagesThe Human Rights Covenants at 50 Their Past Present and Future Daniel Moeckli Full Chaptermartin.gooding213100% (20)

- UQ Australs 2017 Debater Judge Briefing 2017Document48 pagesUQ Australs 2017 Debater Judge Briefing 2017Nguyễn Nhật HùngNo ratings yet

- Math7 Q4 SLM WK5Document7 pagesMath7 Q4 SLM WK5giancarlopellazarNo ratings yet

- Sample Numerical Residence and Capital GainsDocument12 pagesSample Numerical Residence and Capital Gainsholy.taporiNo ratings yet

- Click Here To Download PDFDocument10 pagesClick Here To Download PDFMar Zeus KatigbakNo ratings yet

- Eo For Inventory Committee PDFDocument2 pagesEo For Inventory Committee PDFEduard FerrerNo ratings yet

- (Digest) Villarin-v-PeopleDocument5 pages(Digest) Villarin-v-PeopleJoahnna Paula CorpuzNo ratings yet

- Classification of Hukm Shar'i and Comprehensiveness of ShariahDocument7 pagesClassification of Hukm Shar'i and Comprehensiveness of ShariahAli ArslanNo ratings yet

- Rule 65Document9 pagesRule 65Rochelle GablinesNo ratings yet

- Barangay Regular SessionDocument7 pagesBarangay Regular SessionDexee Giel CanoyNo ratings yet

- 5 International Paper PresentationDocument4 pages5 International Paper PresentationTimeNo ratings yet

- Time Table Semester - V (2022-2023)Document2 pagesTime Table Semester - V (2022-2023)sami sahilNo ratings yet

- Competetion AssignmentDocument12 pagesCompetetion AssignmentRajat MishraNo ratings yet

- House Bill-Robin PadillaDocument3 pagesHouse Bill-Robin PadillaRyan Omar Vallega ReyesNo ratings yet

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

Uploaded by

PRASHANT KANTEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

M16405-RALP15 MAX2000 15HP Horizontal Agitators Ex-R247 Reserve Pits

Uploaded by

PRASHANT KANTECopyright:

Available Formats

7519 Prairie Oak Dr.

Houston TX, 77086

281-893-4774 office

281-893-1027 fax

www.psimax2000.com

Mud Agitator LPM2A-15

Operation, Maintenance, & Technical

Manual (Low Profile Right Angle)

Revision Date of

Number Revision Description of Revision Revision Author

0 12/31/19 Draft David Rupp

Document File: M16405-RALP15

Company Propriety and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

Table of Contents

1.0 SAFETY Page 2

2.0 WARRANTY Pages 3, 4, 5

3.0 INSTALLATION PROCEDURE Pages 6, 7, 8

4.0 START UP PROCEDURE Page 9

5.0 ROUTINE MAINTENANCE Page 9

5.1 TROUBLE SHOOTING GUIDE Page 10

6.0 SHUTDOWN AND STORAGE Page 10

6.1 SHORT TERM STORAGE Page 10

6.2 LONG TERM STORAGE Page 10

7.0 TECHNICAL MANUAL CONTENTS Page 11

7.1 GENERAL DESCRIPTION Page 11

7.2 MAJOR COMPENENTS Pages 12, 13

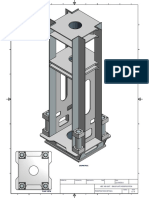

7.3 GENERAL ARRANGEMENT DRAWING Page 14

8.0 PARTS LIST Pages 15, 16

M16405-M2A-15 1 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

1.0 Safety

General safety rules and warnings

This manual contains important information concerning installation, operation, and proper

maintenance of your PSI Mud Agitator. To prevent injury to personnel or equipment

damage, this manual should be read by those responsible for the installation and

operation of the PSI Mud Agitator. In addition, the safety precautions below should be

followed at all times.

1. Follow your companies LOCK-OUT/TAG-OUT Procedures before performing any

maintenance.

2. Inspect equipment for damage, loose fittings, safety guards (if applicable), and

proper installation.

3. Wear proper PPE based on your companies Personal Protective Equipment and

Safety procedures.

4. When lifting equipment, ensure proper lift points are used. Use properly rated slings

that are capable of handling the equipment.

5. Do not use the equipment for anything but its intended use.

***NO ATTEMPT SHOULD BE MADE TO STOP A ROPE OR HOSE OR ANY

OTHER OBJECT ONCE IT HAS BEEN WRAPPED AROUND A MOVING SHAFT

AND/OR IMPELLER!!!

The gearbox on the Agitator has a pre-selected gear ratio to maximize the

suspension of solids in solution. This gear ratio provides an increase in torque that is

transmitted to the impeller. Any object that might fall into or be placed in the mud

tank runs the risk of being caught by and wrapped up by the agitator shaft or impeller

as they spin.

M16405-M2A-15 2 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

2.0 Warranty

Warranty Terms and Conditions

The MAX2000®, MAKDADDY®, and vAK® name are registered trade names of Kelbro, Inc dba

Process Solutions International (PSI). Their use is reserved by Kelbro, Inc. dba Process Solutions

International (PSI) and applicable laws. It shall not be used without permission and written

authorization from Kelbro, Inc. dba Process Solutions International (PSI).

Terms of Sale

Any terms and conditions contained in any purchase order or other form of communication from PSI’s

customers, which are additional to or different from these terms and conditions, shall be deemed

rejected by PSI unless expressly accepted in writing by PSI. In general, no modification, amendment,

waiver or other change of any of these terms and conditions or attachments hereto, or of any of PSI’s

right or remedies thereunder, shall be binding on PSI unless expressly accepted in writing by PSI’s

authorized officers. No course of dealing, usage of trade or course of performance shall be relevant

to explain or supplement any of these terms and conditions. If any document issued by any party

hereto is sent by facsimile or another form of electronic document transmission, the parties hereto

agree that (a) the copy of any such document printed on the facsimile machine or printer of the

recipient thereof is a counterpart original copy thereof and is an “writing”, (b) an electronically stored

and reproduced copy of any such document shall be deemed to be legally sufficient evidence of the

terms of such document for all purposes.

Delivery; Risk of Loss

All sales are F.O.B. PSI’s plant or other point of shipment designated by PSI. Shipping dates are

estimates only which are not guaranteed and are based upon prompt receipt from Buyer of all

necessary shipping and other information. PSI reserves the right to make delivery in installments, all

installments to be separately invoice and paid for by Buyer when due per invoice, without regard to

subsequent deliveries. Delivery of equipment to a commercial carrier at PSI’s plant or other loading

pint shall constitute delivery to Buyer, and any risk of loss and further cost and responsibility thereafter

for claims, delivery, loss or damage, including, if applicable, placement and storage, shall be borne by

Buyer.

When equipment is delivered by PSI’s truck, unloading at Buyer’s dock shall constitute delivery to

Buyer. Claims for shortages or other errors in delivery must be made in writing to PSI within ten (10)

days after receipt of shipment and failure to give such notice shall constitute unqualified acceptance

and a waiver of all such claims by Buyer. Claims for loss or damage to equipment in transit by

common carrier must be made to the carrier and not to PSI. Freight and handling charges by PSI

may not reflect actual freight charges prepaid to the carrier by PSI due to incentive discounts earned

by PSI based upon PSI’s aggregate volume of freight tendered to a carrier or when a carrier must be

used which charges a rate which is different than the rate upon which PSI’s freight and handling

charges were based. When shipments are delivered in PSI’s private trucks, Buyer will be charged an

amount approximating the prevailing common carrier rate.

Excusable Delays; Force Majeure

PSI shall not be liable for any ordinary, incidental, or consequential loss or damage as a result of PSI’s

delay in or failure of delivery or installation due to (i) any cause beyond PSI’s reasonable control, (ii)

an act of God, act of the Buyer, embargo or other government act, authority, regulation or request,

fire, theft, accident, strike, slowdown, or other labor disturbance, war, riot, delay in transportation, or

(iii) inability to obtain necessary labor, material, components, or facilities.

Should any of the aforementioned events of force majeure occur, PSI, at its option, may cancel

Buyer’s order with respect to any undelivered equipment or extend the delivery date for a period equal

to the time lost because of delay. Notice of such election shall be given promptly to Buyer. In the

event PSI elects to so cancel the order, PSI shall be released of and from all liability for failure to

deliver the equipment, including, but not limited to, any and all claims on behalf of Buyer for lost

profits, or any other claim of any nature which Buyer might have.

If shipping or progress of the work is delayed or interrupted by Buyer, directly or indirectly, Buyer shall

pay PSI for all additional charges resulting therefrom.

M16405-M2A-15 3 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

Storage

If the equipment is not shipped within fourteen (14) days after notification has been made to Buyer

that it is ready for shipping, for any reason beyond PSI’s control, including Buyer’s failure to give

shipping instructions, PSI may store the equipment at Buyer’s risk and expense in a warehouse or on

PSI’s premises, and Buyer shall pay all handling, transportation and storage costs at the prevailing

commercial rates promptly following PSI’s submission of invoices for such costs.

Warranty Period

PSI warrants the products manufactured under the Kelbro register trade name mentioned above to be

free from defects in materials and workmanship and to conform to PSI written specifications for a

period of 12 months from the date of manufacture.

Warranty Remedies

If, prior to expiration of the foregoing applicable warranty period, any of such products shall be proved

to PSI’s satisfaction to be defective or nonconforming, PSI will repair or replace such defective

equipment or components thereof, F.O.B. PSI’s plant or other destination designated by PSI, or will

refund or provide Buyer with a credit in the amount of the purchase price paid therefore by Buyer, at

PSI’s sole option. Buyer’s exclusive remedy and PSI’s sole obligation under this warranty shall be

limited to such repair or replacement, F.O.B. PSI’s plant or other destination designated by PSI, or

refund or credit by PSI, and shall be conditioned upon PSI’s receiving written notice of any defect

within a reasonable period of time (but in no event more than thirty (30) days) after it was discovered

or by reasonable care should have been discovered. In no event shall PSI’s liability for such defective

or nonconforming products exceed the purchase price paid by Buyer therefore.

Exclusions

This warranty does not (i) cover shipping expenses to and from PSI factory or other destination

designated by PSI for repair or replacement of defective equipment or any tax, duty, custom,

inspection or testing fee, or any other charge of any nature related thereto, nor does it cover the cost

of disassembling or removing defective equipment or reassembling, reinstalling, or testing repaired or

replaced equipment or finishing the reinstallation thereof, (ii) apply and shall be void with respect to

equipment operated in excess of rated capacity or otherwise not in accordance with installation,

maintenance, or operating instructions or requirements, to equipment repaired or altered by others

than PSI or PSI’s authorized service agencies, or to equipment which was subjected to abuse,

negligence, misuse, misapplication accident, damages by circumstances beyond PSI’s control, to

improper installation (if by others than PSI), operation, maintenance or storage, or to other than

normal use or service, and (iii) apply to equipment or components not manufactured by or for PSI.

With respect to equipment or components not manufactured by PSI, PSI’s warranty obligations shall

in all respects conform and be limited to the warranty actually extended to PSI by its suppliers, but in

no event shall PSI’s obligation be greater than those provided under PSI’s warranty set forth in this

section.

The fore going warranties are in lieu of all other express and implied warranties (except title),

including, without limitation, the implied warranties of merchantability and fitness for a particular

purpose. No employee, representative, or agent of PSI other than an officer of PSI is authorized to

alter or modify any provision of this section or to make any guarantee, warranty, or representation,

express or implied, orally or in writing, which is contrary to the foregoing.

Any description of the equipment, whether in writing or made orally by PSI or PSI’s agents,

specifications, samples, models, bulletins, drawings, diagrams, engineering sheets or similar material

used in connection with Buyer’s order are for the sole purpose of identifying the equipment and shall

not be construed as an express warranty. Any suggestions by PSI or PSI’s agents regarding use,

application or suitability of the equipment shall not be construed as an express warranty unless

confirmed to be such in writing by PSI’s authorized officer.

Consequential Damage Disclaimer

PSI’s liability with respect to equipment proved to its satisfaction to be defective within the warranty

period shall be limited to repair, replacement or refund as provided hereof, and in no event shall PSI’s

liability exceed the purchase price of the equipment involved. Kelbro shall not be subject to any other

M16405-M2A-15 4 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

obligations or liabilities, whether arising out of breach of contract, warranty, tort (including negligence)

or other theories of law, with respect to equipment sold or services rendered by PSI, or any

undertakings, act or omissions relating thereto. Without limiting the generality of the foregoing, PSI

specifically disclaims any liability for property or personal injury damages, penalties, special or punitive

damages, damages for lost profits or revenues, loss of use of equipment or any associated

equipment, cost of capital, cost of substitute products, facilities or services, downtime, shutdown, or

slowdown costs, or for any other types of economic loss, and for claims of Buyer’s customer for any

such damages.

PSI shall not be liable for and disclaims all consequential, incidental and contingent damages

whatsoever. Even if the repair or replacement remedy shall be deemed to have failed of its essential

purpose under section 2-719 of the uniform commercial code, PSI shall have no liability to Buyer for

consequential damages, such as lost profits, lost revenue, damage to other equipment or liability or

injury to a third party.

Indemnification by Buyer

Buyer shall indemnify, hold harmless, and defend PSI and PSI’s employees and agents from and

against any and all damages, liability, claims, losses and expenses (including reasonable attorneys’

fees, court costs, and out-of-pocket expenses) arising out of or resulting in any way from claims by

customers of Buyer or third parties against PSI alleging a breach of contract or warranty by PSI to the

extent that such damages, liability claims, losses and expenses which may be payable by PSI to

Buyer pursuant to the and as limited by PSI’s warranty and damage obligations as contained hereof

so as to effectively limit Kelbro’s obligations to customers of Buyer or third parties to those set forth.

Return of Equipment

No equipment or part shall be returned to Kelbro without written authorization and shipping

instructions first having been obtained from PSI under the company’s Return Policy.

Return Policy:

Client/Customer requests an RMA from Sales Department

Sales shall issue an RMA with an assigned number along with the Product Warranty

information and a quote for replacement cost.

Client/Customer issues a Purchase Order to PSI (pending evaluation), with the RMA properly

filled in.

Product is returned back to PSI at Client/Customers expense with all RMA documents for

reference. If the product is warrantied, then the freight cost will be credited back.

An evaluation will be conducted to determine warranty status.

If product is not returned within 30 days of issued RMA, then an invoice will be issued

regardless of warranty status.

A copy of the evaluation is available upon request.

M16405-M2A-15 5 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

3.0 Installation Procedure

Your companies LOCK-OUT/TAG-OUT Procedures should be followed before performing

any maintenance.

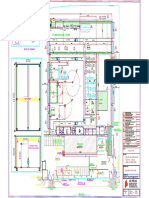

Dimensional Data

It is imperative to have accurate tank dimensions to properly size an agitator with the

proper impeller to give the tank the required turn over rate. The customer must specify all

tank dimensions and obstructions in order to properly size the agitator and impeller.

Note that drawings, if requested or required, provided with the equipment will

take precedence over any information in this manual. “Tank Depth” is obtained by

measuring from the top of the structure (beams, channels, etc.) on which the agitator base

will be supported to the bottom of the tank. Shaft length is typically sized to allow 3 to 6

inches of clearance from the bottom of the tank to the bottom of the agitator shaft

depending on the specific tank. The general rule for impeller location is .75 x Impeller

Diameter from the bottom of the tank. For example a 32" diameter impeller will be located

24" from the bottom of the tank.

Lifting the Agitator

Lift the agitator only at the lift points provided. Use properly rated slings capable of

handling the weight of the equipment. In most cases, the impeller shaft will be installed

after the agitator base has been lifted into the tank but before the base has been securely

mounted. If the agitator is lifted with the impeller shaft installed, make sure that the shaft

coupling has been completely tightened and that the shaft is securely attached before

lifting. It is always good practice to remove the impeller shaft before removing an existing

agitator.

Before Installing the Agitator

Before installing the agitator, care should be taken to ensure that the structure on which

the agitator will be mounted is capable of withstanding both the static load and the

dynamic loads that will be transferred to the tank structure.

Installing the Agitator

Typically, neither the shaft nor the impeller will be installed before lifting the unit into place.

Some conditions, like limited head room above the tank, may require that the shaft be

installed after the unit has been lifted in place. Anti-seize compound should be applied to

all threaded fasteners.

Lift the unit where indicated and place in position on the mud tank using blocks to provide

at least 18 inches of clearance between the bottom of the shaft and tank bottom.

Before removing the blocks and fastening the base to the tank structure, the impeller

must be installed.

BE SURE TO INSTALL THE BREATHER/VENT PLUG THAT HAS BEEN PROVIDED

WITH THE EQUIPMENT. FAILURE TO DO WILL CAUSE THE GEARBOX TO BUILD

UP INTERNAL PRESSURE OVER TIME AND POSSIBLY RESULT IN A LEAK FROM

THE SEAL.

M16405-M2A-15 6 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

Installing Impellers with Keyless Bushings:

**Do not use Molybdenum Disulfide (e.g Molykote, Never Seize, or similar compound)

1. Locate the bushing in its desired location on the shaft.

2. Move the impeller into position. The bushing will be seated on the hub counterbore.

3. Hand tighten 3 or 4 equally spaced locking bolts until contact with the shaft and

bushing is established.

4. Set torque wrench to 5% higher than the specified tightening torque (Ma). Tighten

locking screws in either a clockwise or counter-clockwise sequence (it is not

necessary to tighten locking screws in a diametrically opposite pattern) using ¼ turns

for several passes until ¼ turns can no longer be made.

5. Continue to apply over torque for 1-2 more passes.

6. Reset torque wrench to specified torque (Ma) and check all locking screws. No screw

should turn at this point. If they do, repeat steps 5 & 6. See next page for installation

illustration.

Locking Screw Sizes & Specified

Tightening Torque (Ma)

Tightening

Screw Hex Key

Shaft Size (in) Torque MA

Size Size (mm)

(ft-lb)

¾ - 1 1/2 11 M6 5

1 5/8 – 2 9/16 26 M8 6

2 5/8 – 3 3/4 51 M10 8

3 7/8 - 6 91 M12 10

CTX Coupling (shaft coupling) Installation

M16405-M2A-15 7 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

Electrical Installation

TURN OFF. LOCK OUT AND TAG OUT the electrical power supply to the agitator before working on

the agitator or opening the motor starter or junction box on the side of the motor. A qualified electrician

should make electrical connections inside the junction box on the side of the motor. Care should be

taken to make sure that voltage and frequency of the power supply match the motor nameplate

voltage and frequency.

Checking Motor Rotation

BEFORE STARTING OR EVEN “BUMPING’” THE MOTOR, CHECK THE SIGHT GLASS TO

MAKE SURE THAT GEARBOX IS PROPERLY LUBRICATED AND CHECK TO SEE IF THE

“BREATHER” VENT PLUG IS PROPERLY INSTALLED.

The electrical installation is not complete until the motor rotation has been checked. Reversing any

two legs on a three-phase power will reverse direction of rotation if necessary.

Checking and Filling Oil

All Agitators are shipped from the factory filled with the proper type and quantity of gear oil.

Nonetheless, gear units must be checked for oil level before startup. Oil level should be checked

using the sight glass on the side of the gearbox housing. If the equipment requires additional oil, use

ISO 220 Gear Oil to refill at an Ambient Temperature of 4oC-40oC. Outside of this temperature range,

contact the factory. When mounted level, the oil level should hit the mid-point to 3/4 on the sight glass.

All Agitators are lubricated at the factory.

Typical sightglass visual inspection of oil, mounting

position can raise or lower oil level in sightglass.

M16405-M2A-15 8 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

4.0 Startup Procedure

Before proceeding, check all fasteners to make sure that they are tight and that all parts are

secure prior to continuing.

Once installation is complete and proper lubrication levels have been confirmed, pressing the

start button on the motor starter will start the unit.

Note that motor starters are NOT supplied with agitators unless they have been ordered

separately.

As is good practice with all rotating equipment, check for unusual noise or vibration upon start

up.

As with centrifugal pumps, agitators will consume more horsepower as mud weight increases.

There is no adjustment of the agitator that is required to compensate for changes in drilling

conditions. During drilling operations, mud agitators are kept running at all times.

5.0 Routine Maintenance

Use proper lock-out/tag-out precautions when performing maintenance.

Once the unit is placed into full operation, a Preventative Maintenance Program should begin.

This program should include regular inspection set up on a periodic basis.

The Preventive Maintenance Program should include a general inspection of:

• The primary maintenance item for the Agitator is a weekly check of lubrication levels.

• This includes the oil level coating the gearing and the grease in the lower bearing. The oil

level can be easily checked through the sight glass on the side of the gearing section.

• It is recommended to change out the oil once a year at the minimum.

The gears sets are so exactly positioned that without the proper tools and presses, it is

discouraged to attempt any field repair. If any field attempt is made to repair the gearing

section of the MAX2000® Gearbox, any warranty either implied or express is voided,

IMMEDIATELY. Please advise any and all personnel to observe this important statement.

M16405-M2A-15 9 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

5.1 Trouble Shooting Guide

Problem Cause Action - Solution

Motor will not start -Power problem -Check electrical supply

-Defective motor -Replace motor

-Wrong or bad heaters/coil -Check heaters/starters

Motor quits running -Starter tripping out -Reset starter

-Burned out heater -Replace heater

-Motor burned out -Replace motor

Tripped Starter -Bad heaters -Replace heater

-Over amp draw -Check amp draw

-Agitator undersized -Replace agitator

Whining noise -Check the motor bearings -Replace the motor

Random noise (gear box) -Contamination in oil -Drain and replace oil

Rhythmic noise (gear box) -Possible bur on the gear set -See next line...

A bur on a gear set has a tendency to correct itself over time. In the event that the noise is overly

obtrusive, remove gearbox and return to factory for evaluation.

Vibration -Assembly loose -Tighten all bolts

-Broken Weld (tank base) -Re-weld base to tank

6.0 Shutdown and Storage

6.1 Short Term Shutdown

1. LOCKOUT/TAGOUT ALL POWER.

2. Inspect all components for damage or wear.

6.2 Long Term Shutdown

1. Inspect all components for damage or wear.

2. Remove the breather/vent plug and place a set screw in its place. This keeps

condensation out of the gearbox.

3. If the agitator has been in operation for longer than 6 months, then drain the oil from the

gearbox and replace with fresh oil.

4. If possible keep the equipment covered to help protect against weathering.

5. Spray down any non-painted metal, such as shafts and couplings with a rust protectant.

6. It is good practice to turn the gearbox and motor bearings every 30 days during a long

term shutdown.

M16405-M2A-15 10 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

7.0 Technical Manual Contents

7.1 General Description

Agitators or “mud mixers” serve an important role in the surface treatment of drilling fluids.

Using an impeller that promotes both axial and radial flow will lower mud costs and improve

mud properties. Unlike centrifugal pumps or sub-guns, impeller mixers are relatively low shear

and low energy devices making them easy to maintain and inexpensive to operate. Using low

shear mixers to suspend and mix mud additives minimizes particle size degradation and

polymer shear.

Properly sized agitators serve three purposes:

1. Mixers ensure that mud additives are homogeneously mixed. This prevents spot over

treatment of chemicals, dilution water or weighting agents.

2. Agitators keep the active mud system moving when the mud pumps are disengaged and

will prevent the pits from “gelling”.

3. When drilling with weighted mud, properly selected agitators will keep the weighting agents

in suspension and minimize any tendencies for solids to settle in corners or dead spots.

4. Process Solutions International strongly recommends that we have all tank dimensions and

obstructions before sizing the agitator and impeller. This will ensure the proper tank turn over

rate and reduce pump problems in the field.

Radial Flow Radial Flow

Axial Flow Axial Flow

M16405-M2A-15 11 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

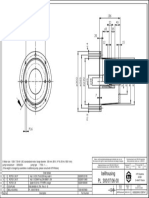

7.2 Major Components

GEARBOX

A rugged cast iron gearbox case houses either a double or triple reduction helical bevel gearing set

that is so precisely ground that there is a minimal amount of back lash in the gear sets. Vertical units

are double reduction inline helical and Right angle units are triple reduction helical-bevel. This feature

eliminates a “slamming” effect of the gears at start up, promoting longer life. Each gear set is 98%

efficient. The internal gears are lubricated with oil. For ambient temperatures below –23o F or above

140o F a synthetic lubricant should be substituted. When operated outside of this ambient

temperature range, consult the factory for alternative lubrication details. External oil sight glasses are

provided so that the oil level can be checked at a single glance. Vent plugs are supplied, installed

in the gearbox housing, to maintain a homeostatic internal pressure, preventing a pressure build

up that could cause premature oil seal failure or unexpected leakage.

M16405-M2A-15 12 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

MOTORS

The electric motors supplied are designed to adhere to the specifications required by your project. If

your project uses NEMA/UL Explosion Proof motors, then the minimum ratings are: Class 1, Division

1, Group D, T2D, IP54 and are designed to operate in the ambient temperature range of -20°C to

40°C. If your project uses ATEX/IECEx motors, then the minimum ratings are: Exd, IIB, Gb, T4, IP55

and are designed to operate in the ambient temperature range of -20°C to 40°C. Due to the range of

worldwide locations and installations the following information should be verified on the motor’s main

nameplate: Voltage, Amperage, RPM, IP Rating, Ambient Temperature and Temperature Code.

***Please note that some motor manufacturers can/will install auxiliary name plates to include

this data that can be considered of a higher level or increased protection level above the minimum

levels stated above.

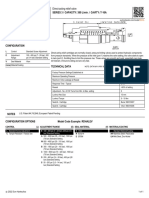

IMPELLERS

Impellers create optimal suspension and mixing results from the axial and radial flow patterns. Using a

600, 450, an axial or a hydrofoil impeller the optimal situation can be created for your application. In

addition to the standard welded impeller, the MAX2000® Agitator is offered with a “bolt-on” blade

option in both carbon steel and stainless steel. Impellers are attached to the impeller shaft using 3

possible methods: QD bushings, Keyless Bushing and for small diameter/low horsepower units, set

screws are provided to allow for adjustment of the height of the impeller.

PSI LOW HP IMPELLER

PSI CANTED BLADE IMPELLER

PSI MAXFLOW HYDROFOIL IMPELLER

M16405-M2A-15 13 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

7.3 General Arrangement Drawing

M16405-M2A-15 14 Company Propriatary and Confidential

Process Solutions International Mud Agitator Manual LPM2A-15 Rev. 0

M16405-M2A-15 15 Company Propriatary and Confidential

PB123-250TC GEARBOX PART # DESCRIPTION

Part Number Descripton Gearbox Section

52/2503342 Motor Coupling Half Input Flange Assembly

52/2510647 Input Spider Element Input Flange Assembly

52/2001033 Seal Plug Input Flange Assembly

52/2503354 Reducer Coupling Input Flange Assembly

52/2507782 Pinion Hub Input Flange Assembly

52/2001688 Input Flange Key "B" Input Flange Assembly

52/2001593 Input Flange Key "A" Input Flange Assembly

52/2507801 Reducer Pinion Input Flange Assembly

52/2000615 Input Retaining Ring "A" Input Flange Assembly

52/2000480 Input Bearing "A" Input Flange Assembly

52/2000588 Input Retaining Ring "B" Input Flange Assembly

52/2000456 Input Bearing "B" Input Flange Assembly

52/2002323 Shim Input Flange Assembly

52/2000622 Input Retaining Ring "C" Input Flange Assembly

52/2000918 Input Oil Seal Input Flange Assembly

52/2002376 Oil Level Plug & Washer Input Flange Assembly

52/2001413 Input Assembly Bolt Input Flange Assembly

52/2502033 Input Flange Input Flange Assembly

52/2001430 Screw Input Gear Set Components

52/2506203 Washer Input Gear Set Components

52/2503372 Red Gear Input Gear Set Components

52/2000580 Retaining Ring Input Gear Set Components

52/2002323 Shim Input Gear Set Components

52/2000251 Taper Roller Bearing Input Gear Set Components

52/2001698 Input Gear Set Key "B" Input Gear Set Components

52/2511227 Bevel Pinion Input Gear Set Components

52/2000526 Taper Roller Bearing Input Gear Set Components

52/2001040 Seal Plug 2nd Stage Components

52/2000582 2nd Stage Retaining Ring "A" 2nd Stage Components

52/2505996 2nd Stage Spacer 2nd Stage Components

52/2000354 2nd Stage Bearing "A" 2nd Stage Components

52/2507871 Low Speed Pinion 2nd Stage Components

52/2001688 2nd Stage Key 2nd Stage Components

52/2513427 Flange Housing 2nd Stage Components

52/2511227 Bevel Pinion 2nd Stage Components

52/2000354 2nd Stage Bearing "B" 2nd Stage Components

52/2505996 2nd Stage Spacer 2nd Stage Components

52/2000582 2nd Stage Retaining Ring "B" 2nd Stage Components

52/2001040 Seal Plug 2nd Stage Components

52/2001007 Output Oil Seal Output Stage Components

52/2000592 Output Retaining Ring Output Stage Components

52/2002327 Output Shim Output Stage Components

52/2000222 Output Bearing Output Stage Components

52/2506201 Output Spacer Output Stage Components

52/2503402 Low Speed Gear Output Stage Components

52/2002365 Closed Oil Plug Output Stage Components

52/2510652 Casing Cover Output Stage Components

52/2001223 Casing Screw Output Stage Components

52/3033136 Breather Plug Output Stage Components

52/2001716 Output Key Output Stage Components

52/2511226 Hollow Shaft Output Stage Components

52/2000222 Output Bearing Output Stage Components

52/2002327 Output Shim Output Stage Components

52/2000592 Output Retaining Ring Output Stage Components

52/2001007 Output Oil Seal Output Stage Components

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Rotary Shouldered Connections HandBook Smith InternationalDocument212 pagesRotary Shouldered Connections HandBook Smith InternationalPRASHANT KANTE100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- G.R. No. 181455-56 Case DigestDocument2 pagesG.R. No. 181455-56 Case DigestKevin Jeason PerdidoNo ratings yet

- Ae 101963362 PDFDocument4 pagesAe 101963362 PDFPRASHANT KANTENo ratings yet

- Demand LetterDocument109 pagesDemand LetterLex Anne100% (1)

- G16 Chapter 7Document11 pagesG16 Chapter 7PRASHANT KANTENo ratings yet

- MHA ZENTGRAF 144-147 BKH Gas SteelDocument3 pagesMHA ZENTGRAF 144-147 BKH Gas SteelPRASHANT KANTENo ratings yet

- HES 340 UNIT Jack FrameDocument9 pagesHES 340 UNIT Jack FramePRASHANT KANTENo ratings yet

- $R4370IQDocument3 pages$R4370IQPRASHANT KANTENo ratings yet

- $R076ZVFDocument1 page$R076ZVFPRASHANT KANTENo ratings yet

- $RR55O0PDocument1 page$RR55O0PPRASHANT KANTENo ratings yet

- RP205Document1 pageRP205PRASHANT KANTENo ratings yet

- $R0AZ43FDocument1 page$R0AZ43FPRASHANT KANTENo ratings yet

- Psi Mud Agitators Product SheetDocument2 pagesPsi Mud Agitators Product SheetPRASHANT KANTENo ratings yet

- Ground Floor Plan - Rev 6Document1 pageGround Floor Plan - Rev 6PRASHANT KANTENo ratings yet

- Fluid Power Metric Catalogue 2018 780 WebDocument8 pagesFluid Power Metric Catalogue 2018 780 WebPRASHANT KANTENo ratings yet

- Aol / Bol / Oca Series: General Information MaintenanceDocument1 pageAol / Bol / Oca Series: General Information MaintenancePRASHANT KANTENo ratings yet

- Pipe ScheduleDocument20 pagesPipe SchedulePRASHANT KANTENo ratings yet

- Beam ColumnDocument6 pagesBeam ColumnPRASHANT KANTENo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- Electronic Temperature Sensors: Technical DataDocument7 pagesElectronic Temperature Sensors: Technical DataPRASHANT KANTENo ratings yet

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADocument1 pageModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENo ratings yet

- Viswanath ResumeDocument3 pagesViswanath ResumePRASHANT KANTENo ratings yet

- Advanced Oilfield Technology Company: Member of Al Sulaimi GroupDocument1 pageAdvanced Oilfield Technology Company: Member of Al Sulaimi GroupPRASHANT KANTENo ratings yet

- Cenlub Dimensional CatalogueDocument34 pagesCenlub Dimensional CataloguePRASHANT KANTE100% (1)

- Taper Bushing Installation: IMPORTANT NOTE: Please Follow The Instructions On This Sheet in Order For TheDocument6 pagesTaper Bushing Installation: IMPORTANT NOTE: Please Follow The Instructions On This Sheet in Order For ThePRASHANT KANTENo ratings yet

- O RingDocument50 pagesO RingPRASHANT KANTE100% (1)

- Atlas Copco PDFDocument6 pagesAtlas Copco PDFPRASHANT KANTENo ratings yet

- 2023-2024 Competition Rules Price Media Law Moot CourtDocument23 pages2023-2024 Competition Rules Price Media Law Moot CourtSamridhi BajoriaNo ratings yet

- Touchstone LicenseDocument4 pagesTouchstone LicensenoblexoutNo ratings yet

- Alex Latimer Gordon Latimer Patrick LatimerDocument18 pagesAlex Latimer Gordon Latimer Patrick LatimerPriya KNo ratings yet

- The Silence of The Lambs 1991 1080p BluRay X264 YIFYDocument94 pagesThe Silence of The Lambs 1991 1080p BluRay X264 YIFYFernando Peña FloresNo ratings yet

- Purchase Agreement Template: Seller Name of BuyerDocument3 pagesPurchase Agreement Template: Seller Name of BuyerMochamad Bilal, SH.No ratings yet

- Accounts Practicle First YearDocument33 pagesAccounts Practicle First YearMITESHKADAKIANo ratings yet

- Current Issues Trends Psychology Applied To LawDocument18 pagesCurrent Issues Trends Psychology Applied To LawDimple GuiraNo ratings yet

- Oprita Marius FR 2024-04-08 2024-04-09Document1 pageOprita Marius FR 2024-04-08 2024-04-09Dumitru IftodeNo ratings yet

- Answers To ClarificationsDocument3 pagesAnswers To ClarificationskuhussNo ratings yet

- 153.CIR Vs La FlorDocument9 pages153.CIR Vs La FlorClyde KitongNo ratings yet

- Satyam 2040 Labour FinalDocument17 pagesSatyam 2040 Labour FinalSatyam SinghNo ratings yet

- Judge ScriptDocument9 pagesJudge ScriptLara Mae EnajeNo ratings yet

- Omega-Ventures WL Trading Corp.: Subject: Letter of Commitment and UndertakingDocument2 pagesOmega-Ventures WL Trading Corp.: Subject: Letter of Commitment and Undertakingrodel vallartaNo ratings yet

- Annexure 1 Self DeclarationDocument1 pageAnnexure 1 Self DeclarationnagaNo ratings yet

- The Human Rights Covenants at 50 Their Past Present and Future Daniel Moeckli Full ChapterDocument56 pagesThe Human Rights Covenants at 50 Their Past Present and Future Daniel Moeckli Full Chaptermartin.gooding213100% (20)

- UQ Australs 2017 Debater Judge Briefing 2017Document48 pagesUQ Australs 2017 Debater Judge Briefing 2017Nguyễn Nhật HùngNo ratings yet

- Math7 Q4 SLM WK5Document7 pagesMath7 Q4 SLM WK5giancarlopellazarNo ratings yet

- Sample Numerical Residence and Capital GainsDocument12 pagesSample Numerical Residence and Capital Gainsholy.taporiNo ratings yet

- Click Here To Download PDFDocument10 pagesClick Here To Download PDFMar Zeus KatigbakNo ratings yet

- Eo For Inventory Committee PDFDocument2 pagesEo For Inventory Committee PDFEduard FerrerNo ratings yet

- (Digest) Villarin-v-PeopleDocument5 pages(Digest) Villarin-v-PeopleJoahnna Paula CorpuzNo ratings yet

- Classification of Hukm Shar'i and Comprehensiveness of ShariahDocument7 pagesClassification of Hukm Shar'i and Comprehensiveness of ShariahAli ArslanNo ratings yet

- Rule 65Document9 pagesRule 65Rochelle GablinesNo ratings yet

- Barangay Regular SessionDocument7 pagesBarangay Regular SessionDexee Giel CanoyNo ratings yet

- 5 International Paper PresentationDocument4 pages5 International Paper PresentationTimeNo ratings yet

- Time Table Semester - V (2022-2023)Document2 pagesTime Table Semester - V (2022-2023)sami sahilNo ratings yet

- Competetion AssignmentDocument12 pagesCompetetion AssignmentRajat MishraNo ratings yet

- House Bill-Robin PadillaDocument3 pagesHouse Bill-Robin PadillaRyan Omar Vallega ReyesNo ratings yet