Professional Documents

Culture Documents

Strength and Durability Properties of Plastic - Formatted Paper

Strength and Durability Properties of Plastic - Formatted Paper

Uploaded by

shalom napoleonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strength and Durability Properties of Plastic - Formatted Paper

Strength and Durability Properties of Plastic - Formatted Paper

Uploaded by

shalom napoleonCopyright:

Available Formats

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

Strength and Durability Properties of Plastic Aggregate Concrete

and Its Structural Applicability- A Review

Aleesha Anna Saju1*, Dr. Smitha K K2

1

PG Student, 2Associate Professor

Department of Civil Engineering, Toc H Institute of Science and Technology, Arakkunnam,

Kerala, India.

*Corresponding Author

E-Mail Id:-achu1596@gmail.com

ABSTRACT

The use of plastic wastes in concrete has gained attention all over the world. The addition or

partial replacement of aggregates by plastic wastes in concrete produce an economic

construction material. The polyethylene terephthalate (PET) bottle wastes are widely used

nowadays and it can be utilized as aggregates in concrete. The plastic aggregate concrete

shows similar compressive strength development as conventional concrete and gives a

comparable compressive strength and increased toughness and impact strength. This type of

concrete displays more resistance to loads after crack formation. Reduction in water

absorption, increased chemical resistance and workability were observed in plastic

incorporated concrete. The elastic modulus of concrete depends on the compressive strength,

type of aggregate, water-cement ratio. The elastic modulus of different types of concrete

varies with its compressive strength but, not as same as that of the conventional concrete.

For structural application of plastic aggregate concrete, its elastic modulus has to be

evaluated. The inclusion of plastic aggregate concrete in construction industry is a great step

towards the sustainable development and green civil engineering concept.

Keywords:-Plastic aggregate concrete, PET bottle waste, Elastic modulus of concrete,

Compressive strength

INTRODUCTION produced with these aggregates. Plastic

The population growth leading to waste is widely used in flexible pavement

increasing and unsustainable consumption construction and non-bearing wall

of natural resources results in excessive constructions for the buildings. The

production of construction and demolition incorporation of these plastic wastes in

waste, which is a great concern for the structural elements is still not studied and

environment and economy. Plastic usage analyzed. Proper evaluation of the

increased substantially and this resulted in modulus of elasticity and the deflection

huge waste generation. Plastic cannot be characteristics of the plastic aggregate

dumped or thrown simply to landfills concrete will help in reducing the

because of its bulk and has slow exploitation of nature. This will lead the

degradation rate. Use of waste materials as construction industry towards sustainable

aggregate in concrete production will and green construction.

reduce the pressure on the exploitation of

natural resources. The inclusion of plastic PLASTIC AS AGGREGATE IN

aggregate in concrete enhances some CONCRETE

properties like toughness, abrasion Rafiq Ahmad Pirzada et.al,[15] conducted

behaviour. Lightweight concrete can be an experimental study on use of waste

HBRP Publication Page 1-6 2020. All Rights Reserved Page 1

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

plastic as coarse aggregate in concrete strength and chloride penetration was

with admixture super plasticizer found respectively in plastic coarse

polycarboxylate ether. 0,5,10,15,20 aggregate concrete, which is light weight

percentages of coarse aggregate were and durable.

replaced with plastic waste. Slump value

showed 62.5% increase on 20% Nabajyoti Saikiaa et.al, [10] conducted

replacement of coarse aggregate with study on waste polyethylene terephthalate

plastic waste. 6.3% increase in 7day as an aggregate in concrete. Coarse flakes

compressive strength was observed on (PC), fine fraction (PF), plastic pellets

15% replacement with plastic aggregates. (PP) were used in 0,5,10,15 percentages.

4.05% increase was observed in 28day Development of compressive strength of

compressive strength on 15% replacement. PET aggregate concrete was similar to

A 14.67% and 9.75% increase observed in normal concrete. Plastic pellets showed

tensile and flexural strength respectively. less reduction in 28day compressive

The use of superplasticizer increased the strength and was almost equal for all the

bonding of plastic waste. mixes. Tensile/compressive strength ratio

gives idea about toughness of concrete and

Lhakpa Wangmo, Thingh Tamang et.al, it was 49.38% higher for 15% PC

(2017) and Subramani T et.al, [8] aggregate concrete than normal mix.

conducted a study on use of plastics in Concrete specimens with PET-aggregate

concrete as coarse aggregate. 0,10,15,20 are able to withstand additional loading

percentages of coarse aggregate were after they crack.

replaced with plastic wastes. On

replacement, 32.55% increase in 7day Nabajyoti and Jorge de Brito[10] reviewed

compressive strength and 6% increase in the use of plastic waste as aggregate in

28day compressive strength was observed cement mortar and concrete preparation.

for 10% replacement with plastic waste. Plastic has low thermal conductivity and

20.9% increase in split tensile strength was high heat capacity comparing to natural

observed for 10% replacement of coarse aggregates. Plastic content lowered the

aggregate. On 10% replaced concrete, workability and compressive strength of

48.8% increase in flexural strength was concrete. Low strength is due to the low

obtained.Replacement of coarse aggregate bond strength of plastic. Higher water

with plastic wastes gives a comparable absorption and gas permeability was

strength with conventional concrete. observed while plastic aggregate concrete

showed lower fresh and hardened density.

Mathew et.al, and Alqahatani et.al, It exhibited high frost resistance and

[14]conducted a study on recycled plastics durability. The plastic aggregates were

as coarse aggregate for structural more susceptible to temperature than fine

concrete.20,40,60,80,100% were replaced natural aggregates.

with plastic waste in M20 grade of

concrete. Workability of 20% plastic Yun Wang Choi et.al, [19] studied the

coarse aggregate concrete showed 9% characteristics of mortar and concrete

increase, which is due to the lower water containing fine aggregate manufactured

absorption rate of plastic aggregates. from plastic wastes. 25,50,75%

27.4% increase in cube compressive replacement was done and a 16% increase

strength and 37.8% increase in cylinder in flow value and porosity increased by

compressive strength was observed on 25% in mortar. Workability of plastic

20% replacement with plastic aggregates. aggregate concrete increased and a

3.7% and 13% reduction in flexural comparable compressive strength values

HBRP Publication Page 1-6 2020. All Rights Reserved Page 2

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

were observed. Up to 25% replacement predict elastic modulus with reasonable

with plastic waste was found acceptable. prediction accuracy;

𝐸𝐶 = 8010𝑓𝑐 0.36 , 𝐸𝐶 in MPa

Francisco Casanova-del-Angel et.al, KlaraKrizova et.al,[7] evaluated modulus

(2012) and Yun Wang Choi et.al, (2005) of elasticity of different types of concrete

[6] studied the effects of PET bottle compared with Eurocode 2. It

aggregates on concrete.Light weight demonstrates impossibility of elastic

concrete was manufactured using this modulus derivation from table values and

aggregate which was 16% less dense than thereby shows need for different equations

normal concrete. PET bottle aggregates for different concretes. They used different

gave better consistency to the mixture and cement, aggregates of different sizes (4-

the slump value increased up to 52%. The 8,8-16,11-22,16-22mm). Measured elastic

strength properties were affected and a modulus showed variations from

slightly lower values were observed for Eurocode. With evaluated concrete the

compressive, tensile and flexural strengths. growth of 3000–4000 N/mm2 was found in

Ankur C Bhogayata et.al, [3] studied the elastic modulus and uniquely even 6000

impact strength, permeability and chemical N/mm2. The growth of modulus of

resistance of concrete mixed with elasticity essentially depends on

metallized plastic waste fibres. 5,10,20 compressive strength increase though this

mm fibres were used in this study and 1- assumption is not binding for all types of

2.5% addition was done. Longer fibre concretes.

mixed concrete showed 28 to 40%

increase in impact resistance. Shorter fibre Rui Vasco Silva et.al, [16] conducted a

concrete showed better crack resistance, study on establishing a relationship

thus made 22% and 34% reduction in acid between modulus of elasticity and

ingress and sulphate ingress respectively. compressive strength of recycled

16 to 27% reduction in oxygen aggregate concrete. Test results from 121

permeability and 8 to 17% reduction in publications over a period of 43 years were

chloride ingress were observed. Shorter collected and a statistical analysis is done

fibres reduced corrosion of steel bars in with the purpose of understanding the loss

concrete up to 10%. of modulus of elasticity based on quality

and replacement level of recycled

IMPORTANCE OF EVALUATION OF aggregates. Up to 30% replacement of

MODULUS OF ELASTICITY IN recycled aggregates has minimal effects on

DIFFERENT CONCRETES elastic modulus. Use of recycled

Alsalman Ali et.al, [1] evaluated modulus aggregates as coarse aggregate and fine

of elasticity of ultra-high-performance aggregates showed 15% and 40%

concrete.Ultra- high-performance reduction in elastic modulus. Equations

concretes are highly durable and has high from different studies were compared.

compressive and tensile strength. Data 𝑓𝑐 0.3

𝐸𝐶 = 12.96(10) (50% replacement)

were collected from literatures and also

tested to evaluate its accuracy and the 𝑓𝑐 0.3

𝐸𝐶 = 18.26 (10) (100% replacement)

accuracy depends on the size of collected

NejadiShami et.al, [13] conducted study

data. When compressive strength increased

on empirical models and design codes in

elastic modulus also increased but not at

prediction of modulus of elasticity of

the same rate as normal concrete.

concrete. Evaluation and comparison of

Compressive strength varied from 124-

analytical models to estimate elastic

162MPa and elastic modulus from 37-46

modulus in normal strength concretes were

GPa. New equation was proposed to

HBRP Publication Page 1-6 2020. All Rights Reserved Page 3

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

done in this study.The models including aggregates were analysed. Relation

the density effect give better estimation of between elastic modulus of coarse

elastic modulus from compressive aggregate and that of concrete is evaluated.

strength. Accurate prediction of elastic Mechanical properties of high strength

modulus is crucial and models in 35 codes concrete depend on w/c ratio, silica fume

were analysed. The proposed model was ratio, types of aggregates. Equations from

based on the equation EC = 9.19 fc 0.354 , different codes were used and its

gives good estimation of elastic modulus credibility was checked with new mixes

of concrete for compressive strength from and a new relation was developed.

20 -50MPa. Equations were proposed based on

Bilir Turhan et.al,[4] Investigated the compressive strength.

performance of some empirical and 𝐸𝐶 = 10.25𝑓𝑐 0.316 (limestone)

composite models for predicting the 𝐸𝐶 = 8𝑓𝑐 0.352 (Andesite)

modulus of elasticity of high strength 𝐸𝐶 = 10.75𝑓𝑐 0.312 (Quartzite)

concretes incorporating ground pumice

and silica fume. Compressive strength and CONCLUSION

unit weight of concrete was used to predict Plastics can be used as a replacement for

elastic modulus by common empirical aggregate in concrete mixture. This leads

models. Model predictions were then to the reduction in the total weight of

compared to experimental elastic modulus concrete. The application of plastic waste

and it was found that prediction equations in concrete contributes to the production of

depend on temperature, aggregate type, lightweight concrete. The development of

w/c ratio. Better performance among the the compressive strength of plastic

models were selected with good prediction aggregate concrete is similar to that of

abilities. Compressive strength is an conventional concrete. A slight decrease in

important parameter for predicting elastic the compressive strength is observed in

modulus of high strength concrete. resulting concrete. For maintaining the

strength factors and workability, the use of

Vakhshouri Behnam et.al,[13] conducted admixture is advisable. The addition of

an analytical study on modulus of plastic flakesmake concrete more ductile.

elasticity of concrete in design codes and The incorporation of plastic aggregate in

empirical models. Evaluation and concrete improves the toughness

comparison of the existing analytical behaviour as well as durability properties.

models to estimate the elastic modulus in The modulus of elasticity depends on the

normal strength concrete and the proposal type of aggregate, size of aggregate,

and verification of a new model. replacement level, curing, compressive

Conventional concrete in the compressive strength etc. Evaluation of modulus of

strength range between 20 and 50 M Pa elasticity is very crucial and important for

were evaluated and the models presented the structural applicability of plastic

range predictions that were lower than the aggregate concrete.

experimental values.

REFERENCE

MostofInejad D et.al,[9] and Nemati K M 1. Alsalman, A., Dang, C. N., Prinz, G.

et.al,[12] conducted a study on prediction S., & Hale, W. M. (2017). Evaluation

of the modulus of elasticity of high of modulus of elasticity of ultra-high

strength concrete.45 mix proportions performance concrete. Construction

including 0,5,10,15,20% of silica fume, and Building Materials, 153, 918-928.

0.24,0.3,0.4 w/c ratios and limestone, 2. Bhogayata, A. C., &Arora, N. K.

quartzite, andesite types of coarse (2018). Impact strength, permeability

HBRP Publication Page 1-6 2020. All Rights Reserved Page 4

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

and chemical resistance of concrete Waste polyethylene terephthalate as

reinforced with metalized plastic an aggregate in concrete. Materials

waste fibers. Construction and Research, 16(2), 341-350.

Building Materials, 161, 254-266. 12. Noguchi, T., &Nemati, K. M. (1995).

3. Bhogayata, A. C., &Arora, N. K. Relationship between compressive

(2018). Workability, strength, and strength and modulus of elasticity of

durability of concrete containing high strength concrete. Journal of

recycled plastic fibers and styrene- Structural and Construction

butadiene rubber latex. Construction Engineering, 474(1), 1-10.

and Building Materials, 180, 382-395. 13. Vakhshouri, B., &Nejadi, S. (2019).

4. Bilir, T. (2016). Investigation of Empirical models and design codes in

performances of some empirical and prediction of modulus of elasticity of

composite models for predicting the concrete. Frontiers of Structural and

modulus of elasticity of high strength Civil Engineering, 13(1), 38-48.

concretes incorporating ground 14. Mathew, P., Varghese, S., Paul, T., &

pumice and silica fume. Construction Varghese, E. (2013). Recycled plastics

and Building Materials, 127, 850-860. as coarse aggregate for structural

5. Alqahtani, F. K., Ghataora, G., Khan, concrete. International Journal of

M. I., Dirar, S., Kioul, A., & Al- Innovative Research in Science,

Otaibi, M. (2015). Lightweight Engineering and Technology, 2(3),

concrete containing recycled plastic 687-690.

aggregates. Proceedings of the 2015 15. Pirzada, R. A., Kalra, T., &Laherwal,

ICMEP, Paris, France, 13-14. F. A. (2018). Experimental Study on

6. Casanova-del-Angel, F., &Vázquez- Use of Waste Plastic as Coarse

Ruiz, J. L. (2012). Manufacturing Aggregate in Concrete with

light concrete with PET Admixture

aggregate. International Scholarly SuperplasticizerPolycarboxylate

Research Notices, 2012. Ether. International Research Journal

7. Tamang, L. W. T., Wangmo, T., of Engineering and Technology

Darjay, K. T., Phuntsho, K. S., (IRJET), 5(03), 558-563.

Namgyal, P., &Wangchuk, U. (2017). 16. Silva, R. V., De Brito, J., &Dhir, R.

Use of plastics in concrete as coarse K. (2016). Establishing a relationship

aggregate. Int. J. Educ. Appl. Res, 7, between modulus of elasticity and

9-13. compressive strength of recycled

8. Tamang, L. W. T., Wangmo, T., aggregate concrete. Journal of

Darjay, K. T., Phuntsho, K. S., Cleaner Production, 112, 2171-2186.

Namgyal, P., &Wangchuk, U. (2017). 17. Subramani, T., &Pugal, V. K. (2015).

Use of plastics in concrete as coarse Experimental study on plastic waste as

aggregate. Int. J. Educ. Appl. Res, 7, a coarse aggregate for structural

9-13. concrete. International Journal of

9. Mostoufinezhad, D., &Nozhati, M. Application or Innovation in

(2005). Prediction of the modulus of Engineering & Management

elasticity of high strength concrete. (IJAIEM), 4(5), 144-152.

10. Saikia, N., & De Brito, J. (2012). Use 18. Vakhshouri, B. (2018). Modulus of

of plastic waste as aggregate in Elasticity of Concrete in Design

cement mortar and concrete Codes and Empirical Models:

preparation: A review. Construction Analytical Study. Practice Periodical

and Building Materials, 34, 385-401. on Structural Design and

11. Saikia, N., &Brito, J. D. (2013). Construction, 23(4), 04018022.

HBRP Publication Page 1-6 2020. All Rights Reserved Page 5

Journal of Advanced Cement & Concrete Technology

Volume 3 Issue 3

19. Choi, Y. W., Moon, D. J., Kim, Y. J., 20. Choi, Y. W., Moon, D. J., Chung, J.

&Lachemi, M. (2009). Characteristics S., & Cho, S. K. (2005). Effects of

of mortar and concrete containing fine waste PET bottles aggregate on the

aggregate manufactured from recycled properties of concrete. Cement and

waste polyethylene terephthalate concrete research, 35(4), 776-781.

bottles. Construction and Building

Materials, 23(8), 2829-2835.

HBRP Publication Page 1-6 2020. All Rights Reserved Page 6

You might also like

- The Use of Plastic Waste As Fine Aggregate in The Self-Compacting Mortars - Effect On Physical and Mechanical PropertiesDocument7 pagesThe Use of Plastic Waste As Fine Aggregate in The Self-Compacting Mortars - Effect On Physical and Mechanical PropertiesNicolas PitaNo ratings yet

- Unit 8 (SERVICEABILITY LIMIT STATE (SLS) )Document26 pagesUnit 8 (SERVICEABILITY LIMIT STATE (SLS) )Zara Nabilah100% (2)

- Lime Stabilization On Expansive Soils For PavementsDocument106 pagesLime Stabilization On Expansive Soils For PavementsPriyadarshini DasNo ratings yet

- Performance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteDocument10 pagesPerformance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteShakil Bin AzizNo ratings yet

- 4 s2.0 S2214785322045795 MainDocument6 pages4 s2.0 S2214785322045795 Mainaijaz bhatNo ratings yet

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- A Study On Plastic Waste For Replacement of Coarse Aggregate With Soft and Hard Plastic in ConcreteDocument3 pagesA Study On Plastic Waste For Replacement of Coarse Aggregate With Soft and Hard Plastic in ConcreteInternational Journal of Innovative Science and Research Technology100% (1)

- Properties of Self-Compacting Lightweight Concrete Containing Recycled PDFDocument10 pagesProperties of Self-Compacting Lightweight Concrete Containing Recycled PDFAniel DiasNo ratings yet

- Pradeeep UrsDocument3 pagesPradeeep UrsArun kumar ANo ratings yet

- Used Plastic bags EDIT 1Document12 pagesUsed Plastic bags EDIT 1shaluinvincibleNo ratings yet

- TanviDocument12 pagesTanvishaluinvincibleNo ratings yet

- 2-Impact Resistance and Energy Absorption Capacity of Concrete Containing Plastic WasteDocument7 pages2-Impact Resistance and Energy Absorption Capacity of Concrete Containing Plastic WasteUsman AkmalNo ratings yet

- Use of Plastic Aggregates in Concrete: A5088119119/2019©BEIESP A5088Document7 pagesUse of Plastic Aggregates in Concrete: A5088119119/2019©BEIESP A5088Rana Talal RaziNo ratings yet

- Thesis ProposalDocument7 pagesThesis ProposalMEHIDE HASANNo ratings yet

- Influence of Plastic Aggregate Geometry on StrengtDocument10 pagesInfluence of Plastic Aggregate Geometry on Strengtvineetbahadduri10No ratings yet

- Fiber 2Document21 pagesFiber 2CHHABIRANI TUDUNo ratings yet

- 1778390Document25 pages1778390Ibrahim Tuhin PICUNo ratings yet

- The Effect of Using Polyethylene Terephthalate Particles On Physical and PDFDocument8 pagesThe Effect of Using Polyethylene Terephthalate Particles On Physical and PDFAniel DiasNo ratings yet

- I VationsDocument12 pagesI VationsDharma banothuNo ratings yet

- Article 1Document11 pagesArticle 1Vinod KanapathyNo ratings yet

- Case Studies in Construction MaterialsDocument14 pagesCase Studies in Construction MaterialskarthiNo ratings yet

- Research Article: Modification of Waste Aggregate PET For Improving The Concrete PropertiesDocument11 pagesResearch Article: Modification of Waste Aggregate PET For Improving The Concrete PropertiesSaurabh Saran SatsangiNo ratings yet

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 pagesAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonNo ratings yet

- The Effect of The Shape and SiDocument11 pagesThe Effect of The Shape and Si박 데시 영No ratings yet

- Construction and Building Materials: Fahad K. Alqahtani, Gurmel Ghataora, M. Iqbal Khan, Samir DirarDocument12 pagesConstruction and Building Materials: Fahad K. Alqahtani, Gurmel Ghataora, M. Iqbal Khan, Samir Dirarrajaram huptaNo ratings yet

- Experimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesDocument7 pagesExperimental Investigation On The Properties of Concrete With Plastic Pet Bottle Fibers As Partial Replacement of Fine AggregatesEditor IJTSRDNo ratings yet

- My Final ReportDocument20 pagesMy Final Reportg.amruthaNo ratings yet

- Author's Accepted Manuscript: Journal of Building EngineeringDocument30 pagesAuthor's Accepted Manuscript: Journal of Building EngineeringRamanNo ratings yet

- Edmund 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012018Document8 pagesEdmund 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012018Faye AudanNo ratings yet

- Paper Con PetDocument9 pagesPaper Con Petcarlos delgadoNo ratings yet

- Cea2 14823279Document7 pagesCea2 14823279shalom napoleonNo ratings yet

- Utilization of Recycled Plastic For Plastic-BasedDocument7 pagesUtilization of Recycled Plastic For Plastic-BasedBhupesh GoyalNo ratings yet

- Ijce V6i7p101Document6 pagesIjce V6i7p101Ibrahim Tuhin PICUNo ratings yet

- Chapter-1 General:: Light Weight Concrete Block Using Plastic Dept of CeDocument51 pagesChapter-1 General:: Light Weight Concrete Block Using Plastic Dept of CeNaveen Gowda k sNo ratings yet

- Polyethylene Terephthalate (PET) WasteDocument5 pagesPolyethylene Terephthalate (PET) WasteleniucvasileNo ratings yet

- Utilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteDocument5 pagesUtilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteEditor IJTSRDNo ratings yet

- Experimental Investigation On The Properties of Concrete Containing Post-Consumer Plastic Waste As Coarse Aggregate ReplacementDocument9 pagesExperimental Investigation On The Properties of Concrete Containing Post-Consumer Plastic Waste As Coarse Aggregate ReplacementZasiah TafheemNo ratings yet

- Experimental Investigation On Waste-Plastic Reinforced Concrete BrickDocument5 pagesExperimental Investigation On Waste-Plastic Reinforced Concrete BrickInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Waste PlasticDocument18 pagesWaste PlasticAshwath100% (1)

- Improving Strength of Concrete Using Crushed Tiles and Nylon FiberDocument16 pagesImproving Strength of Concrete Using Crushed Tiles and Nylon FiberIJRASETPublicationsNo ratings yet

- 1 s2.0 S0950061822012296 MainDocument20 pages1 s2.0 S0950061822012296 MainANAND KUMARNo ratings yet

- Jurnal SemestaDocument7 pagesJurnal SemestaSteven Raynaldo HNo ratings yet

- Stress-Strain Behaviour and Mechanical Strengths of Concrete Incorporating Mixed Recycled PlasticsDocument22 pagesStress-Strain Behaviour and Mechanical Strengths of Concrete Incorporating Mixed Recycled PlasticsbharatpradhanNo ratings yet

- To Study The Properties of Concrete With Partial Replacement of Aggregates by Waste PlasticDocument4 pagesTo Study The Properties of Concrete With Partial Replacement of Aggregates by Waste PlasticEditor IJTSRDNo ratings yet

- 2022 V13i7247Document5 pages2022 V13i7247Ibrahim Tuhin PICUNo ratings yet

- Journal Article ReviewDocument2 pagesJournal Article ReviewAndjie LeeNo ratings yet

- Mechanical Properties of Plastic Concrete Containing BentoniteDocument7 pagesMechanical Properties of Plastic Concrete Containing Bentonitejuan munera100% (1)

- Sustainability 15 16602 v2Document21 pagesSustainability 15 16602 v2Erwin Jake CalivosoNo ratings yet

- Construction and Building Materials: Ankur C. Bhogayata, Narendra K. AroraDocument9 pagesConstruction and Building Materials: Ankur C. Bhogayata, Narendra K. AroraYara MounaNo ratings yet

- CoSBEE 2022 Paper 4Document12 pagesCoSBEE 2022 Paper 43ricChanNo ratings yet

- An Overview On Characteristic Strength of Concrete by Using Plastic FibreDocument6 pagesAn Overview On Characteristic Strength of Concrete by Using Plastic FibreIJRASETPublicationsNo ratings yet

- Concrete With Recycled Plastic WasteDocument11 pagesConcrete With Recycled Plastic WasteWilliam RuizNo ratings yet

- Cement & Concrete Composites: R.V. Silva, J. de Brito, Nabajyoti SaikiaDocument9 pagesCement & Concrete Composites: R.V. Silva, J. de Brito, Nabajyoti SaikiaGustavo dos Santos PinheiroNo ratings yet

- Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Particles PDFDocument12 pagesMechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Particles PDFCristina HleonNo ratings yet

- Construction and Building Materials: Hamsa Mahir Adnan, Abbas Oda DawoodDocument13 pagesConstruction and Building Materials: Hamsa Mahir Adnan, Abbas Oda DawoodkarthiNo ratings yet

- Influence of Waster UnytDocument15 pagesInfluence of Waster UnytMd AzrieNo ratings yet

- ProjectDocument22 pagesProjectSrikanth S SanamoNo ratings yet

- Case Studies in Construction Materials: Hamsa M. Adnan, Abbas O. DawoodDocument19 pagesCase Studies in Construction Materials: Hamsa M. Adnan, Abbas O. DawoodRoger RibeiroNo ratings yet

- IRJET-Replacement of Natural Sand in Con PDFDocument5 pagesIRJET-Replacement of Natural Sand in Con PDFRana Talal RaziNo ratings yet

- Akhil ProDocument100 pagesAkhil ProNI KH ILNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Shalo Aluminiprintreciept RequestDocument1 pageShalo Aluminiprintreciept Requestshalom napoleonNo ratings yet

- A Road Embankment 10 M Wide at The Formation Level 60260bc4adf4ee28005ddae8Document3 pagesA Road Embankment 10 M Wide at The Formation Level 60260bc4adf4ee28005ddae8shalom napoleonNo ratings yet

- Collection of Result Application LetterDocument1 pageCollection of Result Application Lettershalom napoleon100% (3)

- OSDBU Acquisition Forecast - January 2024Document1,827 pagesOSDBU Acquisition Forecast - January 2024shalom napoleonNo ratings yet

- GTWorld - Transaction ReceiptDocument1 pageGTWorld - Transaction Receiptshalom napoleonNo ratings yet

- Marking CriteriaDocument2 pagesMarking Criteriashalom napoleonNo ratings yet

- Shalom Second View Invoice - ReceiptDocument1 pageShalom Second View Invoice - Receiptshalom napoleonNo ratings yet

- CommercialWall 10Document1 pageCommercialWall 10shalom napoleonNo ratings yet

- Granodiorite - WikipediaDocument7 pagesGranodiorite - Wikipediashalom napoleonNo ratings yet

- Cea2 14823279Document7 pagesCea2 14823279shalom napoleonNo ratings yet

- The Performance of Concrete Containing Recycled Plastic AggregateDocument20 pagesThe Performance of Concrete Containing Recycled Plastic Aggregateshalom napoleonNo ratings yet

- Effect of Coarse Aggregate On Concrete Pavement Performance in inDocument11 pagesEffect of Coarse Aggregate On Concrete Pavement Performance in inshalom napoleonNo ratings yet

- CivilDocument4 pagesCivilshalom napoleonNo ratings yet

- TS07D Fadason Danladi Et Al 8746Document15 pagesTS07D Fadason Danladi Et Al 8746shalom napoleonNo ratings yet

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 pagesAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonNo ratings yet

- Modibbo Adama University, Yola: Student Registration FormDocument1 pageModibbo Adama University, Yola: Student Registration Formshalom napoleonNo ratings yet

- Survey of The Old Testament 1: History: Genesis-EstherDocument14 pagesSurvey of The Old Testament 1: History: Genesis-Esthershalom napoleonNo ratings yet

- Siwes ReportDocument24 pagesSiwes Reportshalom napoleonNo ratings yet

- BVN Enrolment FormDocument2 pagesBVN Enrolment Formshalom napoleonNo ratings yet

- Evidence of Road Traffic Overcrowding Effect On Rental Values of Adjoining Commercial PropertiesDocument29 pagesEvidence of Road Traffic Overcrowding Effect On Rental Values of Adjoining Commercial Propertiesshalom napoleonNo ratings yet

- Implementation of Guidance and Counseling Services in Nigerian SchoolsDocument5 pagesImplementation of Guidance and Counseling Services in Nigerian Schoolsshalom napoleonNo ratings yet

- Determining The Physical Properties of Aggregate Products and Its Suitability For Road Base Construction Ethiopia IJERTV8IS120113Document7 pagesDetermining The Physical Properties of Aggregate Products and Its Suitability For Road Base Construction Ethiopia IJERTV8IS120113shalom napoleonNo ratings yet

- Napoleon LauraDocument2 pagesNapoleon Laurashalom napoleonNo ratings yet

- Assessing The Influence of Project Management On Quality During The Early Phases of Construction ProjectsDocument9 pagesAssessing The Influence of Project Management On Quality During The Early Phases of Construction Projectsshalom napoleonNo ratings yet

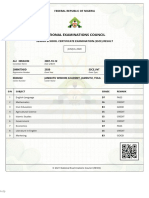

- National Examinations Council: Federal Republic of NigeriaDocument1 pageNational Examinations Council: Federal Republic of Nigeriashalom napoleon100% (1)

- Human Rights and Social JusticeDocument17 pagesHuman Rights and Social Justiceshalom napoleonNo ratings yet

- GST C-9404 (Ex) SounderDocument2 pagesGST C-9404 (Ex) SounderReinaldo SouzaNo ratings yet

- Diy Sls 3d PrinterDocument32 pagesDiy Sls 3d PrinterTF Escritório MGNo ratings yet

- CHW Piping SpecsDocument42 pagesCHW Piping SpecsEugen LupanNo ratings yet

- MetallizationDocument51 pagesMetallizationjust4u2cjoshy67% (3)

- Final Intership Report - Shivam PhadatareDocument51 pagesFinal Intership Report - Shivam PhadatareNishantNo ratings yet

- Effect of Admixtures On Properties of Alkali-Activated Slag ConcreteDocument8 pagesEffect of Admixtures On Properties of Alkali-Activated Slag ConcreteZhu PengfeiNo ratings yet

- Final Denkstatt Report (Vers 1 3) September 2010Document45 pagesFinal Denkstatt Report (Vers 1 3) September 2010Yesid Nieto MuñozNo ratings yet

- Ji 2008 JB00 K NNLC 000 0001 PDFDocument41 pagesJi 2008 JB00 K NNLC 000 0001 PDFHamza ChemmamNo ratings yet

- Structural Linear BucklingDocument18 pagesStructural Linear BucklingKhusi1100% (1)

- Camara de Espuma ANSUL AFC 170 PDFDocument6 pagesCamara de Espuma ANSUL AFC 170 PDFfercho`sNo ratings yet

- Precast-Concrete-Sec2-Lifting and Fixing Sockets PDFDocument12 pagesPrecast-Concrete-Sec2-Lifting and Fixing Sockets PDFRenee HumphreyNo ratings yet

- Product Datasheet: Closed Toroid A Type, For Vigipact and Vigilhom, Ga300, Inner Diameter 300 MM, Rated Current 630 ADocument3 pagesProduct Datasheet: Closed Toroid A Type, For Vigipact and Vigilhom, Ga300, Inner Diameter 300 MM, Rated Current 630 ATosikur RahmanNo ratings yet

- Flexible Metallic TubingDocument10 pagesFlexible Metallic TubingMica RemollinoNo ratings yet

- Catalogo Mktextil 2022Document144 pagesCatalogo Mktextil 2022Yadira Martinez ElizondoNo ratings yet

- 2 Quarter Examination General Chemistry 2Document3 pages2 Quarter Examination General Chemistry 2Mary Jane Tamondong BaniquedNo ratings yet

- Bidsheet - SMO CS WUR Earthwork General Package 4 - FINAL MITRADocument8 pagesBidsheet - SMO CS WUR Earthwork General Package 4 - FINAL MITRAbara laksaniNo ratings yet

- Composite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingDocument6 pagesComposite Action of Ferrocement Slabs Under Static and Cyclic Loading-Composite Action of Ferrocement Slabs Under Static and Cyclic LoadingKarrar MonarchNo ratings yet

- Design Collection 2012: Modern Simplicity I Modern Simplicity II Cool Vintage BasicDocument2 pagesDesign Collection 2012: Modern Simplicity I Modern Simplicity II Cool Vintage BasicAbdelmuneimNo ratings yet

- Erapol EHP70DDocument2 pagesErapol EHP70DqwepoolNo ratings yet

- Vane Pump SelectionDocument25 pagesVane Pump SelectionGirlish JackieNo ratings yet

- Nitoproof 230 PDFDocument2 pagesNitoproof 230 PDFmilanbrasinaNo ratings yet

- Housekeeping's Cleaning Responsibilities in Front-Of-The-House Areas of The HotelDocument5 pagesHousekeeping's Cleaning Responsibilities in Front-Of-The-House Areas of The HotelThandar Swe ZinNo ratings yet

- Reg - Institutewise - CLOUSER 2021Document17 pagesReg - Institutewise - CLOUSER 2021opNo ratings yet

- Cyprus International University: Civil Engineering (MSC) Syllabus 2019-20 SpringDocument3 pagesCyprus International University: Civil Engineering (MSC) Syllabus 2019-20 Springzeyad sbaihNo ratings yet

- Dokumen - Tips - Method Statement For Steel Balustrade and Railing InstallationDocument6 pagesDokumen - Tips - Method Statement For Steel Balustrade and Railing InstallationKhaing Zin WaikonicNo ratings yet

- Jindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident SteelDocument4 pagesJindal Seamless Pipe Price List - Jindal Seamless Pipe Price List - Jindal Pipes Price List - Jindal Pipes Prices - Jindal Seamless Pipe Suppliers - Trident Steelkaruna0% (1)

- Astm C642 97Document1 pageAstm C642 97teimimineNo ratings yet

- 42Document8 pages42Syed Ali KhanNo ratings yet