Professional Documents

Culture Documents

2.11 - Documented Information Management & Control Process

2.11 - Documented Information Management & Control Process

Uploaded by

Unachukwu SopuluCopyright:

Available Formats

You might also like

- Anime Studio Pro 11 Tutorial ManualDocument303 pagesAnime Studio Pro 11 Tutorial ManualCristmart Tití73% (11)

- Total Balance KriyaDocument6 pagesTotal Balance Kriyaclaudiosala1957100% (8)

- QMS 010 Classification Definition and Approval Matrix of GMP Documents SampleDocument5 pagesQMS 010 Classification Definition and Approval Matrix of GMP Documents SampleRosella Planta100% (1)

- Eimm 5669 eDocument1 pageEimm 5669 ekuro Aishiro100% (1)

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Quality Record Control ProcedureDocument6 pagesQuality Record Control ProcedurePrime CapNo ratings yet

- 9.1.20 Foreign Object Debris (Fod) DamageDocument12 pages9.1.20 Foreign Object Debris (Fod) DamageDawit KumsaNo ratings yet

- Sop 7.4.4 Counterfeit Parts PreventionDocument6 pagesSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZNo ratings yet

- Project Proposal For ISO9001 2015 Implementation ENDocument5 pagesProject Proposal For ISO9001 2015 Implementation ENMihaela MafteiNo ratings yet

- Procedure For Internal AuditDocument5 pagesProcedure For Internal AuditDaniel Cheng MahsaNo ratings yet

- Procedure - Configuration Management - Rev 0Document4 pagesProcedure - Configuration Management - Rev 0Venkat BhagavatiNo ratings yet

- ISO 9001 Quality Management SystemDocument13 pagesISO 9001 Quality Management SystemAnonymous qRbPsLpuNNo ratings yet

- Qms Guidelines Appendix A 0Document3 pagesQms Guidelines Appendix A 0BranErikNo ratings yet

- Car & Par ReportDocument1 pageCar & Par ReporthabibrgfNo ratings yet

- PM - 5.03 Management ReviewDocument3 pagesPM - 5.03 Management ReviewMangBedjoNo ratings yet

- Procedure For Management ReviewDocument6 pagesProcedure For Management ReviewAman JasujaNo ratings yet

- 1 Internal & Product AuditDocument3 pages1 Internal & Product AuditPrafull BhamareNo ratings yet

- Procedure For Design and Development Control-01Document29 pagesProcedure For Design and Development Control-01Ahmad MukhtarNo ratings yet

- QP 56001 Rev 04 Management Review ProcedureDocument5 pagesQP 56001 Rev 04 Management Review ProcedureAllison SontowinggoloNo ratings yet

- QP01 Document ControlDocument5 pagesQP01 Document ControldhistaNo ratings yet

- MFG Procedure ManualDocument46 pagesMFG Procedure ManualAdinanNo ratings yet

- DCC F04 NCRDocument2 pagesDCC F04 NCRSyahir AhmadNo ratings yet

- ProceduresDocument22 pagesProceduresRajVardhan100% (1)

- Template - Management Review ReportDocument2 pagesTemplate - Management Review ReportIslam WayNo ratings yet

- Work Instruction Template PDFDocument2 pagesWork Instruction Template PDFdrg. Bobet Evih Hedi I.R., MMRNo ratings yet

- ISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0Document37 pagesISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0umtNo ratings yet

- 4.1a - 4.1d Process PlanningDocument2 pages4.1a - 4.1d Process PlanningFendiNo ratings yet

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaNo ratings yet

- Customer Satisfaction Process PDFDocument1 pageCustomer Satisfaction Process PDFmilou88No ratings yet

- Hsp38 Documents Records Control ProcedureDocument6 pagesHsp38 Documents Records Control Procedurezakaria almohiaNo ratings yet

- QMS 04 A Interested Parties FreeDocument5 pagesQMS 04 A Interested Parties FreeLisardo ConstelaNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- QAF-109 Supplier Corrective Action Request - GIDEP 6-1-18Document15 pagesQAF-109 Supplier Corrective Action Request - GIDEP 6-1-18AlineMeirelesNo ratings yet

- Star Ecn Form 2012Document4 pagesStar Ecn Form 2012BERK YENİLMEZNo ratings yet

- ISO 13485 2003 Vs FDA QSR 42 69Document28 pagesISO 13485 2003 Vs FDA QSR 42 69Ancuta FeierNo ratings yet

- QMS-010 SampleDocument6 pagesQMS-010 SampleMostafa FawzyNo ratings yet

- Effectiveness of The QMSDocument33 pagesEffectiveness of The QMSvavvavNo ratings yet

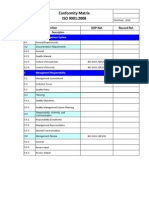

- ISO 9001 Conformity MatrixDocument3 pagesISO 9001 Conformity Matrixkashifbutty2kNo ratings yet

- CounterfeitDocument5 pagesCounterfeitVivek GoudNo ratings yet

- MGT PRO-10 Control of Documented Information ProcedureDocument10 pagesMGT PRO-10 Control of Documented Information ProcedureAbla NedjmaNo ratings yet

- Manufacturing Process Audit Excel FormDocument2 pagesManufacturing Process Audit Excel FormTri Hdyvtdt100% (1)

- Supplier Deviataion Request Form RevBDocument2 pagesSupplier Deviataion Request Form RevBwdavid81100% (1)

- Centurion Power Cables (P) LTD.: 1.0 PurposeDocument4 pagesCenturion Power Cables (P) LTD.: 1.0 PurposetriveshNo ratings yet

- MP12 Monitoring, Measurment and ImprovementDocument6 pagesMP12 Monitoring, Measurment and ImprovementSuchhanda SarkarNo ratings yet

- This Procedure Explains How To Control Documents 1 Year: Name of InstitutionDocument5 pagesThis Procedure Explains How To Control Documents 1 Year: Name of InstitutionAmer RahmahNo ratings yet

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremNo ratings yet

- 14 - P11 Production Scheduling and Planning Process-May'17Document9 pages14 - P11 Production Scheduling and Planning Process-May'17Rohini GadhaweNo ratings yet

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberDocument1 pageSupplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberBESNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- Auditee Feedback Form: Internal Audit DepartmentDocument2 pagesAuditee Feedback Form: Internal Audit DepartmentNiomi GolraiNo ratings yet

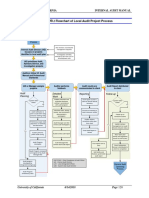

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyNo ratings yet

- Fiat Control ChartDocument6 pagesFiat Control Chartsudar1477No ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- INTERNAL QUALITY AUDIT - AgendaDocument1 pageINTERNAL QUALITY AUDIT - AgendaJeaneth Dela Pena CarnicerNo ratings yet

- Clause 9 PerformanceDocument8 pagesClause 9 Performancesharif1974No ratings yet

- Iso 9001-2015 Clause 7 SupportDocument14 pagesIso 9001-2015 Clause 7 SupportalexrferreiraNo ratings yet

- BF Aerospace QA ManualDocument46 pagesBF Aerospace QA ManualJoginder Kaur100% (2)

- Quality Manual: Foreword From Top ManagementDocument2 pagesQuality Manual: Foreword From Top ManagementmuthuselvanNo ratings yet

- Temporary Deviation RequestDocument3 pagesTemporary Deviation RequestSead ZejnilovicNo ratings yet

- ISO 9001 - 2015 Organisational RequirementsDocument6 pagesISO 9001 - 2015 Organisational RequirementsRommel BaesaNo ratings yet

- FDGS Stop Work PolicyDocument1 pageFDGS Stop Work PolicyUnachukwu SopuluNo ratings yet

- A MAN OF DESTINY - Word For Father's SundayDocument3 pagesA MAN OF DESTINY - Word For Father's SundayUnachukwu SopuluNo ratings yet

- FDGS Quality Policy StatementDocument1 pageFDGS Quality Policy StatementUnachukwu SopuluNo ratings yet

- Truck SpecDocument1 pageTruck SpecUnachukwu SopuluNo ratings yet

- FDGS Brochure2 PDFDocument5 pagesFDGS Brochure2 PDFUnachukwu SopuluNo ratings yet

- UntitledDocument1 pageUntitledUnachukwu SopuluNo ratings yet

- FDGS Code of Conduct & EthicsDocument8 pagesFDGS Code of Conduct & EthicsUnachukwu SopuluNo ratings yet

- 2022-09-10-FDGS Technical Capability SlidesDocument15 pages2022-09-10-FDGS Technical Capability SlidesUnachukwu SopuluNo ratings yet

- 2.14 - Change Management ProcessDocument7 pages2.14 - Change Management ProcessUnachukwu SopuluNo ratings yet

- 2.9 - Control of Customers Properties - BDocument4 pages2.9 - Control of Customers Properties - BUnachukwu SopuluNo ratings yet

- Samsung s860 s760 (ET)Document59 pagesSamsung s860 s760 (ET)jota_60254No ratings yet

- Agile PLM Data Mart Data Reference ManualDocument612 pagesAgile PLM Data Mart Data Reference ManualTirumalesha DadigeNo ratings yet

- Planning The EDT Installation: © 2006 Landmark Graphics CorporationDocument40 pagesPlanning The EDT Installation: © 2006 Landmark Graphics Corporationahmed_497959294No ratings yet

- Managin ProjectsDocument557 pagesManagin ProjectsJose Uriel GarciaNo ratings yet

- PreptoolDocument47 pagesPreptoolVagif VerdiNo ratings yet

- Inmath 1.7.6 Cs3 Quick StartDocument5 pagesInmath 1.7.6 Cs3 Quick StartmadhusivaNo ratings yet

- WFC70 ReportsRefGuideDocument364 pagesWFC70 ReportsRefGuideluckycharmhNo ratings yet

- Hyster PCST Readme-EN PDFDocument3 pagesHyster PCST Readme-EN PDFPra Zuar Silk Screen ConfecçãoNo ratings yet

- Literature Review TemplateDocument5 pagesLiterature Review Templatec5qj4swh100% (1)

- Posco DRMDocument32 pagesPosco DRMLarryMatiasNo ratings yet

- Facewizardinstructions PDFDocument3 pagesFacewizardinstructions PDFLarry0% (1)

- CT System E-User Leaflet: Multi-Language Operator Documentation IntroductionDocument16 pagesCT System E-User Leaflet: Multi-Language Operator Documentation IntroductionNayer Alfredo Marrugo GutierrezNo ratings yet

- He Leadth MeDocument63 pagesHe Leadth MeAlex TisoNo ratings yet

- Konica Minolta 920Document110 pagesKonica Minolta 920copimaserv100% (1)

- IBM Content Manager OnDemand and FileNet-3Document88 pagesIBM Content Manager OnDemand and FileNet-3David ResendizNo ratings yet

- Click Here For Download CRACKDocument9 pagesClick Here For Download CRACKRadoi RaduNo ratings yet

- SIS User's Guide: Service Information SystemDocument28 pagesSIS User's Guide: Service Information SystemvisnupadaNo ratings yet

- Halo 2 For Windows Vista Readme File: © 2007 Microsoft Corporation. All Rights ReservedDocument6 pagesHalo 2 For Windows Vista Readme File: © 2007 Microsoft Corporation. All Rights ReservedxBom StyleNo ratings yet

- PDF Portfolio TutorialDocument7 pagesPDF Portfolio Tutorialanon_193257742No ratings yet

- Timetable Deviation and Additional Sessions Preparation Form 2Document2 pagesTimetable Deviation and Additional Sessions Preparation Form 2ajichristianbaniadamNo ratings yet

- Advanced Hybrid System Getting Started KX-TES824 KX-TEM824Document32 pagesAdvanced Hybrid System Getting Started KX-TES824 KX-TEM824Ásgeirr Ánsgar Ósgar CanuroNo ratings yet

- Preflight Report HelpDocument140 pagesPreflight Report HelpAhmed SalievNo ratings yet

- CoreAPIReference PDFDocument3,322 pagesCoreAPIReference PDFRicardo GriãoNo ratings yet

- Form 3-Damaged-Or-Opened-Question-Paper-Packet-Before-The-ExamsDocument2 pagesForm 3-Damaged-Or-Opened-Question-Paper-Packet-Before-The-ExamsajichristianbaniadamNo ratings yet

- Application For Admission: SW1 - 1st Floor, 3700 Willingdon Avenue, Burnaby, BC V5G 3H2 1.866.434.1610Document3 pagesApplication For Admission: SW1 - 1st Floor, 3700 Willingdon Avenue, Burnaby, BC V5G 3H2 1.866.434.1610Wasawat JoongjaiNo ratings yet

- Adobe Solutions For Learning Management Systems (LMS)Document10 pagesAdobe Solutions For Learning Management Systems (LMS)ronaldoatanNo ratings yet

- Creating Quiz CaptivateDocument12 pagesCreating Quiz CaptivateSumit BhardwajNo ratings yet

2.11 - Documented Information Management & Control Process

2.11 - Documented Information Management & Control Process

Uploaded by

Unachukwu SopuluOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.11 - Documented Information Management & Control Process

2.11 - Documented Information Management & Control Process

Uploaded by

Unachukwu SopuluCopyright:

Available Formats

Control of Documented Information

OP-75-01 Rev NC

Effective Date: 11-17-17

Control of Brian Darby, AS9100 Coordinator, on 11-17-17

Documented Management Approval by Craig O. Garneau, President on 11-17-17

Information Printed copies of this document are for information purposes only and are uncontrolled.

Printed copies are not valid after the date of printing.

1. PURPOSE

To establish a consistent process for controlling the documented information required to maintain

QNP’s quality management system.

2. RESPONSIBILITY

The table below identifies QNP personnel and their responsibility relating to this procedure:

Person Responsibility

President Gives final approval on all QNP quality system documents

Ensure that QNP quality system documents are formatted,

identified and issued per the requirements of this operating

procedure.

Ensure that revisions to quality system documents are reviewed

and approved by the same functions that performed the original

review and approval.

Quality Assurance Manager

And/or AS9100 Coordinator

Ensure that the necessary documents are accessible to

appropriate personnel.

Prevent the use of obsolete or invalid documents.

Maintain the computer system and files on the online server.

Draft, review, and update quality system documents applicable to

their areas of expertise and process ownership.

Document Owners and

Work with the Quality Assurance Manager/AS9100 Coordinator or

QNP Management

designee to ensure that their documents are up to date and

accurately logged within the Document Master List, FM-75-01

Control of Documented Information OP-75-01 Rev NC Date Printed

Work with the Quality Assurance Manager and/or AS9100

Coordinator to ensure that documented information is available as

necessary through QNP’s computer network.

IT Manager

Assist the Quality Assurance Manager and/or AS9100 Coordinator

in setting up appropriate network and file security features, as well

as maintaining necessary data backups.

3. APPLICABLE FORMS OR REFERENCES

The table below identifies the code number and title of documents and references applicable to this

procedure;

Form/Reference Number Title

Quality Management Systems - Requirements

AS9100

for Aviation, Space and Defense Organizations

QM-44-01 QNP Quality Policy Manual

FM-75-01 Document Master List with Revision History

FM-75-02 External Document Control List

FM-81-01 Quality Plan/Shop Order

4. General Document Control Policies

4.1. QNP’s quality management system includes the documented information

required by AS9100 as well as the documented information determined by QNP

as being necessary for the effectiveness of our quality management system.

4.2. Examples of QNP’s documented information are:

Our Quality Manual, QM-44-01

Operating Procedures

Work Instructions

Forms and Quality Records

Control of Documented Information OP-75-01 Rev NC Date Printed

4.3. QNP’s Quality Manual, QM-44-01 and our operating procedures are maintained

as pdf files and hosted at qnp.com/as9100 for the convenience our employees,

customers, and other interested parties. These files can be accessed through

any standard web browser, such as Internet Explorer, Chrome, Safari or

FireFox. They can be opened and viewed with the Adobe Acrobat browser plug-

in or standalone application.

4.4. QNP’s work instructions are maintained as .pdf files and made available

throughout QNP’s internal computer network. Work instructions are generally not

posted on the internet.

4.5. QNP’s forms are generated in a variety of formats appropriate to the nature of

information to be captured. The format for generating any given form, and the

media required (paper or electronic) is documented in the Document Master List,

FM-75-01.

4.6. This documented information is made accessible through computer stations and

mobile devices located throughout QNP’s factory and office. Controlled paper

copies of documents may be issued in areas where it is not practical to maintain

computer equipment.

4.7. QNP’s quality system documents are protected from unauthorized or unintended

changes by passwords, restricted read/write privileges, and saved backup files.

4.8. QNP’s quality system documents are written in English.

5. Document Identification/Numbering

5.1. The documents required for our QMS are assigned code numbers by the Quality

Assurance Manager and/or the AS9100 Coordinator.

5.2. SAMPLE OPERATING PROCEDURE IDENTIFICATION: The following table

shows the sections of a sample QNP document number, OP-75-01:

Document Related AS9100 Document

Code Prefix Clause Number Identification Number

OP 75 01

Note: The sections of the code are separated by a dash “-“.

Control of Documented Information OP-75-01 Rev NC Date Printed

5.3. Document Code Prefixes - The following list of 2 letter prefixes is used to identify

the quality documents maintained by QNP and generate the Document Code

Prefix section of the Document Number.

2 Letter Prefix Document Type

QM Quality Manual

OP Operating Procedure

WI Work Instruction

FM Form/Record

5.4. The middle section of a Document Number is derived from the closest related

clause of the AS9100 standard relative to the purpose of the document.

5.5. Documents drafted to the requirements of AS9100 revision B and C, were given

a 3 digit Clause Number code. See the following table for examples:

AS9100 rev B/C Clause Corresponding Clause Number

7.5.4 Customer Property 754

8.5.2 Corrective Action 854

5.6. Documents created to the requirements of AS9100 revision D have been/will be

given 2 or 3 digit Clause Number codes. See the following table for examples:

Corresponding

AS9100 rev D Clause

Clause Number

7.5.3 Control of Documented Information 75

8.5.3 Property Belonging to Customers or External

85

Providers

10.2 Nonconformity and Corrective Action 102

Control of Documented Information OP-75-01 Rev NC Date Printed

5.7. To ensure that all QNP documents are uniquely identified, Document Numbers

are further distinguished by sequential Document Identification Numbers. e.g.

01, 02, 03. The Document Master List, FM-75-01 should be reviewed as

appropriate to ensure that document numbers are not duplicated.

5.8. Exceptions - Quality documents or forms that were assigned code numbers

corresponding to the elements of ISO 9002:1994 may retain their original

identification codes. When a quality document or form with an ISO 9002: 1994

identification code is revised, it should be given a new identification code per this

procedure.

6. Document Formatting - Operating Procedures

6.1. Quality system operating procedures have the following information in the

header;

Document Identification Number

Document Title

Revision

Effective Date

Document owner/originator name, position and date of approval

Management name, position, and date of approval

"Printed copies of this document are for information purposes only and are

uncontrolled. Printed copies are not valid after the date of printing.

6.2. Operating procedures shall have a Print Date Stamp in the footer that indicates

the print date of paper copies. (Note: the Print Date Stamp is a dynamic element

added to the pdf version of the operating procedure.)

Control of Documented Information OP-75-01 Rev NC Date Printed

6.3. The body of each operating procedure should address these main topics, as

applicable. The table below identifies the title of the heading, and a description

of the content.

Item Heading Title Content Description

This section states the intended purpose or

1 PURPOSE

need for generating the document.

This section identifies the personnel,

department, and/or authority in the

2 RESPONSIBILITIES organization that is responsible for

maintaining, and/or implementing the steps

within the document.

This section provides a list of the operating

APPLICABLE FORMS OR procedures, work instructions, forms or

3

REFERENCES external documents referenced in the

document.

Statements of principle that apply to the

4 POLICIES

document as a whole.

Where appropriate, step-by-step flowcharts

5 PROCEDURES

should illustrate the procedures.

This section directs users to the FM-75-01

RECORDS/OBJECTIVE Document Master List for the retention

6

EVIDENCE duration of records referenced in the

procedure.

This section records the history for each

procedure and should be noted in the

document with the following or similar text:

7 REVISION HISTORY "Revision, approved date, effective date and a

document change summary are available FM-

75-01 Document Master List with Revision

History.”

7. Approval and Issue of Quality System Documentation

7.1. Prior to issue, the Document Owner and the President shall review and approve

controlled documents. Records of the approval process shall be maintained

within the Document Master List, FM-75-01.

Control of Documented Information OP-75-01 Rev NC Date Printed

7.2. Revisions to existing documents are reviewed and approved by the same

functions that performed the original review and approval.

7.3. Digital formatting is the preferred method for maintaining quality system

documents. Computers shall be protected by the use of virus protection

software, regular data backups, and off-site storage when appropriate.

7.4. Uncontrolled documents are not valid after the date of printing. Printed work

instructions that are made available at the point of use are controlled by the

document owner and unauthorized copies should not be made.

7.5. Obsolete printed copies of internal documents retained for legal and/or

knowledge preservation shall be marked "OBSOLETE" and/or held in a

binder/folder marked "OBSOLETE".

7.6. Superseded/Obsolete Documents are moved to a segregated location and made

inaccessible to prevent unintended use. The Quality Assurance Manager or

AS9100 Coordinator should be contacted for access to obsoleted documents.

7.7. The current revision for any quality system document can be verified through the

Document Master List, FM-75-01. Unless otherwise specified, the current

revision of a quality system document should be referenced or followed.

8. Control of Customer Supplied Information

8.1. Examples of customer supplied information are blueprints, art files, sketches,

samples, purchase orders, and emailed correspondences.

8.2. A printed copy of a blueprint and any relevant customer supplied information

should travel with quote requests and shop orders. If the electronic file is later

accessed to generate artwork or be reprinted, the contents of the file should be

checked to verify that it matches the customer's current requirements.

8.3. Typically, the current revision for a blueprint or other customer supplied

information can be verified by referencing a current purchase order, a

customer’s supplier portal, or checking with the customer’s purchasing or quality

representative.

8.4. Obsolete blueprints and other customer supplied information that is retained for

legal and/or knowledge preservation shall be marked "OBSOLETE" or held in a

binder/folder marked "OBSOLETE". It should not be assumed that blueprints or

other customer supplied information stored within closed shop orders represent

the current revision.

Control of Documented Information OP-75-01 Rev NC Date Printed

9. Control of External Documents

9.1. External documents are defined as documents whose origin and control is by a

body outside QNP. Examples:

Equipment manuals regarding the operation, safety, repair or maintenance

of equipment used by QNP in the processing of customer orders.

Supplier manuals, specifications, or standards from customers that are

provided to QNP, which contain customer requirements that are not part

specific.

Documents necessary for the planning and operation of the quality

system.

International Quality Standards, example: AS9100.

9.2. External documents are maintained as digital files whenever possible. When

practical, external documents that are readily available on the internet should not

be maintained at QNP. The External Document Control List, FM-75-02 is able to

store a link to the online location of the document.

9.3. Printed copies of obsolete, external documents that are retained for legal and/or

knowledge preservation shall be marked "OBSOLETE" and/or held in a

binder/folder marked "OBSOLETE".

9.4. Electronic files of obsolete, external documents that are retained for legal and/or

knowledge preservation shall be overwritten with notes to indicate that the file is

obsolete. If the contents of the file is write-protected, the file name shall be

appended with "OBSOLETE".

9.5. The personnel responsible for periodically verifying that QNP has access to the

current revision of an external document is identified in the External Document

Control List, FM-75-02. When appropriate, the schedule, method for verification,

and other means for control shall be recorded there as well.

9.6. The Customer Master List Database can be used to save files and URL links to

customer-specific external documents. External documents saved in the

Customer Master List Database are considered “For Reference Only”

Control of Documented Information OP-75-01 Rev NC Date Printed

10. Control of Quality Records

10.1. Quality records at QNP consist of those documents that describe the results

of some activity. Examples of quality records include inspections, tests, reviews,

audits, measurements, training records, meeting minutes. The control of quality

records refers to the originals.

10.2. The Document Master List with Revision History, FM-75-01, lists for each

quality record;

The document code and title,

The current revision and issue date,

A description of revision changes,

The index for sorting or filing the records,

The location of active records and the personnel responsible for

maintaining them,

The active retention time for records, and the total retention time for

archived records,

The means for retrieving records,

The methods for disposing of the records, when their total retention

time is up and they are no longer useful.

Additional notes regarding access, distribution, use and risk as

applicable

10.3. QNP quality records are maintained to demonstrate product quality,

effectiveness of the quality system and/or conformance to specified

requirements.

10.4. QNP personnel involved with filling out forms and storing company related

records are to ensure that the records are:

Filled out properly, accurately, and completely

Documented in ink or other permanent marker

Signed or initialed and dated, when appropriate

Legible when hand written

Printed through all copies of multiple carbons

Stored in a clean, dry area in such a manner as to prevent damage or

deterioration to prevent loss or unintended alterations

Stored either on paper (hard copy) or stored on the computer

(electronic media) for the proper retention period

Made available to the customer or regulatory authority upon request,

when required by contract.

Control of Documented Information OP-75-01 Rev NC Date Printed

10.5. Quality records are generated internally within QNP and externally from

customers, suppliers and subcontractors.

10.6. Exclusion to procedure 5.2 Making Corrections on Quality Records:

Scheduled ship dates are frequently changed on Shop Order Envelopes, FM-81-

01. In order to keep them legible, the ship date field on the envelope may be

covered over with a label to replace information. Changes should be recorded

online in Job Tracking.

10.7. Typically, QNP asks that suppliers provide all necessary quality records so

they may be retained and controlled internally. When a QNP supplier is required

to maintain quality records, the means for retaining and controlling the records

are specified on purchasing documents. When required, QNP suppliers should

maintain quality records to the same standards as referenced in Policy Note 4 of

this procedure.

11. Making corrections on quality records

Pens with permanent ink should be used to make corrections or changes to quality

records. White-out or pencil should not be used to make corrections or changes to

quality records.

Follow the steps in the table below to make corrections to a quality record. Corrections

to quality records are to be made so that traceability and any significant history is

maintained. Corrections are to be made in ink.

Step Action

ASK: Will corrections made to this document be clear and legible?

1. If “No”, create a new record.

If “Yes”, go to Step 2.

2. Cross out what is to be changed with a single line.

3. Initial and date what has been crossed out.

4. Make the change required.

Control of Documented Information OP-75-01 Rev NC Date Printed

12. Maintaining Quality Records

The table below identifies the type of quality records maintained at QNP and how

each is maintained.

Type of Quality Record How It Is Maintained

Protect the record from becoming dirty or soiled.

Paper Keep records away from sources of contamination.

Use a plastic sleeve if appropriate.

Use virus protection practices.

Electronic Media

Backup data on a regular basis.

(Computers)

Maintain backups off site if appropriate.

13. Identifying quality record retention requirements

Quality record retention requirements are specified in Document Master List with

Revision History, FM-75-01.

Specified retention requirements are established in accordance with the:

Duration of the contract

Life of the product, and

Requirements of applicable standards, and

Government, customer, legislative, statutory, regulatory, and/or contract

requirements.

Reference FM-75-01 to determine the filing index, active location,

responsibility, active retention time, total retention time, and disposal method

of the record.

Control of Documented Information OP-75-01 Rev NC Date Printed

14. Archiving quality records

Authorized personnel use the steps in the table below to properly archive quality

records.

Currently, outside storage services are not used to archive quality records.

Step Task Action

1. Labeling the box Indicate the names of the records being archived.

Indicate the period covered by the records being

archived.

2.

Example: From (the date of the first record ) to (date of

the last record)

3. Indicate the date the box is being archived.

Place the records in a designated archive storage area

that will:

4. Storing the box

Protect the record from becoming dirty or soiled.

Keep records away from sources of contamination.

15. Disposition of original quality records

Authorized personnel use the steps in the table below to assure the proper disposal of

original quality records.

Step Action

1. Review the records to be disposed.

2. Ask: Has the useful life of the records ended?

If "No", do not dispose of the records.

If "Yes", go to Step 3.

3. Ask: Have the contractual requirements of the records been satisfied?

If "No", do not dispose of the records.

If "Yes", go to Step 4.

4. Dispose of quality records.

QNP Management determines disposal methods for quality records based

on the type of quality record, data contained in the record, and/or security

requirements. Records are shredded when appropriate.

Control of Documented Information OP-75-01 Rev NC Date Printed

16. RECORDS/OBJECTIVE EVIDENCE

The retention duration for records referenced in this procedure are available on-line in

the FM-75-01 Master Document List with Revision History.

17. REVISION HISTORY

Revision, approved date, effective date, and a document change summary for this

document is located on-line in the FM-75-01 Master Document List with Revision

History.

Control of Documented Information OP-75-01 Rev NC Date Printed

You might also like

- Anime Studio Pro 11 Tutorial ManualDocument303 pagesAnime Studio Pro 11 Tutorial ManualCristmart Tití73% (11)

- Total Balance KriyaDocument6 pagesTotal Balance Kriyaclaudiosala1957100% (8)

- QMS 010 Classification Definition and Approval Matrix of GMP Documents SampleDocument5 pagesQMS 010 Classification Definition and Approval Matrix of GMP Documents SampleRosella Planta100% (1)

- Eimm 5669 eDocument1 pageEimm 5669 ekuro Aishiro100% (1)

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Quality Record Control ProcedureDocument6 pagesQuality Record Control ProcedurePrime CapNo ratings yet

- 9.1.20 Foreign Object Debris (Fod) DamageDocument12 pages9.1.20 Foreign Object Debris (Fod) DamageDawit KumsaNo ratings yet

- Sop 7.4.4 Counterfeit Parts PreventionDocument6 pagesSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZNo ratings yet

- Project Proposal For ISO9001 2015 Implementation ENDocument5 pagesProject Proposal For ISO9001 2015 Implementation ENMihaela MafteiNo ratings yet

- Procedure For Internal AuditDocument5 pagesProcedure For Internal AuditDaniel Cheng MahsaNo ratings yet

- Procedure - Configuration Management - Rev 0Document4 pagesProcedure - Configuration Management - Rev 0Venkat BhagavatiNo ratings yet

- ISO 9001 Quality Management SystemDocument13 pagesISO 9001 Quality Management SystemAnonymous qRbPsLpuNNo ratings yet

- Qms Guidelines Appendix A 0Document3 pagesQms Guidelines Appendix A 0BranErikNo ratings yet

- Car & Par ReportDocument1 pageCar & Par ReporthabibrgfNo ratings yet

- PM - 5.03 Management ReviewDocument3 pagesPM - 5.03 Management ReviewMangBedjoNo ratings yet

- Procedure For Management ReviewDocument6 pagesProcedure For Management ReviewAman JasujaNo ratings yet

- 1 Internal & Product AuditDocument3 pages1 Internal & Product AuditPrafull BhamareNo ratings yet

- Procedure For Design and Development Control-01Document29 pagesProcedure For Design and Development Control-01Ahmad MukhtarNo ratings yet

- QP 56001 Rev 04 Management Review ProcedureDocument5 pagesQP 56001 Rev 04 Management Review ProcedureAllison SontowinggoloNo ratings yet

- QP01 Document ControlDocument5 pagesQP01 Document ControldhistaNo ratings yet

- MFG Procedure ManualDocument46 pagesMFG Procedure ManualAdinanNo ratings yet

- DCC F04 NCRDocument2 pagesDCC F04 NCRSyahir AhmadNo ratings yet

- ProceduresDocument22 pagesProceduresRajVardhan100% (1)

- Template - Management Review ReportDocument2 pagesTemplate - Management Review ReportIslam WayNo ratings yet

- Work Instruction Template PDFDocument2 pagesWork Instruction Template PDFdrg. Bobet Evih Hedi I.R., MMRNo ratings yet

- ISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0Document37 pagesISO9001 Supplier Manual-SQE-QGS-001 - IMI Group SQA Manual Approved 20180823 0umtNo ratings yet

- 4.1a - 4.1d Process PlanningDocument2 pages4.1a - 4.1d Process PlanningFendiNo ratings yet

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaNo ratings yet

- Customer Satisfaction Process PDFDocument1 pageCustomer Satisfaction Process PDFmilou88No ratings yet

- Hsp38 Documents Records Control ProcedureDocument6 pagesHsp38 Documents Records Control Procedurezakaria almohiaNo ratings yet

- QMS 04 A Interested Parties FreeDocument5 pagesQMS 04 A Interested Parties FreeLisardo ConstelaNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- QAF-109 Supplier Corrective Action Request - GIDEP 6-1-18Document15 pagesQAF-109 Supplier Corrective Action Request - GIDEP 6-1-18AlineMeirelesNo ratings yet

- Star Ecn Form 2012Document4 pagesStar Ecn Form 2012BERK YENİLMEZNo ratings yet

- ISO 13485 2003 Vs FDA QSR 42 69Document28 pagesISO 13485 2003 Vs FDA QSR 42 69Ancuta FeierNo ratings yet

- QMS-010 SampleDocument6 pagesQMS-010 SampleMostafa FawzyNo ratings yet

- Effectiveness of The QMSDocument33 pagesEffectiveness of The QMSvavvavNo ratings yet

- ISO 9001 Conformity MatrixDocument3 pagesISO 9001 Conformity Matrixkashifbutty2kNo ratings yet

- CounterfeitDocument5 pagesCounterfeitVivek GoudNo ratings yet

- MGT PRO-10 Control of Documented Information ProcedureDocument10 pagesMGT PRO-10 Control of Documented Information ProcedureAbla NedjmaNo ratings yet

- Manufacturing Process Audit Excel FormDocument2 pagesManufacturing Process Audit Excel FormTri Hdyvtdt100% (1)

- Supplier Deviataion Request Form RevBDocument2 pagesSupplier Deviataion Request Form RevBwdavid81100% (1)

- Centurion Power Cables (P) LTD.: 1.0 PurposeDocument4 pagesCenturion Power Cables (P) LTD.: 1.0 PurposetriveshNo ratings yet

- MP12 Monitoring, Measurment and ImprovementDocument6 pagesMP12 Monitoring, Measurment and ImprovementSuchhanda SarkarNo ratings yet

- This Procedure Explains How To Control Documents 1 Year: Name of InstitutionDocument5 pagesThis Procedure Explains How To Control Documents 1 Year: Name of InstitutionAmer RahmahNo ratings yet

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremNo ratings yet

- 14 - P11 Production Scheduling and Planning Process-May'17Document9 pages14 - P11 Production Scheduling and Planning Process-May'17Rohini GadhaweNo ratings yet

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberDocument1 pageSupplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberBESNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- Auditee Feedback Form: Internal Audit DepartmentDocument2 pagesAuditee Feedback Form: Internal Audit DepartmentNiomi GolraiNo ratings yet

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyNo ratings yet

- Fiat Control ChartDocument6 pagesFiat Control Chartsudar1477No ratings yet

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- INTERNAL QUALITY AUDIT - AgendaDocument1 pageINTERNAL QUALITY AUDIT - AgendaJeaneth Dela Pena CarnicerNo ratings yet

- Clause 9 PerformanceDocument8 pagesClause 9 Performancesharif1974No ratings yet

- Iso 9001-2015 Clause 7 SupportDocument14 pagesIso 9001-2015 Clause 7 SupportalexrferreiraNo ratings yet

- BF Aerospace QA ManualDocument46 pagesBF Aerospace QA ManualJoginder Kaur100% (2)

- Quality Manual: Foreword From Top ManagementDocument2 pagesQuality Manual: Foreword From Top ManagementmuthuselvanNo ratings yet

- Temporary Deviation RequestDocument3 pagesTemporary Deviation RequestSead ZejnilovicNo ratings yet

- ISO 9001 - 2015 Organisational RequirementsDocument6 pagesISO 9001 - 2015 Organisational RequirementsRommel BaesaNo ratings yet

- FDGS Stop Work PolicyDocument1 pageFDGS Stop Work PolicyUnachukwu SopuluNo ratings yet

- A MAN OF DESTINY - Word For Father's SundayDocument3 pagesA MAN OF DESTINY - Word For Father's SundayUnachukwu SopuluNo ratings yet

- FDGS Quality Policy StatementDocument1 pageFDGS Quality Policy StatementUnachukwu SopuluNo ratings yet

- Truck SpecDocument1 pageTruck SpecUnachukwu SopuluNo ratings yet

- FDGS Brochure2 PDFDocument5 pagesFDGS Brochure2 PDFUnachukwu SopuluNo ratings yet

- UntitledDocument1 pageUntitledUnachukwu SopuluNo ratings yet

- FDGS Code of Conduct & EthicsDocument8 pagesFDGS Code of Conduct & EthicsUnachukwu SopuluNo ratings yet

- 2022-09-10-FDGS Technical Capability SlidesDocument15 pages2022-09-10-FDGS Technical Capability SlidesUnachukwu SopuluNo ratings yet

- 2.14 - Change Management ProcessDocument7 pages2.14 - Change Management ProcessUnachukwu SopuluNo ratings yet

- 2.9 - Control of Customers Properties - BDocument4 pages2.9 - Control of Customers Properties - BUnachukwu SopuluNo ratings yet

- Samsung s860 s760 (ET)Document59 pagesSamsung s860 s760 (ET)jota_60254No ratings yet

- Agile PLM Data Mart Data Reference ManualDocument612 pagesAgile PLM Data Mart Data Reference ManualTirumalesha DadigeNo ratings yet

- Planning The EDT Installation: © 2006 Landmark Graphics CorporationDocument40 pagesPlanning The EDT Installation: © 2006 Landmark Graphics Corporationahmed_497959294No ratings yet

- Managin ProjectsDocument557 pagesManagin ProjectsJose Uriel GarciaNo ratings yet

- PreptoolDocument47 pagesPreptoolVagif VerdiNo ratings yet

- Inmath 1.7.6 Cs3 Quick StartDocument5 pagesInmath 1.7.6 Cs3 Quick StartmadhusivaNo ratings yet

- WFC70 ReportsRefGuideDocument364 pagesWFC70 ReportsRefGuideluckycharmhNo ratings yet

- Hyster PCST Readme-EN PDFDocument3 pagesHyster PCST Readme-EN PDFPra Zuar Silk Screen ConfecçãoNo ratings yet

- Literature Review TemplateDocument5 pagesLiterature Review Templatec5qj4swh100% (1)

- Posco DRMDocument32 pagesPosco DRMLarryMatiasNo ratings yet

- Facewizardinstructions PDFDocument3 pagesFacewizardinstructions PDFLarry0% (1)

- CT System E-User Leaflet: Multi-Language Operator Documentation IntroductionDocument16 pagesCT System E-User Leaflet: Multi-Language Operator Documentation IntroductionNayer Alfredo Marrugo GutierrezNo ratings yet

- He Leadth MeDocument63 pagesHe Leadth MeAlex TisoNo ratings yet

- Konica Minolta 920Document110 pagesKonica Minolta 920copimaserv100% (1)

- IBM Content Manager OnDemand and FileNet-3Document88 pagesIBM Content Manager OnDemand and FileNet-3David ResendizNo ratings yet

- Click Here For Download CRACKDocument9 pagesClick Here For Download CRACKRadoi RaduNo ratings yet

- SIS User's Guide: Service Information SystemDocument28 pagesSIS User's Guide: Service Information SystemvisnupadaNo ratings yet

- Halo 2 For Windows Vista Readme File: © 2007 Microsoft Corporation. All Rights ReservedDocument6 pagesHalo 2 For Windows Vista Readme File: © 2007 Microsoft Corporation. All Rights ReservedxBom StyleNo ratings yet

- PDF Portfolio TutorialDocument7 pagesPDF Portfolio Tutorialanon_193257742No ratings yet

- Timetable Deviation and Additional Sessions Preparation Form 2Document2 pagesTimetable Deviation and Additional Sessions Preparation Form 2ajichristianbaniadamNo ratings yet

- Advanced Hybrid System Getting Started KX-TES824 KX-TEM824Document32 pagesAdvanced Hybrid System Getting Started KX-TES824 KX-TEM824Ásgeirr Ánsgar Ósgar CanuroNo ratings yet

- Preflight Report HelpDocument140 pagesPreflight Report HelpAhmed SalievNo ratings yet

- CoreAPIReference PDFDocument3,322 pagesCoreAPIReference PDFRicardo GriãoNo ratings yet

- Form 3-Damaged-Or-Opened-Question-Paper-Packet-Before-The-ExamsDocument2 pagesForm 3-Damaged-Or-Opened-Question-Paper-Packet-Before-The-ExamsajichristianbaniadamNo ratings yet

- Application For Admission: SW1 - 1st Floor, 3700 Willingdon Avenue, Burnaby, BC V5G 3H2 1.866.434.1610Document3 pagesApplication For Admission: SW1 - 1st Floor, 3700 Willingdon Avenue, Burnaby, BC V5G 3H2 1.866.434.1610Wasawat JoongjaiNo ratings yet

- Adobe Solutions For Learning Management Systems (LMS)Document10 pagesAdobe Solutions For Learning Management Systems (LMS)ronaldoatanNo ratings yet

- Creating Quiz CaptivateDocument12 pagesCreating Quiz CaptivateSumit BhardwajNo ratings yet