Professional Documents

Culture Documents

Dokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0

Dokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0

Uploaded by

Mez NacerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0

Dokumen - Tips - Concept Mill 55 Operate 840d SL 828d Siemens 810d840d Fanuc Series 0

Uploaded by

Mez NacerCopyright:

Available Formats

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 1/20

TECHNICAL SPECIFICATION

Concept MILL 55

PC-controlled 3-axis Milling Machine

for universal CNC Training

With/without 8-station tool turret

Control Systems

Sinumerik Operate 840D sl / 828D

FANUC Series 31i

HEIDENHAIN TNC 640

HEIDENHAIN TNC 426/430

FAGOR 8055 MC

CAMCONCEPT

EMCO Gesellschaft m.b.H. Salzburger Straße 80 A-5400 Hallein/Austria

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 2/20

Contents

Technical Data of the Machine ................................................................................. 3

PC Control.................................................................................................................. 5

Description EMCO Easy2control ............................................................................. 6

Description EMCO Easy2Operate ............................................................................ 6

Basic Machine ........................................................................................................... 7

Accessories ............................................................................................................. 10

Engraving Spindle Facility...................................................................................... 11

Accessories for Automation................................................................................... 12

Clamping Devices ................................................................................................... 13

Tool Holders ............................................................................................................ 14

Cutting Tools ........................................................................................................... 15

Setting Tools............................................................................................................ 17

Manuals .................................................................................................................... 18

Courseware .............................................................................................................. 19

Brochures ................................................................................................................ 20

Packing .................................................................................................................... 20

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 3/20

Technical Data of the Machine

Working area

Slide travel (X-axis) [mm] 190 (7,5 inch)

Cross travel (Y-axis) [mm] 140 (5,5 inch)

Vertical travel (Z-axis) [mm] 260 (10,2 inch)

120/190

Effective Z-stroke, with / without turret [mm]

(4,7/7,5 inch)

77 – 337

Distance spindle nose – table surface [mm]

(3,0-13,3 inch)

Milling table

420 x 125

Clamping surface (L x W) [mm]

(16,5 x 4,9 inch)

Maximum table load [kg] 10

2 T-slots acc. to DIN 650 [mm] 11 (0,4 inch)

T-slots distance [mm] 90 (3,5 inch)

Milling spindle

Bearing type Roller bearing

Tool system (F1F P02)

Pick-up system with swivel arm on the left of the milling head placed;

incl. blow out facility

System drive / expiry electr., mech.

10

Proceeding speed tool turret trick plate [m/min]

(393,7 inch/min)

Tool mounting similar DIN 2079 SK30

Draw bolts Works standard

Tool clamping automatic

Number of tool stations 8

Maximum tool weight [kg] 1

40 / 60

Maximum tool diameter with / without turret [mm]

(1,6 / 2,4 inch)

Main drive

Asynchronous AC motor, power [kW] 0,75

Speed range (stepless) [rpm] 150 - 3500

Maximum torque [Nm] 3,7

Speed per minute with option high speed spindle [rpm] 14.000

Feed drives

0,0005

3 phase step motor in X/Y/Z axis with resolution of [mm]

(0,00002 inch)

2

Feed rate and rapid traverse in X/Y/Z axis [m/min]

(78,7 inch/min)

0.008

Middle positioning variation acc. to VDI 3441 in X, Y, Z [mm]

(0,0003 inch)

Maximum feed force X/Y/Z [N] 800 / 1000

Lubrication system

Guideways oil lubrication

Main spindle bearing lifetime grease lubrication

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 4/20

Basic pneumatic (standard included in basic machine)

Pneumatic service unit for tool taper blow-out device (with filter),

[bar] 6

supply pressure

Air hose connection [mm] ø 10

Compressed air quality (acc. DIN ISO 8573-1) cleanliness class 4

Painting

light gray RAL Nr. 7035

traffic red RAL Nr. 3020

graphite gray RAL Nr. 7024

Electrical connection

Voltage supply (adjustable) 1/N/PE [V] 115/230

Admissible voltage fluctuation [%] +5/-10

Frequency [Hz] 50/60

Connection value [kVA] 0,85

Maximum pre-fusing of machine [A] 12

Safety devices

Fully enclosed working area, axis limit switch

Safety category 3

door limit switch, emergency-off switch

Step motor drive with brake At tool turret

Procedures with the tool turret only with closed door,

without setting function

Dimensions/weight (approx. values !)

Overall height [mm] 980 (38,6 inch)

960 x 1000

Floor requirement WxD [mm]

(37,8x39,4 inch)

Overall weight incl. tool turret [kg] ca. 220

Sound pressure level

Mean sound pressure level [dB(A)] 70

Machine acceptance

Works standard similar DIN 8615

Safety rules/norms

Acc. to EEC-rules / acc. to CE

EN292 part 1 / 2, EN60204 part 1

EEC machine guiding rules appendix 1

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 5/20

PC Control

The machine is controlled by a standard PC.

The PC is provided by the customer.

Machine license

Does the direct control of the CONCEPT Machines and includes machine specific data.

For every CONCEPT machine a new machine license is to be produced.

Input possibilities

EMCO Easy2Operate (Option)

Panel for machine functions and onscreen display of the control keyboard (Easy2Control is

included)

EMCO control keyboard – basic case and key module (Option)

Keys for machine functions are on the basic case and keys for the control are on the

changeable key module.

PC keyboard and mouse

possible, but not recommended

PC system requirements

Processor PC Dual Core 2GHz

Operating system Windows 7 or higher (32 bit or 64 bit)

Working memory 4 GB RAM

Monitor 16:9 Full HD 1920x1080 (only for easy2control / easy2operate)

Free hard disk memory 2 GB

Interfaces easy2control: 1x USB for Dongle

easy2operate: 2x USB for Dongle + machine keyboard

Machine connection 1x LAN (cable) – only for machine licence

optional: LAN or WLAN for network connection

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 6/20

Description EMCO Easy2control

EMCO Easy2control is a software visualizing the control- and machine-specific keyboards of the

WinNC-controls on a 16:9 Full-HD screen.

The diverse operation fields for machine, control and short-cuts can be switched by tabs.

e.g.:

The buttons and regulation keys can be operated by the mouse.

When using a Full-HD-Touchscreen, you can operate these buttons and keys with this screen.

For operating the Software on the programming station (without machine), you need a license dongle.

For every work station an Easy2Control single license must be acquired. There is no multiple license.

Monitor requirements

16:9 Full-HD monitor with min. 1920 × 1080 pixel

For operating the machines CT 60, CM 55, CT 105 und CM 105, Easy2Operate is required.

Description EMCO Easy2Operate

Easy2Operate is used to operate the machines CT 60, CM 55, CT 105 und CM 105.

Easy2Operate consists of Easy2Control (incl.dongle) + panel

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 7/20

Basic Machine

ATTENTION:

PC, software and control keyboard are not included in scope of supply of basic machine.

EMCO Concept MILL 55

F1F P01

PC-controlled 3-axis milling machine for basic

CNC training with various industrial control

systems.

Machine complete with fully enclosed working area,

safety units acc. to CE, stepless adjustable main

drive, automatic movement to the reference

position, electrical and mechanical preparation for

automation, connection cable for PC-machine,

machine lamp.

USB stick with machine data, tool set for operating,

operating instruction manual with spare parts list.

Possibility for remote monitoring,

Tool turret Factory installed only !!

EMCO Concept MILL 55 with tool turret

F1F P02

PC-controlled 3-axis milling machine for basic

CNC training with various industrial control

systems

Machine complete with fully enclosed working area,

safety units acc. to CE, stepless adjustable main

drive, automatic movement to the reference

position, electrical and mechanical preparation for

automation, connection cable for PC-machine,

machine lamp.

8-station tool turret with

electric/mechanical pick-up system with blow out

facility milling spindle

incl. pneumatic unit (for blow out facility)

USB stick with machine data, tool set for operating,

operating instruction manual with spare parts list.

Possibility for remote monitoring,

Power supply cable

Indicate type of cable when ordering

Power supply cable VDE A4Z 010

Power supply cable BSI A4Z 030

Power supply cable UL A4Z 050

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 8/20

WinNC Machine License

Operating the machine. Works only with connected

machine.

SINUMERIK OPERATE 840D sl / 828D X3Y 400

FANUC Series 31i X3Y 360

HEIDENHAIN TNC 640 (Milling only) X3Y 460

HEIDENHAIN TNC 426/430 (Milling only) X3A 200

FAGOR 8055 TC X3A 300

Former versions On request

… will be produced only for justified cases.

Anyhow the technical preconditions have to be

considered because old Windows versions could

be requested.

EMCO CAMCONCEPT, machine license

For CAD/CAM Programming and direct operation X3A 400

of PC controlled CNC machines.

Only for:

PC and Concept Turn 55/60 + Mill 55

PC and Concept Turn 105 + Mill 105

EMCO Win 3D-View, Milling

X5A 260

3D graphic simulation

Option for all WinNC

EMCO Win 3D-View, Milling, single and machine

license

Not necessary for CAMCONCEPT!

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 9/20

Easy2Operate

Portable machine operating panel to operate the X9C E2C

machine via hardware, includes axis buttons, feed

override switch, mode switch etc. inclusive

Easy2control single license with dongle

Preferrable to operate CT60, CM55, CT105 and

CM105

Control keyboard – basic case

X9B 000

incl. USB cable

Note:

Either Easy2Operate or basic case + key module

Control keyboard – key module

SINUMERIK OPERATE 840D sl / 828D X9Z 060

SIEMENS 810 X9Z 010N

SIEMENS 820 X9Z 020N

SIEMENS 810D/840D X9Z 040N

FANUC Series 0 X9Z 110N

FANUC Series 21 X9Z 130N

FANUC Series 31i X9Z 030

EMCOTRONIC X9Z 210N

HEIDENHAIN TNC 426/430 (Milling only) X9Z 426N

HEIDENHAIN TNC 640 (Milling only) X9Z 640

FAGOR 8055 TC X9Z 050N

FAGOR 8055 MC X9Z 055N

TFT- Display

incl. display cable, power supply and attaching set X9Z 600

Note: older model, no touchscreen

Mains cable VDE A4Z 010

Mains cable BSI A4Z 030

Mains cable UL A4Z 050

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 10/20

Accessories

Machine base

A7Z 210

Base including: drawer for tools and other devices,

deposit for PC-tower. WxDxH 1035x1100x800 mm.

Cover sheet for machine base A6Z 670

Only for ConceptTurn 60 and ConceptMill 55

Swivel table A7Z 430

Deposit for monitor and control keyboard.

With drawer for PC-keyboard. Height adjustment

with gas-pressure-spring from 720 to 970 mm.

Swivelling range +/- 30°. Installation on both sides

possible. Installation left: Extension lead for

monitor, keyboard and mouse necessary!

WxD 845x550 mm. Table area 700x550 mm.

Levelling element

F3Z 150

4 pieces required, when using with machine base

View Window left F1Z420

Minimum- lubrification unit

Container volume 500ml

2 oil volume regulators

2 nozzles with flexible hose F1Z 400

Pressured air connection 4bar with regulator and

pressure gauge

Level display

Coaxial supply hoses

Pneumatic unit A6Z540 and extension board

A6Z640 necessary!!

Factory installed only !!

Electronic handwheel

For moving the machine’s axes manually to Q1Z 340

proceed zero point- and tool offsets

Retrofit able by EMCO technician !!

Possible with ACC-Hardware V2 and higher!!

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 11/20

4th axix Dividing Head (without chuck)

F1Z 240

Dividing head Ries RSC-20 with casing and

mounting pieces for Montage on the Milling table

- continuously adjustable

- Nominal moment: 42 Nm

- Fast traverse: 8 min-1

- Accuracy of indexing: +/- 100''

- Repeating accuracy: +/- 15''

- Spindle height: 48 mm

- Total height: 95 mm

- No hole through spindle !

- No control possible with the PAL and the

EMCOTRONIC

Retrofitable by EMCO technician !!

3-jaw lathe chuck dividing head

A6Z 630

Chuck diameter 74mm, throat 15 mm with chuck

wrench,

incl. 1 set inside/outside graduated jaws

Tailstock for dividing head (without live center)

- Center height: 48 mm F1Z 450

- Connection cone MK 1

- Displace range: 20 mm

- Max. workpiece lenght: 100 mm

Live center MT1 for dividing head

A5Z 260

Triple-beared live center for supporting long work-

pieces.

Engraving Spindle Facility

Engraving spindle facility

Including 6 collets (1/1,5/2/2,4/3/3,2 mm), F1Z 190

union nut and holder.

Transmission case with EMCO spindle acceptance

similar SK 30 and mechanically belt driven step-up

gear. The spindle facility is directly mounted at the

main spindle.

Transmission 4:1

Set of engraving tools

5 pcs. Engraving tools 223 180

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 12/20

Accessories for Automation

I/O – Extension board

A6Z 640

I/O - extension board is required for ALL

automation accessories and the minimum

lubrication unit necessary.

Retrofitable by EMCO technician!!

Pneumatic unit

A6Z 540

For connection of automatic door, pneumatical

machine vice with blow out facility

and the Minimum- lubrification unit.

Factory installed only !!

Automatic door

F1Z 210

Incl. stroke control

A6Z 540, A6Z640 necessary !!

Factory installed only !!

Pneumatic machine vice

F1Z 740

Type Gressel

Stroke and blow-out unit

Jaw width: 72 mm

Jaw opening: max. 70 mm

Total length: 344 mm

Total height: 63 mm

Clamping force: 700 to 3000 N

Pneum. pressure: 2 to 6 Bar

A6Z 540, A6Z640 necessary!!

Factory installed only !!

Robotic Interface

Necessary for FMS/CIM operation. X1A 000

Robotik-Interface Hardware or

I/O extension board required!!

DNC Interface

Enables the remote control of WinNC via a X5A 050

software- protocol.

The communication is done via TCP/IP interface

Not available for Heidenhain TNC426/430 and

Fagor 8055 MC

The accessories are containing all electrical and mechanical parts for mounting on the machine and a

mounting manual.

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 13/20

Clamping Devices

Machine vice

F1Z 310

Machine vice complete with adjustable longitudinal

limit stop.

Width of jaws 60 mm, clamping width 60 mm

Stepped clamping shoe

C3Z 300

Stepped clamping shoe complete with clamping

screw.

Clamping range up to 60 mm

Clamping rails

F1Z 060

1 set of clamping rails

3-jaw lathe chuck

V4W 186R

Chuck diameter ø82 mm

Incl.1 set of inside/outside graduated hardened

jaws

Adapter plate

F1Z 800

Required for mounting the chuck V4W 186R on

the milling table

Clamping jaws

V0W 013R

Jaws suitable to V4W 186R

1 set of toothed soft jaws

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 14/20

Tool Holders

Tool holder package CM55

consisting of: F1Z 970

Collet holder ESX25 - 5x

Set of collets ESX25 - 1x

Collet ESX25 dmr. 10 - 1x

Collet ESX25 dmr. 6 - 1x

Shell end mill arbor dmr. 16 - 1x

Tap holder M5-M8 - 1x

Collet holder

F1Z 100

For double coned ESX-25 collets, complete with

operating key

Set of 14 Collets ESX 25

In wooden box 225 000

Nominal-ø 2 - 14 mm

Collet ESX 25 DIN 6499 B

Nominal-ø Clamping area

2,0 1,5 - 2,0 225 020

2,5 2,0 - 2,5 225 025

3,0 2,5 - 3,0 225 030

4,0 3,0 - 4,0 225 040

5,0 4,0 - 5,0 225 050

6,0 5,0 - 6,0 225 060

7,0 6,0 - 7,0 225 070

8,0 7,0 - 8,0 225 080

9,0 8,0 - 9,0 225 090

10,0 9,0 - 10,0 225 100

11,0 10,0 - 11,0 225 110

12,0 11,0 - 12,0 225 120

13,0 12,0 - 13,0 225 130

14,0 13,0 - 14,0 225 140

15,0 14,0 - 15,0 225 150

16,0 15,0 - 16,0 225 160

Milling Arbor

F1Z 110

For milling cutter with 16 mm bores, with key and

milling machine arbor collars.

Screw tap holder

With length compensation

M3 F1Z 360

M4 F1Z 370

M5, M6, M8 F1Z 380

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 15/20

Cutting Tools

Tool Package “Basic”

with F1Z 980

2x 225 060 Collet 6mm

1x 225 100 Collet 10mm

1x 764 301 Slot End Mill 3mm

1x 764 303 Slot End Mill 5mm

1x 764 308 Slot End Mill 10mm

1x 764 410 Heavy Duty Shell End Mill

3x F1Z 100 Collet Holder

1x F1Z 110 Milling Arbor

Tool Package “Extended”

with F1Z 990

1x 225 100 Collet 10mm

2x 764 301 Slot End Mill 3mm

2x 764 303 Slot End Mill 5mm

2x 764 308 Slot End Mill 10mm

1x 764 410 Heavy Duty Shell End Mill

1x 771 010 NC-start Drill

1x 771 030 Radius Milling Cutter 6mm

1x 771 050 Angle Milling Cutter

1x 771 120 Drills For Core Holes 5 pcs.

2x 781 152 Heavy Duty Shank End Mill 10mm

1x 781 280 Twist Drills 25 pcs.

1x 781 303 Screw Tap M5

1x 781 304 Screw Tap M6

1x F1Z 970 Tool Holder Package CM55

Heavy duty shell end mill, HSS

With roughing finishing teeth 764 410

ø 40 x 20 mm, bore hole ø 16 mm

Staggered tooth side mill, HSS

Bore hole ø 16 mm 764 900

ø 35 x 5 mm

Radius milling cutter, HSS

Two edged, with parallel shank

shank- ø6 mm 771 030

shank- ø12 mm 771 040

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 16/20

Slot end mill, HSS

Acc. to DIN 327, shape B

cutting- ø3 mm / shank- ø6 mm 764 301

cutting- ø4 mm / shank- ø6 mm 764 302

cutting- ø5 mm / shank- ø6 mm 764 303

cutting- ø6 mm / shank- ø6 mm 764 304

cutting- ø8 mm / shank- ø8 mm 764 306

cutting- ø10 mm / shank- ø10 mm 764 308

cutting- ø12 mm / shank- ø12 mm 773 100

Heavy duty shank end mill, HSS

Acc. to DIN 844, shape A

cutting- ø8 mm / shank- ø8 mm 764 200

cutting- ø10 mm / shank- ø10 mm 781 152

cutting- ø12 mm / shank- ø12 mm 781 151

cutting- ø16 mm / shank- ø16 mm 771 020

Angle milling cutter, HSS

Acc. to DIN 1833, shape A 764 400

60°, ø16 mm, shank- ø12 mm

Angle milling cutter , HSS

Acc. to DIN 1833, shape B 771 050

45°, ø16x4 mm, shank- ø12 mm

Boring bar

F1Z 050

For bore hole ø16-40 mm

shank- ø15 mm

NC-start drill, HSS

771 010

Shank ø10 mm, acute angle 120°

Centre drill, HSS

ø6,8 mm 573 770

A8, HSS, DIN 333 271 220

Twist drills, HSS

25 twist drills ø1-13 mm, (0.5 mm graded) 781 280

9 twist drills ø2-10 mm, (1 mm graded) 260 628

Twist drills for core holes, HSS

5 core hole drills ø2.5, 3.3, 4.2, 5.0, 6.8 mm 771 120

6 twist drills for core holes ø2.5 - ø8.5 mm 271 230

Screw taps, HSS

Set of 5 screw taps M3 - M8, DIN 352 + 371 781 300

Screw tap M3, (shank ø 3,5 mm) 781 301

Screw tap M4, (shank ø 4,5 mm) 781 302

Screw tap M5, (shank ø 6 mm) 781 303

Screw tap M6, (shank ø 6 mm) 781 304

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 17/20

Setting Tools

Dial gauge with magnetic stand

565 065

Outside ring ø58 mm, division 0,01 mm

measuring range 10 mm,

with shock protection.

Edge indicator

F1Z 390

Probe ø6

Shank ø6 mm

3D sensor

764 841

incl. short probe tip ø4 mm

clamping shank ø10 mm

length without shaft 96 mm

measuring range 2 mm

accuracy 0,01 mm

Spare Probe Ball Tip for 3D-Sensor

764 842

length 25mm

probe tip ø4 mm

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 18/20

Manuals

Machine description Concept Mill 55 DE 2055

EN 2055

FR 2055

SP 2055

TA 2055

HL 2055

SK 2055

CZ 2055

Programmieranleitungen WinNC für SINUMERIK OPERATE 840Dsl/828D M DE 1848

Fräsen EN 1848

Manual WinNC Sinumerik Operate - M FR 1848

Programming Instructions HL 1848

Milling SP 1848

TA 1848

CZ 1848

Ältere WinNC’s und weitere

Sprachen WinNC FANUC Series 31i - M DE 1846

Auf Anfrage EN 1846

Manual WinNC FANUC Series 31i - M FR 1846

Former WinNC’s and further HL 1846

languages SP 1846

On request TA 1846

CZ 1846

EMCO Win3D-View - Fräsen WinNC HEIDENHAIN TNC 640 DE 1844

Die Anleitung für Win3DView EN 1844

wurde aufgelassen und in die Manual WinNC HEIDENHAIN TNC 640 - M SP 1844

Anleitung für WinNC integiert.

WinNC HEIDENHAIN TNC 426/430 DE 1816

EMCO Win3D-View - Milling EN 1816

The manual for Win3DView has Manual WinNC HEIDENHAIN TNC 426/430 - M HL 1816

been abandoned and integrated SP 1816

into the manual for WinNC. TA 1816

WinNC FAGOR 8055 MC DE 1818

EN 1818

Manual WinNC FAGOR 8055 MC - M FR 1818

SP 1818

Bedienungsanleitung CamConcept DE 1828

Instruction Manual CamConcept EN 1828

FR 1828

Manual CAMConcept M HL 1828

SP 1828

TA 1828

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 19/20

Courseware

E[MCO] Campus

E-Learning 2.0 for machining.

Multimedia teaching and learning

materials

for CNC

.

E[MCO] Campus

is a multimedia training program that teaches all

the basics of modern CNC technology.

The cleverly-designed teaching format makes

even complex concepts easy to grasp and learn.

Interactive dialog features allow students to

progress at their own pace. Views are displayed

using attractive 2 and 3D graphics, animations,

and videos, sustainably improving the success of

the learning process..

Languages

German, English, Spanish, Chinese, Czech,

Romanian, Polish, Slovenian

Single-user license 1 X2Y 400

Multiple-user license 20 X2Y 410

Multiple-user license 50 X2Y 420

Multiple-user license 100 X2Y 430

Campus License On request

A Campus-License consists of several Multiple

licenses.

The Software is working without any time

restriction, a renewal of the version is not

necessary.

A Software Maintenance Contract (SMC) is not

available right now.

Subject to technical modifications!

DIVISION: CNC-Training Systems Concept MILL 55

DATE: March 29, 2018 Page 20/20

Brochures

EMCONOMY moves DE 2801

EN 2801

FR 2801

SP 2801

RU 2801

CZ 2801

CONCEPT MILL 55 DE 4536

EN 4536

TA 4536

SP 4536

FR 4536

Packing

Europe packing

Standard packing incl.

Options to european packing for

Machine Mill55:

Climate packing

ZVP 547 120

Pallet, Alu-bandage, various accessories

Seaworthy packing

Requires climate packing ZVP 547120! ZVP 301 124

Options to european packing for

machine base:

Climate packing

ZVP 547 120

Pallet, Alu-bandage, various accessories

Seaworthy packing

ZVP 301 124

Requires climate packing ZVP 547120!

Subject to technical modifications!

You might also like

- Elumatec SBZ 130 Software ManualDocument108 pagesElumatec SBZ 130 Software ManualDavid BraileyNo ratings yet

- TraubDocument28 pagesTraubskidamdnevno0% (1)

- Emco Concept TURN 55 Brochure ENDocument4 pagesEmco Concept TURN 55 Brochure ENP72097100% (1)

- 20100716172219667Document6 pages20100716172219667김두리No ratings yet

- KV25 P PDFDocument14 pagesKV25 P PDFAbel Rivera Cuatlayotl100% (1)

- Milling OperationsDocument4 pagesMilling Operationsinboxsweets100% (1)

- Spec Cm55 enDocument20 pagesSpec Cm55 enNilxon Alejandro Jaramillo DíazNo ratings yet

- Emco Concept Mill Techspec PDFDocument23 pagesEmco Concept Mill Techspec PDFprimayuwanaNo ratings yet

- Milling Machine Concept Mill 55 En-1Document4 pagesMilling Machine Concept Mill 55 En-1EmzyNo ratings yet

- Galaxy Midas 0Document2 pagesGalaxy Midas 0suresh0% (1)

- Lathe Concept Turn 105 ENDocument4 pagesLathe Concept Turn 105 ENandrefirewallbrNo ratings yet

- Mill 55Document4 pagesMill 55Manuel XamanNo ratings yet

- Emco Mill250 SpecifDocument43 pagesEmco Mill250 Specifandre sebastian ruiz trujilloNo ratings yet

- FT5 ITCM enDocument18 pagesFT5 ITCM enMez NacerNo ratings yet

- Cka6130 CNC Lathe: Detailed DescriptionDocument6 pagesCka6130 CNC Lathe: Detailed DescriptionIvona JovanovskaNo ratings yet

- List of Needed MachinesDocument6 pagesList of Needed MachinesAyech NabilNo ratings yet

- JWX-10 Product Guide: Roland DG CorporationDocument21 pagesJWX-10 Product Guide: Roland DG CorporationSupport BiomedNo ratings yet

- NEW Cataogue LineUp EnglishDocument44 pagesNEW Cataogue LineUp EnglishReginaldo AlvesNo ratings yet

- 01.2021 Line-Up ENG - v1.3Document48 pages01.2021 Line-Up ENG - v1.3Mohamed EssamNo ratings yet

- Datasheet Robocut A C400ic ENDocument2 pagesDatasheet Robocut A C400ic ENbureau d'études techniques et méthodesNo ratings yet

- Galaxy200406 M6 PDFDocument2 pagesGalaxy200406 M6 PDFsureshNo ratings yet

- CNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCDocument2 pagesCNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCdesetekNo ratings yet

- Milling Concept MILL 55 en 01Document4 pagesMilling Concept MILL 55 en 01Heineken Ya PraneetpongrungNo ratings yet

- Tsugami M08J Focus Brochure 1Document8 pagesTsugami M08J Focus Brochure 1Aryan DhimanNo ratings yet

- 160 Series: HYUNDAI WIA Efficient Type CNC Turning CenterDocument20 pages160 Series: HYUNDAI WIA Efficient Type CNC Turning CenterAleksei MakarevichNo ratings yet

- Sales Manual of VESTA-660 (6.2) (20200408)Document59 pagesSales Manual of VESTA-660 (6.2) (20200408)Văn Duy ĐinhNo ratings yet

- Total Solution 5-Axis Universal Machining Center: HS-M272-R8.12-20120925Document62 pagesTotal Solution 5-Axis Universal Machining Center: HS-M272-R8.12-20120925tsmutz5No ratings yet

- New Robocut: Fast, Accurate, Multipurpose EDM With Rigid 800 MM Table For Even More VersatilityDocument2 pagesNew Robocut: Fast, Accurate, Multipurpose EDM With Rigid 800 MM Table For Even More VersatilityMAKHLOUKA IbrahimNo ratings yet

- Ds Romi D in Aq Final BXDocument12 pagesDs Romi D in Aq Final BXjubileuNo ratings yet

- PLATINO 1530 HS Technical Description 1-1-10Document10 pagesPLATINO 1530 HS Technical Description 1-1-10nimrhsNo ratings yet

- Emcomat 14DDocument8 pagesEmcomat 14Dnord2500No ratings yet

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- X.mill M 640Document1 pageX.mill M 640Frederik HenderwanzaNo ratings yet

- 24r Spec Sheet 1019Document1 page24r Spec Sheet 1019Ben LernerNo ratings yet

- F VM Series (Eng) Ver2Document32 pagesF VM Series (Eng) Ver2filiposkivNo ratings yet

- KFE MATERIALOGRAPHIC EquipmentDocument21 pagesKFE MATERIALOGRAPHIC Equipmentkrisna pangersaNo ratings yet

- Berline Machine Catalog PuneDocument12 pagesBerline Machine Catalog PuneDINESHNo ratings yet

- F400-500-650 (Eng) - Ver2 PDFDocument42 pagesF400-500-650 (Eng) - Ver2 PDFpatr01No ratings yet

- Machine Data SheetDocument3 pagesMachine Data SheetThaslimNo ratings yet

- Btd110h r16 Shibaura Leaflet1 1Document2 pagesBtd110h r16 Shibaura Leaflet1 1Manikandaperumal CNo ratings yet

- Juno Brochures INDocument5 pagesJuno Brochures INeclipser0067No ratings yet

- Ball Screw Drive, Ball Guide, Single Ball Nut, Short Carriage General Specifications Carriage Idle Torque (M Idle) (NM)Document2 pagesBall Screw Drive, Ball Guide, Single Ball Nut, Short Carriage General Specifications Carriage Idle Torque (M Idle) (NM)Abbas ZaidiNo ratings yet

- Cutex 160Document49 pagesCutex 160Néstor CastilloNo ratings yet

- Machine Specifications: Item Unit 100 150 200 250Document3 pagesMachine Specifications: Item Unit 100 150 200 250Happy DaysNo ratings yet

- Concept Mill 450 en PDFDocument6 pagesConcept Mill 450 en PDFLê TíNo ratings yet

- Maxmill Fanuc Manual PDFDocument426 pagesMaxmill Fanuc Manual PDFRaul LupuNo ratings yet

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesNo ratings yet

- Decision Support For Machine Tools Selection in Process Planning and Equipment InvestmentDocument9 pagesDecision Support For Machine Tools Selection in Process Planning and Equipment InvestmentMichaels MedasheNo ratings yet

- TSM1000D CNC Double Rollers Spinning and Turning MachineDocument3 pagesTSM1000D CNC Double Rollers Spinning and Turning MachineMahendra AdityaNo ratings yet

- Concept Turn 105 - enDocument41 pagesConcept Turn 105 - enGerman Bello PeraltaNo ratings yet

- Genos-En CNC OkumaDocument13 pagesGenos-En CNC Okumahggil380250% (2)

- VX750Document6 pagesVX750Tombong100% (1)

- CNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCDocument2 pagesCNC Notching and Marking Machines: at 820 E CNC - at 820 E HD CNCjeorgepolettoNo ratings yet

- Mazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006Document1 pageMazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006voho nhattanNo ratings yet

- E1. MC-044 CNC Milling Machine (Siemens Controller)Document3 pagesE1. MC-044 CNC Milling Machine (Siemens Controller)manual imbNo ratings yet

- CNC Milling and Horizontal Milling MachineDocument7 pagesCNC Milling and Horizontal Milling MachineAsma PrinceNo ratings yet

- QP L SeriesDocument16 pagesQP L Seriesluis arriagaNo ratings yet

- DL Texturing OBA DTY 2023 02 Datasheet Manual enDocument2 pagesDL Texturing OBA DTY 2023 02 Datasheet Manual enOrang BodoNo ratings yet

- Specification PagesDocument44 pagesSpecification PagesGerardo Daniel Arroyo GarciaNo ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- Folleto General SMEC Año 2021 PRODUCT LINE UP - 12p - 2021 - enDocument12 pagesFolleto General SMEC Año 2021 PRODUCT LINE UP - 12p - 2021 - enOsvaldo arayaNo ratings yet

- A001Document1 pageA001Mez NacerNo ratings yet

- B002Document1 pageB002Mez NacerNo ratings yet

- FT5 ITCM enDocument18 pagesFT5 ITCM enMez NacerNo ratings yet

- Kurzanleitung WinNC Update EN ADocument10 pagesKurzanleitung WinNC Update EN AMez NacerNo ratings yet

- Computer Aided Manufacturing LabDocument4 pagesComputer Aided Manufacturing LabMez NacerNo ratings yet

- CNC Milling Center Training Purposes Concept MILL 55Document4 pagesCNC Milling Center Training Purposes Concept MILL 55Mez NacerNo ratings yet

- 3CX 4CX IssueDocument26 pages3CX 4CX IssueMez Nacer0% (1)

- N210 MD1GD3 PDFDocument1 pageN210 MD1GD3 PDFMez NacerNo ratings yet

- SUSAN SCHOENIAN (Shāy-Nē-Ŭn) Sheep & Goat Specialist Western Maryland Research & Education CenterDocument49 pagesSUSAN SCHOENIAN (Shāy-Nē-Ŭn) Sheep & Goat Specialist Western Maryland Research & Education CenterMez NacerNo ratings yet

- Cherry 2020 Price List WsDocument64 pagesCherry 2020 Price List WsMez NacerNo ratings yet

- Parasites in GoatsDocument57 pagesParasites in GoatsMez NacerNo ratings yet

- الطيور الرومية و أساليب تربيتهاDocument48 pagesالطيور الرومية و أساليب تربيتهاMez NacerNo ratings yet

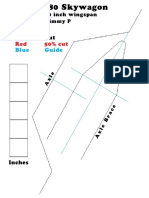

- Cessna 180 Skywagon: Key Black Cut Red 50% Cut Blue GuideDocument1 pageCessna 180 Skywagon: Key Black Cut Red 50% Cut Blue GuideMez NacerNo ratings yet

- 180 Scale Test. Landing GearDocument1 page180 Scale Test. Landing GearMez NacerNo ratings yet

- Tech D (048-069)Document22 pagesTech D (048-069)Alejandro CouceiroNo ratings yet

- 04 Manual G Code Programming-1Document79 pages04 Manual G Code Programming-1Dado Maja ArseninNo ratings yet

- Fundamentals of Numerical ControlDocument67 pagesFundamentals of Numerical ControlSanjay MehrishiNo ratings yet

- Sce en 700-020 CNC Shopturn Basics r1508Document208 pagesSce en 700-020 CNC Shopturn Basics r1508Trung Quoc LeNo ratings yet

- XT20101227 Turning Lathe CNC Controller CNC4620Document99 pagesXT20101227 Turning Lathe CNC Controller CNC4620Mohammed MagdyNo ratings yet

- Industrial Training Report On Plastic Moulding Industry (Roop Polymer)Document21 pagesIndustrial Training Report On Plastic Moulding Industry (Roop Polymer)Suraj MauryaNo ratings yet

- Eurotech Multipla SeriesDocument4 pagesEurotech Multipla SeriesCNC SYSTEMSNo ratings yet

- Numerical Investigation of Effects of Cutting Conditions TitaniumDocument23 pagesNumerical Investigation of Effects of Cutting Conditions TitaniumviniciusadsNo ratings yet

- 3 Fundamentals of CNC Programming I (CNC Course CD)Document38 pages3 Fundamentals of CNC Programming I (CNC Course CD)Jimmy RodriguezNo ratings yet

- Unit - 1 Introduction To Machine Tools & MachinesDocument17 pagesUnit - 1 Introduction To Machine Tools & MachinesWeld Tech100% (1)

- Metal Cuuting SyllabusDocument1 pageMetal Cuuting SyllabusAnonymous wrSPc7Bh05No ratings yet

- Gunsmithing - Building Bolt-Action Rifles PDFDocument120 pagesGunsmithing - Building Bolt-Action Rifles PDFdiglemar86% (14)

- Vdocuments - MX Automationprouction Systems and Cim MP Groover Chapter 7 SolutionDocument25 pagesVdocuments - MX Automationprouction Systems and Cim MP Groover Chapter 7 SolutionxXElcaXxNo ratings yet

- A Report: Manufacturing of Machine Tool BedsDocument11 pagesA Report: Manufacturing of Machine Tool BedsKumarChirraNo ratings yet

- Okuma Manuals 368Document71 pagesOkuma Manuals 368AminNo ratings yet

- NTN TR72 en P002Document4 pagesNTN TR72 en P002murali036No ratings yet

- Spe 170487 MsDocument11 pagesSpe 170487 MsolsencoreycNo ratings yet

- CBS Camlock On HBMDocument1 pageCBS Camlock On HBMMarcos VieroNo ratings yet

- Trocando Correia Fresadora AtlasDocument2 pagesTrocando Correia Fresadora Atlasdfirmo4925No ratings yet

- Control Functions and Specifications:: Standard: Optional: NoneDocument14 pagesControl Functions and Specifications:: Standard: Optional: NoneAbhishek VelagaNo ratings yet

- Bielomatik MMS Prospekt enDocument16 pagesBielomatik MMS Prospekt enAnonymous 67TvRPYdRBNo ratings yet

- 4507TU - C - Section Mill TUDocument17 pages4507TU - C - Section Mill TUGrigore BalanNo ratings yet

- Technology and Application: WIRTGEN Cold Milling ManualDocument15 pagesTechnology and Application: WIRTGEN Cold Milling ManualСергей КарасенкоNo ratings yet

- Milling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD IsDocument10 pagesMilling Machines: Milli e Ains A Ause e H Ma - Why A - Up Rio e E, MD Isnitin gaikwadNo ratings yet

- 09-Hardox Tool Recommendations For Hardox Wear Plate PDFDocument4 pages09-Hardox Tool Recommendations For Hardox Wear Plate PDFMartin AsatoNo ratings yet

- Fanuc Mill PDF ProgramingDocument2 pagesFanuc Mill PDF ProgramingAshley33% (3)

- Report On Cascading TransformersDocument28 pagesReport On Cascading Transformerspalak yadavNo ratings yet