Professional Documents

Culture Documents

Duranar Solid Sunstorm XL Brochure v3!10!02 19 LowRes 2

Duranar Solid Sunstorm XL Brochure v3!10!02 19 LowRes 2

Uploaded by

Mani KaruppiahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Duranar Solid Sunstorm XL Brochure v3!10!02 19 LowRes 2

Duranar Solid Sunstorm XL Brochure v3!10!02 19 LowRes 2

Uploaded by

Mani KaruppiahCopyright:

Available Formats

Trusted performance.

Exceptional color.

PPG DURANAR® solid color,

mica and metallic coil coatings

Via 57 West

Duranar Sunstorm Coatings

Tough. Colorful. Trusted for over 50 years. Suggested markets

Duranar coil coatings are multi-coat systems consisting of, at a minimum, Building products

a corrosion-inhibitive primer and a fluoropolymer topcoat. Depending on

substrate, color, effect and end-use location, some Duranar products may

Suggested end uses

require additional barrier coat and clear coat layers.

Building panels

These products deliver outstanding aesthetics and durability for an array

High-end storefronts

of high-end architectural applications, including metal roof and wall

panels. Duranar coil coating systems combine PPG-proprietary resin and Curtain walls

pigment technologies with 70% fluoropolymer base resins. Trusted by Roof panels

architects and builders for more than 50 years, they have set the standard

for excellence in architectural finishes with their proven resistance to

color fading, acid rain, ultraviolet rays, chipping and peeling when properly

applied by an approved applicator.

Duranar coil coating systems meet or exceed AAMA 2605 performance

requirements. They are available in a wide range of consistent and stable

colors, and approved for use on properly cleaned and treated aluminum

and coated steel products such as G90 hot-dip galvanized, GALFAN®,

GALVALUME® and ZINCALUME® substrates.

The PPG Benefit

• Long-term durability • High resistance to chemical attack

• Excellent resistance to chalk and • Minimal maintenance: can be

color fade, preserving building cleaned with mild detergents

aesthetics and solvents

• Outstanding corrosion resistance • Minor scratches can be repaired

• Excellent flexibility helps with in the field

rigorous post-forming operations

Bridgeport Active Healthcare

Duranar Sunstorm Coatings

Duranar coil coating products

Duranar Solid Color Coil Coating System

When it comes to architectural design, color matters. So does

performance. That is why generations of architects and building owners

have counted on Duranar coil coatings to protect and beautify their metal

building surfaces in various climates around the world. PPG offers an

extensive color palette in a wide range of formulations, each designed to

provide the desired balance of cost, aesthetics and performance.

Nemours / Alfred I. DuPont

Hospital for Children

Duranar SUNSTORM® Mica-Effect Coil Coating System Duranar Sunstorm

and Duranar XL Coatings

Duranar Sunstorm coating systems feature the same two-coat

application as conventional Duranar solid color coating systems,

adding pearlescent mica flake to the color layer to create a dazzling

metalescent look — without the need for aluminum flake or a third-layer

clear coat. Duranar Sunstorm coatings can also be formulated with PPG’s

proprietary ULTRA-COOL® infrared (IR)-reflective coating technology to

help make buildings cooler, more comfortable and more energy-efficient.

Duranar XL Metallic Coil Coating System

Duranar XL metallic coating systems offer added protection on metal

roofs, wall panels and architectural components in difficult seacoast and

industrial environments. The three- and four-coat systems consist of a

primer, a barrier coat, a color coat (with or without mica flake) and a clear

topcoat. The clear topcoat protects the color coat from atmospheric

pollutants and enhances its durability. The barrier coat provides excellent

UV protection for the primer when semi-transparent colors are applied.

The overall film thickness creates a system with outstanding barrier

protection, corrosion resistance, chemical resistance and toughness.

Duranar coil coating products

Characteristics and performance apply to Duranar Solid, Duranar Sunstorm and Duranar XL coating systems.

Product Characteristics Test Standard Aluminum Coated Steel1

0.20-0.30 mil primer 0.20 mil primer

0.70-0.80 mil color/metallic 0.75 mil barrier

Dry Film Thickness ASTM D1400 0.30-0.40 mil clear topcoat 0.75 mil color/metallic

0.50 mil clear topcoat

ASTM D523

Gloss Standard @ 60˚ 25 - 35 25 - 35

Low gloss @ 85˚ < 10 < 10

Performance Properties* Test Standard Aluminum Coated Steel1

Pencil Hardness ASTM D3363 F – 2H F – 2H

Flexibility (T-Bend)2 ASTM 4145 0 – 2 T-bend; no pick-off 0 – 2 T-bend; no pick-off

Adhesion ASTM D3359 No adhesion loss No adhesion loss

ASTM D2794

Reverse Impact 1.5 x metal thickness (aluminum) No cracking or adhesion loss No cracking or adhesion loss

3.0 x metal thickness (coated steel) No cracking or adhesion loss No cracking or adhesion loss

ASTM D1308

Acid Resistance 10% muriatic acid – 24 hours No effect No effect

20% sulfuric acid – 18 hours No effect No effect

15 cycles minimum 15 cycles minimum

Acid Rain Test Kesternich SO2, DIN 50018

No objectionable change No objectionable change

ASTM D1308

Alkali Resistance No effect No effect

10%, 25% NaOH, 1 hour

None or few #8 blisters; None or few #8 blisters;

ASTM B117

Salt Spray Resistance > 1/16” scribe creep average > 1/16” scribe creep average

5% salt fog @ 95˚ F (35˚ C)

Passes 4,000 hours Passes 1,000 hours

ASTM D714, ASTM D2247,

Passes 4,000 hours Passes 1,500 hours

Humidity Resistance 100% relative humidity

No #8 blisters No #8 blisters

@ 95° F (35˚ C)

ASTM D2244, ASTM D4214 Maximum 5 fade Maximum 5 fade

Exterior Exposure

10 Years @ 45°, South Florida Maximum 8 chalk Maximum 8 chalk

Coated steel includes G90 hot-dip galvanized, Galfan, Galvalume and Zincalume substrates.

1

2

Fracturing or rupturing of substrate will rupture coatings. Heavy-gauge and clad steel substrates impose limitations on formability.

Duranar coatings are generally flexible beyond the point of substrate rupture.

Shown:

432 Park Avenue Bridgeport Active Healthcare Nemours / Alfred I. DuPont Via 57 West

New York, NY Toronto, ON Hospital for Children New York, NY

Photos by Tom Kessler Photo by Tom Arban Wilmington, DE Photos by Tom Kessler

Photos by Tom Kessler

This document contains general information only and should not be construed as creating any warranties, express or implied.

Please contact a PPG representative for additional information.

Duranar, the PPG Logo, Sunstorm and ULTRA-Cool are registered trademarks and We protect and beautify the world is a

trademark of PPG Industries Ohio, Inc. Galfan is a registered trademark of Galfan Technology Centre Inc. Galvalume is a registered

trademark of BIEC International, Inc. Zincalume is a registered trademark of BlueScope Steel Limited. The IN Logo is a registered

trademark of LinkedIn Corporation. ©2019 PPG Industries, Inc. All rights reserved. 09/19 PPG-146

PPG Industrial Coatings • One PPG Place, Pittsburgh, PA 15272 • 1.800.258.6398 • ppgmetalcoatings.com

You might also like

- Director of Fundraising Competency FrameworkDocument4 pagesDirector of Fundraising Competency FrameworkRobert BrownNo ratings yet

- PTR SigmaDur 550 H Performance Test ReportDocument2 pagesPTR SigmaDur 550 H Performance Test ReportMilton Jesus Tapia Villarreal100% (2)

- Altissimo Fingerings For Tenor SaxophoneDocument8 pagesAltissimo Fingerings For Tenor Saxophonesouthernutahsaxman100% (3)

- 2603 2604 2605 - Comparisons - 4 6 11 PDFDocument1 page2603 2604 2605 - Comparisons - 4 6 11 PDFuocmogiandi_a100% (1)

- Metal Silicone 2 Sealant Technical Data SheetDocument6 pagesMetal Silicone 2 Sealant Technical Data Sheetremarkhb.maintenanceNo ratings yet

- Corian Exterior Cladding: Technical BulletinDocument6 pagesCorian Exterior Cladding: Technical BulletinnaheedahmedNo ratings yet

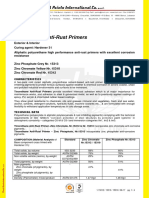

- Tinorethane Anti-Rust PrimersDocument4 pagesTinorethane Anti-Rust PrimersAbed samadsureyft7vewyrNo ratings yet

- ROCKMAX Folleto GeneralDocument12 pagesROCKMAX Folleto GeneralAnonymous UCKYGHcLNo ratings yet

- ALUBOND SpecificationsDocument2 pagesALUBOND SpecificationssoosanantonyNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Basf Masterprotect 300 SpecDocument2 pagesBasf Masterprotect 300 SpecWilfredoEnghoyNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Tata Steel Colorcoat PVDF Datasheet ENG FINAL 032012Document2 pagesTata Steel Colorcoat PVDF Datasheet ENG FINAL 032012Simon KennyNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Jotun Facade 2286, 2287, 2288: Technical Data SheetDocument4 pagesJotun Facade 2286, 2287, 2288: Technical Data SheetWan Mohd ThariqNo ratings yet

- Nukote STDocument4 pagesNukote STMarco Dos Santos NevesNo ratings yet

- Corro-Coat PE-SDF Series 2003 and 2006Document2 pagesCorro-Coat PE-SDF Series 2003 and 2006jessNo ratings yet

- ColorcoatŽ PE 25 DatasheetDocument2 pagesColorcoatŽ PE 25 Datasheetprimoz1No ratings yet

- Technical Data of Powder CoatingDocument1 pageTechnical Data of Powder CoatingLahore 4C2No ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Tilara Polyplast EcatalogueDocument16 pagesTilara Polyplast EcatalogueRohit ChudasamaNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Anti-Heat Paint Finish On HandrailsDocument28 pagesAnti-Heat Paint Finish On Handrailsblackk7No ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Devcon Plastic Steel Putty ADocument3 pagesDevcon Plastic Steel Putty AAZLAN ABDULLAINo ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelNo ratings yet

- Estimation Cost For W32 & W29Document10 pagesEstimation Cost For W32 & W29SENG ZHeng CHIEWNo ratings yet

- 589enint Greencoat Pural BTDocument4 pages589enint Greencoat Pural BTkokrasniqiNo ratings yet

- FIBREGUTTER (Talang FRP)Document8 pagesFIBREGUTTER (Talang FRP)Intan PancariNo ratings yet

- Kuliah Coating-1Document34 pagesKuliah Coating-1Agustina Sri PurnamiNo ratings yet

- COLORBONDUltra ACTIVATETDS200706Document4 pagesCOLORBONDUltra ACTIVATETDS200706Ramiro RivasNo ratings yet

- Amercoat 450HDocument2 pagesAmercoat 450HJairo ArroyoNo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- NEI Anticorrosion Paints & Coatings BrochureDocument3 pagesNEI Anticorrosion Paints & Coatings Brochurefallen010% (1)

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocument1 pageAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- ShaliProtek PuR 100Document3 pagesShaliProtek PuR 100Rana MahatoNo ratings yet

- Counter Top SpecsDocument12 pagesCounter Top Specsapi-3797031100% (3)

- Sonolastic Ultra Asean 0509Document2 pagesSonolastic Ultra Asean 0509Andri AjaNo ratings yet

- PPG Touch Up PaintDocument10 pagesPPG Touch Up PaintTheAnh TranNo ratings yet

- GL XX Mobilgrease XHP Mine SeriesDocument3 pagesGL XX Mobilgrease XHP Mine SeriesNavneet YadavNo ratings yet

- AlugardDocument2 pagesAlugardmk779900mkNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationKamalakar SastryNo ratings yet

- Apn Knitting Oil 22Document2 pagesApn Knitting Oil 22Elbi SalesTindoNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- RS PRO 10kΩ Carbon Film Resistor 0.25W ±5%: FeaturesDocument6 pagesRS PRO 10kΩ Carbon Film Resistor 0.25W ±5%: FeatureslodapaveNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- TDS Nitoflor SL3000 UT Saudi ArabiaDocument5 pagesTDS Nitoflor SL3000 UT Saudi ArabiaShaikhRizwanNo ratings yet

- Corro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308Document2 pagesCorro-Coat PE-F Façade: Series 1301, 1303, 1307 and 1308girlie fabroNo ratings yet

- Silicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeDocument2 pagesSilicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeTran Tuan anhNo ratings yet

- Corrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionFrom EverandCorrosion Engineering and Cathodic Protection Handbook: With Extensive Question and Answer SectionNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Case-Studies Discovery-CenterDocument2 pagesCase-Studies Discovery-CenterMani KaruppiahNo ratings yet

- Case Studies - DLL Convention CenterDocument2 pagesCase Studies - DLL Convention CenterMani KaruppiahNo ratings yet

- 18602pgmc Mesa CC Cs047 Lo ResDocument2 pages18602pgmc Mesa CC Cs047 Lo ResMani KaruppiahNo ratings yet

- Case Studies - Atlanta Int AirportDocument2 pagesCase Studies - Atlanta Int AirportMani KaruppiahNo ratings yet

- Case Studies - CA State UniversityDocument2 pagesCase Studies - CA State UniversityMani KaruppiahNo ratings yet

- Final DLCDocument2 pagesFinal DLCMani KaruppiahNo ratings yet

- Duranar XLPlusDocument2 pagesDuranar XLPlusMani KaruppiahNo ratings yet

- 60 Degree Gloss MeterDocument3 pages60 Degree Gloss MeterMani KaruppiahNo ratings yet

- DFTTB-000 Delfleet Evolution Technical Data Sheet Index 03112020 FinalDocument2 pagesDFTTB-000 Delfleet Evolution Technical Data Sheet Index 03112020 FinalMani KaruppiahNo ratings yet

- Discovery Center Lo ResDocument2 pagesDiscovery Center Lo ResMani KaruppiahNo ratings yet

- RE Poster - ModernDocument5 pagesRE Poster - ModernMani KaruppiahNo ratings yet

- Duranar XLDocument2 pagesDuranar XLMani KaruppiahNo ratings yet

- DFT-067 F3946 01302015 FinalDocument4 pagesDFT-067 F3946 01302015 FinalMani KaruppiahNo ratings yet

- Literacy Lesson 3Document15 pagesLiteracy Lesson 3Mani KaruppiahNo ratings yet

- Solved Land in Sonoma California Can Be Used To Either GrowDocument1 pageSolved Land in Sonoma California Can Be Used To Either GrowM Bilal SaleemNo ratings yet

- Final EssayDocument17 pagesFinal EssayfalakNo ratings yet

- Yawmc-0406-Us (2) Valvulas YarwayDocument8 pagesYawmc-0406-Us (2) Valvulas YarwayLuis Manuel VazquezNo ratings yet

- Establishing A Change RelationshipDocument10 pagesEstablishing A Change Relationshipravelyn bresNo ratings yet

- GR9 - Q4 - Lesson 1 - Motion in One DimensionDocument5 pagesGR9 - Q4 - Lesson 1 - Motion in One DimensionJerome HizonNo ratings yet

- Orifice Meter Is Type of Variable Head MeterDocument2 pagesOrifice Meter Is Type of Variable Head MeterMourougapragash SubramanianNo ratings yet

- Business English 4 - Teacher'S Lecture Notes: 2 Signposting - Page 8Document12 pagesBusiness English 4 - Teacher'S Lecture Notes: 2 Signposting - Page 8AndraStefaniaNo ratings yet

- Cacwacs Com Download Id 1259Document8 pagesCacwacs Com Download Id 1259Devesh RathiNo ratings yet

- Skill Development Sector - Achievement ReportDocument10 pagesSkill Development Sector - Achievement ReportShivangi AgrawalNo ratings yet

- BCG MatrixDocument18 pagesBCG Matrixsamm78992% (12)

- Company Introduction PDFDocument14 pagesCompany Introduction PDFJeff SmithNo ratings yet

- Badminton Is A Court or Lawn Game Played With Lightweight Racketsand AshuttlecockDocument14 pagesBadminton Is A Court or Lawn Game Played With Lightweight Racketsand Ashuttlecocktaehyung trash100% (1)

- Yanbu: Export Refinery ProjectDocument5 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- Orient Ship Management & Manning Pvt. LTD.: Licence No. RPSL-MUM-019 Validity: 15.02.20 21Document2 pagesOrient Ship Management & Manning Pvt. LTD.: Licence No. RPSL-MUM-019 Validity: 15.02.20 21anujNo ratings yet

- Spesifikasi Produk - Yumizen H500Document1 pageSpesifikasi Produk - Yumizen H500Dexa Arfindo PratamaNo ratings yet

- Nivel Básico de Inglés Septiembre 2016 Comprensión de Lectura Modelo de CorrecciónDocument8 pagesNivel Básico de Inglés Septiembre 2016 Comprensión de Lectura Modelo de CorrecciónEsther León JorgeNo ratings yet

- Homework 13.3.2024Document2 pagesHomework 13.3.2024vothaibinh2004No ratings yet

- Math NCF 268-293Document26 pagesMath NCF 268-293natureyt4No ratings yet

- CCS Field Setting The NZ Scene CCS ELA May 2013 Wellington Brad FieldDocument20 pagesCCS Field Setting The NZ Scene CCS ELA May 2013 Wellington Brad Fieldab1chfNo ratings yet

- Intermolecular Forces of Liquids and Solids Solids and Their Properties PDFDocument13 pagesIntermolecular Forces of Liquids and Solids Solids and Their Properties PDFpieNo ratings yet

- Veselin RmušDocument24 pagesVeselin RmušMato KankarašNo ratings yet

- Case Digests in PropertyDocument95 pagesCase Digests in PropertyRemelyn SeldaNo ratings yet

- Spare Parts Price List - DeluxeDocument13 pagesSpare Parts Price List - Deluxesrikanthsri4uNo ratings yet

- Download: Mosaic TechniquesDocument2 pagesDownload: Mosaic TechniquesJohnny LaounNo ratings yet

- Rman Standby Copy-2Document8 pagesRman Standby Copy-2SHAHID FAROOQNo ratings yet

- Hq004 Hq006 Oplusm Manual Rev BDocument7 pagesHq004 Hq006 Oplusm Manual Rev BadrianioantomaNo ratings yet

- Class 9th CBSE Blue PrintDocument2 pagesClass 9th CBSE Blue PrintYash BawiskarNo ratings yet

- Eastgate PDF BrochureDocument9 pagesEastgate PDF BrochurealincostinNo ratings yet