Professional Documents

Culture Documents

User Manual DC - 10000S

User Manual DC - 10000S

Uploaded by

Juan Pablo Hdez.0 ratings0% found this document useful (0 votes)

159 views78 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

159 views78 pagesUser Manual DC - 10000S

User Manual DC - 10000S

Uploaded by

Juan Pablo Hdez.Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 78

COLLATOR SYSTEM

DC-10000S

USER MANUAL

re eee eed

Duplo

eo

TABLE OF CONTENTS

1. Precautions 1

2. Names and Functions of the Components.....3

3. Names and Functions of the Control Panel

‘Components. a

4, Functions of the DIP Switches and Their Use... 10,

4-1, Tower Names and Setting the DIP

SWIYCHES nrreserre 10

4-2. Connecting the Towers and Setting

the DIP Switches. sett

4-3, Selecting the FUNCHONS ..nsnenennnne 12

5. Selecting the Paper Ejection Direction 15

6. Setting the Program Mode and

the Block Mode ...

7. Functions of the Program Modes and

Theit USE enn

7-1. Auto Mode,

7-2. 5-Bin Mode...

7-3. 10-Bin Mode

7-4. Alt All Mode

7-5. AltCover Mode

8. Functions ofthe Block Modes and Examples

of Their Use

8-4. Setting the Block Mode F

8-2, Example of Using the 1/2 Mode...

8-3. Example of Using the 1/4 Mode...

8-4, Example of Using the 1/3 Mode ..

9. Using the Cover Insert Mode...

9-1, Setting the Cover Insert Mode .....

9-2, Setting When to Insert Cover 30

9-3, Setting the Number of Volumes to be

Collated 31

10. Loading the Paper. 82

40-1. Precaution “

This lights up when only the set including a mis-fed paper sheet is conveyed

into the reject tray.

-

Check the set ejected last to the downstream processing machine as itis mis-

collated.

19

Error 2 lamp

-

This lights up when the machine stops operation after one set including a mis-

ted paper sheet has been conveyed into the downstream processing machine

and affer the next set has been conveyed to the reject tray.

Check the last two sets ejected to the downstream processing machine as

they are mis-collated

3, NAMES AND FUNCTIONS OF THE CONTROL PANEL COMPONENTS:

No. Item Fun

20 | Error 3 lamp Not used

at | Error 4 lamp Not used

22 | Door lamp ‘The door lamp on the relevant tower lights up when the vertical conveyance

board, conveyance bridge or lifting unit is open.

‘The machine does not work while this is lit.

23 | Empty lamp ‘The empty lamp on the relevant tower lights up when paper runs out on the

paper feed bin, and the machine stops operation.

24 | Feed lamp “The feed lamp on the relevant tower lights up when a double-feed, mis-feed or

paper jam is detected, and the machine stops operation.

28 | Paper jam lamp The paper jam lamp on the relevant tower lights up when the paper jams on

the conveyor, and the machine stops.

26 | Left connected unit. _| The left connected unit error lamp lights up when a problem arises in the

error lamp downstream processing machine connected on the left, and the machine

stops.

27 | Right connected unit | When an error occurs in the connected unit on the right, this lamp lights up and.

error lamp the machine stops operation except the jogger device (DC-12JR).

28 | Numbers ‘These are bin numbers.

29 | Paper lamp This lights up when paper is placed on the paper feed bin.

‘The paper lamp on the relevant bin goes on and off when the paper runs out,

and the machine stops.

30 | Double-feed lamp ‘The double-feed lamp (red) on the relevant bin blinks when a double-feed

‘occurs, and the machine stops.

31 | Mis-feed lamp ‘The mis-feed lamp (yellow) on the relevant bin blinks when a mis-feed occurs,

and the machine stops.

32 | Jam lamp ‘The jam lamp (red) on the relevant bin lights up when a paper jam occurs, and

the machine stops.

33 | Double-feed sensitivity | This switch adjusts the sensitivity of the double sheet detector according to

switch paper weight and type,

34 | Stop key Press this key to stop the machine.

35 | Start key Press this key to commence operation.

36 | Start lamp The start lamp lights up when the machine starts operation.

87 | DIP switches Refer to "a, FUNCTIONS OF THE DIP SWITCHES AND THEIR USE”.

4. FUNCTIONS OF THE DIP SWITCHES

AND THEIR USE

DIP switches are attached to the control panel.

DIP switches are set at the factory as follows:

OPEN OPEN

[ IN |

12345678 1234567899 |

DIP Sws DP swe

+ As shown in the figure, four DIP switches are builtin: DIP SW1, DIP SW2, DIP SW3 and DIP SW4.

Tower Names and Setting the DIP Switches

In setting a tower name to the installed devices, the DIP SW1 is set on each tower as follows:

Tower A Tower B Tower C Tower D Tower E Tower F

OPEN OREN

rr

ni Cy

123456 123456 123456 123456 123456 123456

DIP Swi DIP Swi DIP Swi DIP Swi DIP Swi DIP Swit

10

4, FUNCTIONS OF THE DIP SWITCHES AND THEIR USE

4-2. Connecting the Towers and Setting the DIP Switc!

DIP SWis set on Tower A. Connect the towers as follows:

Towers A,B, | Towers A,B, | Towers A,B,

F

Tower Aonly | Towers A&B |Towers A,B & C| C&D C,D&E C,D,E&

Oren ores [Tore on

aera | Inmet |

| | | |

12456 425456 t2oase| | [129456] | [12sese 129456

DP Swi Dip Swi DP Swi pesmi | (IP Swi DIP Swi

"1

4, FUNCTIONS OF THE DIP SWITCHES AND THEIR USE

* The following functions are selected with the DIP SW2.

‘OPEN

72345678

DP swWa

Setting the switch

SW No. Functions Down Up Factory setting

(numerats) (open)

1 | DC-8o00s sT Yes No Up

2 | DC-8000S ST sideways vibration Yes No Up /—

3 | Use of LU-HM manual feed unit (A) Yes No Up

4 | Use of LU-HM SW a) Yes No Up

(Valid when switch 8 is set to the

“numerals” side.)

5 | Change in LU-HM solenoid timing (A) Yes No Up

6 | Connecting DBM-100 or DBM-200 (A) Yes No Up

7 | Notused Up

8 | Double-feed detection % switching Yes No Up

* LU-HM timing adjustment .. shift +0

Initial value: 3

When the switch is pressed, switches in the following order. 4-5 -6>7-+8-+ 12-3

Double-feed detection % switching shift + 4

Initial value: 20%

When the switch is pressed, switches in the following order. 25%>33%-*50%—> 12% >

16% 20%

* (A) indicates that only the settings for tower A are valid.

12

4, FUNCTIONS OF THE DIP SWITCHES AND THEIR USE

The following functions are selected with the DIP SW3.

OPEN

B

45078

DIP Sw3

Setting the switch

SWNo. Functions Down Up Factory setting

(numerals) (open)

1 | Buzzer sounds when ended in error Yes No Down

2 | Counter repeated a) Yes No Up

3 | Conveyance jam detection Yes No Down

4 | Separator B used Yes No Down

5 | Notused Up

6 | Stops at paper feed errorset? (A) 2 sets 1 set Down

: Downstre

7 _ | Elected to side ? when reset A) |processing machine| _Relect tray Down

8 | Main clutch tums on simultaneously (A) No Yes Down

* (A) indicates that only the settings for tower A are valid.

13

4, FUNCTIONS OF THE DIP SWITCHES AND THEIR USE

The following functions are selected with the DIP SW4,

A feed error detecting device is built into the conveyance way on each paper feed bin.

The DIP SW4 is used to detect whether the paper feed error detection function (detecting a

double-feed, mis-feed or paper jam) is effective or not.

This function is selected on each tower.

‘OPEN.

CUI

12345678910

DIP Swe

Setting the switch a

sw 7

Functions Down Up setting

(numerals) | __(open)

1 | Paper feed error detection function on paper feed bin No.1 | Effective | Ineffective | Down

Paper feed error detection function on paper feed bin No.2 | Effective | Ineffective | | Down

Paper feed error detection function on paper feed bin No. Effective | Ineffective | Down

3

4. | Paper feed error detection function on paper feed bin No.4 | Effective | Ineffective | | Down

5

5 | Paper feed error detection function on paper feed bin No. Effective | Ineffective | Down

6 | Paper feed error detection function on paper feed bin No.6 | Effective | Ineffective | Down

7 | Paper feed error detection function on paper feed bin No.7 | Effective | Ineffective | Down

'@_| Paper feed error detection function on paper feed bin No.8 | Effective | Ineffective | Down

‘9 | Paper feed error detection function on paper feed bin No.9 | Etfective | Ineffective | Down

40 | Paper feed error detection function on paper feed bin No. 10| Effective | Ineffective | Down

14

5. SELECTING THE PAPER EJECTION

DIRECTION

Select the paper ejection direction: to the right or left.

* The left ejection is initially set and displayed

when the power is turned on.

+ Every time the “6” key on the keypad is

pressed with the shift key held down, the

paper ejection direction is switched and the

display shows right or left repeatedly.

* When DC-8000S RD is not connected, it will not be

switched,

* When the right ejection is selected with two

‘or more towers connected, only the paper on

the last connected tower is ejected to the

right.

The paper on the other connected bins is not

fed.

* The block mode and some of the program

modes cannot be used when the right

ejection is selected.

Refer to the list below.

exit option

al fe

Program mode

‘Auto | 5-bin | 10-bin | Altall {Alt cover|

» |of| 0 x x | o}]o

3 -

2|12| 0 x x x x

|i] x x x |>x x

o

wa] x x x x x

Ozcan be set X=cannot be set

6. SETTING THE PROGRAM MODE AND

THE BLOCK MODE

‘Some of the program modes and block modes cannot be used according to tower connecting

conditions.

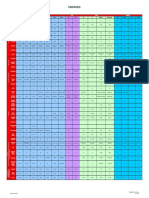

The following are connected towers and the availability of setting the modes

Hin the case of Tower A only

Hin the case of Towers A and B

pega

aulo. Shin 10bin_altall_alt cover

ai eee eee

Bock

we 1

oo

Program mode

Auto | S-bin | 10-bin | Altall Alt cover

el#}o]|o}x|ol]o

Blwlolx |x |x |] x

x

g || x x a x x

a

wa} x x x x ee

O-can be set X=cannot be set

pogam ;

‘aulo Skin. —10bin_altall_ all cover

oo -w oo

ck

2 mw ou

ooo 6

Program mode

‘Auto | S-bin | 10-bin | Alt all |Alt cover

[afro |.o |o | o]|o

3

2|12]| 0 O° x °O O°

x

8 jw} x x x x x

o

| O x x x x

Oscan be set X=cannot be set

16

6. SETTING THE PROGRAM MODE AND THE BLOCK MODE,

Min the case of Towers A, B and C

TowerA TowerB Tower program

= auto, 10bin alt all_alt cover

ce a ooo

co

Black

IK

es

‘Auto 5-bin | 10-bin | Altall | Alt cover!

al oflolololo

3 2 x x x x x

$iwlololx|olo

® 4 x x x x x

Osean be set X=cannot be set

Min the case of Towers A, B, C and D

program

auio Stn altallaltcover

oo o

Beek

of =

gees eee el

Program mode

Auto 10-bin | Alt all |Att cover

: off | O fe) oO O° °

. : w}o{of;oj|olo

- x

~ 1Ziw] x x x x x

~|a

wa) O oO x O oO

O=can be set X=cannot be set

7

|

6, SETTING THE PROGRAM MODE AND THE BLOCK MODE,

Min the case of Towers A, B, C, D and E

Tower A

Tower ToworE

Ee

Ee

TH

SHAN

5 o sooo OO

Program mode

‘Auto | 5:bin | 10-bin | attatt [art cover

~ja| of x |x | xfo

Bla] x | x | x [x | x

Blas] x x x x x

=Talx |x lx fx [x

O=can be set X=cannot be set

Win the case of Towers A, B, C, D, E and F

— r | Ex — Ez

E = PLE Ble

| cE f t | Ee | EE) ee

EFIE|El|E| EIB

JE\EIBIBIBIE

Ca SO OR OOO

Program mode

‘Auto S-bin | 10-bin | Alt all | Alt cover!

o [of O° x x x °

8 2 x x x x x

3 3 x x x x x

® V4 x x x x x

Oscan be set X=cannot be set

18

6. SETTING THE PROGRAM MODE AND THE BLOCK MODE

iin the case of the right ejection

Program mode

‘Auto | S-bin | 10-bin | Altall |Alt cover

» [of] O x x Oo °

3 ww} O x x x x

3 13 | x x x x x

* aa] x x x x x

Oscan be set X=cannot be set

19

7. FUNCTIONS OF THE PROGRAM MODES

AND THEIR USE

Five kinds of functions are programmed for the paper feed method in this collator system.

Select a most suitable program mode according to conditions.

If the program mode is used when there are only a few collating pages, the processing speed

will increase.

* “Auto” mode is set when the power is tuned

on.

* Press the “3” key on the keypad with the shift

key held down to select the program mode.

* Every time the “3” key on the keypad is

pressed, the program mode display shows

5-bin, 10-bin, alt all, alt cover Auto and

repeats them.

Program

EEL ; Depending on tower connecting conditions, some of the program modes cannot be selected.

For further details, refer to “6. SETTING THE PROGRAM MODE AND THE BLOCK MODE”.

LG else ceded

All the sheets of paper on the paper feed bins

are fed.

program

Wey mae ols od

All the paper feed bins are divided into blocks

‘one of which consists of 5 bins, to feed and

process paper on the 5 bins as a block.

This mode is suitable for printed matter of 5

pages or less.

mam

auto Shin t0bin

ao oa

alt cover

o

20

Tower A

Tower 8

i es

7. FUNCTIONS OF THE PROGRAM MODES AND THEIR USE |

7-3. 10-Bin Mode

|

|

All the bins are divided into blocks (one block ToworA Tower

consists of 10 bins) to feed and process paper

on the 10 bins as a block.

This mode is suitable for printed matter of 10

pages or less.

Program

Tie Aes

* The paper is fed from either bin of a pair 5

consisting of an even and uneven number of er

bins.

The paper is fed preferentially from the

upper bin.

rogran

* Feeding is switched to the lower bin when

the paper runs out on the upper bin.

a

7. FUNCTIONS OF THE PROGRAM MODES AND THEIR USE

EN Teele

* The paper is fed from either of paper feed ‘rogram

bin No. 1 or No. 2. ee an alt all alt cover

* The paper is fed preferentially from bin No.

1, and feeding is switched to bin No. 2 when

the paper runs out on bin No. 1.

The paper on bin No. 3 or the following is fed

accordingly in order.

TowerA Tower B

22

8. FUNCTIONS OF THE BLOCK MODES

AND EXAMPLES OF THEIR USE

There are three block modes: 1/2 block mode, 1/3 block mode and 1/4 block mode.

All the feed bins are divided into the designated block by selecting the block mode (1/2, 1/3, 1/4),

to commence feeding by block.

The time for placing the paper is shortened with this function when the number of sets to be

collated is small. (While the machine is running, paper can be loaded in the block which is not

working.)

Select a block mode referring to examples of the following cases.

Sau

« The block mode is off when the power is (Bak

tumed on. oa

HHSo

©

TRUM =e a ced d

* The “1/2" display lamp lights up and “1/2”

block mode is set when “4” on the keypad is

pressed with the shift key held down.

Every time “4” on the keypad is pressed with

the shift key held down, the block mode

display shows 1/2, 1/3, 1/4, Off, and repeats

‘them.

Depending on ones oer conitons, some ck modes ae usable

Portus dart t"6 SETTING THE PROGRAM MODE AND THE BLOCK MODE"

Ps a ka

I Press the “4” key on the keypad with the (Bc z

shift key held down to select the block o =

mode.

+ In case 1/2 block mode is set

+ The paper feed bins are divided into two blocks,

Nos. 1 and 2, to perform feeding by block.

23

8. FUNCTIONS OF THE BLOCK MODES AND EXAMPLES OF THEIR USE

2 designate from which block to

‘commence operation.

+ Commence operation from Tower A.

+ Two block selection display lamps light up on

Tower A, when the “5” key on the keypad is

pressed with the shift key held down,

+ Collation starts to be processed from block No. 1 on

‘Tower A when the start key is pressed.

+ When the paper runs out on block No. 1, the

machine stops and the block selection display is

switched to Tower B.

+ Press the start key to restart operation in block No. 2.

Tower A

Tower 8

24

8. FUNCTIONS OF THE BLOCK MODES AND EXAMPLES OF THEIR USE

Example of Using the 1/4 Mode

I Press the “4” key on the keypad with the fie years

shift key held down to set the block

mode to “1/4”

«+ All the bins are divided into 4 blocks Nos. 1 to 4 to

feed and process the paper on the feed bins by block

as shown in the figure.

Bleck

8, FUNCTIONS OF THE BLOCK MODES AND EXAMPLES OF THEIR USE

2 Designate from which block to

commence operation.

* Commence operation from block No. 1

‘+ When the “5” key on the keypad is pressed with the

shift key held down, the lower block selection lamp,

(Block No. 1) on Tower A lights up.

+ Collation starts to be processed from block No. 1 on

‘Tower A when the start key is pressed.

+ When the paper runs out in block No. 1, the

machine stops and the block selection display is

switched to the upper block (block No. 2) on Tower

A

+ Press the start key to restart collation in block No. 2.

‘+ When the paper runs out in the block, the block

display shows No. 1, No. 2, No. 3, No. 4, and then

repeats them.

‘lock select

8, FUNCTIONS OF THE BLOCK MODES AND EXAMPLES OF THEIR USE

Example of Using the 1/3 Mode

This mode is set when three towers are connected.

I Press the “4” key on the keypad with the

shift key held down to set the block

mode to “1/3".

TowerA Tower Tower

+ All the bins are divided into 3 blocks Nos. 1 to 3 to

feed and process the paper on the feed bins by

block.

Bleck

os

ar

Designate from which block to

‘commence operation.

+ Commence operation from block No. 1

+ When the “S” key on the keypad is pressed with the

shift key held down, the blocks are selected in the

order [PB-"C—rA- each time the key is pressed.

+ Collation starts to be processed from block No. 1 on

‘Tower A when the start key is pressed.

+ When the paper runs out in block No. 1, the

‘machine stops and the block selection display is

switched to Tower B (block No. 2).

+ Press the start key to restart collation in block No. 2.

+ Every time the paper runs out in the block, the block

display shows No. 1, No. 2, No. 3, then repeats.

28

‘8. FUNCTIONS OF THE BLOCK MODES AND EXAMPLES OF THEIR USE

‘lock select

9. USING THE COVER INSERT MODE

This mode is used to collate printed matter with a cover.

9-1. Setting the Cover Insert Mode

This mode is initially set OFF when the power ‘cover insert

is turned on.

Ow

T setthe program mode to “Auto” mode. rogram

alo hin 10bin alta altoover

“oo oo

2. Press the “7” key on the keypad with the & © © oO

shift key held down to select any mode.

oe © ©

+ Every time the “7” key on the keypad is pressed

with the shift key held dow, the display shows eee ©

OFF, 1, 2, then repeats.

‘+ When the cover insert mode | is selected, one sheet

of cover paper is inserted as shown in the figure.

aaa D> = Som

Cover 1

+ When the cover insert mode 2 is selected, two

sheets of cover paper are inserted as shown in the po

figure.

coverinser

of 4 2

oo ‘Cover 2

‘Covers

~cover2

9. USING THE COVER INSERT MODE

9-2. Setting When to Insert Cover

Determine the number of sets after which the

cover paper is inserted.

L input the number of sets on the keypad

with the set qty key held down.

‘cover inser

2 For example, input 5 on the keypad to

insert a cover into every 5 sets.

+ The input number of sets is displayed on the display

‘window while the set qty key is pressed.

+ The maximum number of sets is 999.

+ When the cover insert mode is set to “1”, the cover

‘paper is inserted at the following intervals.

+ When only one tower is used, one set consists of 9

sheets of paper.

+ A sheet of cover paper is inserted into every 5 sets.

1 Volume )

2 Volumes:

9. USING THE COVER INSERT MODE

es

Setting the Number of Volumes to be Collated

Take the following procedures to input the

number of volumes to be collated with cover

inserted.

* Input the value of sets to be collated on the

keypad.

Calculate the value to be input as follows.

! Number of sets X Required volumes:

Input value (Number of volumes processed)

For example, if 100 volumes of 5 sets (the cover is

inserted after every 5 sets) are required, input 500

from the above equation,

* For the cover insert mode, the machine will stop if a

paper feed error occurs in one set regardless of the

setting of DIP SW3-6.

31

10. LOADING THE PAPER

* Thick paper such as covers should be

loaded on the first and second, or ninth and

tenth bins.

* Make sure that the ink on the paper surface

is dry.

* Be careful not to use the paper with wet ink

on it as this may dirty the paper, ink rub off

on the conveyance way and this may cause

problem

* Curled or folded paper should be flattened

before use.

* The folded paper should be pressed even

and be flattened before use.

* Stack the paper from the right side of the

paper feed bin so that the paper does not

damage the paper switch.

aly

eR kisi

When only one tower is used:

I Load paper with the printed surface up.

2 when the number of sheets to be

collated is 10, load the last page on bin

No. 10 with the printed surface up, from

the bottom in order.

‘+ As shown in the figure, load the last page on paper

feed bin No. |, from the top in order, when the

right ejection mode is selected.

+ Refer to “10-5. Precautions to be Taken in the

Right Bjection Mode”

33

10, LOADING THE PAPER

mired eukereetien

Printed suriace

410. LOADING THE PAPER

When two towers are connected

1 when the number of sheets to be

collated is 20, load the last page on bin

No. 10 on Tower B from the bottom in

order as shown in the figure.

2 when the number of sheets to be

collated is 14, load paper as shown in

the figure.

MPT amos

Cover insert mode 1

1 itacoveris inserted into every xxth sets

one of which consists of pages, load

cover paper on the bottom bin.

2 When two or more towers are

connected, also load the last page on

the bottom bin of the last connected

tower already containing paper.

Tower B

age

13 page

1 pa

xx: Insertion interval of cover

\\

\B:

Cover ES the tt sot

When the block mode is used

* The cover can be inserted by using the block mode function.

* Take the following procedures to set the block mode to “1/2” with two towers connected:

T ‘cad cover paper on the bottom bin of

each tower already containing paper as

shown in the figure.

2. Press the “5” key on the keypad with the

shift key held down to designate the

tower to operate.

+ When Tower A is designated, collation operation

start from Tower A.

+ When the paper runs out on Tower A, the machine

‘stops and collation operation is switched to Tower B.

When the cover insert mode 2 is selected

* Load cover sheets on the upper and lower

bins so that they are inserted to cover the

top and bottom sets as shown in the figure.

10. LOADING THE PAPER

1x: Insertion interval of cover

A,

ASS the sat sot

The fst set

Cover 1

10, LOADING THE PAPER

a

I ‘cad thick paper on bins Nos. 1 and 2, 9

or 10 on the tower.

2. switch the conveyance pressure.

“= There is a hole on the non-operating side frame as

shown in the figure. Insert the hexagonal wrench

into these holes and rotate it at an angle of about

180" in the clockwise direction.

TE3: Do not attempt to insert the hexagonal

wrench into the machine while it is

working,

Return the conveyance pressure to its initial

state when thick paper is replaced with normal

| paper. Conveyance pressure is set to the

ressure for feeding normal paper at the factory.

3 switch the double-feed sensitivity switch

down on the bin on which thick paper is

loaded.

36

kk me Cumann ln muna sce

Sar bei tik peer

Thick paper

RB

&

Normal papor

LY || [> |Hexdgonal wrench

ie i

Double-feed sensitivity witch

10, LOADING THE PAPER

L

Precautions to be Taken in the Right Ejection Mode

When this mode is selected, the paper is

ejected reversely and the printed surface is

down.

panei Printed surtaco

37

11. OPERATION PROCEDURES

1 Connect the power supply for the dry

pump.

Dry pump

*+ Connect the communication cord of the pump to the 7

collator,

—

f

|

2 Connect the power supply for each

tower main body.

3 > Tumthe power for each tower ON.

Tum th ower or Tower A ON st

38

Switch the valve opening/closing

according to paper size.

+ Refer tothe list of the valve opening/closing.

+ There are five valves as shown in the figure.

+ The state of the valve opening/closing is shown

below.

11. OPERATION PROCEDURES

Vawve: closed

Valve: opened

\

Shutter I i

WEE ME [i

=H = “

vate E VaveD Vale VaNe® valve A

11 Una (as tateran

ty atera

|| pecesinwan

[AS (At latoray

5 my a3 ‘ABSR BS Ba

Valve | lateral |longitudinal| longitudinal longitudinal) lateral _|longitudinal

feeding | feeding | feeding | feeding | feeding | feeding

A Oo Oo O° oO oO oO

B O° ° O° Oo oO Oo

c Oo oO ° fe) O° oO

D x x x x Oo O°

E x x ° ° x x

Invoice | Letter [Doubleletter] Legal

Valve | lateral | longitudinal] tongitudinal longitudinal

feeding | feeding | feeding | feeding

A fe) Oo oO O°

8 fe) Oo oO oO

c oO oO Oo oO

D x x ° x

E x x x x

(O: switch to open: switch to close

39

11, OPERATION PROCEDURES:

5 Move the sub-guide's position according

to paper size.

Inn te bude ithe sae poston

rarer aioe

6 Move the reject tray stopper position

according to paper size.

7 Set the paper guide to the standard

position “Level 3".

+ Adjust the paper guide according to paper feeding

conditions as follows:

‘Standard position: “Level 3”

‘When mis-feed occurs: “Level 2" or “Level 1”

When a double-feed occurs: “Level 4”

Paper guide switch

7 Tongiuaral

5 format \ 360 nasi)

As Gongitudinaly, \

i ii

{Conveyance bors jj

\

===

i

Sub guide

Reject ray

il

g

i

‘i

>]

q

|

Ib,

i

2)

|

APSe] Rea

aft

Ss

Ss

Od

Paper guido

[When mis-feed occurs]

40

Levet3 Level 4

t I

[Standard position] [When a double-feed occurs}

Adjust pad height with the adjusting

knob.

+ Adjust the suetion pad position so that the pad is in

the center ofthe brush and the paper feed bin.

+ The pad goes up when the knob is rotated in the

clockwise direction, and it goes down when the

knob is rotated in the counterclockwise direction.

+ Move the suction pad up little by litle by rotating

the knob in the clockwise direction when a double-

feed occurs.

+ Move the suction pad down little by little by

rotating the knob in the counterclockwise direction

‘when mis-feed occur.

a

11, OPERATION PROCEDURES:

‘Sustion pad

‘Adjusting knob

hy

Bes

ic

iS

[Adjusting knob

11, OPERATION PROCEDURES

9 Determine the bin pressure switch lever

position according to paper quality.

+ Set the lever position referring to the list below.

List for setting the bin pressure switch lever

i, Fine quality paper

A4 A4 A3 A3

Paper size | 52.3 gi? | 157g /m? | 52.3g/m* | 157 gim?

Setting bin

Pressure : J 2 :

* The standard bin pressure is the pressure with paper of 55 mm loaded on the bin.

Coated paper

F Aa Aa | AS. A3

‘aper siz°| 79.1 gim? | 157 g/m? | 79.1 g/m? | 157 gm?

Setting bin] 3 | 2 | 2

pressure

10 Close the three holes with the shutter.

+ Slide the shutter sideways and open the hole step by

step to adjust the suction pressure when a double~

feed occurs.

42

11. OPERATION PROCEDURES:

1 Press the paper feed bin key to lower the

paper feed bin.

12 Load paper

+ Load paper with the tip of the paper in contact with

the guide plate after it is separated

* Attach the comer guide lightly tothe rear end of the

paper as shown in the figure.

13 Press the paper feed bin key to lift the

paper feed bin.

Make sure thatthe paper on the bi sin

contact with the stopper when the paper

feed bin moves up and stops inthe top limit

position

If the paper onthe bin is notin contact with

the stopper, increase the bin pressure.

11, OPERATION PROCEDURES:

14 Processing speed is set to the maximum

when the power is turned on. Adjust the

processing speed according to paper

ejection conditions.

+ Press the “I” key on the keypad with the shift key

held down to switch the processing speed.

+ Every time the “1” key is pressed, the display is

switched to the direction of (-).

15 petermine the paper ejection direction. ‘it opton

«Teton dreton isin tothe hen te

the power is turned on.

+ Press the “6” key on the keypad with the shift key

held down to switch paper ejection direction.

+ Every time the “6” key is pressed, the paper

jection direction is switched.

16 Determine the program mode.

+ The mode is initially set to the “auto”, when the

power is turned on.

+ Press the “3” key on the keypad with the shift key

held down to switch the mode.

+ Every time the “3” key is pressed, the mode is

switched,

17 Determine the block mode.

* The block mode is set to “off” when the power is

turned on,

+ Press the “4” key on the keypad with the shift key

held down to select the block mode.

+ Every time the “4” key on the keypad is pressed, the

‘mode display is switched,

44

11, OPERATION PROCEDURES

+ The cover insert mode is set to “off” when the

power is turned on. Start operation to perform

normal collation operation.

+ Set the cover insert mode as required to perform

collation with cover inserted.

+ Press the “7” key on the keypad with the shift key

held down to select the mode.

‘+ Every time the “7” key on the keypad is pressed, the

mode display is switched.

For further details, refer to “9. USING THE !

! COVER INSERT MODE”,

19 Select the double-feed sensitivity switch.

* Set the switch up when paper thickness is 157 g/m?

or less, Set the switch down when paper thickness is

157 g/m? or more.

+ Set the switch to “off” to cut the double-feed

detection function when the following paper is mis-

detected.

folded paper

colored paper

@ paper printed within a margin of 10 mm from

the detective seetion.

ene sin oes aap ee

Ab faa wi prick

11, OPERATION PROCEDURES

20 Press the reset key.

+ One set of sheets of paper is ejected. Check whether

the set is normally collated,

Select the ejection direction with the DIP !

! switch: to the reject tray or to the downstream |

! processing machine.

For further details, refer to “4. FUNCTION OF

‘THE DIP SWITCHES AND THEIR USE”.

+ Check and adjust the following sections when @

double-feed or mis-feed occurs.

© Paper guide section

@ Pad height

© Bin pressure

@ Shutter section

© Switch the double-feed detective sensitivity.

* Some types of paper are not applicable to the

standards described in the item (19). Set the

sensitivity switch to the suitable setting

according to paper type.

‘The reset key can be used when the set qty

isplay is “0”.

Note that the reset key cannot be used when “O”

snot displayed

| When the double-feed error is displayed while resetting,

indicates thatthe data of the paper of that bin could

} not be read properly. Check the double-feed detection sensitivity SW and reset again.

11, OPERATION PROCEDURES:

21 input the number to be processed.

+ Input the number to be processed on the keypad. iia

‘The number to be processed input will only be

22 Press the start key to commence

operation.

47

12, FEEDING SMALL PAPER oonty wien pen-200 is CONNECTED)

When feeding paper less than 7.88 inch wide, change the air feeding position with the

separator shutter as shown in the figure.

$3 : Paper less than 7.88 inch wide can be fed only when DBM-200 is connected. In this case, use the corner guide

provided with DBM-200.

‘Separator shutter

Paper feed bin

l ‘Separator pipe

_ TS z

Y CT a

@

iat

‘Separator shuter

Paper food bin

‘Separator pipe

\ ‘Separator shutter

2S |,

Paper feed bin

48

13. USING THE LU-HM

The LU-HM feeds paper automatically when inserting several sheets (below 10) of paper

manually.

13-1. Manual Mode 1

I Push 3 and 4 of DIP SW2 of tower A OPEN

down (numerals).

This mode can be used only for the “Aut

} mode and when the block mode is off.

* When set to the manual mode, the first digit

will blink.

2 Adjust the HM section paper guide to the

size of the paper.

3 insert the auxiliary table into the square

holes according to the size of the paper

as shown in the figure.

4 Press the start key of the tower to start

the machine.

+ Set collated sets (less than 10 sheets) in the HM TT

/

section. I /} y fo. of paper

{The tower wl stand od paper unl paper a

bis set in the HM section. 4

: se > [RSJ

18. USING THE LU:HM

5 Paper will be fed from the tower when

the paper switch of the HM section is

pressed.

+ The claws of the HM section will open, and sets of

paper from the HM section and the sets of paper

from the tower will be combined in the conveyance

route.

13.

13. USING THE LU-HM

Manual Mode 2

This mode allows sets of paper to be set in the HM section according to the paper feeding

operation. Therefore, its efficiency is higher than mode 1 as more sets of paper can be

processed.

1

Push 3 of DIP SW2 of tower A down

(numerals).

* When set to the manual mode, the first digit “d.p”

will blink.

Adjust the HM section paper guide to the

size of the paper.

Insert the auxiliary table into the square

holes according to the size of the paper

as shown in the figure.

Press the start key of the tower to start

the machine.

+ Set paper in the HM section according to the paper

feeding operation of the tower.

ss of

nether there are sets of paper in the HM

51

OPEN

12345678

DIP Swe

14, SUPPLEMENTARY OPERATION TO BE PERFORMED

WHEN THE MACHINE IS IN OPERATION

SP reir Mawel Lem RoC IM NLL LS Kee

Press the T key to check the accumulated

total number “300” of sets collated.

| displayed on the display window while the

| key is pressed,

Once the power is turned off, the number

becomes 0.

Check the number of sets rejected to the

reject tray as follows.

* Press the T key with the shift key held down.

The number of sets rejected is displayed on

the display window while the T key is

pressed.

The display in the figure on the right

indicates that 12 sets have been rejected.

“The counter can be cleared using “Shift” + “T”

(approx. 1 second)

14-3. Decreasing Processing Speed

* Press the “1” key on the keypad with the shift

key held down.

Every time the “1” key on the keypad is

pressed, the display moves in the direction

of (-) and processing speed of the machine

is decreased

n type of the downstream

machine, the paper conveyance

be widened.

FRleaED ; Stop operation to decrease processing speed.

52

44, SUPPLEMENTARY OPERATION TO BE PERFORMED WHEN THE MACHINE IS IN OPERATION

14-4. Changing the Overlap Volume in Conveying Pape!

Change the overlap volume in conveying paper so that the ejected paper is in alignment, when

the ejected paper is not in alignment.

Take the following procedures to change the overlap volume.

* Press the “2” key on the keypad with the shift

key held down.

Every time the “2” key on the keypad is

pressed, the display moves in the direction

of (+) and paper conveyance intervals is

widened.

(TERE: Stop operation to switch the intervals

* Overlap amount and conveyance intervals

are listed below:

(eS: The following overlap amounts will differ

according to the downstream processing

machine connected.

— ey fe ovetan

ono + (Countermeasure)

‘© When the mact

start operation

ls “0” displayed on the display Input the number of sets

Mirco lore nombeset ro,

saa?

| -((tetne jam iano i? aor th je pape ae

- Fev ie anid pparas

+(iineaanerrenpine (bemoan ened as

SEmmaRD Bye sash.

| _ (“Taine downaeam processing») (“Chockas oui araes one

takin oor am wear pense maine.

cae Baleio FUNCTIONS OF

L-(nemenrremanesset >) 5 (Se Symrcaes ans

THER USE

‘When mis-feed occurs too

often

-=(istepatheh over} (Bae erATON =)

| Isthe valve setto "Close"? |e Set the valve to “Open”.

Is the pump pressure lower )

[7 than the standard value? ‘Adjust the pump pressure.

Is the bin pressure switch Refer to “11. OPERATION

(lever set to the right position? PROCEDURES.”

3 The mis-feed lamp lights up

when the paper is fed

correctly

‘Does the paper sip on the

1=( conveyance rubber roler Clean the rot.

Section?

Le-(_ Is the paper conveyed askew? Load paper in alignment.

18, TROUBLESHOOTING GUIDE

Cc State > ie Check > (C Countermeasure)

Is the paper guide attached Refer to"11. OPERATION

correctly? PROCEDURES.”

Le (“en snort corecty? Rute tt1, OPERATION

¢ @wnen a double feed occurs ny

ih

(@eaperie ea normaly butte»), (te theresa! operation Perform the reset operation

double-feed lamp lights up performed in advance? when the paper is replaced.

Is the double-feed detection Refer to “11. OPERATION

F(_ sensitivity switch set property? J—*-\_ PROCEDURES.”

+=( Has paper boen conveyed

prodier' } (Load the paper neatly

Le(_ Set the double-feed detection sensitivity switch to “Off.

4

(e When “E-C1LT are displayed }—=-( Contact the dealer in your area.

or

L/

19. EVERYDAY CLEANING

When the conveyance rubber roller, conveyance roller and conveyance belt become dirty with

ink or paper shreds, they may cause mechanical trouble or malfunction. Clean the machine

once a month.

Clean the machine with a soft cloth wet with water or synthetic detergent.

@ Cleaning the conveyance rubber roller @® Cleaning the conveyance roller

@ Cleaning the vertical conveyance

Tuber roller

20. CHECKING AND MAINTENANCE OF

THE DRY PUMP

T the gauge pressure of the dry pump is Roa porer

set in advance as follows:

Exhaust pressure: 0.5 kgf/cm?

Suction pressure : 20cm Hg

GELS : Do not operate the machine in the higher

pressure than the above as that is

dangerous.

Suton peaua el =) aha ss tr

2 When the dry pump filter is clogged, the

gauge pressure does not change but

feeding performance may be

deteriorated.

Contact the dealer in your area.

69

21. SPECIFICATIONS

Model Dc-10000s

Type Floor type

The number of sheets | 10 sheets/tower

to be collated

The number of towers | Six towers (max. 60 bins)

to be connected

Feeding method ‘ir suction method

Paper separator brush, air blowing method.

Conveyance system

Twin roller belt system

Bin capacity Max. 2.16 inch

(Maximum bin capacity is 1.57 inch in case of less than 7.88 inch feeding width)

Paper | Min. '5.52X7.88 inch

size | Max. 18.77X19.68 inch

Feeding width | 7.88 to 13.77 inch

Feeding length | 5.52 to 19.68 inch

(Minimum feeding width is 4.73 inch, only when connected DBM-200)

Paper quality Fine quality paper Bins Nos. 1 to 2, 9 to 10 52.3 to 250 g/m?

3108 52.3 to 157 g/m?

‘Stencil fine quality paper, medium quality paper

Art/coated paper 79.1 to 157 gm

Paper style ‘Sheet

Single-folded paper (less than 80 g/m®, 8 bins or less)

Double-folded paper (less than 80 g/m®, 4 bins or less)

Processing speed Max. 3000 setsihour (when L jogger (left ejection) connected, 10 sheets/iower used)

Max. 4700 sets/hour (when 5 bins in two or more connected towers are used in the

program mode with the jogger connected)

jogger (right ejection): max. 1980 sets/hour (when 10 bins used )

Mis-eed detection

Double-feed detection (2 settings or off) mis-feed detection paper jam detection

Other detection No paper detection, conveyance way paper jam detection, conveyance way door

functions openiclose detection

Error display Displayed on the control panel

Each tower door close/open, empty, feed error, conveyance error, downstream

processing machine error, empty bin, double-feed, mis-feed, paper jam

Counter Input on the keypad, 5-figure subtraction counter (repeat motion)

‘Additional functions

Cover insert mode

Program functions (5-bin cluster mode, 10-bin cluster mode)

Alternate all mode (2 bins to 1 bin)

Block functions (1/2, 1/8, 1/4)

Changing processing speed : 4 settings

Processing speed change according to downstream processing machine conditions

Paper intervals :4 settings:

Intervals change according to downstream processing machine conditions

Counter back up function

Paper thickness memorizing function:

‘normal paper, thick paper detection off, switching function

Double-feed non-detection on each bin

Non-multi-feed function

Double-feed, mis-feed paper jam non-detection function

Startistop switch

Jog switch, feed bin up/down switch

Ejection direction selection switch (left ejection: only Tower A)

Manual ON/OFF (only when DC-48SH 3 is connected)

Air blowing ON/OFF

Reject function

70

21. SPECIFICATIONS

Model Dc-10000S.

Dimensions [Main body | 29.93 (W)X27.56 (4)X80.52 (h) inch

2-connected | 64.57 (W)X27.56 (d)X80.52 (h) inch

S-connected | 99.22 (W)X27.56 (d) 80.52 (h) inch

4-connected | 133.86 (W)X27.56 (d)X80.52 (h) inch

S-connected | 163.39 (W)X27.56 (d)X80.52 (h) inch

_|6-connected_| 198.04 (W)X27.56 (d) 80.52 (h) inch

Mass

(weighty [Main body | 617 1b

Power “

a Main body | 120 v “S96 60 Hz

Acoustic | Main body (4) | The measurement method - Based upon EN 27779

Noise | LU-HM 4

Do-soons P (2) Front Back Left Right

DC-48SH 3 77.248 (A) 76.0 dB (A) 74.8 dB (A) 76.5 dB (A)

Acoustic | Main body (3) | The measurement method - Based upon EN 27779

Noise | LU-HM

¢-8000S P (2) Front Back Left Right

DC-48SH 3

DC-4aF 3 77.7 dB (A) 77.248 (A) 76.0 dB (A) 75.2 4B (A)

DC-48T 3

* Main body (4) means when four units are connected, Main body (3) means when three units are connected.

DC-8000S P (2) means two of use.

Specifications and dimensions are subject to change without prior notice for improvements.

a

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BA - NoLabel - PIM C85-C120Document20 pagesBA - NoLabel - PIM C85-C120Juan Pablo Hdez.No ratings yet

- G&J ClaenOut C85-C120 PreInstall InglesDocument17 pagesG&J ClaenOut C85-C120 PreInstall InglesJuan Pablo Hdez.No ratings yet

- Tabla de Programación de Parámetros de G&JDocument1 pageTabla de Programación de Parámetros de G&JJuan Pablo Hdez.No ratings yet

- G&J ClaenOut C85-C120 Manual Usuario EspañolDocument26 pagesG&J ClaenOut C85-C120 Manual Usuario EspañolJuan Pablo Hdez.No ratings yet

- G&J Raptor CFree Guia RapidaDocument2 pagesG&J Raptor CFree Guia RapidaJuan Pablo Hdez.No ratings yet

- G&J CleanOut+ BrochureDocument4 pagesG&J CleanOut+ BrochureJuan Pablo Hdez.No ratings yet

- Agfa Placas Digitales 2011 - 12Document1 pageAgfa Placas Digitales 2011 - 12Juan Pablo Hdez.No ratings yet

- Quick Installaton Manual Collator System 96F-92173-97030200M-0Document20 pagesQuick Installaton Manual Collator System 96F-92173-97030200M-0Juan Pablo Hdez.No ratings yet

- Instruction Manual Trimmer DBM-250T Collator Sistem (120V)Document36 pagesInstruction Manual Trimmer DBM-250T Collator Sistem (120V)Juan Pablo Hdez.No ratings yet

- Maintenance Manual Collator SystemDocument297 pagesMaintenance Manual Collator SystemJuan Pablo Hdez.100% (1)

- Installation Manual Collator System DC10000S, DC8000S RD, LU-HM, DC 8000S D (96f-92173-97030200M-0)Document20 pagesInstallation Manual Collator System DC10000S, DC8000S RD, LU-HM, DC 8000S D (96f-92173-97030200M-0)Juan Pablo Hdez.No ratings yet