Professional Documents

Culture Documents

Bioremediation of Seafood Processing Plant Effluent: Collection and Biochemical Analysis of Effluent

Bioremediation of Seafood Processing Plant Effluent: Collection and Biochemical Analysis of Effluent

Uploaded by

Anonymous CwJeBCAXpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bioremediation of Seafood Processing Plant Effluent: Collection and Biochemical Analysis of Effluent

Bioremediation of Seafood Processing Plant Effluent: Collection and Biochemical Analysis of Effluent

Uploaded by

Anonymous CwJeBCAXpCopyright:

Available Formats

Scholarly Research Journal for Interdisciplinary Studies,

Online ISSN 2278-8808, SJIF 2021 = 7.380, www.srjis.com

PEER REVIEWED & REFEREED JOURNAL, NOV-DEC, 2022, VOL- 10/74

BIOREMEDIATION OF SEAFOOD PROCESSING PLANT EFFLUENT:

COLLECTION AND BIOCHEMICAL ANALYSIS OF EFFLUENT

Mehta Samixa Rameshchandra1 & Jadeja J. Vasantba2

1

Department of Biosciences, Saurashtra University, Rajkot 360005

2

Shree M. & N. Virani Science College, Saurashtra University, Rajkot 360005

Paper Received On: 25 DECEMBER 2022

Peer Reviewed On: 31 DECEMBER 2022

Published On: 01 JANUARY 2023

Abstract

Microorganism bioremediation of seafood processing plant wastewater is a viable alternative to the

traditional effluent treatment technique of recovery and removal. Five seafood processing plants in

and around Veraval were sampled for waste water. This water was transported to lab in controlled

condition and were analysed for eutrophic component present and BOD, COD value evaluation. Soil

samples from the same places were collected for bacterial isolation. From them over 40 bacterial

strains were collected from five different seafood processing industry soil samples near Veraval.

Keywords: bioremediation,effluent treatment, eutrophic componenet degradation, bacterial isolates,

IMViC test

Scholarly Research Journal's is licensed Based on a work at www.srjis.com

Introduction: The world population is expected to continue to grow, which means that the

demand for food, water, and energy is expected to climb significantly. The availability of

fresh water is critical to the sustainability and safety of food. The utilization of fresh water in

current food production systems is a major issue, as is the environmental impact of the sector.

Global fresh water withdrawals, which include agriculture and livestock production, are

estimated to account for approximately 60% of the world's water use. In the next 30 years,

freshwater consumption for food and livestock production is expected to rise by 65 percent.

Wastewater from the processing of food contains a wide range of nutrients and other

important components. Wastewater discharged carelessly and without treatment is a leading

cause of pollution and other harmful effects on the environment. More than half of the

biodegradable organic matter in one-third of the food produced worldwide (1.3 billion tons)

is lost or abandoned, according to a recent estimate [2]. Proper treatment of wastes, including

effluents, is one way to combat pollution while simultaneously preventing the loss of food

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17940

Pg. (17940-17948)

constituents during manufacture of clean food. Increasing food production's overall economic

and environmental sustainability by recovering resources from waste streams is possible.

In order to offer consumers with a wide variety of fish and shellfish, the seafood business

relies on both traditional fishing methods and more modern farming techniques. 178.5 million

tons of seafood were produced around the world in 2018. (MT). Fish like tuna, herring, and

mackerel, crustaceans like shrimp, krill, crab, and lobster, bivalves like mussels and oysters,

and cephalopods like squid and cuttlefish are all examples of marine seafood. At 82.1 MT in

2018, aquaculture production has expanded at a pace of 5.8 percent per year since 2001.

Carp, tilapia, and shellfish are common farmed in fresh water, whereas Atlantic salmon, sea

bsssssass, and sea bream are farmed in salt water. Products such as chilled, frozen, smoked,

dried, fermented or marinated or other commodities make up roughly 78% of the industry's

entire crop. Chilled fish, finfish steaks, shrimp goods, and squirmy (mechanically deboned,

water washed minced fish meat) are some of the most popular consumer products that are

traded in a wide variety of marketplaces around the world. Both aquaculture and capture

fisheries play complimentary roles in enhancing the availability of seafood for nutritional and

health gains.

In spite of this, the available seafood isn't all being utilized. By-catch, garbage, and waste on

land all contribute to a huge number of wastes. About 40% of raw material is used to make

products such skins, heads and frames; viscera; fillet cut-offs; and others. Offal production is

being bolstered by the expansion of aquaculture plants. An estimated 8% of the world's

seafood production is lost each year, totaling 7.3 metric tons (MT) between 1992 and 2001.

Putrefaction is much quicker in fish waste than in municipal garbage because of the high

protein and other nitrogenous content. On a dry weight basis, the average protein content in

seafood wastes is 60 percent, the fat content is 19 percent, and the ash content is 21 percent.

Increasing fishing wastes, particularly effluents, pose expanding environmental challenges as

a result of the growing seafood industry. Solid waste is often disposed of in one of three

ways: in a landfill, as silage, fishmeal, or fertilizer, or as a component of animal or poultry

feed, depending on the material.

Aquaculture water use:

The fishing sector relies heavily on water. Capture fishing, cage and pen aquaculture, and the

harvesting of fry or juveniles for aquaculture all make use of fresh, brackish, or saline surface

waters to offer fish habitats. For aquaculture to be successful, a substantial amount of fresh

water is needed. The amount required depends on the type of aquaculture system used, the

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17941

Pg. (17940-17948)

species being farmed, and the location of the farm. Due to evaporation, farm water is also

lost. Sea bass farmed in cages can use up to 48, 782 m3 of water per ton, while spiny lobsters

use only 1.5 m3 and generic fish only 6 m3. Indirect uses of water include farming, aqua feed

production, and sanitation and hygienic maintenance of machinery and equipment, to name a

few. Cleaning, beheading, filleting, scaling, peeling, frying, icing, and other pre-processing

activities necessitate the use of water, as is the use of cold chain systems to keep fishery

products fresh throughout the handling process. Storage and transportation of raw and

finished products also necessitates the use of water. Approximately 10–40 m3 of fresh water

per tonne of processed raw material is used in the processing process. According to India's

current industrial water pricing, this comes to about $22 USD. Because surimi production

involves a lot of washing, it uses more water than other processes like canning and curing.

Marinated herring or peeled shrimp take about 7,000–8,000 and 50,000 liters of water,

respectively, to create one ton of each. There is a constant flow of effluents from the boiling,

filleting, and marination processes. Over 1500m3 of wastewater is produced daily by one of

Europe's largest herring processing plants, which processes about 50,000 tons of fish each

year. Figure 1 depicts the effluent generation process used in the seafood processing industry.

There is a worldwide worry about the amount of water used in the fish processing sector and

the amount of highly concentrated post-processing wastewater that is discharged. Despite the

fact that the seafood sector, including aquaculture, uses a lot of water, the cost-benefit

analysis of that water has gotten little attention. As the global demand for seafood rises and

aquaculture becomes one of the most rapidly expanding animal food industries, the'seafood

gap' in the food-water nexus is expected to become increasingly problematic. This

necessitates water conservation measures.

Fig1: Effluent generation during seafood processing

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17942

Pg. (17940-17948)

Waste water from the manufacture of fish meal is known to have a high organic load because

of this. Surimi washing wastewater has also been found to have a pretty significant organic

load. Bioremediation is not always possible due to the presence of diverse bacteria in

wastewater. There must be a high-quality, fast-growing inoculum that can suppress the

growth of heterotrophic microorganisms in wastewater to prevent contamination. Fish and

marine invertebrates have a lot of protein, which raises nitrogen levels in the water. In

processing plants, raw materials have a significant impact on effluent properties. When it

comes to the quality of raw materials, time has also been shown to have an effect on their

quality while nitrates and phosphates are commonly found in fish waste, their concentrations

are usually quite low. Phosphorus can also be introduced into the food chain through the use

of processing and cleaning chemicals. Fish meal production wastewaters are known to be

diluted with cooling water from the overall process prior to disposal if they contain high

concentrations of toxins.

Treatment of seafood industry effluents:

Regulatory bodies have imposed increasingly strict standards on effluent treatment,

particularly in terms of BOD, COD, and TSS values. Effective treatment is mostly

determined by the effluent type and quality (BOD/COD/TSS/FOG and the BOD/COD ratio).

The influent volume also plays a significant role in determining the most appropriate

treatment. Sustainable seafood processing, clean air, and water conservation are all tied to the

issues of wastewater treatment.

Primary treatments, such as screening and sedimentation, are first applied to the effluents.

Larger particles, such as bones and shells, are removed by screening. The nitrogen load was

lowered by pretreatment with a 0.8 mm filter and a two-stage flotation process. lipids and

hydrophobic sludge can form in the presence of FOG, causing blockage and hindering

sedimentation. It was possible to remove up to 40% of the suspended particles by using a

decanter as a physical pre-treatment device. The sludge removal system guarantees that

settled sludge is quickly removed while causing the sludge blanket as little disruption as

possible. Physio-chemical, biological, membrane, and other methods can be used to treat fish

waste.

Physicochemical methods: There are a variety of physicochemical treatment options,

such as pH adjustment, coagulation, flocculation, chemical precipitation, chemical

oxidation (such as ozonation, UV irradiation, halogenation), electrolysis, polymeric

adsorption, granular activated carbon adsorption, dissolved air flotation (DAF), sludge

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17943

Pg. (17940-17948)

treatments, and more.. When using bactericidal chemicals like chlorine or ozone (O3) or

ultraviolet (UV) radiation, effluents are disinfected. Hydrogen peroxide (H2O2) treatment

with ozonation or UV irradiation leads to more oxygen-rich, less hydrophobic, and more

biodegradable organic material in effluent streams. FOG and BOD can be effectively

reduced through the use of coagulation, flocculation, flotation, and emulsification

techniques. Coagulation and flocculation can go more smoothly if colloidal particles are

lowered in pH, which removes charges from them. Anionic and cationic polyelectrolytes

can be added to the protein suspension to aid in protein aggregation.

Biological treatment: Microorganisms such as bacteria, fungus, and protozoa are used to

breakdown organic materials in the effluents using aerobic or anaerobic conditions.

Activated sludge systems, aerobic lagoons, trickling filters, and rotating disc contactors

are the most prevalent aerobic processes. It is typical practice in activated sludge

treatment systems to use an optimal, mixed flora of microbes to decompose organic waste

materials in the presence of excess dissolved oxygen and nutrients, including nitrogenous

chemicals. To reduce soluble BOD5, lipids, and nutrients, the treatment is particularly

effective in this regard.

Membrane processes: Organic matter separation using membrane-based separation

processes (MBSPs) is a relatively new development. For biowaste, MBSPs can also

remove pathogens like bacteria and viruses. It is important to note that the key MBSPs are

ultrafiltration and nanofiltration (UF), as well as microfiltration and MF (FO). MF, UF,

NF, RO, and FO approaches, as well as hybrid technologies, offer a good chance of

providing clean water from wastewater streams at a low cost and with minimal energy

use. Water softening, wastewater treatment, vegetable oil, and other industries could

benefit from the use of NF. Wastewater treatment systems, both municipal and industrial,

are now using hybrid RO/NF membranes.

Combination processes: Most effluents can't be successfully treated with a single

technique in most cases. A synergistic effect can be achieved by combining several

processes to improve efficiency, quality, yield, and costs. The COD in the effluents of

tuna processing plants was reduced by up to 95% using an integrated system that included

a decanter to remove lipids and TSS, an anaerobic digester, and an activated sludge

aerated bio-reactor, whereas individual processes were only moderately successful in

reducing the COD.

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17944

Pg. (17940-17948)

Treatment of aquaculture effluents: Aquaculture requires careful attention to avoid

environmental dangers, such as the loss of fish species and a possible decrease in aquatic

productivity, in the farm waters. This is necessary for sustainable aquaculture. In order to

improve the effluent quality, it is necessary to follow best practices in pond building, feed

selection, proper feeding of fish and shellfish, erosion management, moderate stocking

densities, and the use of settling basins. These include filtration and mechanical

separation as well as sedimentation, filtration, chemical and biological treatments.

Resource recovery from effluents:

Food, pharmaceutical, and other businesses could benefit from the valuable components

found in seafood processing wastes and waste streams. In addition to protecting the

environment, the utilization of fishing wastes can have a significant impact on marine

resource conservation and product development costs. Seafood solid discards and wastewater

must be acknowledged as sources of diverse components, water, and energy in order for

seafood processing to be sustainable. Bio-compounds that can be recovered from food

process effluents can be useful in nutrition, healthcare, pharmaceutical, and other industries,

as well as in reducing environmental dangers. There is a major advantage to using fish

byproducts for valorisation, despite the fact that both processes have the same environmental

impact. As a contrast to effluents, the bioactive compounds found in solid wastes such as fish

oils, proteins and peptides; collagen; gelatin; enzymes; chitin; and minerals have received

more attention as sources of high-value bioactive ingredients. Because of advancements in

green technology and biotechnology, it has become more easier to isolate these chemicals.

Microwave, ultrasound, super-critical fluid extraction, enzyme extraction, fermentation-

dependent extraction, membrane-filtration, and other techniques are among the possible

methods of extraction. The U.S. Environmental Protection Agency (EPA), which focuses on

recycling resources in addition to treating waste goods, remarked that the high quantities of

nitrogen and phosphorus in wastewater might be used as nutrient resources for agriculture.

Recovering nutrients, reusing water, and harnessing energy from effluents through holistic

secondary processing might help maximize the benefits of marine resources.

A. Food ingredients:

Seafood business effluents contain a wide range of important substances for the food

industry. Fishery effluents should be used as soon as possible, since the longer they are held,

the more BOD and COD they contain, which reduces the amount of high-quality products

that may be recovered.

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17945

Pg. (17940-17948)

B. Argo-industry applications

Proteins can be recovered from effluent treatment sludge by disintegration, alkali treatment,

ultrasonication, precipitation, and drying. Aflatoxin B1 and ochratoxin A were eliminated by

this method. The proteins could be employed as a safe and nutritious animal feed that is

comparable to commercial protein diets in terms of nutritional value. When applied to the soil

and the plants, bio-stimulants aren't fertilizers, but rather aid in nutrient uptake by enhancing

metabolic processes.

C. Bio-energy

Interest in biological materials as new sources of energy has grown as a result of the global

concern over energy security. There is a lot of emphasis on biogas, bio-hydrogen and

bioethanol as well as the production of biodiesel in the bioenergy sector. Methanogenic

bacteria may be inhibited by the sludge's high concentrations of light metals and fats and

proteins.

Fig2: Products recovered from seafood effluents.

MATERIALS AND METHODS

A. Collection, Isolation and Identification of bacterial strains:

It was necessary to collect effluent samples from five different seafood processing plants in

and around Veraval and bring them to the lab in an ice box for testing. Physical and chemical

properties of the sample were analyzed in the beginning. Samples from this collection were

utilized to isolate and identify microorganisms that could be employed as bioremediators in

the future. Incubation was place at 30oC for 48 hours with serially-diluted samples plated

onto nutrient agar plates. The visual, biochemical, and molecular characteristics of isolated

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17946

Pg. (17940-17948)

bacterial colonies cultured on agar plates were used to sort them. A variety of biochemical

tests were used to help pinpoint the isolates. This included Gram stains, Catalase testing,

Indole production testing, Starch hydrolysis testing, Triple Sugar Iron agar (TSI) testing,

Methyl Red testing, Voges-Proskaeur testing, Nitrate testing, Citrate testing, the Oxidative

Fermentation testing, and the motility testing. It was possible to identify the genomic strain

using 16S rDNA.

RESULTS AND DISCUSSION:

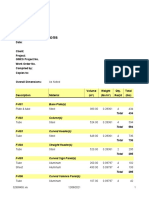

Ammonia (NH3-N), nitrite (NO2-N), nitrate(NO3-N), phosphate(PO4-P), chemical oxygen

demand, and biochemical oxygen demand were all used to evaluate the effluent quality of a

seafood processing plant. The average ammonia (NH3-N) concentration was 9.12 mg/l in the

wastewater from the seafood processing plants. The average concentration of nitrite (NO2-N)

was 93.48 mg/l, while the average concentration of nitrate (NO3-N) was 0.13 mg/l.

A total of 13.71 mg/l of PO4-P, 12.7 mg/l of COD and 161 mg/l of BOD were found. Figure

3 depicts the mean values obtained from the effluents of five different seafood processing

plants. The number of viable plates in the sample is an important metric for assessing the

water's quality. Different sampling units had total viable bacterial counts ranging from 1.4107

cfu/ml to 1.0109 cfu/ml.

Quality(mg/l) of

Seafood effluents

9.12

Ammonia

Nitrite

93.48 Nitrate

161 Phosphate

COD

0.13

BOD

13.71

12.7

Fig3: Graphical representation of average physico-chemical value (mg/l) of five

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17947

Pg. (17940-17948)

Table1: The average physico-chemical value (mg/l) of five

Effluents Quality(mg/l)

Ammonia 9.12

Nitrite 93.48

Nitrate 0.13

Phosphate 13.71

COD 12.7

BOD 161

Conclusion:

Bioremediation is a promising technology for removing environmental pollutants, restoring

contaminated sites, and preventing further pollution. This environmentally friendly

technology uses bioconversion, pollution cleanup, and pollutant degradation. Fish processing

waste water management is a major environmental problem. The current study used

bioremediation to clean up seafood processing waste water. Biodegradation of seafood

processing factory effluents utilizing microbes is in the early stages, with a bright potential

for bioremediation of waste waters. This study identified bacterial strains for seafood

processing plant wastewater bioremediation. This study suggests these microbes can

bioremediate seafood plant effluents.

References:

P. Cozma, R. -M. Hlihor, M. Rosca, I. -M. Simion, M. Apostol and M. Gavrilescu, "Progress in

Microbial Bioremediation of Industrial Effluents using Different Bioreactors Design: an

Overview," 2021 International Conference on e-Health and Bioengineering (EHB), 2021, pp.

1-4, doi: 10.1109/EHB52898.2021.9657749.

P. Pusporini and I. Vanany, "Challenges in implementing cleaner production: Barriers and strategies

in the Indonesian seafood processing industry," 2017 IEEE International Conference on

Industrial Engineering and Engineering Management (IEEM), 2017, pp. 1520-1524, doi:

10.1109/IEEM.2017.8290147.

X. Tao, H. Li, J. Lu and X. Wang, "Computer Vision Technology for Seafood Quality Evaluation,"

2012 International Conference on Computer Science and Service System, 2012, pp. 1888-

1891, doi: 10.1109/CSSS.2012.470.

V. Sherimon and P. C. Sherimon, "ONTO SQAM - A Model for Analyzing Seafood Quality Based on

Ontology," 2018 International Conference on Innovation and Intelligence for Informatics,

Computing, and Technologies (3ICT), 2018, pp. 1-6, doi: 10.1109/3ICT.2018.8855751.

P. Pusporini and I. Vanany, "Challenges in implementing cleaner production: Barriers and strategies

in the Indonesian seafood processing industry," 2017 IEEE International Conference on

Industrial Engineering and Engineering Management (IEEM), 2017, pp. 1520-1524, doi:

10.1109/IEEM.2017.8290147.

P. Pusporini, K. Abhary and L. Luong, Intelligent design of environmental performance evaluation

using fuzzy expert system, Trans Tech Publ, vol. 330, 2013

H. Shi, S. Peng, Y. Liu and P. Zhong, "Barriers to the implementation of cleaner production in

Chinese SMEs: government industry and expert stakeholders' perspectives", Journal of

cleaner production, vol. 16, pp. 842-852, 2008.

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

Mehta Samixa Rameshchandra & Jadeja J. Vasantba 17948

Pg. (17940-17948)

B.L. Jamieson, G.A. Gagnon, A.A. Gonçalves, Physicochemical characterization of Atlantic Canadian

seafood processing plant effluent, Mar. Pollut. Bull. 116 (2017) 137–142,

https://doi.org/10.1016/j.marpolbul.2016.12.071.

Z.G. Rosas-Romero, J.C. Ramirez-Suarez, R. Pacheco-Aguilar, M.E. Lugo-Sanchez, ´ G. Carvallo-

Ruiz, G. García-S´ anchez, Partial characterization of an effluent produced by cooking of

Jumbo squid (Dosidicus gigas) mantle muscle, Bioresour. Technol. 101 (2010) 600–605,

https://doi.org/10.1016/j.biortech.2009.08.074.

R.O. Cristov´ ˜ ao, C.M.S. Botelho, R.J.E. Martins, R.A.R. Boaventura, Chemical and biological

treatment of fish canning wastewaters, Int. J. Biosci. Biochem. Bioinforma. (2012) 237–242,

https://doi.org/10.7763/ijbbb.2012.v2.108.

A. Tukker, B. Jansen, Environmental impacts of products: a detailed review of studies, J. Ind. Ecol. 10

(2006) 159–182, https://doi.org/10.1162/ jiec.2006.10.3.159.

P.T. Anh, C. Kroeze, S.R. Bush, A.P.J. Mol, Water pollution by Pangasius production in the Mekong

Delta, vietnam: causes and options for control, Aquac. Res. 42 (2010) 108–128,

https://doi.org/10.1111/j.1365-2109.2010.02578.x.

B.L. Jamieson, A.A. Gonçalves, G.A. Gagnon, Toxicology evaluation of Atlantic Canadian seafood

processing plant effluent, Environ. Toxicol. 25 (2009) 137–146,

https://doi.org/10.1002/tox.20479.

M.B. Vallejos, M.S. Marcos, C. Barrionuevo, N.L. Olivera, Fish-processing effluent discharges

influenced physicochemical properties and prokaryotic community structure in arid soils

from Patagonia, Sci. Total Environ. 714 (2020) 136882,

https://doi.org/10.1016/j.scitotenv.2020.136882.

R.D. Astuti, H. Hadiyanto, Estimating environmental impact potential of small scale fish processing

using life cycle assessment, J. Ecol. Eng. 19 (2018) 65–74,

https://doi.org/10.12911/22998993/91879.

U.S.E.P.A. US EPA, Ocean Disposal Of Fish Wastes, 2017a, 2017, Https://Www. Epa.Gov/Ocean-

Dumping/Ocean-Disposal-Fish-Wastes..

K. Kümmerer, D.D. Dionysiou, O. Olsson, D. Fatta-Kassinos, Reducing aquatic micropollutants -

increasing the focus on input prevention and integrated emission management, Sci. Total

Environ. 652 (2019) 836–850, https://doi.org/ 10.1016/j.scitotenv.2018.10.219.

G. Ozbay, G. Blank, T. Thunjai, Impacts of aquaculture on habitats and Best management practices

(BMPs). Sustain. Aquac. Tech., InTech, 2014, https://doi. org/10.5772/57471

Copyright © 2022, Scholarly Research Journal for Interdisciplinary Studies

You might also like

- Focus Life Sciences Grade 10 Learner's Boo - UnknownDocument308 pagesFocus Life Sciences Grade 10 Learner's Boo - UnknownAaliyah Ballim80% (25)

- Astm E202Document12 pagesAstm E202andreNo ratings yet

- PET Production Technical ReportDocument78 pagesPET Production Technical ReportMiguel Eduardo Sanchez Ramos100% (1)

- Aquaculture Impacts On The EnvironmentDocument7 pagesAquaculture Impacts On The EnvironmentAderonke Lawal-AreNo ratings yet

- Odey Peter A Project-1Document33 pagesOdey Peter A Project-1edetedet840No ratings yet

- Organic Aquaculture-A New Approach in Fisheries DevelopmentDocument19 pagesOrganic Aquaculture-A New Approach in Fisheries Developmentmrd4856No ratings yet

- Research ReportDocument18 pagesResearch Reportsandip mitraNo ratings yet

- The Problem: Water Pollution in The PhilippinesDocument12 pagesThe Problem: Water Pollution in The PhilippinesDrei JamisolaNo ratings yet

- Blue Revolution Presentation V2Document25 pagesBlue Revolution Presentation V2kanetoh100% (2)

- Part Ii. Thailand Catfish Mortalities in Farm Ponds: 1. Background InformationDocument5 pagesPart Ii. Thailand Catfish Mortalities in Farm Ponds: 1. Background InformationaneeshmscNo ratings yet

- Introduction To PeryphetonDocument33 pagesIntroduction To PeryphetonrejdasukiNo ratings yet

- SBT1608Document138 pagesSBT1608Suchismita BanerjeeNo ratings yet

- A Q U A C U L T U R eDocument6 pagesA Q U A C U L T U R eChel GualbertoNo ratings yet

- Araujo 2020Document9 pagesAraujo 2020Rey AlegrosoNo ratings yet

- Principle of Aquaculture ICAR EcourseDocument83 pagesPrinciple of Aquaculture ICAR Ecoursecontact.arindamdas7No ratings yet

- Env Sci AquacultureDocument6 pagesEnv Sci AquacultureĶxňğ ŘeňňyNo ratings yet

- Coastal Aquaculture and MaricultureDocument57 pagesCoastal Aquaculture and MaricultureCandy BoyNo ratings yet

- Aquicultura e Piscicultura 17 33Document17 pagesAquicultura e Piscicultura 17 33Cybele PinheiroNo ratings yet

- Bio 1 - Ecosystem Slide 2Document19 pagesBio 1 - Ecosystem Slide 2Matthew LimboNo ratings yet

- Fish FarmingDocument5 pagesFish FarmingStephanie JeffereysNo ratings yet

- Freshwater and AquacultureDocument2 pagesFreshwater and AquacultureAngelika E. Delos SantosNo ratings yet

- Aquaculture Food Processing in India: Aquatic Biotechnology Da2Document11 pagesAquaculture Food Processing in India: Aquatic Biotechnology Da2chelsea charlesNo ratings yet

- Environmental Impact of Aquaculture and Countermeasures To Aquaculture Pollution in ChinaDocument11 pagesEnvironmental Impact of Aquaculture and Countermeasures To Aquaculture Pollution in ChinammiliyasNo ratings yet

- Water 09 00013Document17 pagesWater 09 00013muratout3447No ratings yet

- Should Shrimp Culture Be Blamed? The Interactions of Diverse Natural Resources Utilization in Shrimp CultureDocument15 pagesShould Shrimp Culture Be Blamed? The Interactions of Diverse Natural Resources Utilization in Shrimp CultureProf. U.P.K. Epa - University of KelaniyaNo ratings yet

- Impact of Aquaculture Solid Waste On Environment in The Delta Region of Andhra Pradesh: A Case StudyDocument6 pagesImpact of Aquaculture Solid Waste On Environment in The Delta Region of Andhra Pradesh: A Case StudyPrabu ThannasiNo ratings yet

- Aquaculture EncironmentDocument14 pagesAquaculture EncironmentOrgil MandarNo ratings yet

- Sustainability 10 00003 PDFDocument16 pagesSustainability 10 00003 PDFEriNo ratings yet

- Cee ProjectDocument22 pagesCee Projectapi-546221808No ratings yet

- AD21 - On Farm Fish CultureDocument67 pagesAD21 - On Farm Fish CultureKenny CasillaNo ratings yet

- Life Cycle Environmental Impact Assessment of Aquaculture Products in The Gaza Strip, PalestineDocument10 pagesLife Cycle Environmental Impact Assessment of Aquaculture Products in The Gaza Strip, PalestineMais OmerNo ratings yet

- Advances in Marine and Brackish AquacultureDocument266 pagesAdvances in Marine and Brackish AquacultureWaleed El-Hawarry100% (3)

- Overview of Mariculture: G. GopakumarDocument10 pagesOverview of Mariculture: G. GopakumarNehaNo ratings yet

- Sustainable Improvement in Aquatic Food Production SystemsDocument6 pagesSustainable Improvement in Aquatic Food Production SystemsJerome Earl AmarantoNo ratings yet

- Water Hyacinth ( (Eichhornia Crassipes (Mart.) Solms) Chopper Cum CrusherDocument9 pagesWater Hyacinth ( (Eichhornia Crassipes (Mart.) Solms) Chopper Cum CrusherAlexander DeckerNo ratings yet

- Major Categories of Fish AquacultureDocument20 pagesMajor Categories of Fish Aquacultureit rewaNo ratings yet

- Fish Culture in Undrainable PondsDocument219 pagesFish Culture in Undrainable Pondsdilipkumarnayak20033595100% (1)

- Factors Limiting Adoption of Biofloc TechnologyDocument23 pagesFactors Limiting Adoption of Biofloc TechnologySachin PatilNo ratings yet

- Water Conservation and BiodiversityDocument34 pagesWater Conservation and Biodiversityparvati_hsrNo ratings yet

- The Growth of Microalgae in Shrimp Hatchery: Impact of Environment On Nutritional ValuesDocument8 pagesThe Growth of Microalgae in Shrimp Hatchery: Impact of Environment On Nutritional ValuesIOSRjournalNo ratings yet

- GP Checkpoint ArvinthakshanDocument5 pagesGP Checkpoint Arvinthakshanben63forceeNo ratings yet

- Utilization of Fish Processing Waste: A Waste To Wealth ApproachDocument5 pagesUtilization of Fish Processing Waste: A Waste To Wealth Approachsumaiya rahmanNo ratings yet

- Review of Aquaculture and Fish Consumption in BangladeshDocument76 pagesReview of Aquaculture and Fish Consumption in BangladeshBen BeltonNo ratings yet

- Biofilters The Need For A New Comprehensive Approach. Aquacultural EngineeringDocument7 pagesBiofilters The Need For A New Comprehensive Approach. Aquacultural EngineeringMiriam AguirreNo ratings yet

- Avances en Acuicultura. 2015 PDFDocument266 pagesAvances en Acuicultura. 2015 PDFRosmaris LopezNo ratings yet

- Updated FishingDocument38 pagesUpdated FishingsyedsalmanahmedrazviNo ratings yet

- Shrimp Pond Culture in The PhilippinesDocument5 pagesShrimp Pond Culture in The PhilippinesSuvam ShahNo ratings yet

- Reuse of Treated Wastewater and Sludge For Agriculture in India - Case StudyDocument10 pagesReuse of Treated Wastewater and Sludge For Agriculture in India - Case StudyPravin SonawaneNo ratings yet

- GP Checkpoint ArvinthakshanDocument5 pagesGP Checkpoint Arvinthakshanben63forceeNo ratings yet

- I - Granada Et Al. 2015 - Imta ReviewDocument18 pagesI - Granada Et Al. 2015 - Imta ReviewGiulia GentiliniNo ratings yet

- Crawfish Management .Document28 pagesCrawfish Management .mongchayNo ratings yet

- A Review On Recirculating Aquaculture System Influence of Stocking DensityDocument13 pagesA Review On Recirculating Aquaculture System Influence of Stocking Densityparma coolNo ratings yet

- Fish Farming (Aquaculture) : Cultivating Fish for Food and ConservationFrom EverandFish Farming (Aquaculture) : Cultivating Fish for Food and ConservationNo ratings yet

- Facts About Fish: Earth Day NetworkDocument3 pagesFacts About Fish: Earth Day NetworkAlexander Pernia DiazNo ratings yet

- Sustainability 10 01805Document29 pagesSustainability 10 01805naidu60606No ratings yet

- Bioremediationarticle-S AanandDocument5 pagesBioremediationarticle-S AanandMaritaFGNo ratings yet

- Tilapia in Aquaculture: Henk StanderDocument2 pagesTilapia in Aquaculture: Henk StanderJuan AriasNo ratings yet

- Source Water QualityDocument76 pagesSource Water QualityfreitajNo ratings yet

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaFrom EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaNo ratings yet

- Aquaponics systems, fish. Volume 3: Sistemas de acuaponíaFrom EverandAquaponics systems, fish. Volume 3: Sistemas de acuaponíaNo ratings yet

- Management and Environmental Dynamics of Lake and Reservoir FisheriesFrom EverandManagement and Environmental Dynamics of Lake and Reservoir FisheriesNo ratings yet

- 25.suresh ChenuDocument9 pages25.suresh ChenuAnonymous CwJeBCAXpNo ratings yet

- 29.yuvraj SutarDocument4 pages29.yuvraj SutarAnonymous CwJeBCAXpNo ratings yet

- 13.nasir RasheedDocument9 pages13.nasir RasheedAnonymous CwJeBCAXpNo ratings yet

- Critical Analysis of Depression Among Higher Education Students of KolkataDocument12 pagesCritical Analysis of Depression Among Higher Education Students of KolkataAnonymous CwJeBCAXpNo ratings yet

- 4.Dr Gagandeep KaurDocument13 pages4.Dr Gagandeep KaurAnonymous CwJeBCAXpNo ratings yet

- 1.prof. Ajay Kumar AttriDocument8 pages1.prof. Ajay Kumar AttriAnonymous CwJeBCAXpNo ratings yet

- 19.Dr Ibrahim Aliyu ShehuDocument29 pages19.Dr Ibrahim Aliyu ShehuAnonymous CwJeBCAXpNo ratings yet

- An Analysis of The Rights and Duties of Parents Towards Their Children Under Islamic Law in NigeriaDocument29 pagesAn Analysis of The Rights and Duties of Parents Towards Their Children Under Islamic Law in NigeriaAnonymous CwJeBCAXpNo ratings yet

- Homesh RaniDocument7 pagesHomesh RaniAnonymous CwJeBCAXpNo ratings yet

- Technostress, Computer Self-Efficacy and Perceived Organizational Support Among Secondary School Teachers: Difference in Type of School, Gender and AgeDocument13 pagesTechnostress, Computer Self-Efficacy and Perceived Organizational Support Among Secondary School Teachers: Difference in Type of School, Gender and AgeAnonymous CwJeBCAXpNo ratings yet

- Sociological Gaze of Tare Zameen ParDocument4 pagesSociological Gaze of Tare Zameen ParAnonymous CwJeBCAXpNo ratings yet

- "The Effective Learning of English Grammar ' Tenses' Through Multi Media Package For The Students of Standard IxDocument10 pages"The Effective Learning of English Grammar ' Tenses' Through Multi Media Package For The Students of Standard IxAnonymous CwJeBCAXpNo ratings yet

- Investigation of The Satus of The Social Development Programs Under Sansad Adarsh Gram Yojana in Rajgoli Village in Kolhapur DistrictDocument12 pagesInvestigation of The Satus of The Social Development Programs Under Sansad Adarsh Gram Yojana in Rajgoli Village in Kolhapur DistrictAnonymous CwJeBCAXpNo ratings yet

- A Study of Awareness About Online Information Resources of Student TeachersDocument7 pagesA Study of Awareness About Online Information Resources of Student TeachersAnonymous CwJeBCAXpNo ratings yet

- A Study of Effect of Age and Gender On Stress of AdolescentsDocument5 pagesA Study of Effect of Age and Gender On Stress of AdolescentsAnonymous CwJeBCAXpNo ratings yet

- Customers' Consciousness About Financial Cyber Frauds in Electronic Banking: An Indian Perspective With Special Reference To Mumbai CityDocument13 pagesCustomers' Consciousness About Financial Cyber Frauds in Electronic Banking: An Indian Perspective With Special Reference To Mumbai CityAnonymous CwJeBCAXpNo ratings yet

- Student Engagement and Goal Orientation, Resilience: A Study On Senior Secondary School StudentsDocument6 pagesStudent Engagement and Goal Orientation, Resilience: A Study On Senior Secondary School StudentsAnonymous CwJeBCAXpNo ratings yet

- A Study On Pre-Investment Due Diligence by Capital Market Investors of Mumbai Suburban AreaDocument11 pagesA Study On Pre-Investment Due Diligence by Capital Market Investors of Mumbai Suburban AreaAnonymous CwJeBCAXpNo ratings yet

- Exploitation of The Ones Who Have No OneDocument15 pagesExploitation of The Ones Who Have No OneAnonymous CwJeBCAXpNo ratings yet

- Financial Concerns and Requirements of Women EntrepreneursDocument10 pagesFinancial Concerns and Requirements of Women EntrepreneursAnonymous CwJeBCAXpNo ratings yet

- Women - Right To Survive: Issues of Female Infanticide and FoeticideDocument11 pagesWomen - Right To Survive: Issues of Female Infanticide and FoeticideAnonymous CwJeBCAXpNo ratings yet

- Aggression Among Senior Secondary School Students in Relation To Their Residential BackgroundDocument8 pagesAggression Among Senior Secondary School Students in Relation To Their Residential BackgroundAnonymous CwJeBCAXpNo ratings yet

- Context of Eco-Psychological ImbalanceDocument8 pagesContext of Eco-Psychological ImbalanceAnonymous CwJeBCAXpNo ratings yet

- Techno-Pedagogical Competency of Higher Secondary School Teachers in Relation To Their Work Motivation in Chengalpattu DistrictDocument5 pagesTechno-Pedagogical Competency of Higher Secondary School Teachers in Relation To Their Work Motivation in Chengalpattu DistrictAnonymous CwJeBCAXpNo ratings yet

- A Lookout at Traditional Games Played by Tribes in IndiaDocument4 pagesA Lookout at Traditional Games Played by Tribes in IndiaAnonymous CwJeBCAXpNo ratings yet

- Historical Development of Play Schools in IndiaDocument11 pagesHistorical Development of Play Schools in IndiaAnonymous CwJeBCAXpNo ratings yet

- Effect of Life Skill Training On Mental Health Among B.ed. Interns in Relation To Their Impulsive BehaviourDocument9 pagesEffect of Life Skill Training On Mental Health Among B.ed. Interns in Relation To Their Impulsive BehaviourAnonymous CwJeBCAXpNo ratings yet

- The Need of Remote Voting Machine in Indian Voting SystemDocument7 pagesThe Need of Remote Voting Machine in Indian Voting SystemAnonymous CwJeBCAXpNo ratings yet

- Empowerment and Education of Tribal Women in IndiaDocument12 pagesEmpowerment and Education of Tribal Women in IndiaAnonymous CwJeBCAXpNo ratings yet

- The Impact of Mindfulness Exercise To Change The Body and MindDocument8 pagesThe Impact of Mindfulness Exercise To Change The Body and MindAnonymous CwJeBCAXpNo ratings yet

- Paper 4 - Structured QuestionsDocument20 pagesPaper 4 - Structured Questionsvita iftitahiyahNo ratings yet

- Ecotoxicology and Environmental Safety: A A B A ADocument8 pagesEcotoxicology and Environmental Safety: A A B A APedroLHernandezNo ratings yet

- Sri Chaitanya IIT Academy., India.: KEY SheetDocument10 pagesSri Chaitanya IIT Academy., India.: KEY SheetO SNo ratings yet

- Food AdultrationDocument21 pagesFood AdultrationAshish KumarNo ratings yet

- MSDS Wüfoam 70 Megamax Würth (EN)Document19 pagesMSDS Wüfoam 70 Megamax Würth (EN)BradyNo ratings yet

- Expirement No 1Document4 pagesExpirement No 1Rajiv KharbandaNo ratings yet

- Biomolecules Packet 2011Document6 pagesBiomolecules Packet 2011Nidhi Sisodia100% (1)

- BiomassDocument18 pagesBiomassCyrille Nicole BathanNo ratings yet

- Hydrogels in Drug Delivery - Progress and ChallengesDocument15 pagesHydrogels in Drug Delivery - Progress and ChallengesЕгор ЛетовNo ratings yet

- 22Document4 pages22sachinsaklani23No ratings yet

- 8ch0 02 Rms 20230817Document38 pages8ch0 02 Rms 20230817Baanu Thushyanthan100% (1)

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranNo ratings yet

- Sample Qp12Document41 pagesSample Qp12suchetha manjunthaNo ratings yet

- Enhanced Energy Efficiency in Industrial LubricationDocument125 pagesEnhanced Energy Efficiency in Industrial Lubricationmanoj gupta guptaNo ratings yet

- Lupuli FlosDocument2 pagesLupuli FlosArtem KulikovNo ratings yet

- Production Options For Psilocybin Making of The MagicDocument7 pagesProduction Options For Psilocybin Making of The MagicYingjie ZhouNo ratings yet

- Lindab Round Duct and FittingDocument108 pagesLindab Round Duct and FittingNguyễn Xuân ĐiệpNo ratings yet

- Fish Processing: (From Wikipedia, The Free Encyclopedia)Document8 pagesFish Processing: (From Wikipedia, The Free Encyclopedia)Iris PontoNo ratings yet

- Development Formulation: Lux Shampoo With APISCALP™ ( ) and Capilectine™ SP ( ) SED1410179JDocument2 pagesDevelopment Formulation: Lux Shampoo With APISCALP™ ( ) and Capilectine™ SP ( ) SED1410179JaliNo ratings yet

- Freeze DryingDocument8 pagesFreeze DryingArie YufitasariNo ratings yet

- Jrchemistry Important QuestionsDocument8 pagesJrchemistry Important Questionsprem81% (16)

- PlungerPacking PDFDocument14 pagesPlungerPacking PDFhufuents-1100% (1)

- Ion-Exchange TLC - Separation of Nucleotide Sugars and Nucleoside Monophosphates On PEI-celluloseDocument5 pagesIon-Exchange TLC - Separation of Nucleotide Sugars and Nucleoside Monophosphates On PEI-cellulosekiwi27_87No ratings yet

- K.bender - Case Study - A Collaborative Approach Between DuPont and Renault - 2015Document13 pagesK.bender - Case Study - A Collaborative Approach Between DuPont and Renault - 2015anacarol09No ratings yet

- Instrumentation Part1omkarDocument173 pagesInstrumentation Part1omkaromkarvadlooriNo ratings yet

- Haloalkanes and Haloarenes by Bharat Panchal CBSE 2022 Term 1Document25 pagesHaloalkanes and Haloarenes by Bharat Panchal CBSE 2022 Term 1roceni100% (4)

- Autocad Massprop Weight Calc SpreadsheetDocument4 pagesAutocad Massprop Weight Calc SpreadsheetjmondroNo ratings yet