Professional Documents

Culture Documents

Hanfih 0516

Hanfih 0516

Uploaded by

Javier JiménezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hanfih 0516

Hanfih 0516

Uploaded by

Javier JiménezCopyright:

Available Formats

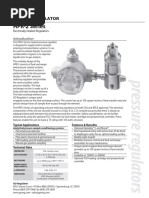

SPECIFICATION SHEET

Flange Immersion Heaters

Agency Certified Tubular

Heaters Ideal for Heating

Liquids, Gases, Tanks and

Pressure Vessels Requiring

Higher Kilowatts

Watlow® flange heaters, with IECEx and ATEX Ex’d’ or Ex’e’ Features and Benefits

certification, are easy to install and maintain. Designed for ANSI and ANSI compatible 2, 21/2, 3 thru 48 inch flanges

heating liquids and gases in tanks and pressure vessels, flange • Provides appropriate heater size-to-application and fit

immersion heaters are ideal for applications requiring higher Element sheath and flange materials

kilowatts. • Meets your application needs

Watlow flange heaters are made with WATROD™ or FIREBAR® Integral thermowells

tubular elements brazed or welded to a flange. Stock flange

• Provides convenient temperature sensor insertion and

heaters are equipped with a general purpose terminal enclosure.

replacement without draining the fluid being heated

Watlow flange heaters possess IECEx and ATEX Ex’d’ or Standard, general purpose terminal enclosure

Ex’e’ ratings certifying that the flange heater enclosure is

• Offers easy access to wiring

flameproof. Every enclosure is pressure tested to ensure

heaters are safe and reliable and meet rigorous standards Element support(s)

for electrical safety. • Provides proper element spacing to maximizing heater

performance and life

Flange heaters, with FIREBAR elements, also answer the need

for liquid immersion applications requiring high kilowatts All units are inspected and/or tested

in small tanks. The FIREBAR element’s unique flat surface • Ensures element-to-flange pressure seals do not leak

geometry packs more power in a smaller bundle, with lower Drilled and tapped eyebolt holes or lift lugs on larger

watt density, making it especially well-suited for petroleum- flange heaters

based liquid heating applications. • Facilitates lifting during installation

Performance Capabilities WATROD hairpins are repressed (recompacted)

• Watt densities up to 100 W/in2 (15.5 W/cm2) • Provides improved heater life, insulation resistance and

• Wattages up to three megawatts heat transfer

• UL® and CSA component recognition up to 600VAC and IEC FIREBAR flange heaters pack more kilowatts into a smaller

and ATEX recognition up to 690VAC bundle

• Alloy 800/840 sheath temperatures up to 1600°F (870°C) • Includes a conventional round tubular 10 in. (254 mm)

• Passivated 316 stainless steel sheath temperatures up ANSI flange which can be replaced by a 6 in. (152 mm)

to 1200°F (650°C) ANSI FIREBAR flange with the same immersed length

• 304 stainless steel sheath temperatures up to Branch circuits are designed for 48 amperes per circuit

1200°F (650°C)

maximum

• Steel sheath temperatures up to 750°F (400°C)

• Reduces risk of failure due to excessive temperatures

• FIREBAR flange heaters deliver more killowatts in smaller

generated by high amperage

bundles

• A conventional round tubular 10-inch ANSI flange can UL® and CSA component recognition under file numbers

be replaced by a 6-inch ANSI FIREBAR flange with same E52951 and 31388 respectively

immersed length • Simplifies obtaining third-party recognition for assembly

• Hazardous area ratings:

• ATEX II 2 G Ex d IIB+H2, T1-6 Gb

• IEC Ex d IIC: TI-6 Gb

• ATEX II 2 G Ex e IIC T1-6 Gb

• IEC Ex e IIC TI-6 Gb

• Class 1, Divisions 1 & 2, Groups B, C & D

• PESO, Zone 1 Group llC

• TR-CU EAC Certification

Typical Applications Stand-off terminal enclosures provide an air-insulating barrier

• Water: between the flange and terminal enclosure by mounting

Deionized the terminations and wiring away from the flange. Stand-off

Demineralized terminal enclosures are recommended whenever a process

Clean operating temperature exceeds 210°F (100°C). This helps

Potable minimize terminal enclosure temperatures.

Process To order, specify stand-off terminal enclosure.

• Industrial water rinse tanks Certified Enclosures

• Vapor degreasers CSA, ATEX, IECEx or PESO certified enclosures protect wiring

• Hydraulic oil, crude, asphalt in hazardous gas environments. For additional information

• Lubricating oils at API specified watt densities contact a Watlow representative.

• Air and gas flow

To order, specify CSA or ATEX, IECEx, PESO or TR-CU EAC

• Caustic solutions

certified enclosure, area classification, protection method,

• Chemical baths

desired temperature code, process temperature (°F),

• Process air equipment

maximum ambient temperature, maximum working pressure

• Boiler equipment

of application (psig), media being heated and heater

• Freeze protection of any fluid

mounting orientation (horizontal or vertical) and flange size.

• Anti-freeze (glycol) solutions

• Paraffin For products that will be installed in hazardous locations,

please provide the following information:

Terminal Enclosure

• Operating conditions

Flange • Minimum and maximum ambient temperatures for the

Thermowell installation location

• Mounting orientation

Watlow must understand this information so that an

FIREBAR

appropriate design can be provided.

Conduit Opening

Heating Element ASME Pressure Vessel Code Welding

Flange assemblies can be provided with an ASME Section VIII,

Div. I pressure vessel stamp upon request.

Thermostats

To provide process temperature control, Watlow offers

WATROD Heating Element

optional single pole, single throw (SPST) and double pole,

Options single throw (DPST) thermostats.

Terminal Enclosures Unless otherwise specified, thermostats are mounted inside

General purpose terminal enclosures, without the terminal enclosure. Please verify that the thermostat’s

thermostats, are standard on all flange immersion heaters. sensing bulb outside diameter is compatible with the flange

Optional terminal enclosures

Stand-off include: heater’s thermowell inside diameter.

Terminal Conduit

• General purpose withEnclosure

a single or double pole Openings

thermostat. Thermocouples

• Moisture resistant. Available with or without a single or ASTM Type J or K thermocouples offer more accurate sensing

double pole thermostat. Ref. 6 in.

(152 mm)

of process and/or sheath temperatures. A thermocouple may

• Corrosion resistant. Available

ANSI

Stand-off

with or without aHeight

single or be inserted into the thermowell or attached to the heater’s

double pole thermostat.

Flange sheath.

Thermocouples are supplied with 120 in. (3050 mm) leads

• Explosion resistant Class 1, Div. 1 and 2, Groups B, C and

(longer lead lengths available). Unless otherwise specified,

D, T1-T6. Available with or without a single or double pole

thermocouples are supplied with temperature ranges.

thermostat.

Using a thermocouple requires an appropriate temperature

• Explosion/moisture resistant combinations. Available with

and power controller. These must be purchased separately.

or without a single or double pole thermostat.

Watlow offers a wide variety of temperature and power

Stand-off Terminal Enclosures controllers to meet virtually all applications. Temperature

Ref. 6 in. ANSI controllers can be configured to accept process variable

(150 mm) Flange

Conduit Stand-off

Openings Terminal

Stand-off inputs, too. Contact a Watlow representative for details.

Enclosure Height

To order, specify Type J or K thermocouple and lead length.

Indicate if the thermocouple is for process temperature

sensing or heater sheath high-limit protection. Please specify

if the flange heater will be mounted vertical or horizontal

in the tank. If vertical, specify if the housing is on top or

bottom.

If the flange heater is part of an in-line circulation heating

application, indicate flow direction relative to the heater’s

enclosure.F

Options (Continued) Flange Materials

Standard Carbon steel

Wattages and Voltages

Direction of Flow 316 SS

Watlow routinely supplies flange immersion heaters with 304 SS

240 to 480VAC as well as wattages from 150 watts to one

megawatt. Pressure Classes

If required, Watlow will make heaters with voltage up to Standard 150 lb

600VAC and wattage beyond one megawatt. For more 300 lb

information on special voltage and wattage configurations, 600 lb

contact a Watlow representative. Gaskets

Sheath Materials Rubber, asbestos-free and spiral wound gaskets are

The following sheath materials are available on WATROD available for all flange sizes. Order by specifying gasket

and FIREBAR flange heaters: type, flange size/rating, process operating temperature

Standard Sheath Materials and pressure.

WATROD Alloy 800, 840 Baffles

316 SS Direction of Flow

Steel

FIREBAR Alloy 800

Extended Sheath Materials

WATROD Titanium

304 and 321 SS For forced circulation applications, 316 stainless steel

Hastelloy® C276 baffles can be arranged on the heating element bundle

Alloy 400 and 600 to enhance and/or modify fluid or gas flow for better heat

FIREBAR 304 SS transfer.

For open tank or convection heating applications,

Exotic Sheath Materials

standard element supports will be supplied.

Contact a Watlow representative for details and

availability. To order, specify baffles and provide vessel drawing with

inlet and outlet size and dimensioned locations on vessel.

External Finishing

Passivation Enclosure Enhancements

During the manufacturing process, particles of iron or • Enclosure heater to solve condensation and freeze

tool steel may become embedded in the stainless steel or problems.

alloy sheath. If not removed, these particles may corrode, • Power distribution blocks to facilitate power feed line

produce rust spots and/or contaminate the process. For wiring.

critical sheath applications, passivation will remove free RTDs

iron from the sheath. To order, specify passivation. If the process requires greater temperature sensing

Other Finishes accuracy than is possible with thermocouples, Watlow can

Bright annealing available to meet cosmetic demands. also supply RTDs in DIN or JIS calibrations. Contact your

Watlow representative for details.

Flanges

Flange Sizes and Styles

Standard: 2j, 21/2j, 3 to 48 inch ANSI raised face/blind

flanges.

Made-to-Order: 16, 18, 20 and 24 inch in any recognized

configuration, as well as customer specified. Over 48 inch

ANSI flange, contact a Watlow representative.

j ANSI bolt pattern only

Watlow® and FIREBAR® are registered trademarks of Watlow Electric Manufacturing

Company.

WATROD™ is a trademark of Watlow Electric Manufacturing Company.

UL® is a registered trademark of Underwriter’s Laboratories, Inc.

Hastelloy® is a registered trademark of Haynes International.

Powered by Possibility

To be automatically connected to the nearest International Technical Sales Offices:

North American Technical Sales Office: Germany +49 7253 9400 0 Mexico +52 442 256 2200

Austria +43 6244 20129 0 India +91 40 6661 2700 Singapore +65 6773 9488

1-800-WATLOW2 • www.watlow.com Australia +61 3 9335 6449 Italy +39 02 4588841 Spain +34 91 675 1292

China +86 21 3532 8532 Japan +81 3 3518 6630 Taiwan +886 7 288 5168

inquiry@watlow.com France +33 1 41 32 79 70 Korea +82 2 2169 2600 UK +44 115 964 0777

©2016 Watlow Electric Manufacturing Company all rights reserved. HAN-FIH-0516

You might also like

- AQA 8464 C 1H Final MS Jun23 v1.0Document20 pagesAQA 8464 C 1H Final MS Jun23 v1.0meherun.hamzaNo ratings yet

- IseceDocument16 pagesIseceManoj PrabakaranNo ratings yet

- SHS11 SMAW11 Q1 Mod1 GROOVEWELD VERSION3 PDFDocument54 pagesSHS11 SMAW11 Q1 Mod1 GROOVEWELD VERSION3 PDFChonie Villanueva80% (5)

- Thesis Proposal: Compressive Strength of Fiber Reinforced Concrete Hollow Blocks (CHB) Using Plastic Bags As Fibers and Palm Oil Fuel Ash (Pofa) As Partial Replacement For CementDocument21 pagesThesis Proposal: Compressive Strength of Fiber Reinforced Concrete Hollow Blocks (CHB) Using Plastic Bags As Fibers and Palm Oil Fuel Ash (Pofa) As Partial Replacement For CementJerrick Wayne VertudazoNo ratings yet

- Ideal For Direct Immersion Heating of Liquids: Features and Benefits Performance CapabilitiesDocument3 pagesIdeal For Direct Immersion Heating of Liquids: Features and Benefits Performance CapabilitiesTayfunwNo ratings yet

- Hanspi 0519Document3 pagesHanspi 0519lychekNo ratings yet

- Immersion Heaters FlangeDocument24 pagesImmersion Heaters FlangeEliasNo ratings yet

- Han Cir 0719Document4 pagesHan Cir 0719Jaime Ocampo SalgadoNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument34 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- Brochure Exi Catalogue enDocument28 pagesBrochure Exi Catalogue enAceel FitchNo ratings yet

- Air 0423Document34 pagesAir 0423AdilsonNo ratings yet

- Watlow Immersion HeatersDocument163 pagesWatlow Immersion HeatersEliasNo ratings yet

- ImmersionDocument164 pagesImmersionsvpd2006No ratings yet

- Watlow Product SheetDocument4 pagesWatlow Product Sheetmatteo2009No ratings yet

- Industrial Air Heater PDFDocument34 pagesIndustrial Air Heater PDFleoNo ratings yet

- Cartridge Heaters0721Document48 pagesCartridge Heaters0721dominhdung263168No ratings yet

- Zerax Cat GB Mu15817 0918 PDFDocument32 pagesZerax Cat GB Mu15817 0918 PDFVenkatesh NaiduNo ratings yet

- Lewco Hec04s Spec SheetDocument2 pagesLewco Hec04s Spec SheetepadillaNo ratings yet

- Cxh-Ep: Convection Heater For Hazardous LocationsDocument16 pagesCxh-Ep: Convection Heater For Hazardous Locationskarim karimNo ratings yet

- Immersion Heaters Haz Area UK+USADocument26 pagesImmersion Heaters Haz Area UK+USAAnonymous ffje1rpaNo ratings yet

- Thermal Fluid Heaters: Model HHC and VHCDocument4 pagesThermal Fluid Heaters: Model HHC and VHCRexx MexxNo ratings yet

- Ieh/Sa-Pro - Industrial Evaporator Stainless Steel Tube Professional Line Amonia / NHDocument12 pagesIeh/Sa-Pro - Industrial Evaporator Stainless Steel Tube Professional Line Amonia / NHDương TrungNo ratings yet

- Cartridge 0124Document48 pagesCartridge 0124estampados25032020No ratings yet

- Iehr-Pro - Industrial Evaporators Professional Line R134A / R404A / R507/ R22Document12 pagesIehr-Pro - Industrial Evaporators Professional Line R134A / R404A / R507/ R22Ion ZabetNo ratings yet

- Cartridge HeatersDocument48 pagesCartridge Heatersprsking187No ratings yet

- Specialty HeatersDocument40 pagesSpecialty Heaterskvanps_kumarNo ratings yet

- T-Series Mid-Size Outdoor: T29 T43 T50 T53Document18 pagesT-Series Mid-Size Outdoor: T29 T43 T50 T53MarioNo ratings yet

- Exhaust Gas Thermocouples: Product Features and BenefitsDocument2 pagesExhaust Gas Thermocouples: Product Features and Benefitsdris mahmoudiNo ratings yet

- Standard, Hot Smoke, Atex and Ex: Zerax® Axial Flow FansDocument32 pagesStandard, Hot Smoke, Atex and Ex: Zerax® Axial Flow FansYorlevy J. Chirinos M.No ratings yet

- Tank Heating: Industrial Heat Tracing SolutionsDocument29 pagesTank Heating: Industrial Heat Tracing Solutionsromero2kNo ratings yet

- AOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedDocument6 pagesAOS Cyclone Mxi BTH English CANCG10210 - 0920 - CompressedMatteo TorresNo ratings yet

- WatLow - Immersion Heaters - 2018Document154 pagesWatLow - Immersion Heaters - 2018Victor PomboNo ratings yet

- Zerax Cat GB Mu16216 0124Document32 pagesZerax Cat GB Mu16216 0124NhanNo ratings yet

- Drum & Tote Heaters: Model: SC8TVDocument3 pagesDrum & Tote Heaters: Model: SC8TVxinying liuNo ratings yet

- Immersion 0124Document154 pagesImmersion 0124lychekNo ratings yet

- Commercial-Grade: Vertex Versatile Power Direct VentDocument2 pagesCommercial-Grade: Vertex Versatile Power Direct VentwhaleeNo ratings yet

- + BARTH GMBH GINO Liquid Motor StartersDocument2 pages+ BARTH GMBH GINO Liquid Motor StartersRandy FajardoNo ratings yet

- Thermax PDS1.0Document2 pagesThermax PDS1.0John SAUERNo ratings yet

- Aoscg10210series300 PDFDocument6 pagesAoscg10210series300 PDFAnonymous PCsoNCt0mFNo ratings yet

- Special HeatersDocument2 pagesSpecial HeatersEliasNo ratings yet

- Tank HeatingDocument28 pagesTank Heatingsnikraftar1406No ratings yet

- Air Cooled Heat ExchangerDocument16 pagesAir Cooled Heat ExchangerModesty100% (1)

- Fincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignDocument2 pagesFincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignSuresh Damu BhadNo ratings yet

- Temperature ControllingDocument8 pagesTemperature ControllingSyaf HudaNo ratings yet

- Large-Tank Heating SystemsDocument4 pagesLarge-Tank Heating Systemsmayukhguha88No ratings yet

- MILLER IN160 ArcReach Heater LiteratureDocument4 pagesMILLER IN160 ArcReach Heater LiteratureMarisol Gonzalez (Soly)No ratings yet

- 2 EGLX Sales BrochureDocument4 pages2 EGLX Sales Brochurehamza ouadiNo ratings yet

- Large Tank Heaters: Application & Equipment SelectionDocument2 pagesLarge Tank Heaters: Application & Equipment SelectionOscar Marino Campo BonellNo ratings yet

- Air Cooled Prasad Chiller SpecificationsDocument6 pagesAir Cooled Prasad Chiller Specificationsanusha darvemulaNo ratings yet

- Omml 0436 05 23ht-30 ADocument17 pagesOmml 0436 05 23ht-30 ARob RhNo ratings yet

- hpr2 Regulator For Model 933 Analyzer PN 300-9478Document7 pageshpr2 Regulator For Model 933 Analyzer PN 300-9478Jose JohnNo ratings yet

- Evaporadores - Arctigo IsDocument2 pagesEvaporadores - Arctigo IsedamiandcrNo ratings yet

- Brochure Válvulas MaxonDocument8 pagesBrochure Válvulas MaxonIngeniero Proyectos 1No ratings yet

- Endress-Hauser RTD-Assembly U S Style T14 ENDocument4 pagesEndress-Hauser RTD-Assembly U S Style T14 ENangel uscangaNo ratings yet

- B-Series Switches - Pressure, Differential Pressure, Temperature & HydraulicDocument33 pagesB-Series Switches - Pressure, Differential Pressure, Temperature & HydraulicChockkalingam SubramanianNo ratings yet

- HT12Document16 pagesHT12yasseralwasabi2016No ratings yet

- Flange Immersion Heaters: For Atex/Iecex Hazardous Areas or in Non-Atex VersionDocument8 pagesFlange Immersion Heaters: For Atex/Iecex Hazardous Areas or in Non-Atex VersionVAP BOMBAYNo ratings yet

- RP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogDocument20 pagesRP963 Climatemaster Residential Tranquility Water To Water TCW Series Geothermal Heating and Cooling Systems Product CatalogZulfah NurkholisNo ratings yet

- Fluke 9118ADocument4 pagesFluke 9118Avijay.victorysolutions01No ratings yet

- Your Selection of Valve Technology, Matters.: Isolation ValvesDocument28 pagesYour Selection of Valve Technology, Matters.: Isolation Valvesmohamed badranNo ratings yet

- Aire AcondicionadoDocument31 pagesAire AcondicionadoIvan ParraNo ratings yet

- Up To Efficiency!: MBTU ModelsDocument8 pagesUp To Efficiency!: MBTU ModelslordsethdarknessNo ratings yet

- 639 Rolling Thin Film OvenDocument1 page639 Rolling Thin Film OvenHuda MahdiNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Emax Link 2 Application Guide 9AKK107991A7073Document26 pagesEmax Link 2 Application Guide 9AKK107991A7073Javier JiménezNo ratings yet

- Eaton 108792 ZB65 75 en - GBDocument8 pagesEaton 108792 ZB65 75 en - GBJavier JiménezNo ratings yet

- Thermostat Control Installation Maintenance ManualDocument6 pagesThermostat Control Installation Maintenance ManualJavier JiménezNo ratings yet

- FLANGE CIRC HEATER IM MANUAL ENGLISH Ref 3164281 Rev ADocument21 pagesFLANGE CIRC HEATER IM MANUAL ENGLISH Ref 3164281 Rev AJavier JiménezNo ratings yet

- Hanul 1104Document1 pageHanul 1104Javier JiménezNo ratings yet

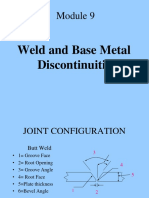

- Weld and Base Metal DiscontinuitiesDocument74 pagesWeld and Base Metal DiscontinuitiesMohamed Saleh100% (1)

- PC I Girder Posttensioned HS20 44 SIDocument5 pagesPC I Girder Posttensioned HS20 44 SIJavier Bosigas100% (1)

- D1208Document3 pagesD1208Ненад КнежевићNo ratings yet

- Fosroc Chemicals India PVT LTD.: Presentation On Lift Pit Waterproofing SystemDocument9 pagesFosroc Chemicals India PVT LTD.: Presentation On Lift Pit Waterproofing SystemPradeep GoudaNo ratings yet

- 2022, 12-13 - Quotation For Boundary WallDocument7 pages2022, 12-13 - Quotation For Boundary WallIslam SanaulNo ratings yet

- Reactivity of Metal & Thermochemistry Question PDFDocument24 pagesReactivity of Metal & Thermochemistry Question PDFAqilah HazwaniNo ratings yet

- Filament: Getting Fibers Into ShapeDocument36 pagesFilament: Getting Fibers Into ShapeSudipto MandalNo ratings yet

- BSR 512: Topic 2: Norehan Haji Mohd Noor Senior Lecturer Program of Building Surveying, Uitm PerakDocument35 pagesBSR 512: Topic 2: Norehan Haji Mohd Noor Senior Lecturer Program of Building Surveying, Uitm PerakaremyulNo ratings yet

- Wood Drying PDFDocument13 pagesWood Drying PDFJahangir MiltonNo ratings yet

- IGCSE Double Award Extended Coordinated Science: Chemistry 2 - Experimental TechniquesDocument4 pagesIGCSE Double Award Extended Coordinated Science: Chemistry 2 - Experimental TechniquesFabian Obame0% (1)

- Centennial FabricsDocument22 pagesCentennial Fabricssanjay chandwaniNo ratings yet

- Comparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsDocument6 pagesComparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsMurtaza SieamNo ratings yet

- 3RD Quarter Chem 1 IonsDocument6 pages3RD Quarter Chem 1 IonsThaddeus BaldonadoNo ratings yet

- Thermal Insulation in Building PDFDocument31 pagesThermal Insulation in Building PDFAkirasNo ratings yet

- Maintenance and Repair of Heat Exchangers PDFDocument73 pagesMaintenance and Repair of Heat Exchangers PDFTehman Alam100% (2)

- 4 5893475375345830339Document5 pages4 5893475375345830339tofikkemalNo ratings yet

- Phosphor Bronze and Nickel Silver Sheet and Strip StandardDocument3 pagesPhosphor Bronze and Nickel Silver Sheet and Strip StandardScott Kramer100% (1)

- CEPEsampleDocument5 pagesCEPEsamplermdarisaNo ratings yet

- LN 2 IbsDocument68 pagesLN 2 IbsthamilNo ratings yet

- Vinyl Sulfone Fiber Reactive DyesDocument12 pagesVinyl Sulfone Fiber Reactive DyesFathi MustafaNo ratings yet

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- MODELO E PÔSTER CBCTA 2018 - FCT - AchioteDocument1 pageMODELO E PÔSTER CBCTA 2018 - FCT - AchioteFiorellaNo ratings yet

- DELVO System Hydration ControlDocument3 pagesDELVO System Hydration ControlArangamar KumaranNo ratings yet

- Chemical Bath Deposition: Mark - Deguire@case - EduDocument21 pagesChemical Bath Deposition: Mark - Deguire@case - EduH Cuarto PeñaNo ratings yet

- Rust Bullet AI & GuideDocument32 pagesRust Bullet AI & GuideImam SitumeangNo ratings yet

- Baroid Completion ManualDocument164 pagesBaroid Completion Manuallatnrythmz100% (1)