Professional Documents

Culture Documents

B73 G - Air Filter Regulator

B73 G - Air Filter Regulator

Uploaded by

kamatamoghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B73 G - Air Filter Regulator

B73 G - Air Filter Regulator

Uploaded by

kamatamoghCopyright:

Available Formats

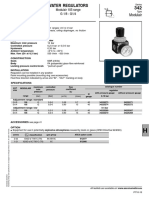

B73G

EXCELON® 73

Filter/Regulator

1/4", 3/8", 1/2" Port Sizes

● EXCELON design allows in-line or modular

installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Full flow gauge ports

● Balanced valve design minimizes effect of variation in

the inlet pressure on the outlet pressure

● Modular installations with EXCELON 72, 73, and 74

series can be made to suit particular applications

Technical Data Materials:

Fluid: Compressed air Body: Aluminum

Maximum pressure: Bonnet: Aluminum

Transparent bowl: 10 bar (150 psig) Valve: Brass

Metal bowl: 17 bar (250 psig) Bowl:

Operating temperature*: Transparent: Polycarbonate

Transparent bowl: -20° to +50°C (0° to +125°F) Transparent with guard: Polycarbonate,

Metal bowl: -20° to +80°C (0° to +175°F) steel guard

* Air supply must be dry enough to avoid ice formation at temperatures below +2°C Metal: Aluminum

(+35°F). Metal bowl liquid level indicator lens:

Particle removal: 5 µm, 25 µm or 40 µm filter element Transparent nylon

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates) Element: Sintered polypropylene

Typical flow with 10 bar (150 psig) inlet pressure, 6,3 bar (90 psig) Elastomers: Neoprene and nitrile

set pressure and 1 bar (15 psig) droop from set:

50 dm3/s (106 scfm) Ordering Information

Manual drain connection: 1/8" See Ordering Information on the following

Automatic drain connection: 1/8" pages.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 0,3 bar ISO Symbols

(5 psig)

Bowl pressure required to open drain: Less than 0,2 bar (3 psig)

Minimum air flow required to close drain: 0,1 dm3/s (0.2 scfm)

Manual operation: Depress pin inside drain outlet to drain bowl

Automatic Drain, Relieving Manual Drain, Relieving

Nominal bowl size: 0,1 litre (3.5 fluid ounce)

Gauge ports:

1⁄4 PTF with PTF main ports

Rc1/4 with ISO Rc main ports

Rc1/8 with ISO G main ports

Automatic Drain, Non-Relieving Manual Drain, Non-Relieving

Our policy is one of continuous research and development.

7/98 We reserve the right to amend, without notice, the specifications given in this document.

N/AL.8.180.300.01

B73G

Typical Performance Characteristics

FLOW CHARACTERISTICS FLOW CHARACTERISTICS

psig

bar

psig

PORT SIZE: 3/8"

bar

PORT SIZE: 3/8"

ELEMENT: 40 µm ELEMENT: 40 µm

INLET PRESSURE: 10 bar (150 psig) INLET PRESSURE: 7 bar (100 psig)

RANGE: 0,3 to 10 bar (5 to 150 psig) RANGE: 0,3 to 10 bar (5 to 150 psig)

100 100

OUTLET PRESSURE

OUTLET PRESSURE

6 6

80 80

60 60 4

4

40 40

2 2

20 20

0 0 0 0

0 20 40 60 80 100 dm3/s 0 10 20 30 40 50 dm3/s

0 40 80 120 160 200 scfm 0 20 40 60 80 100 scfm

AIR FLOW AIR FLOW

Ordering Information. Models listed include ISO G parallel threads, knob adjustment, automatic drain, metal bowl with liquid level

indicator, 40 µm element, relieving diaphragm, and 0,3 to 10 bar (5 to 150 psig) outlet pressure adjustment range*.

Main Port Size Model Number Flow† dm3/s (scfm) Weight kg (lb)

G1/4 B73G-2GK-AD3-RMN Waiting on lab test 0,7 (1.5)

G3/8 B73G-3GK-AD3-RMN 50 (106) 0,7 (1.5)

G1/2 B73G-4GK-AD3-RMN 50 (106) 0,7 (1.5)

† Typical flow with 10 bar (150 psig) inlet pressure, 6,3 bar (90 psig) set pressure and 1 bar (15 psig) droop from set.

Alternative Models B 7 3 G - ★ ★ ★ - ★★ ★ - ★★ ★

Port Size Substitute Gauge Substitute

1/4" 2 With G

3/8" 3 Without N

1/2" 4

Threads Substitute

PTF A Outlet Pressure Adjustment Range* Substitute

ISO Rc taper B 0,3 to 4 bar (5 to 60 psig) F

ISO G parallel G 0,3 to 10 bar (5 to 150 psig) M

0,7 to 17 bar (10 to 250 psig) S

Adjustment Substitute

Knob K

T-bar T Diaphragm Substitute

Relieving R

Drain Substitute Non relieving N

Automatic A

Manual, 1/4 turn Q

Bowl Substitute Element Substitute

Metal with liquid level indicator D 5 µm 1

Transparent with guard P 25 µm 2

Transparent T 40 µm 3

* Outlet pressure can be adjusted to pressures in excess of, and less ** Units with 17 bar (250 psig) outlet pressure range are available only

than, those specified. Do not use these units to control pressures with the standard metal bowl.

outside of the specified ranges.

Our policy is one of continuous research and development. 7/98

N/AL.8.180.300.02 We reserve the right to amend, without notice, the specifications given in this document.

B73G

Accessories

Neck Mounting Bracket Tamper Resistant Cover R1/4 R1/8 1/4 PTF

Wall Mounting Bracket With Zinc Panel Nut and Seal Wire†† Pressure Gauge Connection Connection Connection

4424-50 Bracket and nut: 4461-50 Cover and wire: 4455-51 4 bar (60 psig): 18-013-266 18-013-011 18-013-208

Nut: 5191-88 Replacement seal wire: 2117-01 10 bar (150 psig): 18-013-260 18-013-013 18-013-209

20 bar (300 psig): 18-013-267 18-013-014 18-013-210

†† Use padlock with shackle up to 8 mm (0.3" ) in diameter.

Dimensions mm (inches) 68 (2.68)

31 (1.22)

Panel mounting hole diameter: 48 mm (1.89" )

Panel thickness: 2 to 6 mm (0.06" to 0.25" )

62 (2.45)

56 (2.20)

50 (2.00)

12 (0.45)

103 (4.04)

96 (3.80)

(1.22)

31

207 (8.15) *

216 (8.50) *

147 (5.80)

156 (6.15)

Automatic Drain

1/4 Turn Manual Drain

* Minimum clearance to remove bowl.

Our policy is one of continuous research and development.

7/98 We reserve the right to amend, without notice, the specifications given in this document.

N/AL.8.180.300.03

B73G

Bracket Kit Reference Service Kits

Model Part No. Item Type Part Number

All 73 Series products 4424-50 Service kit Relieving 4383-600

R73, B73 neck mounting bracket with zinc panel nut 5203-06 Non-relieving 4383-601

5 µm 4438-01

Replacement elements 25 µm 4438-02

Bracket Mounting 40 µm 4438-03

Universal Wall Bracket for 73 Series Products Liquid level lens kit Prismatic 4380-020

Automatic 4000-51R

Use 6mm (1/4" ) screws to mount bracket to wall. Replacement drains

Manual quarter turn 619-50

60 (2.37) Service kit includes diaphragm assembly, valve assembly, valve

spring, bowl o-ring, and automatic drain seal.

38 (1.50)

67 (2.64)

Port CL

28

(1.10) 18

(0.71)

4 (0.16)

6 (0.24)

48 (1.89)

61 (2.40)

7 (0.28)

Port CL

19 (0.74)

Neck Mounting Bracket for R73 and B73

Includes zinc panel nut. Use 6mm (1/4" ) screws to mount bracket to

wall.

64 (2.5)

38 (1.5)

70 (2.75)

38

(1.5)

17 (0.66)

38 (1.5)

(1.0)

7 (0.27)

25

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under ‘Technical Data’.

Before using these products with fluids other than those specified, for

non-industrial applications, life-support systems, or other applications not

within published specifications, consult Norgren.

Through misuse, age, or malfunction, components used in fluid power

systems can fail in various modes. The system designer is warned to

consider the failure modes of all component parts used in fluid power

systems and to provide adequate safeguards to prevent personal injury or

damage to equipment in the event of such failure.

System designers must provide a warning to end users in the

system instructional manual if protection against a failure mode

cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with these

products.

Water vapor will pass through these units and will condense into liquid

if air temperature drops in the downstream system. Install an air dryer if

water condensation could have a detrimental effect on the application.

Our policy is one of continuous research and development. 7/98

N/AL.8.180.300.04 We reserve the right to amend, without notice, the specifications given in this document.

You might also like

- Howard Wright M9 TransferTechnical Service Manual-V2Document54 pagesHoward Wright M9 TransferTechnical Service Manual-V2angelo fiorentino0% (2)

- Technical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Document4 pagesTechnical Data: Air Supply Must Be Dry Enough To Avoid Ice Formation at Temperatures Below +2 C (+35 F)Enrique Arellano HidalgoNo ratings yet

- Nor GrenDocument154 pagesNor Grendario.landriel02No ratings yet

- SPUSF73G3AS005Document4 pagesSPUSF73G3AS005Ezequiel 1No ratings yet

- R73G, R73R: Technical DataDocument4 pagesR73G, R73R: Technical DataEnrique Arellano HidalgoNo ratings yet

- 8 (1) 160 105 PDFDocument4 pages8 (1) 160 105 PDFFRANK PRUDENCIO OBREGONNo ratings yet

- B68G, B68E: Ordering InformationDocument4 pagesB68G, B68E: Ordering InformationkamatamoghNo ratings yet

- Filter Regulator - B68G - NORGREN - Data SheetDocument5 pagesFilter Regulator - B68G - NORGREN - Data SheetMBI Heineken RonaldNo ratings yet

- Norgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Document4 pagesNorgren Excelon® Modular Series Ultraire Oil Vapour Removal 74Iswar Rauf Aboo 'AqilahNo ratings yet

- NORGREN - Filter Regulator - B73G Series - DatasheetDocument5 pagesNORGREN - Filter Regulator - B73G Series - Datasheetmanwar3399No ratings yet

- B74GIM Norgren MK3Document2 pagesB74GIM Norgren MK3Ζαχος ΤσελιοςNo ratings yet

- High Flow High Pressure Reducing RegulatorsDocument4 pagesHigh Flow High Pressure Reducing Regulatorsامیر علیNo ratings yet

- C75 GunJet Low-Pressure BDocument10 pagesC75 GunJet Low-Pressure BMohit SinghalNo ratings yet

- En 8 160 300 B72GDocument5 pagesEn 8 160 300 B72GFernando TudónNo ratings yet

- Data Sheet 15-63-3-A - eDocument9 pagesData Sheet 15-63-3-A - eMarko PalekaNo ratings yet

- RegulatorDocument4 pagesRegulatorarunbiswalNo ratings yet

- Luftfilter-+-404671 EN BADocument5 pagesLuftfilter-+-404671 EN BAshaonaaNo ratings yet

- 850 860 870 SpecDocument2 pages850 860 870 SpecJerNo ratings yet

- Norgren Filter RegulatorDocument4 pagesNorgren Filter RegulatorJose JohnNo ratings yet

- 9EM-B18 Air FilterDocument2 pages9EM-B18 Air FilterqcromoilfieldNo ratings yet

- Norgren - FilterDocument2 pagesNorgren - Filtermoudar72No ratings yet

- Norgren PDFDocument18 pagesNorgren PDFAbhayy DevNo ratings yet

- PH 1600 Series Data Sheet en 126926Document4 pagesPH 1600 Series Data Sheet en 126926detroja tusharNo ratings yet

- Data Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09Document3 pagesData Sheet-FIREMIKS-FM-3200-GP-F-Aut 2015-12-09appril26No ratings yet

- A Low Volume Manifold Designed Specifically For Gas SamplingDocument2 pagesA Low Volume Manifold Designed Specifically For Gas SamplingBruno AlfanoNo ratings yet

- 11 4snDocument2 pages11 4snRAHUL TARINo ratings yet

- B07 SeriesDocument3 pagesB07 SeriesKimi HaydenNo ratings yet

- A 4 D 03Document14 pagesA 4 D 03Eng-Mohammed SalemNo ratings yet

- Super Duty Standard FiltersDocument2 pagesSuper Duty Standard FiltersEliasNo ratings yet

- VT IPH 21 BDI 90115 enDocument16 pagesVT IPH 21 BDI 90115 enwag008No ratings yet

- 7400 Snaptrol Liquid Level ControlDocument2 pages7400 Snaptrol Liquid Level Controljose nuñezNo ratings yet

- Regulador American Meter PDFDocument6 pagesRegulador American Meter PDFjmcg1974No ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- SB13 - With Plastic Knob Adjustment. SA13 - With Metal 'T' Handle - Optional (G, G, G, G, G 1)Document2 pagesSB13 - With Plastic Knob Adjustment. SA13 - With Metal 'T' Handle - Optional (G, G, G, G, G 1)upendra0382366No ratings yet

- C72H NorgrenDocument4 pagesC72H NorgrenHernando HerreraNo ratings yet

- Excelon Modular System Pressure Regulators - R72, 73, 74 PDFDocument2 pagesExcelon Modular System Pressure Regulators - R72, 73, 74 PDFJow SilvaNo ratings yet

- HF Pro: Miniature High Flow Proportional ValveDocument6 pagesHF Pro: Miniature High Flow Proportional Valvebiomed2083No ratings yet

- Pilot Operated Pressure Regulator 1/2" To 4" 25P: Typical ApplicationsDocument2 pagesPilot Operated Pressure Regulator 1/2" To 4" 25P: Typical ApplicationsRendy MulyadiNo ratings yet

- Dorot Pilot Valves English Edition 03.2017 8 11 PDFDocument4 pagesDorot Pilot Valves English Edition 03.2017 8 11 PDFMoises Chicchi PeraltaNo ratings yet

- Reguladore SENSUS para Gas CombustibleDocument20 pagesReguladore SENSUS para Gas CombustibleJorge BaronNo ratings yet

- Dorot Pilot Valves English Edition 03.2017!8!11Document4 pagesDorot Pilot Valves English Edition 03.2017!8!11Moises Chicchi PeraltaNo ratings yet

- 2200 Series PDFDocument3 pages2200 Series PDFhendrabudimanNo ratings yet

- Norgren R05Document2 pagesNorgren R05skinkcrowNo ratings yet

- En 8 200 350 B84GDocument11 pagesEn 8 200 350 B84GgoofflineNo ratings yet

- 3400 Series Accumulator Tank: Genneral Installation InstructionsDocument2 pages3400 Series Accumulator Tank: Genneral Installation InstructionsmusebladeNo ratings yet

- Watson Smith Vp50Document3 pagesWatson Smith Vp50ECO Green and BlueNo ratings yet

- Belgas p39Document4 pagesBelgas p39Syach FirmNo ratings yet

- RB 1000-SSDDocument2 pagesRB 1000-SSDkyo8400No ratings yet

- Volume Booster VB60 1-2 3-4-ALDocument4 pagesVolume Booster VB60 1-2 3-4-ALArman MominNo ratings yet

- IOL Series Filter Housings: Design RatingsDocument2 pagesIOL Series Filter Housings: Design RatingsDaniel HernándezNo ratings yet

- P1 Skid Mounted DatasheetDocument1 pageP1 Skid Mounted Datasheetsv purushothNo ratings yet

- ITAPTECH AUTOMATIC-AIR-VENT EngDocument14 pagesITAPTECH AUTOMATIC-AIR-VENT EngCarlos EspNo ratings yet

- Process Equipment Catalog: Pumping Solutions For Process IndustriesDocument120 pagesProcess Equipment Catalog: Pumping Solutions For Process IndustriesRoss Juniamah PengaNo ratings yet

- Pressure Transmitter Selection GuideDocument2 pagesPressure Transmitter Selection Guideابزار دقیق50% (2)

- R Pilot - BWBPSHLDocument2 pagesR Pilot - BWBPSHLalvipin0010% (1)

- EZR ManualDocument40 pagesEZR Manualdancuk99No ratings yet

- Olympian Filter - Regulators - B64G, B68E - GDocument3 pagesOlympian Filter - Regulators - B64G, B68E - GAcep WahyudinNo ratings yet

- Air Regulator FilterDocument4 pagesAir Regulator FilterChandan KumarNo ratings yet

- Page 1271Document1 pagePage 1271EmilyTheDwarfNo ratings yet

- Alfa Laval Unique RV ST Regulating Valve - Product Leaflet - Ese02071Document9 pagesAlfa Laval Unique RV ST Regulating Valve - Product Leaflet - Ese02071GeorgeNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Water RegulatorDocument2 pagesWater RegulatorkamatamoghNo ratings yet

- B68G, B68E: Ordering InformationDocument4 pagesB68G, B68E: Ordering InformationkamatamoghNo ratings yet

- R91 426.280 - Water RegulatorDocument4 pagesR91 426.280 - Water RegulatorkamatamoghNo ratings yet

- Kugel Und Rollenlagerwerk Leipzig GMBH: GermanyDocument2 pagesKugel Und Rollenlagerwerk Leipzig GMBH: GermanykamatamoghNo ratings yet

- AEC AdvertisementDocument1 pageAEC AdvertisementkamatamoghNo ratings yet

- Catalogue 2013 1Document7 pagesCatalogue 2013 1kamatamoghNo ratings yet

- Industrial Suppliers Pvt. LTD.: Authorised Distributor ForDocument1 pageIndustrial Suppliers Pvt. LTD.: Authorised Distributor ForkamatamoghNo ratings yet

- Bagasse Drier CatalogueDocument2 pagesBagasse Drier CataloguekamatamoghNo ratings yet

- Howden Alphair Cyclone ProductDocument6 pagesHowden Alphair Cyclone ProductkamatamoghNo ratings yet

- Custom Centrifugal FanDocument8 pagesCustom Centrifugal FankamatamoghNo ratings yet

- Airochem Bagasse DrierDocument8 pagesAirochem Bagasse DrierkamatamoghNo ratings yet

- Polybond Mounts CatalogueDocument39 pagesPolybond Mounts CataloguekamatamoghNo ratings yet

- ID Fan ManualDocument25 pagesID Fan Manualkamatamogh83% (6)

- Library Punching TechnologyDocument96 pagesLibrary Punching TechnologyMilan Gavrovic100% (2)

- Nanoparticles Synthesis, Stabilization, Passivation, and FunctionalizationDocument7 pagesNanoparticles Synthesis, Stabilization, Passivation, and Functionalizationraul gomezNo ratings yet

- 0 Exercise Instruction Heating ValueDocument7 pages0 Exercise Instruction Heating ValueMurali MuthuNo ratings yet

- Selection of Inherently Safer Process Routes: A Case StudyDocument7 pagesSelection of Inherently Safer Process Routes: A Case StudyJames EdwardsNo ratings yet

- Physics Form 4Document20 pagesPhysics Form 4faizi_ammarNo ratings yet

- 045 - CE8020, CE6021 Repair and Rehabilitation of Structures - Important QuestionsDocument1 page045 - CE8020, CE6021 Repair and Rehabilitation of Structures - Important QuestionsSATHISH KUMAR SNo ratings yet

- BTLED IA 3A Research 1 1Document19 pagesBTLED IA 3A Research 1 1Joevan VillaflorNo ratings yet

- NHF Series BrochureDocument2 pagesNHF Series Brochure3raulcNo ratings yet

- Mat Cscec 12 Me HD 0072 04Document270 pagesMat Cscec 12 Me HD 0072 04Mostafa ElsammanNo ratings yet

- K14Y5Document16 pagesK14Y5MohdBadruddinKarimNo ratings yet

- All About Polyester FinishesDocument16 pagesAll About Polyester FinishessegbukNo ratings yet

- Articol 3Document5 pagesArticol 3pavel badinskyNo ratings yet

- Chevron Base Oils PresentationDocument28 pagesChevron Base Oils PresentationDevelopment Lubricants100% (1)

- RSB Bolt LooseningDocument5 pagesRSB Bolt LooseningmailbkraoNo ratings yet

- Arc 23000 Darc Catalog EmailDocument87 pagesArc 23000 Darc Catalog EmailLazaro CoutinhoNo ratings yet

- Water-Extractable Chloride in Aggregate (Soxhlet Method) : Provisional Standard Test Method ForDocument3 pagesWater-Extractable Chloride in Aggregate (Soxhlet Method) : Provisional Standard Test Method ForOscar Gutiérrez-JuncoNo ratings yet

- ISO-10334-1994 For Stainless SuturesDocument8 pagesISO-10334-1994 For Stainless SuturesDoaa Khalil100% (1)

- 7 Science NCERT Solutions Chapter 4Document5 pages7 Science NCERT Solutions Chapter 4preethaNo ratings yet

- FSI Catalogue PDFDocument8 pagesFSI Catalogue PDFBerkat TehnikNo ratings yet

- 272C PDFDocument4 pages272C PDFWilsonNo ratings yet

- Serbco WP Training Manual For PPR Pipes and FittingsDocument16 pagesSerbco WP Training Manual For PPR Pipes and FittingsDewald Tjatjarag BurzynskiNo ratings yet

- N R B Cargo ExpressDocument3 pagesN R B Cargo Expressapi-267591894No ratings yet

- Two-Storey Residential BuildingDocument10 pagesTwo-Storey Residential BuildingJunibel WenceslaoNo ratings yet

- BorgWarner DCTWet ClutchesFrictionMtrls GoldDocument45 pagesBorgWarner DCTWet ClutchesFrictionMtrls Goldddeeff715No ratings yet

- Man 97055 97041 LXQ Connect Man9705597041 B ENDocument90 pagesMan 97055 97041 LXQ Connect Man9705597041 B ENKike PalaciosNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Ndd010-Mcs Type B - Rev.j Mcs33Document4 pagesNdd010-Mcs Type B - Rev.j Mcs33edgarpatoNo ratings yet

- Used of Hand ToolsDocument19 pagesUsed of Hand ToolsJared MacNo ratings yet

- Direct Shell Production CastingDocument7 pagesDirect Shell Production Castingmanoharanpark_43331550% (2)