Professional Documents

Culture Documents

Metallic Bellow QAP

Metallic Bellow QAP

Uploaded by

Pavul RajOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metallic Bellow QAP

Metallic Bellow QAP

Uploaded by

Pavul RajCopyright:

Available Formats

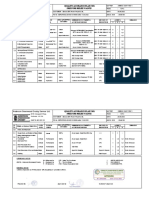

ENMAS EPC POWER PROJECT LIMITED

ENMAS EPC POWER PROJECT LIMITED

CHENNAI - 600 008, INDIA.

QUALITY ASSURANCE PLAN

CUSTOMER : M/S JEFFERSON ENTERPRISE LLC JOB NO. : HC01S1

PROJECT : Renovation of Existing Boiler QAP NO. : EEPC/HC01S1/QAC/IC/333/S/0025

CONSULTANT : ---- REV. NO. : 00

COMPONENT : EXPANSION BELLOW DATE : 05/05/2022

MANUFACTURER :

REV. DATE DESCRIPTION REVISED BY PREPARED REVIEWED APPROVED

NAME M.VENUGOPAL J.PAVUL RAJ B.K.SAHU

SIGNATURE

DATE

ABBREVIATIONS:-

1 MANUFACTURER MT MAGNETIC PARTICAL TEST

2 ENMAS EPC/THIRD PARTY MVR MATERIAL VERIFICATION REPORT

3 THIRD PARTY/CUSTOMER NDT NON DESTRUCTIVE TEST

ASME AMERICAN SOCIETY OF MECHANICAL ENGINEERS P PERFORM

AI/IA AUTHORSISED INSPECTOR/INSPECTING AUTHORITY PO PURCHASE ORDER

AWS AMERICAN WELDING SOCIETY PMI POSITIVE MATERIAL TESTING

CC COMPLIANCE CERTIFICATE LPT LIQIUID PENTRANT TEST

DC DELIVERY CHALLAN PQR PROCEDURE QUALIFICATION RECORD

DFT DRY FILM THICKNESS QAP QUALITY ASSURANCE PLAN

DRG DRAWING R REVIEW

EP EDGE PREPARATION RT RADIOGRAPHY TEST

FICN FINAL INSPECTION CLEARANCE NOTE TC TEST CERTIFICATE

H HOLD(MANDATORY CLEARANCE WITHOUT WHICH NO FURTHER OPERATION PERMITTED) UT ULTRASONIC TEST

HT HEAT TREATMENT W WITNESS (TO BE INFORMED AND FURTHER OPERATION CAN CONTINUE)

HTR HYDRO TEST REPORT WPQ WELDER PERFORMANCE QUALIFICATION

IR INSPECTION REPORT WPS WELDING PERFORMANCE SPECIFICATION

MFR MANUFACTURER

Metallic Bellow QAP Page 1 of 2

ENMAS EPC POWER PROJECT LIMITED

TYPE OF CHECK REFERENCE ACCEPTANCE FORMAT INSPECTION BY

SL.NO. OPERATION CHARACTERISTICS

& QUANTUM DOCUMENT NORM OF RECORD 1 2 3

1.0 Material Control

1.1 Raw material & bellow Chemical, Mechanical TC / Lab report verification - 100% Drawings, Specification Drawings, Specification Test certificates/ Lab reports P R

properties

2.0 Welding control

2.1 Qualification of welding process WPS, PQR, Verification of applicable Verification - 100% Drawings, Drawings, WPS, PQR, WPQ P R

WPQ WPS / Qualification ASME SEC. IX ASME SEC. IX

3.0 In-process Inspection

3.1 Bellow Fit-up & Welding Dimensions Visual, Dimension - 100% Approved Drawings Approved Drawings IR P R

3.2 Visual Inspection Visual Visual - 100% Approved Drawings Approved Drawings IR P H

3.3 NDT of bellow weld joints Weld soundness Visual, PT Test - 100% ASME sec V ASME sec VIII NDT Report P H

4.0 Assembly and final inspection

4.1 Pneumatic/Hydraulic Pressure testing of Bellows Leak tightness Visual - 100%, Air/Water Leak test Approved Drawings Approved Drawings Pneumatic test report P H H

4.2 Final Inspection Dimension, Movement Visual, Dimension - 100% Approved Drg. / Approved Drg. / IR P W H

Test Approved data sheet Approved data sheet

5.0 Surface preparation & Painting Paint type, Finish, Visual, Measurement - 100% Approved Drawings Approved Drawings T.C & Painting Report P R

Coating thickness

6.0 Final Documentation Review of all TC, Visual & Document Review - 100% Drawings, Specification Drawings, Specification Booklet P H

Inpection Reports

Metallic Bellow QAP Page 2 of 2

You might also like

- Pneumatic Test ProDocument4 pagesPneumatic Test ProWalha WassimNo ratings yet

- Piping Engineering: Phillips 66 Lake Charles Project Specific AddendumDocument16 pagesPiping Engineering: Phillips 66 Lake Charles Project Specific AddendumChirag ShahNo ratings yet

- Supplier Quality Management A Complete Guide - 2021 EditionFrom EverandSupplier Quality Management A Complete Guide - 2021 EditionNo ratings yet

- KP ThermostatsDocument9 pagesKP ThermostatsMargaret DaughertyNo ratings yet

- Eamesetal Thermostatic Valves 2014Document10 pagesEamesetal Thermostatic Valves 2014rickitek gaaso100% (1)

- Badger Knowledge Base Metal Bellows Expansion Joint HandbookDocument24 pagesBadger Knowledge Base Metal Bellows Expansion Joint Handbookli100% (1)

- Product Data Sheet: Argon (Ar)Document2 pagesProduct Data Sheet: Argon (Ar)adammzjin100% (1)

- ArgonDocument8 pagesArgonariane8910No ratings yet

- Pressure Reducing and Surplussing Valves For Steam and Industrial Fluids-SB-GCH-29-EnDocument18 pagesPressure Reducing and Surplussing Valves For Steam and Industrial Fluids-SB-GCH-29-EnAgus HermantoNo ratings yet

- Argon Pure GasDocument2 pagesArgon Pure GasRaghu Pathy100% (1)

- X-Bar R ChartDocument3 pagesX-Bar R ChartShanmugam BalasubramaniamNo ratings yet

- X BAR R ChartDocument4 pagesX BAR R ChartGaurao WarungaseNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- List of Approved SupplierDocument4 pagesList of Approved SupplierSachin MeshramNo ratings yet

- Marketing Project On MahindraDocument58 pagesMarketing Project On MahindraAbhishek SutarNo ratings yet

- AVK Product-Programme BrochureDocument20 pagesAVK Product-Programme BrochureChanel100% (1)

- Presentation TemplateDocument18 pagesPresentation Templatesaibabu sai100% (1)

- Optimization Design of The U-Shaped Metal BellowsDocument5 pagesOptimization Design of The U-Shaped Metal BellowsdaymonNo ratings yet

- Air Vents SteamDocument1 pageAir Vents Steamtolis31No ratings yet

- Whitepaper Oeeoverview PDFDocument9 pagesWhitepaper Oeeoverview PDFbasura12345No ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Cyclic Fatigue in Metal BellowsDocument4 pagesCyclic Fatigue in Metal BellowsNayri AkbugaNo ratings yet

- Metal Expansion Joints-Inquiry Form - EagleBurgmannDocument2 pagesMetal Expansion Joints-Inquiry Form - EagleBurgmannMachineryengNo ratings yet

- StallDocument16 pagesStallbhalchandrak1867100% (3)

- ASTM A105 Flange Heat TreatmentDocument16 pagesASTM A105 Flange Heat TreatmentpuffdNo ratings yet

- QG-106 지침Document5 pagesQG-106 지침오덕환Oh Duckhwan100% (1)

- 12 BonnetsDocument15 pages12 Bonnetsfaisal84in100% (1)

- 08 Welltest EquipmentDocument4 pages08 Welltest EquipmentdronneNo ratings yet

- GTAW SMAW 6 Inch CSDocument1 pageGTAW SMAW 6 Inch CSKentDemeterioNo ratings yet

- BPVC - VIII-1 - U-2A FormDocument2 pagesBPVC - VIII-1 - U-2A FormPranesh BhatNo ratings yet

- Case Study - MousetrapDocument6 pagesCase Study - Mousetrapjanela bautistaNo ratings yet

- Review of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Document35 pagesReview of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Omar Ezzat100% (1)

- ASME Manual Edition 2019Document69 pagesASME Manual Edition 2019hgag selimNo ratings yet

- Testing and Maintenance of Steam TrapsDocument5 pagesTesting and Maintenance of Steam Trapsthunderpedro100% (1)

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 pagesSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviNo ratings yet

- HydroFC Promo-GE Bellows ConnectorDocument1 pageHydroFC Promo-GE Bellows ConnectorMike FinazziNo ratings yet

- 2019-5 TechPresentation BeachDocument141 pages2019-5 TechPresentation Beachaneeshta100% (1)

- Cast Carbon Stee ValveDocument28 pagesCast Carbon Stee ValveAlexjohn2009No ratings yet

- Pneumatic, Piston Type: Needle Valve ActuatorsDocument20 pagesPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahNo ratings yet

- Ped 6Document16 pagesPed 6Everton ArrudaNo ratings yet

- Assembly & Maintenance Scotch & YokeDocument48 pagesAssembly & Maintenance Scotch & YokeCesar Carlos MarquezNo ratings yet

- Piping Materials - Olets The Piping Engineering WorldDocument3 pagesPiping Materials - Olets The Piping Engineering Worldrenger20150303100% (1)

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- FH-STR-03 GrinDocument3 pagesFH-STR-03 GrinKarthi ThiyagarajanNo ratings yet

- 4-QAP Heat EXDocument8 pages4-QAP Heat EXAjit Patil100% (1)

- Roadmap For BIS Product Certification PDFDocument2 pagesRoadmap For BIS Product Certification PDFAnkurNo ratings yet

- C-BV6 - Medium - Ball ValvesDocument60 pagesC-BV6 - Medium - Ball ValvesRajendraNo ratings yet

- A234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFDocument9 pagesA234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFRony YudaNo ratings yet

- QMS Awareness ProgramDocument9 pagesQMS Awareness ProgramshravandownloadNo ratings yet

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNo ratings yet

- MGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationDocument16 pagesMGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationKarrar TalibNo ratings yet

- Astm A 234 A234m-15Document9 pagesAstm A 234 A234m-15Mohammed AliNo ratings yet

- Ansi NuclearDocument2 pagesAnsi NuclearAngelique SutantoNo ratings yet

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoNo ratings yet

- Contour™ Flow Conditioner Data Pack PDFDocument14 pagesContour™ Flow Conditioner Data Pack PDFeduryu100% (1)

- Inspection and Test Plan: Fabrication / In-Process InspectionDocument17 pagesInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Gauging Practice For Plain SurfacesDocument20 pagesGauging Practice For Plain SurfacesAVINASHNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- IVR-050212116123 - 22-1-Rev.0 - Enmas - True FabDocument6 pagesIVR-050212116123 - 22-1-Rev.0 - Enmas - True FabPavul RajNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Sa 351Document7 pagesSa 351Pavul RajNo ratings yet

- Sa 178 2019Document5 pagesSa 178 2019Pavul RajNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- Tolerance Table - Boiler StructuresDocument1 pageTolerance Table - Boiler StructuresPavul RajNo ratings yet

- Safety Valve Qap 270622Document2 pagesSafety Valve Qap 270622Pavul RajNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- BR PU High Gloss Enamel PaintDocument2 pagesBR PU High Gloss Enamel PaintPavul Raj100% (1)

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Aprroved QAP-1883-R01-15122022Document1 pageAprroved QAP-1883-R01-15122022Pavul RajNo ratings yet

- Apcosil 605 IzssDocument3 pagesApcosil 605 IzssPavul RajNo ratings yet

- ThesisDocument86 pagesThesisPavul RajNo ratings yet

- NT 900 NavtexDocument1 pageNT 900 NavtexUFUKKK0% (1)

- Opa164X Soundplus™ High-Performance, Jfet-Input Audio Operational AmplifiersDocument46 pagesOpa164X Soundplus™ High-Performance, Jfet-Input Audio Operational Amplifiersupendra6789No ratings yet

- The Keyword Minute ReportDocument36 pagesThe Keyword Minute Reportrizalcb100% (1)

- Parapetni FC AparatiDocument36 pagesParapetni FC AparatiEnis IvkovićNo ratings yet

- Mir100 Hook DatasheetDocument2 pagesMir100 Hook DatasheetS NguyenNo ratings yet

- Chapter 1 OkDocument7 pagesChapter 1 OkUruru EnialeNo ratings yet

- LV-Hub Communication HUB Product Manual (V2.1) 20190808 48VDocument12 pagesLV-Hub Communication HUB Product Manual (V2.1) 20190808 48VJosé Vicente González VivasNo ratings yet

- Resume Mohammed Naveed PDFDocument4 pagesResume Mohammed Naveed PDFSalesOnly BestNo ratings yet

- Email Marketing - ChecklistDocument4 pagesEmail Marketing - ChecklistRahul SharmaNo ratings yet

- Anti Surge ControlDocument15 pagesAnti Surge Controlella arunNo ratings yet

- Overview of Transaction Processing and Enterprise Resource Planning SystemsDocument17 pagesOverview of Transaction Processing and Enterprise Resource Planning Systemshaziqhussin33No ratings yet

- Oracle Developers GuideDocument18 pagesOracle Developers GuideIonel GherasimNo ratings yet

- Modicon Momentum Automation Platform: CatalogDocument111 pagesModicon Momentum Automation Platform: Catalogsalmo83:18No ratings yet

- SD3 & SD6 - 15m Ginpole Tower Foundation DetailDocument9 pagesSD3 & SD6 - 15m Ginpole Tower Foundation Detailjustin100% (1)

- Mobile Telephone History PhilippinesDocument29 pagesMobile Telephone History PhilippinesKyou Chan100% (1)

- Temi Center Users GuideDocument37 pagesTemi Center Users Guidethiago.camposNo ratings yet

- Business: Read The Passage and Answer The Questions. The Just in Time MethodDocument3 pagesBusiness: Read The Passage and Answer The Questions. The Just in Time MethodJaisonEnriqueSabogalGallego100% (1)

- 03 Strategic Management (Slide)Document17 pages03 Strategic Management (Slide)Farmasi RSUDNo ratings yet

- Marketing and Action Plan-08112021Document1 pageMarketing and Action Plan-08112021api-559392378No ratings yet

- Alphabetical List of ExhibitorsDocument102 pagesAlphabetical List of ExhibitorsSharafat AliNo ratings yet

- Assembly 1Document5 pagesAssembly 1Renpin LuoNo ratings yet

- Original Xiaomi Redmi Airdots Bluetooth 5.0 TWS Wireless Active Earbuds Headset EbayDocument1 pageOriginal Xiaomi Redmi Airdots Bluetooth 5.0 TWS Wireless Active Earbuds Headset EbayM Wasim IshaqNo ratings yet

- A Maskless Photolithographic Prototyping System UsDocument5 pagesA Maskless Photolithographic Prototyping System UsAnton PinchukNo ratings yet

- Cat 320 D LLRDocument16 pagesCat 320 D LLRLuis Dilan QE AY100% (1)

- ERP Financial Accounting Accelerator With SAP HANADocument6 pagesERP Financial Accounting Accelerator With SAP HANAtekzNo ratings yet

- Microelectronic CapsuleDocument20 pagesMicroelectronic CapsuleMouni BoomiReddyMounikaNo ratings yet

- Chapter 1Document24 pagesChapter 1Anonymous tytJlPojNo ratings yet

- 9120 G2 BSCDocument250 pages9120 G2 BSCAM MOTO OMCRNo ratings yet

- SEO Audit & Analysis - Vibe EducationDocument17 pagesSEO Audit & Analysis - Vibe EducationMeenakshi ThakurNo ratings yet

- Detailed Fitness For Service Per API 579Document3 pagesDetailed Fitness For Service Per API 579Sajal KulshresthaNo ratings yet