Professional Documents

Culture Documents

Ducting QAP R02 080822

Ducting QAP R02 080822

Uploaded by

Pavul RajOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ducting QAP R02 080822

Ducting QAP R02 080822

Uploaded by

Pavul RajCopyright:

Available Formats

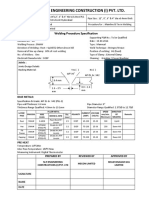

ENMAS EPC POWER PROJECTS LIMITED

CHENNAI - 600 008, INDIA.

QUALITY ASSURANCE PLAN

CUSTOMER : M/S JEFFERSON ENTERPRISE LLC JOB NO. : HC01S1

PROJECT : Renovation of Existing Boiler QAP NO. : EEPC/HC01S1/QAC/IC/333/S/0003

CONSULTANT : ---- REV. NO. : 02

COMPONENT : DUCTING DATE : 02/05/2022

MANUFACTURER :

REV. DATE DESCRIPTION REVISED BY PREPARED REVIEWED APPROVED

01 28.07.22 THIRD PARTY INSPECTION STAGES ADDED JPR NAME M.VENUGOPAL J.PAVUL RAJ B.K.SAHU

02 08.08.22 NOTES ADDED JPR

SIGNATURE

DATE

ABBREVIATIONS:-

1 MANUFACTURER MFR MANUFACTURER

2 ENMAS EPC MT MAGNETIC PARTICAL TEST

3 THIRD PARTY/CUSTOMER MVR MATERIAL VERIFICATION REPORT

ASME AMERICAN SOCIETY OF MECHANICAL ENGINEERS NDT NON DESTRUCTIVE TEST

AI/IA AUTHORSISED INSPECTOR/INSPECTING AUTHORITY P PERFORM

AWS AMERICAN WELDING SOCIETY PO PURCHASE ORDER

CC COMPLIANCE CERTIFICATE PMI POSITIVE MATERIAL TESTING

DC DELIVERY CHALLAN PQR PROCEDURE QUALIFICATION RECORD

DFT DRY FILM THICKNESS QAP QUALITY ASSURANCE PLAN

DRG DRAWING R REVIEW

EP EDGE PREPARATION RT RADIOGRAPHY REPORT

FOT FIRST OF TRIAL R/W RANDOM WITNESS

FICN FINAL INSPECTION CLEARANCE NOTE TDC TECHNICAL DELIVERY CONDITION

H HOLD (MANDATORY CLEARANCE WITHOUT WHICH NO FURTHER OPERATION PERMITTED) TC TEST CERTIFICATE

HT HEAT TREATMENT UT ULTRASONIC TEST

HTR HYDRO TEST REPORT W WITNESS (TO BE INFORMED AND FURTHER OPERATION CAN CONTINUE)

IR INSPECTION REPORT WPQ WELDER PERFORMANCE QUALIFICATION

LS&CS LONG SEAM & CIRCULAR SEAM WPS WELDING PERFORMANCE SPECIFICATION

LPT LIQIUID PENTRANT TEST

NOTES:

1. GEOMETRY MEANS SQUARENESS, STRAIGHTNESS, SWEEP & CAMBER

02

2. MATCH MARKING AND IDENTIFICATION SHALL BE DONE LEGIBLY FOR ALL THE COMPONENTS.

Ducting 080822 Page 1 of 2

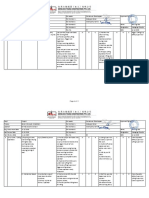

TYPE OF CHECK REFERENCE ACCEPTANCE FORMAT INSPECTION BY

SL.NO. OPERATION CHARACTERISTICS

& QUANTUM DOCUMENT NORM OF RECORD 1 2 3

1.0 Material Control

TC / Lab report verification,

Raw Material inspection for Plates & Rolled Chemical, Mechanical Properties and

1.1 Visual - 100%, Drawings, Specification Drawings, Specification TC/ Lab reports/ CC P R R

sections Dimensions

Dimension - 10%

Material inspection for Bought out items Dimension - 10%,

1.2 Sizes, Specification & Grade Drawings, Specification Drawings, Specification TC/CC P R

(Fasteners etc) Visual - 100%

2.0 Welding Control

Verification of applicable WPS / PQR Verification documents

2.1 Review of WPS ,PQR ASME SEC IX ASME SEC IX WPS, PQR P R R

and Welder Qualification – 100%

Verification /Qualification of Verification documents

2.2 Review of WPQ ASME SEC IX ASME SEC IX WPQ P R

welders/welding – 100%

3.0 In process Control

Dimension &

3.1 Marking, cutting and Edge preparation Bevel angle, Land, Dimension, Visual Drawings Drawings --- P R

Visual – 100%

Root gap, Bevel angle, Dimension &

3.3 Fit up Drawings Drawings IR P R/W R

Mismatch, Visual, Dimension, Visual – 100%

Weld soundness, Weld profile, Visual - 100%,

3.4 Welding Inspection Drawings Drawings IR P H

surface defects, Finish & Size Measurement-100%

SS Lining-- Drilling,Plug welding & finishing (If

3.5 Visual & Dimension Visual & Dimension-100% Drawings Drawings --- P R/W

applicable)

4.0 NDT on Welds

4.1 Butt Weld Material soundness PT-10% ASME Sec V ASME SEC IX PT Report P W R

Butt Weld Gas cut edges 20mm and above & Back

4.2 Weld soundness PT - 10% ASME Sec V ASME SEC IX PT report P W

Grinding area

4.3 All back gouged area Weld soundness PT-100% ASME Sec V ASME SEC IX PT report P W R

4.4 Weldment Others Weld soundness PT-10% Drawings, ASME Sec V Drawings, ASME SEC IX PT Report P W

5.0 Visual Inspection Surface Condition Visual - 100% Drawings Drawings --- P W

Visual – 100%

Trial Assembly of Duct 01 to 04 together (Note- Measurement - 100%

6.0 Dimensions & Geometry Drawings Drawings IR P H H

2) Geometry (Note-1) Match

02 Marking

Overall Dimensions, Dimension &

7.0 Final Dimensional Inspection Drawings Drawings IR P H H

Surface Conditions Visual – 100%

Surface Roughness & DFT check for Visual - 100% &

8.0 Surface Preparation & painting Drawings, PO Drawings, PO Painting Report P W R

painting DFT Check

1.Review of previous test Reports

2.Stenciling of details Verification – 100%

9.0 Final Inspection Drawings, PO, QAP Drawings, PO, QAP FICN Report P H H

3.Match marking and Flow Direction Visual -100 %

for aero foil duct

PAINTING 01

Blasting to SA 2.5 & Inorganic Zinc Rich Silicate - 75 Mic DFT - Grey colour

Ducting 080822 Page 2 of 2

You might also like

- Chris Timberlake Automating DevOps With GitLab CICD Pipelines BuildDocument348 pagesChris Timberlake Automating DevOps With GitLab CICD Pipelines BuildVladimir Degtyarev100% (2)

- Parts Catalog D2848 LE423Document228 pagesParts Catalog D2848 LE423MASPOR GT100% (1)

- SAT Plan & Procedure VMSDocument47 pagesSAT Plan & Procedure VMSMGHIRBI HAYKELNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- QAQC Requirement - O&U EPC PackageDocument34 pagesQAQC Requirement - O&U EPC Packageanjas_tsNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- What TitleDocument17 pagesWhat TitleBernathTurnipNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Tata A2239 Qap Rev.00Document4 pagesTata A2239 Qap Rev.00PRASHANTNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- Samsung VRF Installation Trend For BuildingDocument55 pagesSamsung VRF Installation Trend For BuildingNaseemNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistphilipyap100% (1)

- Quality Control System in The Fabrication of Heat ExchangersDocument5 pagesQuality Control System in The Fabrication of Heat ExchangersCorine CaracasNo ratings yet

- Wps 06Document2 pagesWps 06eldobie3No ratings yet

- Marine Painting CourseDocument57 pagesMarine Painting CourseMin SoeNo ratings yet

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- 1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Document1 page1-PMF-012-COM-005 - v2 - Document - Submittal - Form-029-Copy 1Eng hassan hussienNo ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- Afi SC03 QRBN Ci 00233Document1 pageAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- 8 Material Inspection ReportDocument1 page8 Material Inspection Reportvinson bayNo ratings yet

- Surface Preparation & Painting Procedure r1Document4 pagesSurface Preparation & Painting Procedure r1Wijayanto BekasiNo ratings yet

- Poly Cell Adhesive: Main ApplicationDocument2 pagesPoly Cell Adhesive: Main ApplicationHung Mai VanNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- Cross Hatch Adhesion Testing - ASTM 3359 Method ADocument2 pagesCross Hatch Adhesion Testing - ASTM 3359 Method ASudhakar Mars ConsultantsNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- ITP For Wall Panels InstallationDocument3 pagesITP For Wall Panels InstallationChristos LoutrakisNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- Checklist of PaintingDocument1 pageChecklist of PaintingRanjan KumarNo ratings yet

- Welder CardDocument1 pageWelder CardRaju KumarNo ratings yet

- M-Storm Drainage System - IC-M-SDS-00Document2 pagesM-Storm Drainage System - IC-M-SDS-00achusanachuNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Technical Specification: GID-PIP-TS-630 - (E)Document41 pagesTechnical Specification: GID-PIP-TS-630 - (E)santiagoNo ratings yet

- Method Statement of Sprinkler System Without LogoDocument9 pagesMethod Statement of Sprinkler System Without LogokiranramNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilNo ratings yet

- Weld Identification: Welding Procedures ManualDocument2 pagesWeld Identification: Welding Procedures ManualcarlosNo ratings yet

- Weld Restoration of Disk - Example of Elliott Repair TechnologyDocument49 pagesWeld Restoration of Disk - Example of Elliott Repair TechnologyMachineryengNo ratings yet

- Prebond 220 Acid Resistant PaintDocument4 pagesPrebond 220 Acid Resistant Paintsudhir64No ratings yet

- Method Statement For Flushing & Chemical Cleaning of Chilled Water SystemDocument23 pagesMethod Statement For Flushing & Chemical Cleaning of Chilled Water SystemRAJANo ratings yet

- Report IQ GV Line 2 (Ongoing)Document13 pagesReport IQ GV Line 2 (Ongoing)Anthony ProdeniantaNo ratings yet

- Qualification Procedure No. 7: SSPC: The Society For Protective CoatingsDocument6 pagesQualification Procedure No. 7: SSPC: The Society For Protective CoatingsRinush SinagaNo ratings yet

- Tds of Eterset 2844Document2 pagesTds of Eterset 2844Nandkumar PawarNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- 2 Contractor Quality Control Plan For Civil WorkDocument6 pages2 Contractor Quality Control Plan For Civil Workbehzad esNo ratings yet

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNo ratings yet

- RA For Bored MicropileDocument12 pagesRA For Bored Micropilebaoya sinoNo ratings yet

- Test Report FOR Compacted Density of Mix Aggregate Astm D-1559Document9 pagesTest Report FOR Compacted Density of Mix Aggregate Astm D-1559Jovanni RodriguezNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- 8 UPVc Pressure Pipes and FittingsDocument8 pages8 UPVc Pressure Pipes and FittingsNikita KadamNo ratings yet

- Scope: Method Statement For Welding ControlDocument6 pagesScope: Method Statement For Welding ControlSIBINNo ratings yet

- Hempadur Quattro 17634: Product Characteristics Product SafetyDocument4 pagesHempadur Quattro 17634: Product Characteristics Product Safetyulul100% (1)

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Catalog Swivel Joints PDFDocument24 pagesCatalog Swivel Joints PDFluiggi19970530No ratings yet

- Nspection Eport: EneralDocument3 pagesNspection Eport: Eneralberbin josNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Sa 351Document7 pagesSa 351Pavul RajNo ratings yet

- Sa 178 2019Document5 pagesSa 178 2019Pavul RajNo ratings yet

- IVR-050212116123 - 22-1-Rev.0 - Enmas - True FabDocument6 pagesIVR-050212116123 - 22-1-Rev.0 - Enmas - True FabPavul RajNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul Raj100% (1)

- Tolerance Table - Boiler StructuresDocument1 pageTolerance Table - Boiler StructuresPavul RajNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- Safety Valve Qap 270622Document2 pagesSafety Valve Qap 270622Pavul RajNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- ThesisDocument86 pagesThesisPavul RajNo ratings yet

- BR PU High Gloss Enamel PaintDocument2 pagesBR PU High Gloss Enamel PaintPavul RajNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Aprroved QAP-1883-R01-15122022Document1 pageAprroved QAP-1883-R01-15122022Pavul RajNo ratings yet

- Apcosil 605 IzssDocument3 pagesApcosil 605 IzssPavul RajNo ratings yet

- Downhole Tiltmeter Fracture Mapping: A New Tool For Direct Measurement of Hydraulic Fracture GrowthDocument8 pagesDownhole Tiltmeter Fracture Mapping: A New Tool For Direct Measurement of Hydraulic Fracture GrowthJulian RamírezNo ratings yet

- CO2024 Tutorial Hypothesis TestingDocument4 pagesCO2024 Tutorial Hypothesis TestingPinaNo ratings yet

- Topsis MethodDocument1 pageTopsis MethodGLENN ABACAHINNo ratings yet

- Experiment 2Document8 pagesExperiment 2TharakaKaushalyaNo ratings yet

- PL23XX DriverInstallerv 4.0.0 ReleaseNoteDocument4 pagesPL23XX DriverInstallerv 4.0.0 ReleaseNoteAmir VahidiNo ratings yet

- SPSS ImplicationsDocument3 pagesSPSS ImplicationsAnonymous MMNqiyxBUNo ratings yet

- L4 RocksDocument33 pagesL4 RocksFARHA NAAZNo ratings yet

- Revised Gce As A Level Scheme of Work PhysicsDocument59 pagesRevised Gce As A Level Scheme of Work PhysicsNathaniell Dongo KasekeNo ratings yet

- Basic Comp 1Document15 pagesBasic Comp 1Nilam KumarNo ratings yet

- Manual Cat Grader 24H 31-3-14Document29 pagesManual Cat Grader 24H 31-3-14Ahmad HandokoNo ratings yet

- Iec 61000Document5 pagesIec 61000james wangNo ratings yet

- Mathematical Functions in PythonDocument3 pagesMathematical Functions in PythonNani ShaikhNo ratings yet

- Fundamentals of Airliner Performance Part 6 The EngineDocument9 pagesFundamentals of Airliner Performance Part 6 The EngineupsasaNo ratings yet

- Lipids and Proteins Are Associated in Biological Membranes: What Is A LipidDocument20 pagesLipids and Proteins Are Associated in Biological Membranes: What Is A Lipidcarlette11No ratings yet

- Dynamic Analysis of Structures PDFDocument755 pagesDynamic Analysis of Structures PDFАндрей Николаевич Горев83% (6)

- Hardware Design & Simulation of Advanced Traffic LightDocument16 pagesHardware Design & Simulation of Advanced Traffic LightAnimesh ShrotriaNo ratings yet

- Tu Btech Curriculum-2Document78 pagesTu Btech Curriculum-2Jitul RajbongshiNo ratings yet

- USER-700G英文 (2019.5) (OCR)Document37 pagesUSER-700G英文 (2019.5) (OCR)이리재No ratings yet

- BGD 500 Pull-Off Adhesion Tester NeturalDocument13 pagesBGD 500 Pull-Off Adhesion Tester Neturalaugustus1189No ratings yet

- The Effect of Unemployment On Economic Development in NigeriaDocument56 pagesThe Effect of Unemployment On Economic Development in Nigeriajamessabraham2No ratings yet

- Foundations of Modern Macroeconomics: B. J. Heijdra & F. Van Der PloegDocument52 pagesFoundations of Modern Macroeconomics: B. J. Heijdra & F. Van Der Ploegtegegn mogessieNo ratings yet

- Individual Differences and Undergraduate Academic Success, The Roles of Personality, Intelligence, and ApplicationDocument19 pagesIndividual Differences and Undergraduate Academic Success, The Roles of Personality, Intelligence, and ApplicationSipos GabriellaNo ratings yet

- 2017 - PpoDocument16 pages2017 - PpoTran TuanNo ratings yet

- Superior Windows XP 64Document13 pagesSuperior Windows XP 64Arnel100% (1)

- Piston Engine QuestionsDocument33 pagesPiston Engine QuestionsSky Patel100% (1)

- Music Theory - Note ReadingDocument33 pagesMusic Theory - Note ReadingChristopher KondwelaniNo ratings yet

- Thumper TH100 Owners Manual.v1.0Document16 pagesThumper TH100 Owners Manual.v1.0vocomotionNo ratings yet

- Cytology and Cytological TechniquesDocument29 pagesCytology and Cytological TechniquesNgotelo FunwiNo ratings yet