Professional Documents

Culture Documents

Análise e Cálculo de Clips Soldados em Tubulações

Análise e Cálculo de Clips Soldados em Tubulações

Uploaded by

LDM Man. e Mont. Ind. EIRELI0 ratings0% found this document useful (0 votes)

25 views1 pageThe document summarizes the design of a pipe support clip. It provides dimensions for the clip components and welds. Forces of 4000 lbs are applied to the clip. Calculations show the stress from these forces is 686 psi, which is below the allowable stress of 7500 psi. Therefore, the clip design is sufficient to support the pipe under the given loading conditions.

Original Description:

Original Title

Análise-e-Cálculo-de-Clips-Soldados-em-Tubulações

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the design of a pipe support clip. It provides dimensions for the clip components and welds. Forces of 4000 lbs are applied to the clip. Calculations show the stress from these forces is 686 psi, which is below the allowable stress of 7500 psi. Therefore, the clip design is sufficient to support the pipe under the given loading conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

25 views1 pageAnálise e Cálculo de Clips Soldados em Tubulações

Análise e Cálculo de Clips Soldados em Tubulações

Uploaded by

LDM Man. e Mont. Ind. EIRELIThe document summarizes the design of a pipe support clip. It provides dimensions for the clip components and welds. Forces of 4000 lbs are applied to the clip. Calculations show the stress from these forces is 686 psi, which is below the allowable stress of 7500 psi. Therefore, the clip design is sufficient to support the pipe under the given loading conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

Design and Analysis

of Pipe Support Clips

By: gw

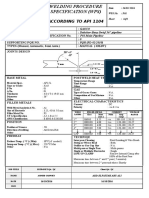

Pipe Matl: A53-B Design Tem., F: 600

I. Clip Dimensions, inches

L: 22 P

T: 0.375

e: 2.75

II. Weld Dimensions, in.

w: 0.1875

T

III. Forces, pounds L F F

P: 0 e

F: 4000

IV. Pipe Allowable, psi w

Sh: 15000 Minimum Weld Size for

Plate Thickness, inches

V. Weld Joint Efficiency T w

T<=1/2 3/16

E: 0.5 1/2<T<=3/4 1/4

3/4<T<=1 1/2 5/16

IV. Calculations

Weld Joint Efficiency

Critical weld area: 5.83 for fillet welds: E=0.45 - 0.55

Weld section modulus: 21.39

Stress from force P, psi

Bending, S1: 0 psi

Direct shear, S2: 0 psi

Maximum Stress, S: 0 psi Allowable stress: 7500 psi

Stress for force F, psi

Shear, S3: 686 psi Allowable stress: 7500 psi

Maximum combined stress due to force F and P, SMAX: 686

Allowable stress: 7500

Reference: Pressure Vessel Design Handbook, Henry H. Bednar

You might also like

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Pipe StackingDocument2 pagesPipe StackingUghojor ElohoNo ratings yet

- Weldment Strength Excel CalculationsDocument38 pagesWeldment Strength Excel CalculationsRAMSINGH CHAUHAN100% (4)

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- Davit CalcDocument4 pagesDavit CalcrustamriyadiNo ratings yet

- Horizontal Pressure Vessel Calculation (Eng)Document59 pagesHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasNo ratings yet

- Vertical Gates Design PDF FreeDocument33 pagesVertical Gates Design PDF FreeAbdul wahid ButtNo ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- Baseplate (Fixed Type 6 Bolts) 123Document15 pagesBaseplate (Fixed Type 6 Bolts) 123vijay10484No ratings yet

- Angle Flex SeatDocument3 pagesAngle Flex Seatitissa INGENIERIANo ratings yet

- Process Piping B 31.3Document6 pagesProcess Piping B 31.3FREDYTOAPANTANo ratings yet

- f M π /4) d S D /2) t P (D/2) : Southern Region Houston, TexasDocument4 pagesf M π /4) d S D /2) t P (D/2) : Southern Region Houston, Texasmohamed amine AtiaNo ratings yet

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahNo ratings yet

- Branch Calculation Sample - B31.1a-2008Document2 pagesBranch Calculation Sample - B31.1a-2008Tam Huynh ThanhNo ratings yet

- FTR#CHSFL/TRG: SPH (Efe (Ate#NDocument2 pagesFTR#CHSFL/TRG: SPH (Efe (Ate#NMaged Lotfy Abdel-aalNo ratings yet

- Material - Specification Hyundai KC02Document3 pagesMaterial - Specification Hyundai KC02DilermandoNo ratings yet

- Proline Master: Electrical Submersible Drainage Pump 60 HZDocument1 pageProline Master: Electrical Submersible Drainage Pump 60 HZRobert ArticaNo ratings yet

- Weldment Strength Excel CalculationsDocument33 pagesWeldment Strength Excel CalculationsYl WongNo ratings yet

- Asme CalculationDocument1 pageAsme Calculationbenabdallah131No ratings yet

- M 259 ContentDocument24 pagesM 259 ContentKing1971No ratings yet

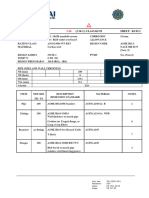

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Beam Clamp DrawingDocument1 pageBeam Clamp DrawingAmit AggarwalNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationthanh100% (1)

- Submitted TR-20-065 - CCP Design OUTLETS 09-04-2020Document8 pagesSubmitted TR-20-065 - CCP Design OUTLETS 09-04-2020Martin HumbirdNo ratings yet

- Mechanical Calculation TANK 53 KL (T-05)Document4 pagesMechanical Calculation TANK 53 KL (T-05)Priyo Jati WahyonoNo ratings yet

- CAT-011 TaeguTurn BorBarsDocument21 pagesCAT-011 TaeguTurn BorBarsnelu34brasovNo ratings yet

- 2 HP Motor DS&GADocument2 pages2 HP Motor DS&GArituNo ratings yet

- ANGLEFLEXSEATDocument3 pagesANGLEFLEXSEATwidNo ratings yet

- Conn MC 2127rev.b Web00Document1 pageConn MC 2127rev.b Web00changiz2220No ratings yet

- Injection MouldingDocument11 pagesInjection Mouldingjogjayusuf4No ratings yet

- Total DataDocument61 pagesTotal DataGANDRETI RAMU (N160267)No ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- Pro Line Drainage Major 50 Data SheetDocument1 pagePro Line Drainage Major 50 Data SheetMARFV06No ratings yet

- Pipe Fitting Losses: Chemical Engineer's GuideDocument8 pagesPipe Fitting Losses: Chemical Engineer's GuideEdu CordonNo ratings yet

- H40 Rebar Welding CalculationDocument1 pageH40 Rebar Welding CalculationcheeseonglawNo ratings yet

- BAJOJODocument3 pagesBAJOJOMark Benjie Molina PaosNo ratings yet

- Strut and WalingDocument2 pagesStrut and WalingChan Kin CheungNo ratings yet

- Lifting LugDocument8 pagesLifting LugEnrique BarajasNo ratings yet

- SC21B-A Along GL-4 SummaryDocument2 pagesSC21B-A Along GL-4 Summarymhazarath murariNo ratings yet

- Circulating Fluidized Bed Boiler Design and OperationDocument9 pagesCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoNo ratings yet

- VMDocument1 pageVMide lbNo ratings yet

- Proline Minor: Electrical Submersible Drainage Pump 60 HZDocument1 pageProline Minor: Electrical Submersible Drainage Pump 60 HZRobert ArticaNo ratings yet

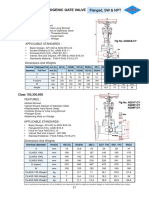

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- Electrical Machine Design: Item NoDocument3 pagesElectrical Machine Design: Item NoJv RodriguezNo ratings yet

- YC100-508-3P SpecDocument1 pageYC100-508-3P SpecNenad PavlovićNo ratings yet

- EE MCC@60AmpsDocument6 pagesEE MCC@60AmpsGlenn GregorioNo ratings yet

- Foundation 1 Design Report (8 Metros)Document7 pagesFoundation 1 Design Report (8 Metros)EdwinBastidasNo ratings yet

- Rectangular Tank Design ExelDocument40 pagesRectangular Tank Design Exelhabibur Rahman Khan100% (1)

- Proline Maxi: Electrical Submersible Drainage Pump 60 HZDocument1 pageProline Maxi: Electrical Submersible Drainage Pump 60 HZRobert ArticaNo ratings yet

- "Angleflexseat" - Allowable Steel Beam End Reaction: Program DescriptionDocument3 pages"Angleflexseat" - Allowable Steel Beam End Reaction: Program DescriptionAamirShabbirNo ratings yet

- CALCULATION SHEET For BoilerDocument6 pagesCALCULATION SHEET For BoilerAliDadKhanNo ratings yet

- Pipe Fitting Losses: Chemical Engineering CalculationsDocument4 pagesPipe Fitting Losses: Chemical Engineering CalculationsDiegoNo ratings yet

- O&M Manaul + Part ListDocument103 pagesO&M Manaul + Part ListShahid Hussain ShahNo ratings yet

- Branch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangDocument6 pagesBranch Wall Thickness Calculation For Split TEE: Gas Pipeline Gresik - SemarangAgus SupriadiNo ratings yet