Professional Documents

Culture Documents

Types of Elevators in Terms of Mechanism

Types of Elevators in Terms of Mechanism

Uploaded by

Eden BekeleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types of Elevators in Terms of Mechanism

Types of Elevators in Terms of Mechanism

Uploaded by

Eden BekeleCopyright:

Available Formats

Types of elevators in terms of mechanism

In the past, most elevators had to be controlled through a central machine room. Today, there are some

elevators that don’t need a machine room because they have a built-in safety mechanism. There are

three main types of elevators: Hydraulic elevators, Traction elevators, Machine-Room-Less Elevators.

Hydraulic elevators:

The hydraulic elevators supported by a piston in the lower part of the elevator, the elevator pushed up

as the electric motor pushes oil or other hydraulic fluid into the piston, and the elevator descends when

the liquid valve is released from the piston. It used for low-rise installations of 2-8 floors, with a top

speed of 200 feet per minute.

Conventional hydraulic elevators

have a sheave that extends below the floor of the elevator pit, which receives the retraction piston

while the elevator is descending. Some configurations have an interlocking piston that collapses and

requires a shallow hole below the hole. The maximum travel distance is about 60 feet.

Hole-less Hydraulic Elevators

have a piston on either side of the cabin. In this design, the interlocking pistons fixed at the base of the

hole and do not require a sheave or a hole below the hole, since the interlocking pistons allow a

distance of up to 50 feet.

Roped Hydraulic Elevators

use a mixture of ropes and a piston to move the elevator, and the maximum travel distance is about 60

feet.

Traction Elevators

This elevator contains ropes that pass over a wheel connected to an electric motor located above the

column,

as the main function of ropes is to raise and lower the elevator compartment.

It can be used in both medium and high installations and can move faster than hydraulic elevators.

Traction elevators are divided into two basic types

Gear traction elevator

It consists of a motor that has a gearbox attached to it,

and the main function of the gears is to operate the wheel that drives the ropes.

This kind of elevator can travel at speeds of up to 500 feet per minute, and the maximum distance that it

can travel is 250 feet.

Gearless traction elevator

These elevators do not have a gearbox to regulate the speed,

which explains why they can move at speeds of up to 2000 feet per minute.

Gearless elevators use to power a little more efficiently than traction elevators with Troyes,and they can

also travel a maximum of 2000 feet,so they are the best choice of skyscraper.

Machine-Room-Less Elevators

These elevators are traction elevators, but without a machine room connected above the shaft, the

engine positioned in the space above the cabin.

You can reach the engine from the top of the elevator cabin for repairs or maintenance,

and the non-room elevators characterized by a speed of travel up to 500 feet per minute and

a maximum travel distance of 250 feet. Energy consumption of machine room-free elevators is relatively

low compared to traction elevators,

and these elevators are also becoming increasingly popular in medium-height installations due to their

operation,reliability, and energy efficiency.

Types of elevators in terms of use

There are many types of elevators with different purposes, and after understanding the mechanism,

understanding the different uses of elevators is essential to determine the appropriate elevator for your

location and your transportation needs. Because of the frequent use of elevators in several sectors,

there are wide types of elevators available:

Passenger elevator

Cargo elevator

Car elevator

Home elevator

Disabled people elevator

Theater elevator

Boat elevator

Dumbwaiter

You might also like

- Hidromek 102B - 102S - Service Manual PDFDocument767 pagesHidromek 102B - 102S - Service Manual PDFMauro Fuentes84% (19)

- Hyster-Yale Cross OverDocument5 pagesHyster-Yale Cross OverEriflona80% (5)

- Trouble Codes Toyota CorollaDocument2 pagesTrouble Codes Toyota CorollaAdrian Fernandez0% (1)

- Motos CDIDocument145 pagesMotos CDILuis Ricardo Reyes Valladolid100% (1)

- Lecture 1 BUILDING UTILITIES 2 Transportation SystemsDocument135 pagesLecture 1 BUILDING UTILITIES 2 Transportation SystemsNicole Dizon0% (1)

- Elevators: Electrical Load Classification According To Load Function Lighting LoadDocument44 pagesElevators: Electrical Load Classification According To Load Function Lighting LoadHassen Lazhar100% (2)

- 320d WiringDocument2 pages320d WiringMohamed Harb100% (6)

- Basic Components of Elevator Elevator Types: Hydraulic ElevatorsDocument4 pagesBasic Components of Elevator Elevator Types: Hydraulic ElevatorsEstiven GierNo ratings yet

- Elevator TypesDocument4 pagesElevator TypesIranthaMuthuNo ratings yet

- Types of ElevatorsDocument6 pagesTypes of Elevatorsnirvaang100% (2)

- ElevatorsDocument27 pagesElevatorsshelmiNo ratings yet

- Types of Elevators - Home Elevators - Residential Elevators - 1626693900854Document9 pagesTypes of Elevators - Home Elevators - Residential Elevators - 1626693900854Aluko Damilare MosesNo ratings yet

- BMC - Escalator, ElevatorDocument23 pagesBMC - Escalator, ElevatorJisniNo ratings yet

- Lecture 7 - Mechanical Transportation - Module 3 - ElevatorsDocument21 pagesLecture 7 - Mechanical Transportation - Module 3 - ElevatorsShubhaNo ratings yet

- Elevators and Shafts: Qurat-Ul-Ain 103 4th YrDocument5 pagesElevators and Shafts: Qurat-Ul-Ain 103 4th Yraini zahidNo ratings yet

- ElevatorsDocument20 pagesElevatorsmanishNo ratings yet

- Elevator TypesDocument4 pagesElevator TypesAngelica SantosNo ratings yet

- What Is Elevator / Lift?: How Does A Lift Work?Document8 pagesWhat Is Elevator / Lift?: How Does A Lift Work?ankitaNo ratings yet

- Types of LiftsDocument13 pagesTypes of Liftsmonica singhNo ratings yet

- Lift 1Document27 pagesLift 1shelmi100% (1)

- As Unit 1 PDFDocument89 pagesAs Unit 1 PDFsaahasitha 14No ratings yet

- Traction ElevatorsDocument2 pagesTraction ElevatorsdalisanjennethcabintoNo ratings yet

- 10 Week NotesDocument39 pages10 Week Notescharusri74No ratings yet

- PPTXDocument18 pagesPPTXHubert John TabogocNo ratings yet

- Traction Elevators: Variety of Elevator TypesDocument3 pagesTraction Elevators: Variety of Elevator TypesharshalNo ratings yet

- An ElevatorDocument50 pagesAn ElevatorJessa Tan100% (1)

- Elevator and EscalatorDocument21 pagesElevator and EscalatorKarla AustriaNo ratings yet

- ElevatorsDocument11 pagesElevatorsDalia M-aNo ratings yet

- Transportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalDocument104 pagesTransportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalManoj JainNo ratings yet

- Elevators: 3 Century B.C.E 1743Document15 pagesElevators: 3 Century B.C.E 1743Mara Erna TagupaNo ratings yet

- LiftDocument22 pagesLiftAmit KumarNo ratings yet

- Lift22 PDFDocument21 pagesLift22 PDFSejal MengajiNo ratings yet

- LIFTDocument28 pagesLIFTBirla RajasekarNo ratings yet

- Elevator Working PrincipleDocument3 pagesElevator Working Principlehen henNo ratings yet

- Mechanism of Passenger LiftsDocument11 pagesMechanism of Passenger LiftsrutujaNo ratings yet

- So How Do Elevators or Lifts WorkDocument12 pagesSo How Do Elevators or Lifts WorkAyesha MAhmoodNo ratings yet

- Bu 1Document120 pagesBu 1Chi De LeonNo ratings yet

- Building Construction Bachelor of Architecture: Submitted byDocument7 pagesBuilding Construction Bachelor of Architecture: Submitted byJaskiratNo ratings yet

- Vertical Transportation: Elevators Escalators TravelatorsDocument52 pagesVertical Transportation: Elevators Escalators TravelatorsParyul JainNo ratings yet

- Vertical Transportation SystemDocument14 pagesVertical Transportation Systempassionpropel100% (3)

- Building ServicesDocument57 pagesBuilding Servicessofiya0% (1)

- Elevator Components 1Document43 pagesElevator Components 1Marc Zerwin MurosNo ratings yet

- Lift NotesDocument28 pagesLift NotesParzival100% (1)

- Unit III - VERTICAL TRANSPORTDocument74 pagesUnit III - VERTICAL TRANSPORTAbi GovindNo ratings yet

- Lifts TypesDocument30 pagesLifts TypesATHMEEYA KRISHNANo ratings yet

- Unit-5-Industrial Electrical Systems-IIDocument12 pagesUnit-5-Industrial Electrical Systems-IIvikram patilNo ratings yet

- Term Paper 2 MENGR 3100Document5 pagesTerm Paper 2 MENGR 3100caytonericazoeNo ratings yet

- 0709kone Article PDFDocument8 pages0709kone Article PDFfury7No ratings yet

- Unit 3Document11 pagesUnit 3SingarayyaNo ratings yet

- Elevators: Sahar Khan Jadoon FA11-BAR-017Document5 pagesElevators: Sahar Khan Jadoon FA11-BAR-017saharkj67No ratings yet

- Importance of LiftDocument10 pagesImportance of LiftmansiNo ratings yet

- Transportation SystemsDocument136 pagesTransportation SystemsKaren Dela Torre100% (1)

- ElevatorDocument11 pagesElevatorsaad ElsheikhNo ratings yet

- Week 10 Tutorial 1Document12 pagesWeek 10 Tutorial 1sonukumarmarchadNo ratings yet

- Lift, Escalators, Moving WalkwaysDocument16 pagesLift, Escalators, Moving Walkways51-Naman JainNo ratings yet

- Functional Requirements of 8 Transportation Systems in A Building.Document40 pagesFunctional Requirements of 8 Transportation Systems in A Building.Umar Faruq AfokeNo ratings yet

- ECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorDocument5 pagesECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorAZUAN BIN AHMAD FAUZINo ratings yet

- Lifts & EscalatorsDocument37 pagesLifts & EscalatorsNikita SalunkheNo ratings yet

- Elevator RescueDocument30 pagesElevator RescueHumberto Arturo AgudeloNo ratings yet

- Fundamentals of Elevators and Escalators in The WorkplaceDocument10 pagesFundamentals of Elevators and Escalators in The WorkplaceTin VillalbaNo ratings yet

- VerticalDocument26 pagesVerticalArt IjbNo ratings yet

- p2 Lift SystemDocument10 pagesp2 Lift SystemZikri RosliNo ratings yet

- Najarro Btech5Document4 pagesNajarro Btech5Rod NajarroNo ratings yet

- Elevators and Escalators Design PDFDocument13 pagesElevators and Escalators Design PDFAmble LamNo ratings yet

- Construction MaterialsDocument74 pagesConstruction MaterialsEden BekeleNo ratings yet

- Safety 2121Document27 pagesSafety 2121Eden BekeleNo ratings yet

- Chap 1&2Document36 pagesChap 1&2Eden BekeleNo ratings yet

- Chapter 1 Principle of Cost Eng'nDocument27 pagesChapter 1 Principle of Cost Eng'nEden BekeleNo ratings yet

- FM CH-3Document45 pagesFM CH-3Eden BekeleNo ratings yet

- FM CH - 2Document19 pagesFM CH - 2Eden BekeleNo ratings yet

- Form SevenDocument1 pageForm SevenANUPA MALLICKNo ratings yet

- Piaggio NRG - Power - PurejetDocument248 pagesPiaggio NRG - Power - PurejetramiroNo ratings yet

- Fluid RecommendationsDocument6 pagesFluid RecommendationsAlfredoNo ratings yet

- Manual Partes BAIFADocument178 pagesManual Partes BAIFAadenyrNo ratings yet

- Review 2 - Test 1Document4 pagesReview 2 - Test 1KenNo ratings yet

- 045220X56ZDocument1 page045220X56ZIrina VarzouNo ratings yet

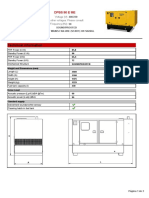

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- Ds Msc-Nastran-Dynamics LTR WDocument2 pagesDs Msc-Nastran-Dynamics LTR WAydinNo ratings yet

- Technical Information: Dpbs 90 E MeDocument3 pagesTechnical Information: Dpbs 90 E MeЛулу ТраедNo ratings yet

- TM 9 2350 311 34 1Document352 pagesTM 9 2350 311 34 1Kenneth Naputi Laitan Jr.No ratings yet

- AHOYADORDocument13 pagesAHOYADORpanchoNo ratings yet

- Air Operated High Viscous Barrel Pump PDFDocument1 pageAir Operated High Viscous Barrel Pump PDFTM HARRISNo ratings yet

- Electric Tow Tractor: SpecificationsDocument6 pagesElectric Tow Tractor: SpecificationsalfredNo ratings yet

- Light Bulb Base Sizes and Socket Types - An Expert GuideDocument31 pagesLight Bulb Base Sizes and Socket Types - An Expert GuideProcurement PardisanNo ratings yet

- Shop Manual Allis-Chalmers: IviodelsDocument78 pagesShop Manual Allis-Chalmers: IviodelsDmitryNo ratings yet

- Report of Servo MotorDocument3 pagesReport of Servo MotorMUHAMMAD KASHIFNo ratings yet

- Manitowoc 777: Operator Manual Luffing Jib AttachmentDocument164 pagesManitowoc 777: Operator Manual Luffing Jib AttachmentRaphaelNo ratings yet

- Ec 1607 Nextgen Drones OnlineDocument19 pagesEc 1607 Nextgen Drones OnlineAlex WellmanNo ratings yet

- CP Battery Impact WrenchesDocument2 pagesCP Battery Impact WrenchesBe HappyNo ratings yet

- 11.5 Chipper Shredder Safety & Operating Instructions: Serial No. Order NoDocument36 pages11.5 Chipper Shredder Safety & Operating Instructions: Serial No. Order NoSara Jane SumngatNo ratings yet

- This Document Has Been Printed From SPI2. NOT FOR RESALE: LicensingDocument1 pageThis Document Has Been Printed From SPI2. NOT FOR RESALE: LicensingAHMADNo ratings yet

- Injector Specification: Assembly No: 35542Document1 pageInjector Specification: Assembly No: 35542johnny sabinNo ratings yet

- Total Surface Coating SolutionsDocument6 pagesTotal Surface Coating SolutionsterebetteNo ratings yet

- Spare Parts List: Hydraulic BreakersDocument28 pagesSpare Parts List: Hydraulic BreakersSeal HubNo ratings yet

- S6.6 CyberchainDocument8 pagesS6.6 Cyberchaindihosid99No ratings yet