Professional Documents

Culture Documents

NC Form

NC Form

Uploaded by

Roohi KatnoriaCopyright:

Available Formats

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- 3 On 3 Basketball Tournament Sponsor ProposalDocument4 pages3 On 3 Basketball Tournament Sponsor ProposalBaba Hans100% (1)

- Total Global Strategy Managing For Worldwide Competitive Advantage PDFDocument292 pagesTotal Global Strategy Managing For Worldwide Competitive Advantage PDFRamiro Fernando MosqueraNo ratings yet

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentSeda De Drasnia100% (4)

- Manufacturing Process Audit ChecklistDocument4 pagesManufacturing Process Audit Checklistgksp100% (4)

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFpandajay100% (1)

- Copia de CQI-23Document79 pagesCopia de CQI-23Ernesto Padilla100% (6)

- Audit Plan - ISO 9001 - ISO 14001 - 2015Document8 pagesAudit Plan - ISO 9001 - ISO 14001 - 2015Corrosion Factory100% (2)

- Apqp Ppap FormatsDocument66 pagesApqp Ppap Formatsjuande6940% (5)

- Archmodels Vol 203Document32 pagesArchmodels Vol 203Guido Gómez SalasNo ratings yet

- GM 1927-16 PCPA ChecksheetDocument4 pagesGM 1927-16 PCPA Checksheetrahul100% (1)

- Delphi Comprehensive Control PlanDocument51 pagesDelphi Comprehensive Control Planss2mrattriNo ratings yet

- GM 1927-30 QSB Audit Master - Final011811Document16 pagesGM 1927-30 QSB Audit Master - Final011811Mohammad GadNo ratings yet

- First Article Inspection - Aerospace FormsDocument6 pagesFirst Article Inspection - Aerospace Formssqalopez100% (1)

- Practical Research 1 - Unpacked CompetenciesDocument91 pagesPractical Research 1 - Unpacked CompetenciesEmem Lim-Asido Simbajon100% (2)

- 16-Port Antenna Frequency Range Dual Polarization HPBW Gain Adjust. Electr. DTDocument7 pages16-Port Antenna Frequency Range Dual Polarization HPBW Gain Adjust. Electr. DTestebanarcaNo ratings yet

- Audit Findings - ISO / TS16949Document2 pagesAudit Findings - ISO / TS16949Rohit SoniNo ratings yet

- Mace ChecksheetDocument48 pagesMace ChecksheetRAHUL rNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- Process Audit ChecklistDocument6 pagesProcess Audit ChecklistzafeerNo ratings yet

- Anexo 06 - PA - Process Audit v1.1Document19 pagesAnexo 06 - PA - Process Audit v1.1BalajiNo ratings yet

- Contract Execution Phase: Project Filling Plan - A4Document1 pageContract Execution Phase: Project Filling Plan - A4stefenjohn36No ratings yet

- Assessment - P06 - 26 - 7 - 2D - Rev 01-06-2015cópia-Portugues - Resp e PrazoDocument22 pagesAssessment - P06 - 26 - 7 - 2D - Rev 01-06-2015cópia-Portugues - Resp e PrazoGuilherme AugustoNo ratings yet

- Dahej Standby Jetty 2264Document9 pagesDahej Standby Jetty 2264Anonymous i3lI9MNo ratings yet

- Audit AnalzDocument10 pagesAudit AnalzGayan BandaraNo ratings yet

- A00F207e Audit ReportDocument8 pagesA00F207e Audit ReportMuhammad HashiNo ratings yet

- Construction Quality Management System Booklet For Cross Country Pipeline ProjectDocument10 pagesConstruction Quality Management System Booklet For Cross Country Pipeline ProjectRakesh Ranjan100% (1)

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- Checklist DocumentDocument46 pagesChecklist DocumentGaurav Vishwakarma100% (2)

- Cara ReportDocument25 pagesCara ReportSurendharNo ratings yet

- Mandatory Documents and Records (Ref: ISO 9001:2008)Document4 pagesMandatory Documents and Records (Ref: ISO 9001:2008)Shashank ChhajerNo ratings yet

- RC 2022 Summary CAFDDocument4 pagesRC 2022 Summary CAFDEjazNo ratings yet

- Quality Management System Manual QM-QUA-001: Nelson-Miller IncDocument34 pagesQuality Management System Manual QM-QUA-001: Nelson-Miller IncAbd Zouhier100% (1)

- 0161 Quality ConstructionDocument38 pages0161 Quality ConstructionjjyotiNo ratings yet

- Quality DocumentDocument15 pagesQuality Documenttanto_deep_15No ratings yet

- Process Audit Check ListDocument24 pagesProcess Audit Check ListSorin FrentoniNo ratings yet

- 4.6 TABC - Air Cooled Split Unit SystemDocument17 pages4.6 TABC - Air Cooled Split Unit SystemOsmahadzir OsrinNo ratings yet

- GM 1927-16a Leak Test Process AuditDocument20 pagesGM 1927-16a Leak Test Process AudithuangjlNo ratings yet

- 4.4 PPAP - ChecklistDocument4 pages4.4 PPAP - ChecklistAndrea InfanteNo ratings yet

- User Manual QMS - Quality ControlDocument58 pagesUser Manual QMS - Quality ControlGamble100% (1)

- ISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsDocument40 pagesISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsleadyourlifeNo ratings yet

- 01 32 17.00 20 - Contractor - Baseline - Project - Schedule - Comm - HVAC - ChecklistDocument3 pages01 32 17.00 20 - Contractor - Baseline - Project - Schedule - Comm - HVAC - ChecklistErwin ObenzaNo ratings yet

- Production Part Approval Process (Ppap)Document20 pagesProduction Part Approval Process (Ppap)Primoz Cermelj100% (1)

- 5) Control of Quality RecordsDocument4 pages5) Control of Quality RecordsSagar DaundNo ratings yet

- Navistar ApqpDocument18 pagesNavistar ApqpAbhijeet MitraNo ratings yet

- Change ControlDocument1 pageChange Controlhinckdogg100% (1)

- PPAP For Aerospace ASQDocument21 pagesPPAP For Aerospace ASQmedi3850% (2)

- Cqi-9 Heat Threatment DetailsDocument34 pagesCqi-9 Heat Threatment DetailshaydarkasnaklarNo ratings yet

- GM 1927-30 QSB AuditDocument38 pagesGM 1927-30 QSB Auditmanune01No ratings yet

- QMS FormDocument4 pagesQMS FormsarvaNo ratings yet

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Document26 pagesTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNo ratings yet

- PPAPDocument4 pagesPPAPMattNo ratings yet

- Joint ReviewDocument126 pagesJoint ReviewDIVAKAR PANIGRAHI100% (1)

- QP03 Management ReviewDocument4 pagesQP03 Management ReviewhastinkakaNo ratings yet

- Requirement For Iso 9001 2015Document3 pagesRequirement For Iso 9001 2015Anonymous r2EiqSrBNo ratings yet

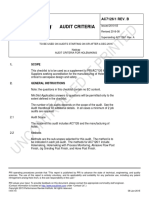

- AC7126-1 Rev B 23-AUG-2016Document26 pagesAC7126-1 Rev B 23-AUG-2016unknown1711No ratings yet

- As 9103 o ReviewDocument28 pagesAs 9103 o ReviewAnonymous Wi2Pd2UgPINo ratings yet

- Global Supplier Quality System AssessmentDocument11 pagesGlobal Supplier Quality System AssessmentPvinoth000No ratings yet

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- The AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesFrom EverandThe AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesNo ratings yet

- Statistical Thinking: Improving Business PerformanceFrom EverandStatistical Thinking: Improving Business PerformanceRating: 4 out of 5 stars4/5 (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Wrapper Tool For Creating Multiple Info ObjectsDocument12 pagesWrapper Tool For Creating Multiple Info ObjectsjothikumarjayaramanNo ratings yet

- Oxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Document2 pagesOxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Alves EdattukaranNo ratings yet

- Modulo Ethernet - Ifbd-He0506 - SPC - enDocument35 pagesModulo Ethernet - Ifbd-He0506 - SPC - enE Moy LandaNo ratings yet

- Amines PDFDocument1 pageAmines PDF최승원No ratings yet

- Perl Cheat SheetDocument2 pagesPerl Cheat Sheetdinokid08100% (1)

- G.L Bajaj Institute of Management and Research Mid Term Assignment Subject - Ssp3 Subject Code-Pg23Document8 pagesG.L Bajaj Institute of Management and Research Mid Term Assignment Subject - Ssp3 Subject Code-Pg23Mansi GuptaNo ratings yet

- Excavator: Yanmar 36.2 KW (49.2 HP) at 2,100 RPMDocument2 pagesExcavator: Yanmar 36.2 KW (49.2 HP) at 2,100 RPMtomas liuNo ratings yet

- Instrucal IIIDocument46 pagesInstrucal IIINorberto Soto100% (1)

- Fh64t6ht GBR EngDocument7 pagesFh64t6ht GBR EngariwibowoNo ratings yet

- Introduction To Microwind: Integrated Electronics Lab 2Document10 pagesIntroduction To Microwind: Integrated Electronics Lab 2Ird Durrani100% (1)

- Account Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancePiyush AgarwalNo ratings yet

- LCD TV Display Failure Symptoms and Possible CausesDocument4 pagesLCD TV Display Failure Symptoms and Possible Causeskachappilly2012No ratings yet

- Vehical No Registrstion No Chassis No Engine No Trolly NoDocument6 pagesVehical No Registrstion No Chassis No Engine No Trolly Norodesa100% (1)

- Glassdoor - Resume - My PVT ResumeDocument3 pagesGlassdoor - Resume - My PVT ResumePrashant TodkarNo ratings yet

- Detailed Lesson Plan in Common Poultry ADocument4 pagesDetailed Lesson Plan in Common Poultry AAlvin NovencidoNo ratings yet

- Hydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDocument1 pageHydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDuc NguyenNo ratings yet

- SpeedTouch™ ST 585 CLI GuideDocument682 pagesSpeedTouch™ ST 585 CLI GuidesertuxNo ratings yet

- Strain Hardening of Copper AlloyDocument5 pagesStrain Hardening of Copper AlloyThien Van TranNo ratings yet

- Bangalore Electricity Supply Company Limited: Thank You!Document12 pagesBangalore Electricity Supply Company Limited: Thank You!Ranjan VNo ratings yet

- Process Design: © Nigel Slack, Stuart Chambers & Robert Johnston, 2004Document30 pagesProcess Design: © Nigel Slack, Stuart Chambers & Robert Johnston, 2004John GeoIKNo ratings yet

- Motor Parameters 03Document2 pagesMotor Parameters 03Miguel eNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-093 - Injection Pump, Naturally Aspirated EngineDocument15 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-093 - Injection Pump, Naturally Aspirated EngineMANUALESNo ratings yet

- Etabs TutorialDocument27 pagesEtabs TutorialSyed Abdul Hannan100% (4)

- Syndicate 10 - GOJEKDocument10 pagesSyndicate 10 - GOJEKAnthony KwoNo ratings yet

- 3.0 Roof: Building Technology (EG 626 CE)Document14 pages3.0 Roof: Building Technology (EG 626 CE)Romharsh OliNo ratings yet

NC Form

NC Form

Uploaded by

Roohi KatnoriaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NC Form

NC Form

Uploaded by

Roohi KatnoriaCopyright:

Available Formats

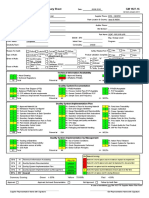

S CUBE ANNOTECH

------------------------------------------------------------------

NC Management

1. Process :-

2. NCR Number-

3. NC classification : MINOR / MAJOR

Justification:

4. Non conformity Reference: IATF 16949 or ISO 9001 QMS / Customers Sp. Reqt. / reference to Internal QMS

5.

5. Non conformity statement :

6. Objective evidence (facts):

7. Correction(s)

Resp. & Date

8. Root Cause(s):

Why-1

Why-2

Why-3

Why-4

Why-5

9. Corrective action(s):

Planned end of implementation date: Resp.:

Final evaluation: Closed /Not acceptable

Seen evidences of corrective actions:

Kind of evidence Review

Root cause analysis

Corrections

(for minor NC)

Change in procedure / Work

instruction/SOP

(numbers, dates, description of

changes)

Training Given by whom & when

(training content & records)

Physical changes

(pictures, drawings, …)

Internal audit

(system/process /product as

applicable)

Review system through MRM /

monthly meetings

(KPI, other performance trend)

Others

Process: Quality Assurance

NCR Number-02-16

NC classification : MINOR + Justification:

Results of layout inspection are acceptable and no comment reported yet.

Pattern inspection methods are in place to avoid process rejection.

No chances of shipment of non-conforming products to customer.

NC Reference: IATF 16949- 8.6.2

Non conformity statement:

Process of conducting layout Inspection is not fully effective.

Objective evidence (facts):

There is no evidence of verification for product characteristic like Radius-0.5 mm & Dimension 1.0 mm for

layout inspection dated 25/03/2015 for the Speedometer Magnet-2H245.

Correction(s) :

Layout inspection done with ballooning drawing for all characteristics of 2H245 Magnet dated on

05/09/2016

Root Cause(s):

Why-1

Why-2

Why-3

Why-4

Why-5 :Quality Manual is not addressing the requirement for layout inspection requirements

Corrective(s) action(s):

Quality manual revised XXXXX

Training is conducted for the concerns for the requirement on XXXXXX

Internal audit is conducted for XXX process XXXXX

Management review is conducted for complete closure of actions on XXXXX

Planned end of implementation date:XXXX By: XXXX

Final evaluation: Closed

Seen evidences of corrective actions:

Kind of evidence Review

Root cause analysis Quality Manual is not addressing the requirement for layout inspection

requirements

Corrections Layout inspection done with ballooning drawing for all characteristics of

(for minor NC) 2H245 Magnet dated on 05/09/2016 like Radius-0.5 mm & Dimension

1.0 mm.

Verified 2H245 magnet ballooned drawing to cover all parameters.

Change in procedure / Work Verified Quality manual-QMSM/13, XXXXXX for monitoring methods for

instruction/SOP layout inspection

(numbers, dates, description of

changes)

Training Given by whom & when Verified Training record F/MR/6XXXXfor Mr. Khandekar by Mr. Chavan

(training content & records) for the concerns for the requirement

Physical changes Not required

(pictures, drawings, …)

Internal audit Verified Internal audit record F/MR/XXXX for calibration process

(system/process /product as dated XXXX

applicable)

Review system through MRM / Verified Management review record F/XXXX for complete closure of

monthly meetings actions dated XXXX

((K)PI, other performance trend)

Others Not required

In case more reviews are needed additional evidences table shall be added

Reviewed by: XXX

You might also like

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- 3 On 3 Basketball Tournament Sponsor ProposalDocument4 pages3 On 3 Basketball Tournament Sponsor ProposalBaba Hans100% (1)

- Total Global Strategy Managing For Worldwide Competitive Advantage PDFDocument292 pagesTotal Global Strategy Managing For Worldwide Competitive Advantage PDFRamiro Fernando MosqueraNo ratings yet

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentSeda De Drasnia100% (4)

- Manufacturing Process Audit ChecklistDocument4 pagesManufacturing Process Audit Checklistgksp100% (4)

- VDA 6.3 Based Supplier AssessmentDocument11 pagesVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- ProQC ExampleReport TS16949 Audit PDFDocument39 pagesProQC ExampleReport TS16949 Audit PDFpandajay100% (1)

- Copia de CQI-23Document79 pagesCopia de CQI-23Ernesto Padilla100% (6)

- Audit Plan - ISO 9001 - ISO 14001 - 2015Document8 pagesAudit Plan - ISO 9001 - ISO 14001 - 2015Corrosion Factory100% (2)

- Apqp Ppap FormatsDocument66 pagesApqp Ppap Formatsjuande6940% (5)

- Archmodels Vol 203Document32 pagesArchmodels Vol 203Guido Gómez SalasNo ratings yet

- GM 1927-16 PCPA ChecksheetDocument4 pagesGM 1927-16 PCPA Checksheetrahul100% (1)

- Delphi Comprehensive Control PlanDocument51 pagesDelphi Comprehensive Control Planss2mrattriNo ratings yet

- GM 1927-30 QSB Audit Master - Final011811Document16 pagesGM 1927-30 QSB Audit Master - Final011811Mohammad GadNo ratings yet

- First Article Inspection - Aerospace FormsDocument6 pagesFirst Article Inspection - Aerospace Formssqalopez100% (1)

- Practical Research 1 - Unpacked CompetenciesDocument91 pagesPractical Research 1 - Unpacked CompetenciesEmem Lim-Asido Simbajon100% (2)

- 16-Port Antenna Frequency Range Dual Polarization HPBW Gain Adjust. Electr. DTDocument7 pages16-Port Antenna Frequency Range Dual Polarization HPBW Gain Adjust. Electr. DTestebanarcaNo ratings yet

- Audit Findings - ISO / TS16949Document2 pagesAudit Findings - ISO / TS16949Rohit SoniNo ratings yet

- Mace ChecksheetDocument48 pagesMace ChecksheetRAHUL rNo ratings yet

- Process AuditDocument15 pagesProcess Auditdesurkarb100% (2)

- Process Audit ChecklistDocument6 pagesProcess Audit ChecklistzafeerNo ratings yet

- Anexo 06 - PA - Process Audit v1.1Document19 pagesAnexo 06 - PA - Process Audit v1.1BalajiNo ratings yet

- Contract Execution Phase: Project Filling Plan - A4Document1 pageContract Execution Phase: Project Filling Plan - A4stefenjohn36No ratings yet

- Assessment - P06 - 26 - 7 - 2D - Rev 01-06-2015cópia-Portugues - Resp e PrazoDocument22 pagesAssessment - P06 - 26 - 7 - 2D - Rev 01-06-2015cópia-Portugues - Resp e PrazoGuilherme AugustoNo ratings yet

- Dahej Standby Jetty 2264Document9 pagesDahej Standby Jetty 2264Anonymous i3lI9MNo ratings yet

- Audit AnalzDocument10 pagesAudit AnalzGayan BandaraNo ratings yet

- A00F207e Audit ReportDocument8 pagesA00F207e Audit ReportMuhammad HashiNo ratings yet

- Construction Quality Management System Booklet For Cross Country Pipeline ProjectDocument10 pagesConstruction Quality Management System Booklet For Cross Country Pipeline ProjectRakesh Ranjan100% (1)

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- Checklist DocumentDocument46 pagesChecklist DocumentGaurav Vishwakarma100% (2)

- Cara ReportDocument25 pagesCara ReportSurendharNo ratings yet

- Mandatory Documents and Records (Ref: ISO 9001:2008)Document4 pagesMandatory Documents and Records (Ref: ISO 9001:2008)Shashank ChhajerNo ratings yet

- RC 2022 Summary CAFDDocument4 pagesRC 2022 Summary CAFDEjazNo ratings yet

- Quality Management System Manual QM-QUA-001: Nelson-Miller IncDocument34 pagesQuality Management System Manual QM-QUA-001: Nelson-Miller IncAbd Zouhier100% (1)

- 0161 Quality ConstructionDocument38 pages0161 Quality ConstructionjjyotiNo ratings yet

- Quality DocumentDocument15 pagesQuality Documenttanto_deep_15No ratings yet

- Process Audit Check ListDocument24 pagesProcess Audit Check ListSorin FrentoniNo ratings yet

- 4.6 TABC - Air Cooled Split Unit SystemDocument17 pages4.6 TABC - Air Cooled Split Unit SystemOsmahadzir OsrinNo ratings yet

- GM 1927-16a Leak Test Process AuditDocument20 pagesGM 1927-16a Leak Test Process AudithuangjlNo ratings yet

- 4.4 PPAP - ChecklistDocument4 pages4.4 PPAP - ChecklistAndrea InfanteNo ratings yet

- User Manual QMS - Quality ControlDocument58 pagesUser Manual QMS - Quality ControlGamble100% (1)

- ISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsDocument40 pagesISO/TS 16949:2009 Checklist - QWBT Issue: Ref. Question CommentsleadyourlifeNo ratings yet

- 01 32 17.00 20 - Contractor - Baseline - Project - Schedule - Comm - HVAC - ChecklistDocument3 pages01 32 17.00 20 - Contractor - Baseline - Project - Schedule - Comm - HVAC - ChecklistErwin ObenzaNo ratings yet

- Production Part Approval Process (Ppap)Document20 pagesProduction Part Approval Process (Ppap)Primoz Cermelj100% (1)

- 5) Control of Quality RecordsDocument4 pages5) Control of Quality RecordsSagar DaundNo ratings yet

- Navistar ApqpDocument18 pagesNavistar ApqpAbhijeet MitraNo ratings yet

- Change ControlDocument1 pageChange Controlhinckdogg100% (1)

- PPAP For Aerospace ASQDocument21 pagesPPAP For Aerospace ASQmedi3850% (2)

- Cqi-9 Heat Threatment DetailsDocument34 pagesCqi-9 Heat Threatment DetailshaydarkasnaklarNo ratings yet

- GM 1927-30 QSB AuditDocument38 pagesGM 1927-30 QSB Auditmanune01No ratings yet

- QMS FormDocument4 pagesQMS FormsarvaNo ratings yet

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Document26 pagesTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNo ratings yet

- PPAPDocument4 pagesPPAPMattNo ratings yet

- Joint ReviewDocument126 pagesJoint ReviewDIVAKAR PANIGRAHI100% (1)

- QP03 Management ReviewDocument4 pagesQP03 Management ReviewhastinkakaNo ratings yet

- Requirement For Iso 9001 2015Document3 pagesRequirement For Iso 9001 2015Anonymous r2EiqSrBNo ratings yet

- AC7126-1 Rev B 23-AUG-2016Document26 pagesAC7126-1 Rev B 23-AUG-2016unknown1711No ratings yet

- As 9103 o ReviewDocument28 pagesAs 9103 o ReviewAnonymous Wi2Pd2UgPINo ratings yet

- Global Supplier Quality System AssessmentDocument11 pagesGlobal Supplier Quality System AssessmentPvinoth000No ratings yet

- Management Review Wasit-1Document7 pagesManagement Review Wasit-1SANUNo ratings yet

- The AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesFrom EverandThe AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesNo ratings yet

- Statistical Thinking: Improving Business PerformanceFrom EverandStatistical Thinking: Improving Business PerformanceRating: 4 out of 5 stars4/5 (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Wrapper Tool For Creating Multiple Info ObjectsDocument12 pagesWrapper Tool For Creating Multiple Info ObjectsjothikumarjayaramanNo ratings yet

- Oxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Document2 pagesOxy Welding/Cutting Equipment Risk Assessment: October 2014 //1Alves EdattukaranNo ratings yet

- Modulo Ethernet - Ifbd-He0506 - SPC - enDocument35 pagesModulo Ethernet - Ifbd-He0506 - SPC - enE Moy LandaNo ratings yet

- Amines PDFDocument1 pageAmines PDF최승원No ratings yet

- Perl Cheat SheetDocument2 pagesPerl Cheat Sheetdinokid08100% (1)

- G.L Bajaj Institute of Management and Research Mid Term Assignment Subject - Ssp3 Subject Code-Pg23Document8 pagesG.L Bajaj Institute of Management and Research Mid Term Assignment Subject - Ssp3 Subject Code-Pg23Mansi GuptaNo ratings yet

- Excavator: Yanmar 36.2 KW (49.2 HP) at 2,100 RPMDocument2 pagesExcavator: Yanmar 36.2 KW (49.2 HP) at 2,100 RPMtomas liuNo ratings yet

- Instrucal IIIDocument46 pagesInstrucal IIINorberto Soto100% (1)

- Fh64t6ht GBR EngDocument7 pagesFh64t6ht GBR EngariwibowoNo ratings yet

- Introduction To Microwind: Integrated Electronics Lab 2Document10 pagesIntroduction To Microwind: Integrated Electronics Lab 2Ird Durrani100% (1)

- Account Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancePiyush AgarwalNo ratings yet

- LCD TV Display Failure Symptoms and Possible CausesDocument4 pagesLCD TV Display Failure Symptoms and Possible Causeskachappilly2012No ratings yet

- Vehical No Registrstion No Chassis No Engine No Trolly NoDocument6 pagesVehical No Registrstion No Chassis No Engine No Trolly Norodesa100% (1)

- Glassdoor - Resume - My PVT ResumeDocument3 pagesGlassdoor - Resume - My PVT ResumePrashant TodkarNo ratings yet

- Detailed Lesson Plan in Common Poultry ADocument4 pagesDetailed Lesson Plan in Common Poultry AAlvin NovencidoNo ratings yet

- Hydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDocument1 pageHydrite®UF 90: (Μm) 0.2 (Laser) 0.4 Screen ResidueDuc NguyenNo ratings yet

- SpeedTouch™ ST 585 CLI GuideDocument682 pagesSpeedTouch™ ST 585 CLI GuidesertuxNo ratings yet

- Strain Hardening of Copper AlloyDocument5 pagesStrain Hardening of Copper AlloyThien Van TranNo ratings yet

- Bangalore Electricity Supply Company Limited: Thank You!Document12 pagesBangalore Electricity Supply Company Limited: Thank You!Ranjan VNo ratings yet

- Process Design: © Nigel Slack, Stuart Chambers & Robert Johnston, 2004Document30 pagesProcess Design: © Nigel Slack, Stuart Chambers & Robert Johnston, 2004John GeoIKNo ratings yet

- Motor Parameters 03Document2 pagesMotor Parameters 03Miguel eNo ratings yet

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-093 - Injection Pump, Naturally Aspirated EngineDocument15 pagesD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 11-093 - Injection Pump, Naturally Aspirated EngineMANUALESNo ratings yet

- Etabs TutorialDocument27 pagesEtabs TutorialSyed Abdul Hannan100% (4)

- Syndicate 10 - GOJEKDocument10 pagesSyndicate 10 - GOJEKAnthony KwoNo ratings yet

- 3.0 Roof: Building Technology (EG 626 CE)Document14 pages3.0 Roof: Building Technology (EG 626 CE)Romharsh OliNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)