Professional Documents

Culture Documents

Ahmad Munir, 00704652,1644-Rewaq Ousha Educational Institut

Ahmad Munir, 00704652,1644-Rewaq Ousha Educational Institut

Uploaded by

sdsdjs sdhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ahmad Munir, 00704652,1644-Rewaq Ousha Educational Institut

Ahmad Munir, 00704652,1644-Rewaq Ousha Educational Institut

Uploaded by

sdsdjs sdhCopyright:

Available Formats

Unit IG2: Risk assessment

Declaration: By submitting this assessment (Parts 1 – 4) for marking I declare that it is entirely my own work. I understand that falsely claiming that

the work is my own is malpractice and can lead to NEBOSH imposing severe penalties (see the NEBOSH Malpractice Policy for further information).

Important note: You must refer to the document ‘Unit IG2: risk assessment – Guidance and information for learners and Learning Partners’ while

completing all parts of this assessment. Your Learning Partner should provide you with a copy, but it can also be downloaded from the relevant

resources section for this qualification on the NEBOSH website.

Part 1: Background

You should aim to complete this section in 150 - 200 words.

Topic Comments

Name of organisation* Unique Engineering Works Company

Site location* Karachi, Pakistan

Number of workers 1600

Unique Engineering Works Company manufactures steel buildings, pressure vessels

(drums, columns, and separators), mill heat exchangers, boilers, and power plant

turbines. Due to the current energy crisis, construction on wind towers has begun. raw

material imports from another country. Heavy machinery was operating in the plant

including automatic welding machine, crushing machine and cutting machine. In the plant,

typically, activities were undertaken including performing welding activity that were all

General description of the organisation

five types of welding used (gas, arc, resistance, solid state and newer welding. Workers

were cutting metal sheets and moulded it for the boiler manufacturing.

Employees work in two shifts from 9:00am to 05:00 pm, 05:00 pm to 01:00 am and in

each shift 800 workers work there. Mostly workers are of mature ages. Plant is closed on

Friday.

Description of the area to be included in the The risk assessment will cover fabricating area, manufacturing section, cutting area,

risk assessment welding unit and designing section and electrical control room.

Plant Manager and HSE team are responsible for health and safety related issues in

Any other relevant information

Unique Engineering Works Company.

Learner number: 00704652 Learner name: Ahmad Munir Page 1 of 19

* If you’re worried about confidentiality, you can invent a false name and location for your organisation but, all other information provided must be

factual.

You should aim to complete this section in 100 - 200 words.

Note: this section can be completed after you have competed your risk assessment.

Outline how the risk assessment was carried International Labour Organisation (ILO) has internationally safety standards, I go through

out this should include: it and got some important codes of standards related to the mechanical manufactures.

sources of information consulted; http://ilo.org/safework/info/standards-and-instruments/codes/WCMS_164653/lang--

who you spoke to; and en/index.htm

how you identified: Beside this HSE has some specific codes related to it

- the hazards; https://www.hse.gov.uk/coronavirus/working-safely/manufacturing/machinery-building-

- what is already being done; and

safety.htm

- any additional controls/actions that

may be required.

within it, I read some important codes and safety measures from International Labour

Organisation (ILO) related to welding and cutting

https://rlsdhamal.com/ilo-regulations-about-welding-and-cutting/

and arranged meeting with the Health and safety Manager related to safety arrangements

in plant. After conduct the meeting for further information, I went through the organisation

for identify the hazards and conduct interview to the supervisors and workers leader

related to their health and safety related issues, welfare facilities and safety culture, From

the meeting I observed that there is lack of positive safety culture in workers and lack of

monitoring and communication between employee and employer.

After this, I read organisation audit report, inspection report, work procedure, absence

and ill health data and previous accidents reports. I analysed that they’re this lack of

training and guidance about positive safety culture. The maintenance of machinery was

also not proper according to standards. I analyse the reasons for ill health and absence

due to fatigue and stress due to work burden and lack of break time. At the welding and

cutting workplace, Glasses and gloves were provided to all workers for controlling the

welding fumes and radiations was not proper at standard suitable for work. After

analysing the control measures, for eliminating fumes and radiation hazardous. I provided

HSE approved document.

https://www.hse.gov.uk/welding/protect-your-workers/index.htm

Learner number: 00704652 Learner name: Ahmad Munir Page 2 of 19

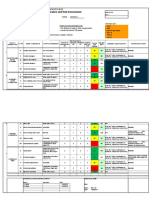

Part 2: Risk Assessment

Organisation name: Unique Engineering Works Company

Date of assessment: August 29, 2022

Scope of risk assessment: Fabricating area, manufacturing section, cutting area, welding unit and designing section and electrical

control room

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

Noise Workers, visitors and PPE like Ear buds provided 1 Make it strictly sure that workers 1 week Safety

area in-charge might be to all workers but not and visitors use comfortable PPE officer

harmed. comfortable. (ear buds or ear muffs).

Cutting and

grinding of Cutting and grinding of Noisy section of plant 2 Close area should be construct 2 months Finance

bulk bulky machinery for separated from other plant for cutting and grinding operation Manager

equipment, as constructing steel sections. to reduce noise level.

well as the structure produce high

fabrication of exposure of noise 3 Use a noise metre to conduct a 1 week Supervisor

steel which can affect noise survey and identify

structures, workers working their or machinery parts that produce high

make a lot of visitors or clients whose noise.

noise. visit there for projects.

That noise can affect 4 There should use some modern 1 month Plant

on their ear drums and cutting machines whose have less manager

can become hearing sound.

disability, physiological

effects and 5 The timing of cutting and grinding

occupational stress. should be separate to the other

Learner number: 00704652 Learner name: Ahmad Munir Page 3 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

duty work timing. 1 week Area

supervisor

6 Proper monitoring and inspection

of machinery and area to maintain HSE

low sound. 1 week Manager

Movement of Drivers and others 1. All the vehicle drivers full 1. Provide banksman and instruct 1 week Plant

people & workers that are in the trained and have licensed. him about hazards associated with Manager

vehicles work area could be his activity.

harmed. 2. Walkways for pedestrians

With an should be clearly marked. 2. Attach Reversing alarms and 2 weeks Plant

elevated load, Reversing a FLT in a train the driver. Manager

the driver was storage and stacking 3. Site speed limit should set

reversing FLT area with a high load at 5kmph. 3. A safe speed limit must be set, 1 week HSE

in the storage and no revering alarm and speed limit signs must be Manager

and stacking will result in the FLT mounted.

area with no overturning due to the

reversing high load and no 4. Pedestrian and vehicles 1 Month Finance

alarm revering alarm, causing crossing bridges must be Manager

attached. a pedestrian to be hit constructed at main locations.

by the FLT, resulting in

serious injury. 5. All vehicles should be proper 1 Week HSE Officer

inspected before use and size of

vehicles according to load.

6. PPE`s like visible jackets should

be provided to the workers of entry Plant

routes 1 Week Manager

Learner number: 00704652 Learner name: Ahmad Munir Page 4 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

Work Workers and 1. The machine inspected 1 1. To protect staff who deal with 2 weeks Mechanical

Equipment technicians who month ago. machinery, a fixed and adjustable Engineer

and operate cutting and guard should be installed on the

Machinery grinding machines can 2. Emergency buttons cutting machine.

be harmed. placed on machinery.

Operating 2. All machinery should be 1 weeks HSE Officer

cutting inspected before the use.

machinery Workers on cutting

without machines were not 3. To ensure that good working 2 Week HSE

wearing wearing robust gloves. practises are followed, monitoring Manager

inappropriate The cutter of the and supervision should be

PPE and machines can touch the implemented.

machinery hand or body of the

guards were workers and they get 4. Robust gloves should be used 1 week Area

missing. harm. While during all workers during work. supervisor

cutting machinery,

cutting blades could cut 5. Weekly training should be 2 weeks HSE

or damage workers conduct for safe system of working. Supervisor

body parts especially

fingers, hand or arms.

Electricity Workers, Staff, as well 1. High voltage sign placed 1. All machinery should be proper 1 week Electrical

as anyone else who beside the Machine. earthed. Supervisor

may be present, may

High voltage be affected. 2. During work, an over voltage, 1 week Machine

mechanical . 2. Proper training was over current and over-heating Worker

manufacturing provided to the workers. metre should be constantly

machinery Working on a high- monitored.

were not voltage machine

Learner number: 00704652 Learner name: Ahmad Munir Page 5 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

earthed. without an earthing can 3. To avoid electric shocks, 1 week HSE Officer

result in extreme appropriate PPE such as rubber

electric shock and even gloves and safety shoes should be

death can cause by worn.

high-voltage access to

critical body parts. 4. All other non-working staff, 1 Week Plant

Muscle cramps, electric visitors not allowed to visit that Manager

burns, numbness area.

and nervous system

damage are all 5. Before starting the machines, 1 week Electrical

potential side effects. make sure that all of the equipment Technician

and wiring are in good working

order.

6. All staff should be trained and 3 Week HSE Officer

given instructions about how to

treat an emergency.

Health, Workers, supervisors Proper ventilation for natural 1. Local lighting, such as spot 1 week HSE

welfare and and client might be light. lights, LED lights located above the Supervisor

working affected. machinery.

Environment

Workers, drivers and 2. All damaged lights should be 1 Week Finance

supervisors working for replaced, and LUX should be Officer

Inadequate a long time period achieved.

lighting in the under the inadequate

production lighting which may 3. Lights should be inspected and 3 Weeks HSE Officer

Area. causes change in their maintained on a regular basis, and

Learner number: 00704652 Learner name: Ahmad Munir Page 6 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

attitude, , fatigue, eye the best practise is to use natural

strain and headaches. light.

4. Provide portable electrical 2 Weeks Plant

devices to the workers for personal Manager

lighting use.

5. Add the monthly inspection 1 Month HSE Officer

method to the lightening

inspection.

Working at 1. Scaffolding and mobile 1. Their must strictly order to wear 1 Week Area

height Workers, visitors, tower appropriate work. PPE and use full body harness supervisor

structure frame and while working on height.

materials could be

working on harmed. 2. Personal protective 2. Proper monitoring and checking 1 week Maintenance

mobile tower equipment (PPE) were by the supervisor at working time. staff

scaffold for Workers was working provided to all workers but

the on height without full they not using that. 3. Scaffolding and mobile tower 2 Days Area

maintenance body harness which should not be overloaded. Supervisor

in the steel may cause fall of

structural workers from the 4. SSOW must be developed and 2 Weeks HSE

area, they height. The implemented for safety of all height Manager

working Consequences of work activities

without full falling from height are

body harness broken of bones, 5. Arrange and install safety nets 1 Week Plant

and head permanent disability and air bags. Manager

protection even death can occur.

6. Permit to work system should be 3 Weeks HSE

develop and also must be followed. manager

Learner number: 00704652 Learner name: Ahmad Munir Page 7 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

Electricity Workers and supervisor 1. The electrical 1. Ensure that all flammable 1 week HSE Officer

and other people that infrastructure is in place. materials are kept a safe distance

Insulation of are in the area might be away from electrical boards and

cable was harmed. circuits.

damaged 2. Trained first aiders are

found in Workers may come into available who can deal with 2. All old wiring components and 1 Month Plant

electrical contact with the minor electric shock. cables will be repaired or replaced Manager

control room. damaged cable, putting with new ones.

themselves at risk of

electric shock, skin 3. For cable safety, wrap flexible 2 weeks Plant

burns, and death. pipes around all tool cables. Manager

Electricity can cause

severe electric shock,

which can lead to 4.Safety shoes should be provided 1 Week HSE

death. It can also cause to the workers. Manager

muscle cramps, electric

burns, discomfort, 5. All workers should train to report 3 Weeks HSE Officer

fatigue, limb pain, and spot electrical damages in

numbness, tingling, and equipment’s and in workplace.

nervous system

damage, as well as 6. All workers should aware of 2 Weeks HSE

memory loss and emergency arrangements. Supervisor

chronic tremors.

Learner number: 00704652 Learner name: Ahmad Munir Page 8 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

Hazardous Workers, materials and 1.Personal protective 1. Proper standard respiratory 1 week Plant

substance visitors might be equipment (PPE) provided to protective equipment’s (RPE) Manager

harmed. workers but they not using provided to workers.

welding the them.

machines and Workers working in 2. All the burning materials should 1 week Area

equipment welding unit producing 2. Work training delivered to be hide and clean the area, Supervisor

without any large number of fumes. workers 1 month ago.

proper PPE, They were not using 3. Proper ventilation in area to 1 Week Finance

and there was respiratory protective 3. Ventilated area but not remove any toxic gases or dust Manager

no proper equipment (RPE). proper separation for materials and inspected regularly

ventilation to During breathing fumes welding.

prevent toxic irritating them they 4. A method of job rotation and rest 3 Week Plant

welding inhaling fumes which breaks should be enforced. Manager

fumes. cause lung damage

and various types of 5. Before beginning work, worker 5 days HSE

cancer, including lung, should check their preparation to Manager

larynx and urinary work and ensure that their health is

tract. Health appropriate for the work.

effects from

certain fumes may

include

metal fume fever,

stomach ulcers, kidney

damage and nervous

system damage.

Learner number: 00704652 Learner name: Ahmad Munir Page 9 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

Work related Workers and staff might 1.Ergonomics risk 1. Conduct an ergonomic risk 1 week HSE

upper limb be harmed. assessment was last carried assessment of the workstation to Manager

disorders out when the area was first ensure the appropriate level of

Workers and set up (4 years ago) comfort.

Staff employees who were

members and expected to work in 2. Monitoring on regularly 2. Provide staff with risk and 1 week Plant

in-charge of front of a computer basis by the Staff manager. precautions knowledge and Manager

construction screen on a daily basis preparation.

were It can cause health

frequently problems such as 3. If necessary, include eye exams 2 weeks Finance

working in tension, exhaustion, and spectacles. Manager

front of eye strain, back pain,

display and WRULD. 4. To allow for a comfortable head 1 week Plant

screen position, the screen height should Manager

equipment, be adjustable.

making prints

for steel 5. Ascertain that the lighting is 1 week HSE Officer

structures. suitable for the job (brightness or

lux level should be relatively for

fine detail work).

HSE

6. Provide training to workers on 2 Weeks Executive

risk and precautions.

Fire Maintenance workers 1. Safety sign boards 1. Management should develop 1 Week HSE

and supervisor to be installed. and enforce a safe system of work Executive

using a gas harmed. for hot work.

cutter to cut a

metal for Carrying out hot work 2.Emergency procedures 2.Fire Extinguisher should be 1 week Plant

Learner number: 00704652 Learner name: Ahmad Munir Page 10 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

shelter near flammable are for fire tested regularly. provided on all hot work activities. Manager

maintenance, materials will result in

and oxygen significant physical and 3. Flammable material removes 2 week Area

and acetylene economic damage due from place and proper ventilation. supervisor

cylinders to fire and explosion.

were right 4. Follow permit system, daily hot 1 Week Area

next to them. work check list. Manager

5. Conduct tool box talks for 1 week HSE

storage of combustible and Supervisor

flammable materials.

6. On-site, a permit-to-work system 1 Month HSE

for hot-working activities in the Executive

workplace should be created.

Slips and All the workers working The walkways were 1.Spill kits must be available on the 2 weeks Finance

trips in the workshops can designed. workplace. manager

be harmed Safety signs were installed.

There was oil Workers moving around 2.Arrange the floor to be HSE

spillage in the this spillage can get degreased as soon as possible. 1 week supervisor

maintenance slipped and can get

workshop due fallen on the floor they 3.Spill resistant Matts must be Plant

to fault in can get injury like head available. 1 week manager

machine injuries, broken bones,

Learner number: 00704652 Learner name: Ahmad Munir Page 11 of 19

Hazard Who might be harmed What are you already doing? What further controls/actions are Timescales for Responsible

category and and how? required? further actions person’s job

hazard to be title

completed

(within …)

internal and external 4.Good housekeeping must be

injuries etc. decided. 1 week Activity

supervisor

Learner number: 00704652 Learner name: Ahmad Munir Page 12 of 19

Part 3: Prioritise 3 actions with justification for the selection

Suggested word counts

Moral, general legal and financial arguments for all actions: 300 to 350 words

For EACH action:

Specific legal arguments: 100 to 150 words

Likelihood AND severity: 75 to 150 words

How effective the action is likely to be in controlling the risk: 100 to 150 words

Moral, general legal and financial arguments for ALL actions

Moral, general legal and financial Moral:

arguments Unique Engineering Works Company have a moral obligation of preventing workplace

accidents so employees can come home safely. Staff are the backbone of every

organisation, and they operate solely on the basis of the organization's will. Organizations

must also take appropriate precautions to keep their employees safe. It is socially immoral

for staff to be injured or killed on the job. Since the worker's family is dependent on him, the

company should take care of his workers' welfare. Furthermore, employees have a moral

responsibility to take good care of their own safety as well as the safety of those who might

be injured as a result of their actions, and they should comply with their employers.

Legal:

Unique Engineering Works Company could face regulatory compliance measures such as

prohibition (Stopping all work on a specific activity) or improvement notices relating to these

activities. If these activities could not be carried out properly, the financial burden on the

company would be immense, and even these activities could limit their certification

achievement in all fields and local Government can also take an action against delay of

work. The government of Pakistan imposes various obligations on employers, including the

requirement that working machines, working practises, and work environments be suitable

to the nature of the work, that all work equipment be inspected and maintained, and that all

high-risk activities be regulated by a permit-to-work system. Under the International Labour

Organization's (ILO) Safety and Health Convention, a firm is legally required to safeguard

Learner number: 00704652 Learner name: Ahmad Munir Page 13 of 19

its employees (C155)

Financial:

If a major accident happens at work, the company may suffer significant financial losses.

These financial implications may be categorised into these groups. Cost associated with

injured employee (sick pay, replacement worker allowance, medical costs, lost working

time), Costs associated with new worker recruitment, Costs related to civil lawsuits, The

cost associated with a rise in insurance premiums, The expense of getting regulatory

authority. When an accident or unwelcome occurrence occurs, it often damages the

organization's property. Beside it the reputation of the company will be down and the result

they loss their client. Furthermore, the organisation must bear the losses of his estate. A

large sum would be required to rebuild and repair damaged buildings, as well as to install

machinery.

Justification for action 1

Action (Taken from column 4 of risk Close area should be construct for cutting and grinding operation to reduce noise level.

assessment) (Hazard category: Noise)

Specific legal arguments ILO C148 - Working Environment (Air Pollution, Noise and Vibration) Convention, 1977

(No. 148) article 8 required that where this is not feasible, technological measures applied

to new plant or processes or installation in design of new close area or added to existing

plant or processes shall be used to keep the working environment free of any danger due

to noise or vibration. And The employer must provide and maintain appropriate personal

protection equipment. The employer does not expect a worker to work without the personal

protective equipment required by this Article.

Similarly, ILO Recommendation R156 recommended for controlling noise in the workplace

should be replaced as much as possible in new areas by processes that produce little to no

pollution, noise, or vibration. In appropriate cases, the competent authority should authorise

requirements for the emission levels of machinery and installations (design, built-in

equipment, or technical measures during installation) in terms of air emissions, noise, and

vibration.

Learner number: 00704652 Learner name: Ahmad Munir Page 14 of 19

Consideration of likelihood AND severity The likelihood of hearing loss to the worker is high.

I set the category when suggesting the severity in following way:

types of injury or ill health Minimal: no injury or damage happened.

number of workers at risk Minor: injury happened requiring the first aid treatment and/or unimportant damage to the

how often the activity is carried equipment and machinery.

out Major: injury happened requiring the hospital treatment, requiring recovery time, and/or

how widespread the risk is important damage to equipment and machinery.

Fatal: injuring which causing disability or death, and loss of equipment, machinery or

building.

The Severity of this hazard is set as Major. Because due to working long period in high

frequency noisy area, workers could need hospital treatment for hearing disability or

physiological effects.

There are ten workers working in this area and are at risk.

Cutting and grinding of bulky machinery for constructing steel structure produce high

exposure of noise. Workers work in this area in two shifts.

The risk is present in the Cutting and grinding and affect workers only that are working in

this section.

How effective the action is likely to be in Construction of separate close area for the noisy place is very helpful for control the noise

controlling the risk. This should include: level. The noise will not travel outside the close area and close area will reduce the

the intended impact of the action; frequency of noise. As a result, I proposed the creation of a separate close area for the

justification for the timescale that noisy area, which would have a positive effect on the workers, improve industry morale,

you indicated in your risk and minimise the risk of noise hazards and accidents. Cost associated with the

assessment; and implementation of the action will be less than the cost of injuries to workers.

whether you think the action will

fully control the risk I've assigned it a two-month time scale for this to be completed because I'll discuss it with

the HSE chairman, executives, and finance manager before authorising the budget. I'm

hoping that this will take the longest period of time to complete.

This action 80% maximum reduce the risk of noise pollution among workers during the

Learner number: 00704652 Learner name: Ahmad Munir Page 15 of 19

construction of a separate close area. Action with suitable controls can help to provide the

fully control of the risk.

Justification for action 2

Action (Taken from column 4 of risk Pedestrian and vehicles crossing bridges must be constructed at main location or main

assessment) gates. (Hazard category: Safe movement of people and vehicles)

Specific legal arguments ILO C167 - Safety and Health in Construction Convention, 1988 (No. 167) article 28

required that All vehicles and earth-moving or material-handling equipment must be

operated by workers who have received proper training in compliance with national laws

and regulations, and all safety requirements in vehicles must be maintained, and traffic

layout on all sites must be transparent and in accordance with a secure work system. The

ILO code of practice ‘Safety of the Movements vehicles and Pedestrian’ gives specific

advice to appropriate control measures that employer must make to protect his employees

against the risk identified by an assessment of risk. The ILO’s code of practice ‘recording

and notification workplace accidents’ requires employers to report cases of major

workplace vehicles accidents to our country’s health and safety regulator.

Consideration of likelihood AND severity The likelihood of serious injury is high due to collision.

Please see the justification 1 for severity category. The severity of this is set as Major

types of injury or ill health because if an accident happens when vehicles are travelling, a severe personal injury will

number of workers at risk occur, and it is possible that the injury will require medical care, such as a head injury or a

how often the activity is carried bone fracture. This may be damage building and another vehicle.

out

how widespread the risk is There are twenty worker working in this area and are at risk.

Driver reversing a FLT in a storage and stacking area with a high load and no revering

alarm will result in the FLT overturning due to the high load and no revering alarm, causing

a pedestrian to be hit by the FLT. Workers work in this area in two shifts.

The risk is present in the storage and stacking area and affects workers only that are

working in this area.

How effective the action is likely to be in Pedestrian and vehicles crossing bridges must be constructed to reduce the risk of collision

Learner number: 00704652 Learner name: Ahmad Munir Page 16 of 19

controlling the risk. This should include: vehicle with pedestrians and another vehicle. This will reduce the severity rating. This

the intended impact of the action; action will decrease the likelihood of serious personal injury. This will also decrease the risk

justification for the timescale that of hit by other vehicle and will also reduce the cost of maintenance of the damaged

you indicated in your risk machinery. This will major impact on the organisation. Cost associated with the

assessment; and implementation of the action will be less than the cost of injuries to workers.

whether you think the action will

fully control the risk I've given a 1 month to be completed for this because construction of the crossing bridges

will take time to be completed and I hope finance manager will agree the action.

The action will 80% control the risk of collide with workers and other vehicles while

construction of crossing bridges. This will also decrease the severity level. Action with

suitable controls can help to provide the fully control of the risk.

Justification for action 3

Action (Taken from column 4 of risk To protect staff who deal with machinery, a fixed and adjustable guard should be installed

assessment) on the cutting machine. (Hazard category: work equipment and machinery.)

Specific legal arguments ILO`s C119 - Guarding of Machinery Convention, 1963 (No. 119) article 11 require that

dangerous parts of the machinery during operation shall be fully guarded and shall be

ensured that guards are placed in right positions and are appropriate to machinery also

required that every machinery that are working in the workplace, should be guarded with

fixed and moveable guards and there should be placed use of safe machinery method.

Emergency button of the machine should also be installed at machine and the machine

operator should be competent. Supervision and monitoring system should be performed to

check the effectively operating.

Consideration of likelihood AND severity The likelihood of serious personal injuries is high.

Please see the justification 1 for severity category. The severity rating for this hazard is set

types of injury or ill health as Major. If accident happen in the workplace about machinery. It may be probably that

number of workers at risk injury of the worker will require hospital treatment. E.g., cut injuries

how often the activity is carried

out There are four workers working on the machine and are at risk.

how widespread the risk is

Learner number: 00704652 Learner name: Ahmad Munir Page 17 of 19

Worker operating cutting machinery in machinery section without wearing inappropriate

PPE and machinery guards were missing. Workers work in this area in to shift.

The risk is present in the machinery section and affects workers only that are working with

machines.

How effective the action is likely to be in Fixed and adjustable guards could be mounted on each machine to limit the number of

controlling the risk. This should include: machine-related injuries. Set and reversible guards have a huge effect because they

the intended impact of the action; minimise the risk of entanglement, slashing, and abrasion, as well as the incidence of

justification for the timescale that fractures and broken bones. Cost associated with the implementation of the action will be

you indicated in your risk less than the cost of injuries to workers.

assessment; and

whether you think the action will I have given 2 weeks’ time scale for this to be completed. I have given this time because

fully control the risk finance manager and Plant manager will discuss it with the mechanical engineer and

mechanical engineer will make an assessment of layout the machinery and hire a

competent maintenance member for this to be completed so this will take time.

This action will 70% control the risk of serious injuries while fixed and adjustable guard will

be installed on the cutting machine and this action will also have decreed the severity level.

Action with suitable controls can help to provide the fully control of the risk.

Part 4: Review, communicate and check

Suggested word counts for each section:

Planned review date or period and reasoning for this: 50 - 100 words

How the risk assessment findings will be communicated and who needs to know the information: 100 - 150 words

Follow up on the risk assessment: 100 - 150 words.

Planned review date/period with The company has a policy that requires a one-year review of the risk assessment. As a

reasoning result, I've set a one-year review period. On August 29, 2023, the risk assessment will be

reviewed. I also ensure that the risk assessment is reviewed before the date when the

following events occur If the number of employees changes, Process Modification, a

change in machinery and any major accident occurs in the plant.

How the risk assessment findings will be I'll schedule a meeting with the HSE manager and the finance director to discuss and agree

communicated AND who you need to tell on the risk-assessment measures I proposed, and then I'll provide a list of conclusions and

risk-area actions (this meeting will have emailed initially with follow up if required). The

Learner number: 00704652 Learner name: Ahmad Munir Page 18 of 19

results of this risk assessment will be included in the training plan and posted on notice

boards in the department. I'll communicate these findings to all relevant departments via

email or company intranet, where I'll also advise the staff about what actions to take. The

finding of the risk assessment and recommended measures will be posted on the company

intranet and notice boards so that all employees can see it. The results of the risk

assessment will be included in the next tool box talk so that every worker will understand

the hazard finding and control measure.

How you will follow up on the risk I will set a small board in my office attach the written form of risk assessment on this board

assessment to check that the actions along with date and timescale for which action is be taken. I will mark the date and action

have been carried out before 20 days of that action due date and set a remainder in my phone with specific ring.

On due date I will call the responsible person and investigate about the progress of

completion. I will identify the reasons if targeted action is not seen to be completed on due

date. If It is due to financial resources or workers behaviour that could create a hurdle in

implementing new controls. I will arrange a meeting with financial manager to give some

funding to implement the necessary controls. I will also arrange the meeting with Plant

Manager and HSE Manager to deal with poor behaviour of workers and try to sort-out with

best agreed actions. If any actions look, they are not to be completed on time I will speak to

managing director to see what additional sources available.

Learner number: 00704652 Learner name: Ahmad Munir Page 19 of 19

You might also like

- Hornbill Property DevelopersDocument20 pagesHornbill Property DevelopersSmiley Suresh89% (9)

- IG2 New Updated FormatDocument9 pagesIG2 New Updated FormatSafety PECPL43% (7)

- Unit IG2: Risk AssessmentDocument24 pagesUnit IG2: Risk AssessmentNowfal Habeeb86% (14)

- Aswin Ashok 00601664 IG2Document17 pagesAswin Ashok 00601664 IG2BALAJI. B100% (7)

- Report NeboshDocument12 pagesReport NeboshAhsan Khan100% (6)

- Sample NEBOSH Ig2 ReportDocument15 pagesSample NEBOSH Ig2 ReportLogeshNo ratings yet

- Nixon Nikhil 00761635 Tciq ProjectDocument17 pagesNixon Nikhil 00761635 Tciq ProjectNikhil Nixon100% (4)

- K S Zamreen 00761734 Tciq ProjectDocument19 pagesK S Zamreen 00761734 Tciq ProjectNikhil Nixon100% (2)

- Ig2-Form - MD Shadab Anwar ProjectDocument21 pagesIg2-Form - MD Shadab Anwar Projectmd shadab anwarNo ratings yet

- Unit IG2 Risk AssessmentDocument17 pagesUnit IG2 Risk AssessmentAli Alahma100% (2)

- Unit IG2: Risk AssessmentDocument14 pagesUnit IG2: Risk Assessmentamin100% (1)

- Construction Report 1Document15 pagesConstruction Report 1Faroo wazir78% (9)

- IG2, Jamal Shah, 00657859, Besi PVT Ltd.Document17 pagesIG2, Jamal Shah, 00657859, Besi PVT Ltd.saqib ali80% (5)

- Nikhil PS - 00579704Document28 pagesNikhil PS - 00579704Nikhil Nixon60% (5)

- Menon P Ravikeerthi 00761732 Tciq ProjectDocument19 pagesMenon P Ravikeerthi 00761732 Tciq ProjectNikhil Nixon100% (7)

- 00587830, Allen MathewDocument30 pages00587830, Allen MathewIrfan Peruvallithodi80% (5)

- Risk Assesssment IG2 ReportDocument18 pagesRisk Assesssment IG2 ReportRashid Jamil33% (6)

- Unit NG2: Risk AssessmentDocument13 pagesUnit NG2: Risk AssessmentShaun-Paul LebenNo ratings yet

- Khaleel Basha Shaik, 00734394,1308-Bharat Safety Training Igc 2 - Report 3Document15 pagesKhaleel Basha Shaik, 00734394,1308-Bharat Safety Training Igc 2 - Report 3s khaleel basha100% (4)

- Sample 4Document25 pagesSample 4Alb AklbNo ratings yet

- Rinesh Vallassery Suresh BabuDocument27 pagesRinesh Vallassery Suresh BabuAnshif RayinNo ratings yet

- IG2 68J S.J Steel PVT LTD 1 - 084932Document16 pagesIG2 68J S.J Steel PVT LTD 1 - 084932Muhammad Farooq Malik100% (1)

- Risk Assesment of Workplace.Document17 pagesRisk Assesment of Workplace.Sufyan SufyanNo ratings yet

- #36 IG2-forms-electronic-submissionDocument6 pages#36 IG2-forms-electronic-submissionHassan Alawami100% (3)

- Unit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDocument17 pagesUnit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsMuhammad FaiSal100% (6)

- Unit IG2: Risk AssessmentDocument22 pagesUnit IG2: Risk Assessmentprijith j100% (6)

- IG2.GTSC EgyptDocument18 pagesIG2.GTSC EgyptAbdellatef Hossam100% (3)

- Ig2 ProjectDocument18 pagesIg2 Projectvivek vjNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document16 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1vivek vj67% (3)

- Unit IG2 Risk AssessmentDocument13 pagesUnit IG2 Risk AssessmentAbdulla KurupkarNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Unit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1Document9 pagesUnit IG2: Risk Assessment: Declaration: by Submitting This Assessment (Parts 1muhammad nadeem100% (1)

- N-16418 Method Statement For Insulator String Replacement With Annex PDFDocument32 pagesN-16418 Method Statement For Insulator String Replacement With Annex PDFantaryami SInghNo ratings yet

- Stem Risk AssessmentDocument3 pagesStem Risk Assessmentapi-462431333No ratings yet

- Hirac Operations Pipeline Cleaning and Pressure TestDocument7 pagesHirac Operations Pipeline Cleaning and Pressure TestNur Alisha Alisha100% (1)

- Faizan Ahmed KhanDocument14 pagesFaizan Ahmed KhanFaizan Ahmed KhanNo ratings yet

- Sample - Majan Glass Company OmanDocument21 pagesSample - Majan Glass Company OmanRizwan Hameed100% (1)

- Edititd GoogleDocument19 pagesEdititd GoogleAlb AklbNo ratings yet

- Yasir Ahmad, 00657735, 1644-Rewaq Ousha Educational Institute. (IG-2)Document18 pagesYasir Ahmad, 00657735, 1644-Rewaq Ousha Educational Institute. (IG-2)ayanNo ratings yet

- IG2 Mohamed HassanienDocument30 pagesIG2 Mohamed HassanienAyman ElHapashy0% (1)

- Nebosh Sample ReportDocument21 pagesNebosh Sample Reportharis bhuttoNo ratings yet

- Unit IG2 Tony BabuDocument14 pagesUnit IG2 Tony Babujithin shankar100% (3)

- Chandu Raveendran 00643493Document13 pagesChandu Raveendran 00643493rah uaeNo ratings yet

- Anthony Mogus Nwoye-00658785 - Avt AcademyDocument19 pagesAnthony Mogus Nwoye-00658785 - Avt AcademyAttachouhdary HseNo ratings yet

- Samal Dattatreya 00724769, Ig2-Nviron Consulting PVT LTDDocument22 pagesSamal Dattatreya 00724769, Ig2-Nviron Consulting PVT LTDanandmg41No ratings yet

- Unit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDocument19 pagesUnit IG2: Risk Assessment: You Should Aim To Complete This Section in 150 - 200 WordsDevil Cinematic Gamer100% (3)

- Faraz Ali Ig2 Report July ExamDocument18 pagesFaraz Ali Ig2 Report July ExamRashid Jamil100% (1)

- Abdur-Rehman-00640317-848 Safety World ME ConsultantsDocument20 pagesAbdur-Rehman-00640317-848 Safety World ME ConsultantsM AbidNo ratings yet

- Tamor 2Document15 pagesTamor 2Akbar GhulamNo ratings yet

- Ig2 Forms Electronic Submission v3Document12 pagesIg2 Forms Electronic Submission v3Nowfal Habeeb100% (1)

- Ig2 of Bikas 00691520 x123Document20 pagesIg2 of Bikas 00691520 x123Engr. Imran Hasan Pathan100% (4)

- Unit IG2: Risk Assessment Part 1: BackgroundDocument9 pagesUnit IG2: Risk Assessment Part 1: BackgroundREVANTH KUMARNo ratings yet

- Unit IG2: Risk AssessmentDocument16 pagesUnit IG2: Risk AssessmentRashid JamilNo ratings yet

- IG-2 Risk Assesment GCF SiteDocument19 pagesIG-2 Risk Assesment GCF SitefahadullahNo ratings yet

- IG 2,,,,00576880, Nwosu Anselem, Novelle Centre, 945Document29 pagesIG 2,,,,00576880, Nwosu Anselem, Novelle Centre, 945Anselem NwosuNo ratings yet

- Unit IG2: Risk Assessment Part 1: Background: WWW - Hse.gov - UkDocument8 pagesUnit IG2: Risk Assessment Part 1: Background: WWW - Hse.gov - UkNomi NoorNo ratings yet

- Ig2 Forms Electronic Submission v3Document21 pagesIg2 Forms Electronic Submission v3Sajo JoseNo ratings yet

- Dyamanna Malapur - IG2Document24 pagesDyamanna Malapur - IG2NIRANJANMURTHY ASST.EXECUTVIE ENGINEER100% (1)

- Ig2 Forms Electronic SubmissionDocument6 pagesIg2 Forms Electronic Submissionakhil100% (2)

- Part 1 ReadyDocument2 pagesPart 1 ReadyMock Project100% (1)

- Unit IG2: Risk AssessmentDocument16 pagesUnit IG2: Risk AssessmentRizwan Hameed100% (2)

- IG2-Bilal Shoukat-00790384-Save Fast Fire & Safety Training L.LDocument18 pagesIG2-Bilal Shoukat-00790384-Save Fast Fire & Safety Training L.Lqadeesbhatti09511No ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Security Supervisor Job DescriptionDocument5 pagesSecurity Supervisor Job DescriptionEmiliano Croes100% (1)

- NEBOSH International General Certificate in Occupational Safety and Health Igc1Document110 pagesNEBOSH International General Certificate in Occupational Safety and Health Igc1harikrishna100% (2)

- Toxicology Risk and HazardDocument21 pagesToxicology Risk and HazardAizat AsyhNo ratings yet

- Master Thesis KJ SyautaDocument173 pagesMaster Thesis KJ SyautaCyrille COUSINo ratings yet

- Life Cycle Risk Assessment of HPLC InstrumentsDocument13 pagesLife Cycle Risk Assessment of HPLC Instrumentsalexg123100% (1)

- Subject:: NoticeDocument33 pagesSubject:: NoticeYogesh Jain (H4CK3RLeX)No ratings yet

- Environment Standard (ENG)Document13 pagesEnvironment Standard (ENG)Nat OffeiNo ratings yet

- Field Safety Considerations and Its Design ImplicationsDocument192 pagesField Safety Considerations and Its Design ImplicationsPRASAD6219100% (1)

- 23.12.23 Web Werks HiraDocument5 pages23.12.23 Web Werks HiraJayendra NaiduNo ratings yet

- Method of Statement For Mechanical Works PDFDocument17 pagesMethod of Statement For Mechanical Works PDFJR De Leon100% (1)

- BSBHRM413 Learning PlanDocument5 pagesBSBHRM413 Learning PlanSakshi DeshmukhNo ratings yet

- Risk Based Inspection RBI 581Document583 pagesRisk Based Inspection RBI 581Sell Ontyres100% (5)

- Fence InstallationDocument10 pagesFence InstallationanoopyohNo ratings yet

- Risk Assessment of Fire Pipe Flange T ConnectionDocument5 pagesRisk Assessment of Fire Pipe Flange T Connectionimran aliNo ratings yet

- Monthly Infoshare Meeting 02 SCE Impaired WorkshopDocument23 pagesMonthly Infoshare Meeting 02 SCE Impaired Workshopcloudno911100% (2)

- Occupational Safety and Health Risk Assessment PDFDocument2 pagesOccupational Safety and Health Risk Assessment PDFStacyNo ratings yet

- Case - Study - RMWG-01 - Internal - GMP - Audit - Program PDFDocument3 pagesCase - Study - RMWG-01 - Internal - GMP - Audit - Program PDFMasthan GMNo ratings yet

- Metod of Staitment CDP (Pasha Construction)Document7 pagesMetod of Staitment CDP (Pasha Construction)GurbanNo ratings yet

- HSG 168Document104 pagesHSG 168BineeshNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument9 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyFadi BoustanyNo ratings yet

- CONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormDocument6 pagesCONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormPerwez21No ratings yet

- ISMS Manual: Version: 2.9 Date: 07 May' 2012Document45 pagesISMS Manual: Version: 2.9 Date: 07 May' 2012Jon DesferNo ratings yet

- JWPCA 2006 Review Water CorpDocument75 pagesJWPCA 2006 Review Water CorpAnonymous e9xp1aQClONo ratings yet

- Building Mtnance, Health and SafetyyDocument17 pagesBuilding Mtnance, Health and Safetyywangolo EmmanuelNo ratings yet

- The Practices of Risk Based Internal Shariah Auditing Within Malaysian Takaful Operators A Multiple Case StudyDocument20 pagesThe Practices of Risk Based Internal Shariah Auditing Within Malaysian Takaful Operators A Multiple Case StudyAngel Jean Hernández NuñezNo ratings yet

- Water ResourcesDocument206 pagesWater Resourcesrendy firmansyah100% (1)