Professional Documents

Culture Documents

HYDAC Messe HydroDams Rückwand

HYDAC Messe HydroDams Rückwand

Uploaded by

Ryan KaneCopyright:

Available Formats

You might also like

- Crude Distiller RBI Intro (Updated)Document31 pagesCrude Distiller RBI Intro (Updated)harrinsonf100% (2)

- L5 - Physical TreatmentDocument67 pagesL5 - Physical Treatmentrushdi100% (1)

- Settleability Problems and Loss of Solids in the Activated Sludge ProcessFrom EverandSettleability Problems and Loss of Solids in the Activated Sludge ProcessNo ratings yet

- Indion Indro 401Document36 pagesIndion Indro 401maksudur4No ratings yet

- Slurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)Document13 pagesSlurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)R_M_M_100% (4)

- Landfill VS WTEDocument49 pagesLandfill VS WTEMuhd FiziNo ratings yet

- Pollution: Causes & RemediesDocument5 pagesPollution: Causes & RemediesSusana CardadorNo ratings yet

- 3 Frederic MollardDocument12 pages3 Frederic MollardEdmilson JersonNo ratings yet

- Online Drying Systems With MoistureDocument51 pagesOnline Drying Systems With MoisturePrasanna Mohandoss100% (1)

- Siemens Refinery BrochureDocument16 pagesSiemens Refinery BrochureAqila LuthfianaNo ratings yet

- 2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Document14 pages2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Hanif Budhi CundomanikNo ratings yet

- Block Diagram Nitric AcidDocument4 pagesBlock Diagram Nitric AcidBatrisyia AtikahNo ratings yet

- (Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Document125 pages(Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Diego FernandoNo ratings yet

- 6B DegradationDocument19 pages6B DegradationThanapaet RittirutNo ratings yet

- 26-Waste Disposal-03-03-2023Document19 pages26-Waste Disposal-03-03-2023Back upNo ratings yet

- Mahad3 - WaterLess Fracturing TechnologyDocument48 pagesMahad3 - WaterLess Fracturing Technologycj100% (1)

- Zero Liquid Discharge System ImprovementDocument13 pagesZero Liquid Discharge System ImprovementGloria Del Carmen Muñoz RamirezNo ratings yet

- DF Systems160108Document57 pagesDF Systems160108Long Nhật PhanNo ratings yet

- Lecture 19 Coagulation Flocculation B 2014Document49 pagesLecture 19 Coagulation Flocculation B 2014ProsperNo ratings yet

- Desalting OverviewDocument9 pagesDesalting OverviewSampat100% (1)

- Polymer Flooding Introduction PDFDocument307 pagesPolymer Flooding Introduction PDFDaniela NietoNo ratings yet

- Lithium Brochure RZ HDocument2 pagesLithium Brochure RZ Hakhmad ashariNo ratings yet

- UpdatedDocument3 pagesUpdatedEeshan NagasingheNo ratings yet

- Oil-Analysis Cause EfectDocument8 pagesOil-Analysis Cause EfectRohmanNo ratings yet

- Best Practices For Water Removal in Hydraulic SystemsDocument26 pagesBest Practices For Water Removal in Hydraulic SystemsAaron SaidNo ratings yet

- Typical Properties Freight Classification Shipping: Sustainable SolutionsDocument14 pagesTypical Properties Freight Classification Shipping: Sustainable SolutionsAmit BishtNo ratings yet

- Horizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsDocument12 pagesHorizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsNoureddine AbidNo ratings yet

- Hydraulic Fracturing NewDocument24 pagesHydraulic Fracturing NewNurrahmisrNo ratings yet

- Predictive and Preventive Maintenance ConttrolDocument19 pagesPredictive and Preventive Maintenance ConttrolLeDuNo ratings yet

- Accumulation Pressure Test, Corrosion of Boilers On ShipsDocument4 pagesAccumulation Pressure Test, Corrosion of Boilers On ShipsibnuharyNo ratings yet

- Adobe Scan 19-Feb-2021Document17 pagesAdobe Scan 19-Feb-2021Sharma P PNo ratings yet

- Richard HarriesDocument22 pagesRichard HarriesSuresh Damu BhadNo ratings yet

- InhibitionDocument17 pagesInhibitionLong Nhật PhanNo ratings yet

- 3M PC - Brochure - Final - LR 7Document1 page3M PC - Brochure - Final - LR 7Fabián SajamaNo ratings yet

- Dai-El: High Performance FluoroelastomersDocument16 pagesDai-El: High Performance FluoroelastomersAtham MuhajirNo ratings yet

- ABB Leaflet Comem Conventiona Air Breather-2018!06!06Document2 pagesABB Leaflet Comem Conventiona Air Breather-2018!06!06erikaNo ratings yet

- Oil Indesalter Wash Water-3lDocument4 pagesOil Indesalter Wash Water-3lmacielNo ratings yet

- TLIMP 1.3 Tools For Clean TechnologiesDocument25 pagesTLIMP 1.3 Tools For Clean TechnologiesgpowerpNo ratings yet

- Polymer Flooding IntroductionDocument293 pagesPolymer Flooding IntroductionoreNo ratings yet

- 06 - Kim Mech Seal API619Document22 pages06 - Kim Mech Seal API619AliNo ratings yet

- Now Is The Time To Go: Water LubricatedDocument1 pageNow Is The Time To Go: Water LubricatedMarlon Alejandro Arboleda TapiaNo ratings yet

- Internal Corrosion Direct Assessment-1Document25 pagesInternal Corrosion Direct Assessment-1Mir AsifNo ratings yet

- INH SON Refining & Petrochemical CO.: II. Identification of Damage MechanismsDocument2 pagesINH SON Refining & Petrochemical CO.: II. Identification of Damage Mechanismstranhuy3110No ratings yet

- WangDocument24 pagesWangaymanNo ratings yet

- Failure AnalysisDocument43 pagesFailure AnalysisTrương Đức ThiệnNo ratings yet

- 8 - Chemical FloodingDocument76 pages8 - Chemical FloodingSyafrina Putri100% (3)

- Drilling Fluid PDFDocument68 pagesDrilling Fluid PDFShiela O100% (1)

- Tt03-Sanitation - OutfallDocument38 pagesTt03-Sanitation - OutfallEmilia BeloNo ratings yet

- PESA 2013 Summer Oil 101 HeiskellDocument27 pagesPESA 2013 Summer Oil 101 HeiskellAtharva HublikarNo ratings yet

- 15853-Article Text-57531-1-10-20130727 PDFDocument6 pages15853-Article Text-57531-1-10-20130727 PDFNicolás Roberto ArgañarazNo ratings yet

- Ethylene Glycol Regeneration Plan: A Systematic Approach To Troubleshoot The Common ProblemsDocument6 pagesEthylene Glycol Regeneration Plan: A Systematic Approach To Troubleshoot The Common ProblemsAksheyNo ratings yet

- Ethylene Glycol Regeneration Plan A Systematic Approach To Troubleshoot The Common ProblemsDocument6 pagesEthylene Glycol Regeneration Plan A Systematic Approach To Troubleshoot The Common ProblemsRichard YentumiNo ratings yet

- Friction ReducersDocument6 pagesFriction ReducersJoann HowardNo ratings yet

- Modern Separation ProcessDocument46 pagesModern Separation ProcessIsha Meshram100% (2)

- Sand Mat 2Document1 pageSand Mat 2HelyaNo ratings yet

- A Quick Look at DesaltingDocument12 pagesA Quick Look at Desaltingananth2012No ratings yet

- 02 - PGP4108 Drilling FluidsDocument52 pages02 - PGP4108 Drilling Fluidsodong anthonyNo ratings yet

- Crude Oil Treatment ProcessDocument73 pagesCrude Oil Treatment ProcessFidal SibiaNo ratings yet

- Customer Presentation - Varnish Pall VRFDocument41 pagesCustomer Presentation - Varnish Pall VRFengrsurifNo ratings yet

- ZLD Presentation 4 PDFDocument23 pagesZLD Presentation 4 PDFVineeth SivarajNo ratings yet

- TK3105-01 Tugas 03aDocument12 pagesTK3105-01 Tugas 03aSharia AuliaannisaaNo ratings yet

- Nitrification and Denitrification in the Activated Sludge ProcessFrom EverandNitrification and Denitrification in the Activated Sludge ProcessNo ratings yet

- Types of AeratorsDocument21 pagesTypes of AeratorsSaji SimonNo ratings yet

- Cee 451 Lecture 8Document23 pagesCee 451 Lecture 8ahmed almhjaniNo ratings yet

- Waterboy RO Unit PamphletDocument7 pagesWaterboy RO Unit PamphletDhiren DayaNo ratings yet

- A Salt-Rejecting Floating Solar Still For Low-CostDocument10 pagesA Salt-Rejecting Floating Solar Still For Low-CostThiru MuruganNo ratings yet

- 2005 Valve Catalog Full ASAHIDocument150 pages2005 Valve Catalog Full ASAHIRicardo Rodriguez MartinezNo ratings yet

- Pompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarDocument7 pagesPompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarVictor HutanuNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Chiksan Piping On Oes TeamworkDocument3 pagesChiksan Piping On Oes TeamworkChukwuma Emmanuel OnwufujuNo ratings yet

- Cassida FM Heat Transfer Fluid 32 - Pi - (Gb-En)Document4 pagesCassida FM Heat Transfer Fluid 32 - Pi - (Gb-En)CriVe OffeNo ratings yet

- Wang 2005Document15 pagesWang 2005Edu CordonNo ratings yet

- 世界鋼管材質對照表Document2 pages世界鋼管材質對照表ChunJung ChenNo ratings yet

- HOLE - 1 (WPT) KuninganDocument78 pagesHOLE - 1 (WPT) Kuningananicetus namangNo ratings yet

- Squeeze Without Tool Engineering Risk AnalysisDocument2 pagesSqueeze Without Tool Engineering Risk AnalysisIbnu HasanNo ratings yet

- Env 20 BodDocument14 pagesEnv 20 BodMsMME123No ratings yet

- Proposed SH Nov17-L4 ScheduleDocument45 pagesProposed SH Nov17-L4 ScheduleAdnan AkhtarNo ratings yet

- MODULE 1. Basic Principles of Sanitary DesignDocument5 pagesMODULE 1. Basic Principles of Sanitary DesignKervin SangalangNo ratings yet

- Flowmeter Measurement ApparatusDocument29 pagesFlowmeter Measurement ApparatusSyafiq Izzuddin100% (2)

- GM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophyDocument42 pagesGM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophySuper 7100% (1)

- Flare Stack ProcessDocument69 pagesFlare Stack ProcessHabib AgazNo ratings yet

- Annex I Hydrological ReportDocument13 pagesAnnex I Hydrological Reportniranjan paudelNo ratings yet

- AQ-8.10 Instructie ManualDocument22 pagesAQ-8.10 Instructie ManualJan MaarschalkerweerdNo ratings yet

- Equipment Program For Well CompletionDocument58 pagesEquipment Program For Well CompletionBenjar FerandezNo ratings yet

- Solution and Colligative Properties: Assertion & ReasonDocument2 pagesSolution and Colligative Properties: Assertion & Reasonom prakashNo ratings yet

- Expt. No. 2 Viscosity MeasurementDocument5 pagesExpt. No. 2 Viscosity MeasurementShinichi KudoNo ratings yet

- Print Vent Uma 02 BL 12X9 2HP 2609CFMDocument1 pagePrint Vent Uma 02 BL 12X9 2HP 2609CFMhector aguilarNo ratings yet

- Sample Problem - ComsolDocument4 pagesSample Problem - Comsolmayuri sritharanNo ratings yet

- Jupiter Metal IndustriesDocument17 pagesJupiter Metal IndustriesSOLEDAD MOJARRONo ratings yet

- Quick Exhaust Valve 13QS38 - 39Document2 pagesQuick Exhaust Valve 13QS38 - 39simplementemoiNo ratings yet

HYDAC Messe HydroDams Rückwand

HYDAC Messe HydroDams Rückwand

Uploaded by

Ryan KaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HYDAC Messe HydroDams Rückwand

HYDAC Messe HydroDams Rückwand

Uploaded by

Ryan KaneCopyright:

Available Formats

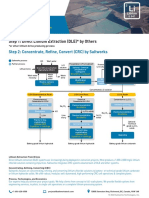

Your Global Partner in Hydropower Systems

Gaseous contamination Solid contamination

Lubrication systems Hydraulics for trash rack cleaner

Origin: for turbines and generators Origin:

llContact with ambient air llInstallation contamination

llOutgassing of the fluid llAmbient contamination

llLeaks llRefilling of operating fluid

llProcess gas (e. g. Nitrogen) llInternal wear processes

Effects: Oil mist separation llOil ageing

llCavitation Effects:

llOxidation llAbrasive wear

llLocal overheating of the fluid llIncreased leakage

Diesel Gen Sets

llIncrease in speed of oil ageing llComponent failure

llControl inaccuracies llControl inaccuracies

llRisk of explosion llBlockage of control pistons

llShort fluid service life

Hydraulic system for hydromechanical

Filters for water hydraulics

Liquid contamination Gel-like contamination

Origin: Origin:

llMoisture from ambient air Cooling water solutions Hydraulics llOil ageing

llCooling system leakages for main inlet valve llOil mixing

llProcess water/process steam Effects:

llSeal leakages llReduced lubrication gaps caused

llHigh-pressure cleaner by deposits

llChemical processes (incineration, oxidation, neutralization) Seal water solutions llIncreased friction and temperature

Effects: llIncreased bearing wear

llCorrosion llMalfunctions in valves

llReduction in dynamic viscosity llUnstable control behaviour

llReduction in lubricating film thickness llDamage to dynamic seals

llWear Hydraulic governor system llLeakages

llChange in the oil properties for turbine control llBlockage of filter elements

llCreation of acidic oil degradation products llShort filter life caused by sludge formation

llFormation of sludge llIncreased bearing temperature caused

llIncrease in speed of oil ageing by caking

llCavitation damage llReduced system efficiency

You might also like

- Crude Distiller RBI Intro (Updated)Document31 pagesCrude Distiller RBI Intro (Updated)harrinsonf100% (2)

- L5 - Physical TreatmentDocument67 pagesL5 - Physical Treatmentrushdi100% (1)

- Settleability Problems and Loss of Solids in the Activated Sludge ProcessFrom EverandSettleability Problems and Loss of Solids in the Activated Sludge ProcessNo ratings yet

- Indion Indro 401Document36 pagesIndion Indro 401maksudur4No ratings yet

- Slurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)Document13 pagesSlurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)R_M_M_100% (4)

- Landfill VS WTEDocument49 pagesLandfill VS WTEMuhd FiziNo ratings yet

- Pollution: Causes & RemediesDocument5 pagesPollution: Causes & RemediesSusana CardadorNo ratings yet

- 3 Frederic MollardDocument12 pages3 Frederic MollardEdmilson JersonNo ratings yet

- Online Drying Systems With MoistureDocument51 pagesOnline Drying Systems With MoisturePrasanna Mohandoss100% (1)

- Siemens Refinery BrochureDocument16 pagesSiemens Refinery BrochureAqila LuthfianaNo ratings yet

- 2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Document14 pages2b - APC-Drilling Fluids (Classification, Function and Selection Criteria)Hanif Budhi CundomanikNo ratings yet

- Block Diagram Nitric AcidDocument4 pagesBlock Diagram Nitric AcidBatrisyia AtikahNo ratings yet

- (Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Document125 pages(Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Diego FernandoNo ratings yet

- 6B DegradationDocument19 pages6B DegradationThanapaet RittirutNo ratings yet

- 26-Waste Disposal-03-03-2023Document19 pages26-Waste Disposal-03-03-2023Back upNo ratings yet

- Mahad3 - WaterLess Fracturing TechnologyDocument48 pagesMahad3 - WaterLess Fracturing Technologycj100% (1)

- Zero Liquid Discharge System ImprovementDocument13 pagesZero Liquid Discharge System ImprovementGloria Del Carmen Muñoz RamirezNo ratings yet

- DF Systems160108Document57 pagesDF Systems160108Long Nhật PhanNo ratings yet

- Lecture 19 Coagulation Flocculation B 2014Document49 pagesLecture 19 Coagulation Flocculation B 2014ProsperNo ratings yet

- Desalting OverviewDocument9 pagesDesalting OverviewSampat100% (1)

- Polymer Flooding Introduction PDFDocument307 pagesPolymer Flooding Introduction PDFDaniela NietoNo ratings yet

- Lithium Brochure RZ HDocument2 pagesLithium Brochure RZ Hakhmad ashariNo ratings yet

- UpdatedDocument3 pagesUpdatedEeshan NagasingheNo ratings yet

- Oil-Analysis Cause EfectDocument8 pagesOil-Analysis Cause EfectRohmanNo ratings yet

- Best Practices For Water Removal in Hydraulic SystemsDocument26 pagesBest Practices For Water Removal in Hydraulic SystemsAaron SaidNo ratings yet

- Typical Properties Freight Classification Shipping: Sustainable SolutionsDocument14 pagesTypical Properties Freight Classification Shipping: Sustainable SolutionsAmit BishtNo ratings yet

- Horizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsDocument12 pagesHorizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsNoureddine AbidNo ratings yet

- Hydraulic Fracturing NewDocument24 pagesHydraulic Fracturing NewNurrahmisrNo ratings yet

- Predictive and Preventive Maintenance ConttrolDocument19 pagesPredictive and Preventive Maintenance ConttrolLeDuNo ratings yet

- Accumulation Pressure Test, Corrosion of Boilers On ShipsDocument4 pagesAccumulation Pressure Test, Corrosion of Boilers On ShipsibnuharyNo ratings yet

- Adobe Scan 19-Feb-2021Document17 pagesAdobe Scan 19-Feb-2021Sharma P PNo ratings yet

- Richard HarriesDocument22 pagesRichard HarriesSuresh Damu BhadNo ratings yet

- InhibitionDocument17 pagesInhibitionLong Nhật PhanNo ratings yet

- 3M PC - Brochure - Final - LR 7Document1 page3M PC - Brochure - Final - LR 7Fabián SajamaNo ratings yet

- Dai-El: High Performance FluoroelastomersDocument16 pagesDai-El: High Performance FluoroelastomersAtham MuhajirNo ratings yet

- ABB Leaflet Comem Conventiona Air Breather-2018!06!06Document2 pagesABB Leaflet Comem Conventiona Air Breather-2018!06!06erikaNo ratings yet

- Oil Indesalter Wash Water-3lDocument4 pagesOil Indesalter Wash Water-3lmacielNo ratings yet

- TLIMP 1.3 Tools For Clean TechnologiesDocument25 pagesTLIMP 1.3 Tools For Clean TechnologiesgpowerpNo ratings yet

- Polymer Flooding IntroductionDocument293 pagesPolymer Flooding IntroductionoreNo ratings yet

- 06 - Kim Mech Seal API619Document22 pages06 - Kim Mech Seal API619AliNo ratings yet

- Now Is The Time To Go: Water LubricatedDocument1 pageNow Is The Time To Go: Water LubricatedMarlon Alejandro Arboleda TapiaNo ratings yet

- Internal Corrosion Direct Assessment-1Document25 pagesInternal Corrosion Direct Assessment-1Mir AsifNo ratings yet

- INH SON Refining & Petrochemical CO.: II. Identification of Damage MechanismsDocument2 pagesINH SON Refining & Petrochemical CO.: II. Identification of Damage Mechanismstranhuy3110No ratings yet

- WangDocument24 pagesWangaymanNo ratings yet

- Failure AnalysisDocument43 pagesFailure AnalysisTrương Đức ThiệnNo ratings yet

- 8 - Chemical FloodingDocument76 pages8 - Chemical FloodingSyafrina Putri100% (3)

- Drilling Fluid PDFDocument68 pagesDrilling Fluid PDFShiela O100% (1)

- Tt03-Sanitation - OutfallDocument38 pagesTt03-Sanitation - OutfallEmilia BeloNo ratings yet

- PESA 2013 Summer Oil 101 HeiskellDocument27 pagesPESA 2013 Summer Oil 101 HeiskellAtharva HublikarNo ratings yet

- 15853-Article Text-57531-1-10-20130727 PDFDocument6 pages15853-Article Text-57531-1-10-20130727 PDFNicolás Roberto ArgañarazNo ratings yet

- Ethylene Glycol Regeneration Plan: A Systematic Approach To Troubleshoot The Common ProblemsDocument6 pagesEthylene Glycol Regeneration Plan: A Systematic Approach To Troubleshoot The Common ProblemsAksheyNo ratings yet

- Ethylene Glycol Regeneration Plan A Systematic Approach To Troubleshoot The Common ProblemsDocument6 pagesEthylene Glycol Regeneration Plan A Systematic Approach To Troubleshoot The Common ProblemsRichard YentumiNo ratings yet

- Friction ReducersDocument6 pagesFriction ReducersJoann HowardNo ratings yet

- Modern Separation ProcessDocument46 pagesModern Separation ProcessIsha Meshram100% (2)

- Sand Mat 2Document1 pageSand Mat 2HelyaNo ratings yet

- A Quick Look at DesaltingDocument12 pagesA Quick Look at Desaltingananth2012No ratings yet

- 02 - PGP4108 Drilling FluidsDocument52 pages02 - PGP4108 Drilling Fluidsodong anthonyNo ratings yet

- Crude Oil Treatment ProcessDocument73 pagesCrude Oil Treatment ProcessFidal SibiaNo ratings yet

- Customer Presentation - Varnish Pall VRFDocument41 pagesCustomer Presentation - Varnish Pall VRFengrsurifNo ratings yet

- ZLD Presentation 4 PDFDocument23 pagesZLD Presentation 4 PDFVineeth SivarajNo ratings yet

- TK3105-01 Tugas 03aDocument12 pagesTK3105-01 Tugas 03aSharia AuliaannisaaNo ratings yet

- Nitrification and Denitrification in the Activated Sludge ProcessFrom EverandNitrification and Denitrification in the Activated Sludge ProcessNo ratings yet

- Types of AeratorsDocument21 pagesTypes of AeratorsSaji SimonNo ratings yet

- Cee 451 Lecture 8Document23 pagesCee 451 Lecture 8ahmed almhjaniNo ratings yet

- Waterboy RO Unit PamphletDocument7 pagesWaterboy RO Unit PamphletDhiren DayaNo ratings yet

- A Salt-Rejecting Floating Solar Still For Low-CostDocument10 pagesA Salt-Rejecting Floating Solar Still For Low-CostThiru MuruganNo ratings yet

- 2005 Valve Catalog Full ASAHIDocument150 pages2005 Valve Catalog Full ASAHIRicardo Rodriguez MartinezNo ratings yet

- Pompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarDocument7 pagesPompa CT Clu 3 Tip S1 L15 N2, 12-30 Bar, 80-95 LH, Sens de Rotatie OrarVictor HutanuNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Chiksan Piping On Oes TeamworkDocument3 pagesChiksan Piping On Oes TeamworkChukwuma Emmanuel OnwufujuNo ratings yet

- Cassida FM Heat Transfer Fluid 32 - Pi - (Gb-En)Document4 pagesCassida FM Heat Transfer Fluid 32 - Pi - (Gb-En)CriVe OffeNo ratings yet

- Wang 2005Document15 pagesWang 2005Edu CordonNo ratings yet

- 世界鋼管材質對照表Document2 pages世界鋼管材質對照表ChunJung ChenNo ratings yet

- HOLE - 1 (WPT) KuninganDocument78 pagesHOLE - 1 (WPT) Kuningananicetus namangNo ratings yet

- Squeeze Without Tool Engineering Risk AnalysisDocument2 pagesSqueeze Without Tool Engineering Risk AnalysisIbnu HasanNo ratings yet

- Env 20 BodDocument14 pagesEnv 20 BodMsMME123No ratings yet

- Proposed SH Nov17-L4 ScheduleDocument45 pagesProposed SH Nov17-L4 ScheduleAdnan AkhtarNo ratings yet

- MODULE 1. Basic Principles of Sanitary DesignDocument5 pagesMODULE 1. Basic Principles of Sanitary DesignKervin SangalangNo ratings yet

- Flowmeter Measurement ApparatusDocument29 pagesFlowmeter Measurement ApparatusSyafiq Izzuddin100% (2)

- GM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophyDocument42 pagesGM479-R0731-000-PR-RP-0002 - 0-Isolation, Vent & Drain PhilosophySuper 7100% (1)

- Flare Stack ProcessDocument69 pagesFlare Stack ProcessHabib AgazNo ratings yet

- Annex I Hydrological ReportDocument13 pagesAnnex I Hydrological Reportniranjan paudelNo ratings yet

- AQ-8.10 Instructie ManualDocument22 pagesAQ-8.10 Instructie ManualJan MaarschalkerweerdNo ratings yet

- Equipment Program For Well CompletionDocument58 pagesEquipment Program For Well CompletionBenjar FerandezNo ratings yet

- Solution and Colligative Properties: Assertion & ReasonDocument2 pagesSolution and Colligative Properties: Assertion & Reasonom prakashNo ratings yet

- Expt. No. 2 Viscosity MeasurementDocument5 pagesExpt. No. 2 Viscosity MeasurementShinichi KudoNo ratings yet

- Print Vent Uma 02 BL 12X9 2HP 2609CFMDocument1 pagePrint Vent Uma 02 BL 12X9 2HP 2609CFMhector aguilarNo ratings yet

- Sample Problem - ComsolDocument4 pagesSample Problem - Comsolmayuri sritharanNo ratings yet

- Jupiter Metal IndustriesDocument17 pagesJupiter Metal IndustriesSOLEDAD MOJARRONo ratings yet

- Quick Exhaust Valve 13QS38 - 39Document2 pagesQuick Exhaust Valve 13QS38 - 39simplementemoiNo ratings yet