Professional Documents

Culture Documents

Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2

Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2

Uploaded by

Andre NovanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2

Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-2

Uploaded by

Andre NovanCopyright:

Available Formats

Disian Las End Plate Balok Melintang Disain Pergudangan

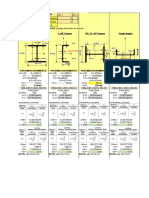

SAMBUNGAN END PLATE BALOK INDUK MELINTANG

WF 300X150 SEGMEN KANTOR ELEV + 8.5

Beban berfaktor Dari Analisa Struktur : Vu = 45.9kN M u = 47.87kN m

Disain Las Balok- End Plate :

Las yang digunakan SMAW E70XX

1

Mutu Flas = 400MPa

2

Las :

bwf = 150mm hwf = 500mm hwf1 = 300mm hwf2 = 200mm

3

tw = 6.5mm tf = 9mm

4

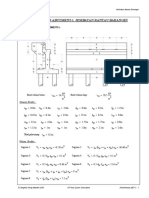

Mencari Titik Berat

Las :

5

Luas Penampang segmen las :

Alas2 = ( b wf - tw) 1 mm = 143.5 mm

2 2

6 Alas1 = bwf 1 mm = 150 mm

7

Alas3 = 2 ( hwf1 - 2tf ) 1 mm = 564 mm

2

8

Alas4 = ( b wf - tw) 1 mm = 143.5 mm

2

Alas5 = ( b wf - tw) 1 mm = 143.5 mm Alas6 = 2 ( hwf2 - tf ) 1 mm = 382 mm

2 2

Alas7 = ( b wf - tw) 1 mm = 143.5 mm

2 2

Alas8 = bwf 1 mm = 150 mm

Titik Berat individual segmen Las Terhadap Sisi Bawah Penampang sambungan :

ylas1 = 0.5mm + h wf + 1mm = 501.5 mm ylas2 = h wf - tf - 0.5mm + 1mm = 491.5 mm

h wf1 - tf

ylas3 = + h wf2 + 1mm = 346.5 mm ylas4 = 0.5mm + h wf2 + 1mm = 201.5 mm

2

h wf2 - tf

ylas5 = h wf2 - tf - 0.5mm + 1mm = 191.5 mm ylas6 = + 1mm = 96.5 mm

2

ylas7 = 0.5mm + tf + 1mm = 10.5 mm ylas8 = 0.5mm

Titik berat konfigurasi las gabungan :

ΣYA = ylas1 Alas1 + ylas2 Alas2 + ylas3 Alas3 + ylas4 Alas4 + ylas5 Alas5 + ylas6 Alas6 + ylas7 Alas7 + ylas8 Alas8

ΣA = Alas1 + Alas2 + Alas3 + Alas4 + Alas5 + Alas6 + Alas7 + Alas8

PT Peputra Maha Raya Las End Plate- Balok Induk Lt-2- 1

Disian Las End Plate Balok Melintang Disain Pergudangan

ΣYA

Ycgblas = = 239.57225 mm

ΣA Ycgalas = ( h wf + 1mm + 1mm) - Ycgblas = 262.42775 mm

Inersia las :

1

b wf ( 1mm) + 1mm b wf ( ylas1 - Ycgblas ) = 10290934.21713 mm

3 2 4

Ix1 =

12

1 bwf tw bwf tw 2

- ( ylas2 - Ycgblas) 2 = 9107611.09978 mm

3 4

Ix2 = - ( 1mm) + 1mm

12 2 2 2 2

1 3

h wf h wf 2

- 2 tf ( ylas3 - Ycgblas ) 2 = 7386358.68017 mm

4

Ix3 = 1 mm - 2 tf + 1mm

12 2 2

1 bwf tw bwf tw 2

- ( ylas4 - Ycgblas) 2 = 208014.69593 mm

3 4

Ix4 = - ( 1mm) + 1mm

12 2 2 2 2

1 bwf tw bwf tw 2

- ( ylas5 - Ycgblas) 2 = 331632.06132 mm

3 4

Ix5 = - ( 1mm) + 1mm

12 2 2 2 2

1 h wf

3

h wf

Ix6 = 1 mm - 2 tf + 1mm

2

- 2 tf ( ylas6 - Ycgblas ) 2 = 11579121.31753 mm

4

12 2 2

1 bwf tw bwf tw 2

- ( ylas7 - Ycgblas) 2 = 7530044.87478 mm

3 4

Ix7 = - ( 1mm) + 1mm

12 2 2 2 2

1

b wf ( 1mm) + 1mm b wf ( ylas8 - Ycgblas ) = 8573343.80505 mm

3 2 4

Ix8 =

12

4

Ixtot = Ix1 + Ix2 + Ix3 + Ix4 + Ix5 + Ix6 + Ix7 + Ix8 = 55007060.75168 mm

Panjang Total las :

Llas = 2 b wf + 4 ( b wf - tw) + ( h wf - 3 tf ) = 1347 mm

Gaya geser arah Y akibat Vp :

Vu N

Ply = = 34.07572

Llas mm

Gaya geser di titik sudut A akibat beban Mp :

1 mm M u Ycgalas N

Plz = = 228.37825

Ixtot mm

PT Peputra Maha Raya Las End Plate- Balok Induk Lt-2- 2

Disian Las End Plate Balok Melintang Disain Pergudangan

Gaya geser gabungan akibat Vp dan Mp :

2 2 N

Ptot = Ply + Plz = 230.90643

mm

Tebal las yang dibutuhkan :

Ptot

tlas = = 1.81445 mm

0.75 0.707 0.6 Flas

Tebal maximum : tlfmax = tw if tw 6mm = 4.9 mm

tw - 1.6mm otherwise

Tebal minimum tlfmin = 3mm if tw 6mm = 5 mm

5mm if tw > 6mm tw 13mm

6mm if tw > 13mm tw 19mm

8mm otherwise

Pakai las dengan tebal 5mm

PT Peputra Maha Raya Las End Plate- Balok Induk Lt-2- 3

You might also like

- MD 11fgnDocument3 pagesMD 11fgnMcDonnell Douglas MD-110% (7)

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- Australian Professional Standards For TeachersDocument1 pageAustralian Professional Standards For Teachersapi-365080091No ratings yet

- Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - Las Balok Kuda Ke Kolom - Endplate GudangDocument3 pagesMathcad - Las Balok Kuda Ke Kolom - Endplate GudangAndre NovanNo ratings yet

- Mathcad - LAS BALOK KE KOLOM KUDA DEPAN WF150.75 - ENDPLATE GUDANGDocument3 pagesMathcad - LAS BALOK KE KOLOM KUDA DEPAN WF150.75 - ENDPLATE GUDANGAndre NovanNo ratings yet

- Mathcad - LAS BALOK KE BALOK KUDA TENGAH - ENDPLATE GUDANGDocument3 pagesMathcad - LAS BALOK KE BALOK KUDA TENGAH - ENDPLATE GUDANGAndre NovanNo ratings yet

- Mathcad - DISAIN STRINGER BEAM RANTAU SBG BALOK LENTURDocument4 pagesMathcad - DISAIN STRINGER BEAM RANTAU SBG BALOK LENTURAndre NovanNo ratings yet

- 52 Mathcad - BTG TENS TB9Document5 pages52 Mathcad - BTG TENS TB9Andre NovanNo ratings yet

- Desain Batang Lentur (GP) : Elemen No. 379Document2 pagesDesain Batang Lentur (GP) : Elemen No. 379Refo AdityansyahNo ratings yet

- 11 Mathcad - BTG TENS BCM 01Document5 pages11 Mathcad - BTG TENS BCM 01Andre NovanNo ratings yet

- Doubly Reinforced BeamDocument2 pagesDoubly Reinforced BeamG.DhanabalNo ratings yet

- 08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURDocument4 pages08 Mathcad - DISAIN CROSS BEAM RANTAU SBG BALOK LENTURAndre NovanNo ratings yet

- Design of Beam To Column SpliceDocument1 pageDesign of Beam To Column SpliceAndro RebuyasNo ratings yet

- 5 Metros MarceloDocument2 pages5 Metros Marcelomarcelo galarzaNo ratings yet

- Laterally UN-supported BeamDocument3 pagesLaterally UN-supported Beamhema kumarNo ratings yet

- 2 Side Beam To Column Connection Fin Plate Minor AxesDocument1 page2 Side Beam To Column Connection Fin Plate Minor Axessamon.itc2019No ratings yet

- Baja UTS IrmaDocument69 pagesBaja UTS IrmaArjuna CrewNo ratings yet

- As' Balok: Tul. Longitudinal Tul. SengkangDocument7 pagesAs' Balok: Tul. Longitudinal Tul. SengkangriandiNo ratings yet

- 2B1.Connection Design (SH400)Document4 pages2B1.Connection Design (SH400)Agnes FerinnaNo ratings yet

- Hasil Perhitungan Struktur Gudang Suzuki R 2Document57 pagesHasil Perhitungan Struktur Gudang Suzuki R 2SUKA SENIMANNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectioncadsultanNo ratings yet

- Sample Problems - TorsionDocument5 pagesSample Problems - TorsionXavier Jhan LouieNo ratings yet

- End Plate Moment ConnectionDocument12 pagesEnd Plate Moment ConnectionDarshan Panchal0% (1)

- DocumentDocument48 pagesDocumentkrishnaNo ratings yet

- End Plate Connection Design Per AISCDocument5 pagesEnd Plate Connection Design Per AISCAdam Michael GreenNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectioncadsultanNo ratings yet

- Minimum Thickness of Two Way SlabDocument3 pagesMinimum Thickness of Two Way SlabWinston AdvinculaNo ratings yet

- Moment End-Plate Connection Design (Flush Type) : + Ve For Comression and - Ve For TensionDocument5 pagesMoment End-Plate Connection Design (Flush Type) : + Ve For Comression and - Ve For TensionSudip ShresthaNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectionSudip ShresthaNo ratings yet

- Design of Ss Connection v.2Document68 pagesDesign of Ss Connection v.2markespinoNo ratings yet

- Design of Column SpliceDocument2 pagesDesign of Column SpliceAndro Rebuyas100% (1)

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- Mathcad - KOLOM WF300.150.5.8Document8 pagesMathcad - KOLOM WF300.150.5.8Andre NovanNo ratings yet

- Mathcad - Main Beam Design Opening2Document2 pagesMathcad - Main Beam Design Opening2mrnaeem76No ratings yet

- BeamDocument18 pagesBeamAfia S Hameed100% (1)

- Proiect Normativ P 118 1 Iunie 2016Document15 pagesProiect Normativ P 118 1 Iunie 2016Mihai AndreiasNo ratings yet

- Beam To Column'S Flange Fixed Connection - Bcff-4: Design DataDocument6 pagesBeam To Column'S Flange Fixed Connection - Bcff-4: Design DataAchmad RifaiNo ratings yet

- PropertY Calculation 75CS40X10X1.2Document15 pagesPropertY Calculation 75CS40X10X1.2kingsuk1980No ratings yet

- 1 BeamDocument18 pages1 BeamARVIND SINGH RAWAT100% (1)

- D. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MDocument2 pagesD. Disain Tumpuan Base Plate Dan Angkur: Gaya Dalam Maksimum, Nu 171.39 KN, Vu 7.94 KN, Mu 1.753 KNM X MMudiyaNo ratings yet

- Beam To Col WebDocument10 pagesBeam To Col WebAlma M. LaraNo ratings yet

- Metal Heb 260Document3 pagesMetal Heb 260Ionela BaiesNo ratings yet

- Mathcad - Besaran Penampang Profil IWFDocument6 pagesMathcad - Besaran Penampang Profil IWFBastian ArtantoNo ratings yet

- Perhitungan Sambungan Baut Profil SikuDocument12 pagesPerhitungan Sambungan Baut Profil Sikuberangketr100% (1)

- Placa de Capat HEA160Document6 pagesPlaca de Capat HEA160Manciu Mihai-CosminNo ratings yet

- Spacing of Bolts in Built-Up BeamsDocument7 pagesSpacing of Bolts in Built-Up BeamsDAN MARK OPONDANo ratings yet

- Bridge Design v1 enDocument98 pagesBridge Design v1 enDjunedNo ratings yet

- Bab 5 Perhitungan Balok BK2Document2 pagesBab 5 Perhitungan Balok BK2DickyArdianFelsaputraNo ratings yet

- Welded Connection With I BeamDocument8 pagesWelded Connection With I BeamНемања КараклајићNo ratings yet

- Verification Example Extended Moment End-Plate: GeometryDocument5 pagesVerification Example Extended Moment End-Plate: Geometryngocnn100% (2)

- 7.minimum Thickness of Two Way SlabDocument1 page7.minimum Thickness of Two Way SlabDodong DiazNo ratings yet

- Mathcad - Balok Kuda Kuda Atas Wf200.100Document8 pagesMathcad - Balok Kuda Kuda Atas Wf200.100Andre NovanNo ratings yet

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- Cópia de Column-Beam Bolted Splice Calculation - ASD AISC 9th - 22-Ago-2017Document19 pagesCópia de Column-Beam Bolted Splice Calculation - ASD AISC 9th - 22-Ago-2017cludioNo ratings yet

- Design of Deep Beam PDFDocument3 pagesDesign of Deep Beam PDFRaju SainiNo ratings yet

- Extended End-Plate ConnectionsDocument9 pagesExtended End-Plate ConnectionsKhắc ĐăngNo ratings yet

- TBeam To ACI318Document1 pageTBeam To ACI318dianfeng.envistaNo ratings yet

- Mathcad - SENGKANG SLOOF S-01 GUDANG CMTFDocument4 pagesMathcad - SENGKANG SLOOF S-01 GUDANG CMTFAndre NovanNo ratings yet

- Mathcad - KOLOM WF300.150.5.8Document8 pagesMathcad - KOLOM WF300.150.5.8Andre NovanNo ratings yet

- Mathcad - BALOK ELEV 4 WF-200.100Document8 pagesMathcad - BALOK ELEV 4 WF-200.100Andre NovanNo ratings yet

- Pembatas BalokDocument1 pagePembatas BalokAndre NovanNo ratings yet

- RC Plank PDFDocument1 pageRC Plank PDFAndre NovanNo ratings yet

- Lamp Math Lembaga PDFDocument15 pagesLamp Math Lembaga PDFAndre NovanNo ratings yet

- Ruas Jalan Wil. Barat Pku - TerbaruDocument5 pagesRuas Jalan Wil. Barat Pku - TerbaruAndre NovanNo ratings yet

- PDF Gambar Jembatan Parit 16Document12 pagesPDF Gambar Jembatan Parit 16Andre NovanNo ratings yet

- Desain Spektra Indonesia Parit 16Document2 pagesDesain Spektra Indonesia Parit 16Andre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MEMANJANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Document3 pagesMathcad - LAS BALOK INDUK MELINTANG - ENDPLATE KANTOR LT-1Andre NovanNo ratings yet

- Mathcad - Las Balok Kuda Ke Kolom - Endplate GudangDocument3 pagesMathcad - Las Balok Kuda Ke Kolom - Endplate GudangAndre NovanNo ratings yet

- Mathcad - ANALISA KAP SLOOF S2 BNIDocument14 pagesMathcad - ANALISA KAP SLOOF S2 BNIAndre NovanNo ratings yet

- 04 Mathcad - PEMBEBANAN ABT 2 RANTAU BERANGINDocument11 pages04 Mathcad - PEMBEBANAN ABT 2 RANTAU BERANGINAndre NovanNo ratings yet

- Quantity Jembatan Parit Gading 1 June 2022Document64 pagesQuantity Jembatan Parit Gading 1 June 2022Andre NovanNo ratings yet

- Grafik Lpile Abt-1 R 1 No MomDocument49 pagesGrafik Lpile Abt-1 R 1 No MomAndre NovanNo ratings yet

- Quantity Jembatan Bukit Condong 1 Juli 2022Document41 pagesQuantity Jembatan Bukit Condong 1 Juli 2022Andre NovanNo ratings yet

- Iterasi Spring Abt 1 R 1Document10 pagesIterasi Spring Abt 1 R 1Andre NovanNo ratings yet

- Quantity Jembatan Parit 16 31 Mei 2022Document58 pagesQuantity Jembatan Parit 16 31 Mei 2022Andre NovanNo ratings yet

- Story Shear SemuaDocument13 pagesStory Shear SemuaAndre NovanNo ratings yet

- 02 Mathcad - PEMBEBANAN PIER 1 2 RANTAU BERANGINDocument10 pages02 Mathcad - PEMBEBANAN PIER 1 2 RANTAU BERANGINAndre NovanNo ratings yet

- 52 Mathcad - BTG TENS TB9Document5 pages52 Mathcad - BTG TENS TB9Andre NovanNo ratings yet

- 10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINDocument10 pages10 Mathcad - SAMBUNGAN END PLATE CROSS BEAM KE JOINAndre NovanNo ratings yet

- MPMR Abt PendekDocument5 pagesMPMR Abt PendekAndre NovanNo ratings yet

- 11 Mathcad - BTG TENS BCM 01Document5 pages11 Mathcad - BTG TENS BCM 01Andre NovanNo ratings yet

- 03 Mathcad - PEMBEBANAN ABT RANTAU BERANGINDocument12 pages03 Mathcad - PEMBEBANAN ABT RANTAU BERANGINAndre NovanNo ratings yet

- Lesson-2-Climate IiDocument30 pagesLesson-2-Climate IiErica NatividadNo ratings yet

- The State of Structural Engineering in The US - IDEA StatiCaDocument6 pagesThe State of Structural Engineering in The US - IDEA StatiCaluisNo ratings yet

- OtooDocument11 pagesOtooStefania DavidNo ratings yet

- CMA Pre Exam Test PDFDocument28 pagesCMA Pre Exam Test PDFVinay YerubandiNo ratings yet

- Dynamic Modelling of Glucose Oxidation W PDFDocument8 pagesDynamic Modelling of Glucose Oxidation W PDFTysir SarhanNo ratings yet

- Experience With The Munster-Type Below-Elbow Prosthesis, A Preliminary ReportDocument5 pagesExperience With The Munster-Type Below-Elbow Prosthesis, A Preliminary ReportrehabeasyNo ratings yet

- A Master Forms Residential IndexDocument70 pagesA Master Forms Residential IndexAlberta Real EstateNo ratings yet

- Analysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFDocument6 pagesAnalysis of Phenolic Content and Antioxidant Activity of Cocoa Pod Husk PDFTài ColeNo ratings yet

- Ra 8294Document2 pagesRa 8294Rio TolentinoNo ratings yet

- Kci Fi001261149Document9 pagesKci Fi001261149minjokcsy99No ratings yet

- Philippine Notices To MarinersDocument42 pagesPhilippine Notices To MarinersTaneo Prince CalebNo ratings yet

- 11.11th IPhO 1979Document11 pages11.11th IPhO 1979fienny37No ratings yet

- Braille PresentationDocument10 pagesBraille PresentationHakeem And Hadrian XDSNo ratings yet

- Lacerte Jennifer ResumeDocument1 pageLacerte Jennifer Resumejennifer_lacerteNo ratings yet

- 08 - Chapter 3 PDFDocument36 pages08 - Chapter 3 PDF1921 Vishwanath PakhareNo ratings yet

- Br2e Adv Readingfile03Document2 pagesBr2e Adv Readingfile03PressCall AcademyNo ratings yet

- Polymers in Our Daily Life PDFDocument2 pagesPolymers in Our Daily Life PDFAnjali Reddy ANo ratings yet

- Sunken SlabDocument2 pagesSunken SlabAlexLionNo ratings yet

- Human Resource Information System: Presented By: Jasleen Dutta Presented To: Prof. Afreen AliDocument22 pagesHuman Resource Information System: Presented By: Jasleen Dutta Presented To: Prof. Afreen AliAmanpreet DuttaNo ratings yet

- SADP User Manual (V2.0)Document10 pagesSADP User Manual (V2.0)tehixazNo ratings yet

- General RelativityDocument401 pagesGeneral RelativityAbdilatif MohamudNo ratings yet

- Diploma in Business: Assignment BriefDocument10 pagesDiploma in Business: Assignment Brief陈肇远No ratings yet

- Occupational Health and Safety of Hydrogen Sulphide (H2S)Document20 pagesOccupational Health and Safety of Hydrogen Sulphide (H2S)hitm357100% (1)

- Final Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeDocument10 pagesFinal Report: Simulation Using Star CCM+ Theory and Practice in Marine CFD BenaoeRaviindra singhNo ratings yet

- What Is SubitizingDocument5 pagesWhat Is Subitizinggrethz doriaNo ratings yet

- 3dea2029ed9eb115091e9ea026cbba8fDocument3 pages3dea2029ed9eb115091e9ea026cbba8fJamie Cea100% (1)

- 7.2 Single-Phase Diode RectifiersDocument32 pages7.2 Single-Phase Diode RectifiersTrương Anh DuyNo ratings yet

- Game Sense ApproachDocument7 pagesGame Sense Approachapi-408626896No ratings yet