Professional Documents

Culture Documents

Just in Time

Just in Time

Uploaded by

Pravin SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Just in Time

Just in Time

Uploaded by

Pravin SinghCopyright:

Available Formats

JUST IN TIME

JUST IN TIME CHAPTER 1 INTRODUCTION

ust-in-time (JIT) is defined in the APICS dictionary as a philosophy of manufacturing based on planned elimination of all waste and on continuous improvement of productivity. It also has been described as an

approach with the objective of producing the right part in the right place at the right time (in other words, just in time). Waste results from any activity that adds cost without adding value, such as the unnecessary moving of materials, the accumulation of excess inventory, or the use of faulty production methods that create products requiring subsequent rework. JIT (also known as lean production or stockless production) should improve profits and return on investment by reducing inventory levels (increasing the inventory turnover rate), reducing variability, improving product quality, reducing production and delivery lead times, and reducing other costs (such as those associated with machine setup and equipment breakdown). In a JIT system, underutilized (excess) capacity is used instead of buffer inventories to hedge against problems that may arise. Some have suggested that "Just on Time" would be a more appropriate name since it emphasizes that production should create items that arrive when needed and neither earlier nor later.

JIT can also help manufacturing businesses big or small; don't have to be a big blue chip company to benefit. And JIT's not just for the manufacturing sector. Streamlining the way we work is just as relevant to high street retailers under pressure to improve sales performance and reduce operating costs.

OBJECTIVES

3

JUST IN TIME

This project deals with understanding Just in Time by:-

Identify and response to consumers needs. Customers needs and wants seem to

be the major focus for business; this objective will help the firm on what is demanded from customers, and what is required of production.

Optimal quality/cost relationship. The organization should focus on zero-defect

production process. Although it seems to be unrealistic, in the long run, it will eliminate a huge amount of resources and effort in inspecting, reworking and the production of defected goods.

Reduce unwanted wastes. Wastes that do not add value to the products itself should

be eliminated.

Develop a reliable relationship between the suppliers. A good and long-term

relationship between organization and its suppliers helps to manage a more efficient process in inventory management, material management and delivery system. It will also assure that the supply is stable and available when needed.

Plant design for maximizing efficiency. The design of plant is essential in terms of

manufacturing efficiency and utility of resources.

Adopt the work ethic of Japanese workers for continuous improvement.

Commit a long-term continuous improvement throughout the organization. It will help the organization to remain competitive in the long run.

Reduction of Wastes. JIT helps significantly in reducing wastes.

JUST IN TIME

You might also like

- Taller Planeación AgregadaDocument3 pagesTaller Planeación AgregadaJulio RodelNo ratings yet

- Fault Code List For Base Module (GM) Control Unit 2 Car Body Styles Wheeled Vehicles PDFDocument1 pageFault Code List For Base Module (GM) Control Unit 2 Car Body Styles Wheeled Vehicles PDFةخشككش سقكقاةشNo ratings yet

- A Handbook of IPE ToolsDocument13 pagesA Handbook of IPE ToolsS M Ataul KarimNo ratings yet

- Chapter 2 Lecture 2Document10 pagesChapter 2 Lecture 2singhsujitNo ratings yet

- Assignment On JIT (Just-in-Time)Document12 pagesAssignment On JIT (Just-in-Time)Roop50% (4)

- Production & Operation ManagementDocument23 pagesProduction & Operation Managementdabzunltd2447No ratings yet

- JIT Manufacturing and Lean ProductionDocument7 pagesJIT Manufacturing and Lean ProductionAhon BatangueñoNo ratings yet

- Spare Parts Management SPM An InventoryDocument14 pagesSpare Parts Management SPM An InventoryRo WellNo ratings yet

- Operation Mamgment12Document38 pagesOperation Mamgment12ShubhamNo ratings yet

- Implication of Just-In-Time (Jit) On Accounting: CommunicationDocument4 pagesImplication of Just-In-Time (Jit) On Accounting: Communicationkahmun616No ratings yet

- Ass No 3 Qulity ControlDocument7 pagesAss No 3 Qulity ControlKashif RasheedNo ratings yet

- Cost Management Technique: AssignmentDocument18 pagesCost Management Technique: Assignmentسرابوني رحمانNo ratings yet

- Just in TimeDocument7 pagesJust in TimeHyunjinNo ratings yet

- C CC CCCC CC CCC CC CCCCC C CCC C C CC C CCC C !C C "C C C C C C C #$ C C #C % !C C C"C CC C C C C CCC C C C C CC&C C C C CC C CC C C C C CC C C CCCCCCCC C C CC CDocument11 pagesC CC CCCC CC CCC CC CCCCC C CCC C C CC C CCC C !C C "C C C C C C C #$ C C #C % !C C C"C CC C C C C CCC C C C C CC&C C C C CC C CC C C C C CC C C CCCCCCCC C C CC CTusharr GoyelNo ratings yet

- Just in Time Inventory SystemDocument24 pagesJust in Time Inventory SystemDabatos, Kristhel - BSA 1No ratings yet

- Assignment On Managerial Implications of Just in Time ManagementDocument9 pagesAssignment On Managerial Implications of Just in Time ManagementheheheheNo ratings yet

- Jit and SCMDocument14 pagesJit and SCMGigi VDNo ratings yet

- A Study On Just in Time Logistics IntroductionDocument81 pagesA Study On Just in Time Logistics IntroductioneswariNo ratings yet

- Improvement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityDocument16 pagesImprovement Programs, Starting With Just-In-Time (JIT) and Passing Onto Total QualityNawshad HasanNo ratings yet

- Yasir Hussain: Subject Quality and Reliability Engineering TopicDocument15 pagesYasir Hussain: Subject Quality and Reliability Engineering TopicYasir HussainNo ratings yet

- Productivity Depends On Both "Lean" Thinking and QualityDocument4 pagesProductivity Depends On Both "Lean" Thinking and QualityLokesh NarasimhaiahNo ratings yet

- Lean Manufacturing 2017Document15 pagesLean Manufacturing 2017Relu CosteaNo ratings yet

- Just-In-Time (JIT) Is Defined in The APICS Dictionary As "A Philosophy of Manufacturing BasedDocument3 pagesJust-In-Time (JIT) Is Defined in The APICS Dictionary As "A Philosophy of Manufacturing BasedKamal JasmanNo ratings yet

- Dokumen - Tips - Quality Engineering and ManagementDocument32 pagesDokumen - Tips - Quality Engineering and ManagementJhordins GustavoNo ratings yet

- Q.1 Meaning & Nature of Operation Management? Explain Product Design & Process Design..?Document14 pagesQ.1 Meaning & Nature of Operation Management? Explain Product Design & Process Design..?Pooja RajputNo ratings yet

- Just-In-Time (JIT)Document7 pagesJust-In-Time (JIT)Damianaso GANo ratings yet

- Final Final Report of OpmDocument19 pagesFinal Final Report of OpmphirlayayadilNo ratings yet

- Creating QRM EnterprisesDocument6 pagesCreating QRM EnterprisesMohamed YassinNo ratings yet

- Assignment-01: MB0044 - Production & Operations Management - 4 CreditsDocument23 pagesAssignment-01: MB0044 - Production & Operations Management - 4 CreditsMorris RatanNo ratings yet

- Jit Report UpdatedDocument17 pagesJit Report UpdatedRaja AinNo ratings yet

- Abstract On JITDocument5 pagesAbstract On JITAshish ChauhanNo ratings yet

- Whitepaper 2rDocument6 pagesWhitepaper 2rgreatone88No ratings yet

- JIT JustDocument21 pagesJIT Justsurusworl281No ratings yet

- Just in Time HardDocument19 pagesJust in Time Hardbarotviral05No ratings yet

- Operations ManagmnetDocument6 pagesOperations ManagmnetGorakhpuria MNo ratings yet

- Just in Time ReluDocument16 pagesJust in Time ReluRelu CosteaNo ratings yet

- Dgavejero Assignment 2Document7 pagesDgavejero Assignment 2Dexter AvejeroNo ratings yet

- Just in Time ProjectDocument19 pagesJust in Time Projectprasadpagdhare100% (1)

- Manufacturing Excellence Through JIT ApproachDocument11 pagesManufacturing Excellence Through JIT ApproachInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Categories of Goods: Inventory Management Component of InventoryDocument17 pagesCategories of Goods: Inventory Management Component of InventoryEva Zunaida KurniawantiNo ratings yet

- The PAR Stock, Reorder Point and Safety Stock andDocument3 pagesThe PAR Stock, Reorder Point and Safety Stock andJorge Yeshayahu Gonzales-LaraNo ratings yet

- Assignment - Operations Management: Answer No. 1)Document7 pagesAssignment - Operations Management: Answer No. 1)harshit singhalNo ratings yet

- Topic 3 BPR in Manufaturing IndustryDocument9 pagesTopic 3 BPR in Manufaturing Industryneyom bitvooNo ratings yet

- Just-In-Time: Study Unit Six Operational Efficiency and Business Process PerformanceDocument21 pagesJust-In-Time: Study Unit Six Operational Efficiency and Business Process PerformanceAhmed Mostafa ElmowafyNo ratings yet

- Just in Time - InventoryDocument10 pagesJust in Time - Inventoryapurva chaturvediNo ratings yet

- 04 Just-In-Time ConceptsDocument4 pages04 Just-In-Time ConceptsSujeewa LakmalNo ratings yet

- Lean Manufacturing: Just in Time (JIT)Document11 pagesLean Manufacturing: Just in Time (JIT)Vijay SinghNo ratings yet

- Lean Manufacturing, or Lean Production DefinitionDocument8 pagesLean Manufacturing, or Lean Production DefinitionAnjan KumarNo ratings yet

- Unit 6Document5 pagesUnit 6vikrant gulhaneNo ratings yet

- The Lean Supply ChainDocument21 pagesThe Lean Supply ChainArchana GanapathyNo ratings yet

- JIT FinalDocument10 pagesJIT FinalMarie Antoinette HolandaNo ratings yet

- LOMDocument6 pagesLOMrajkumar0507No ratings yet

- Enterprise Resource PlanningDocument3 pagesEnterprise Resource PlanningElvis Pahigo MarataNo ratings yet

- Text For PresantationDocument2 pagesText For PresantationIceNo ratings yet

- Chapter 6: Just-in-Time (Lean) Purchasing: Group 6: Holanda, Olleras and SabantoDocument10 pagesChapter 6: Just-in-Time (Lean) Purchasing: Group 6: Holanda, Olleras and SabantoMarie Antoinette HolandaNo ratings yet

- A Study On Just in Time Nicrome Leather Processing Industry at ChennaiDocument103 pagesA Study On Just in Time Nicrome Leather Processing Industry at ChennaiMeena SivasubramanianNo ratings yet

- SCM Assignment DoneDocument12 pagesSCM Assignment DoneAdarsh Kumar RoyNo ratings yet

- 367 ErpBookDocument13 pages367 ErpBooksravankumar248No ratings yet

- Material Management by Using Lean Manufacturing Principles A Case StudyDocument9 pagesMaterial Management by Using Lean Manufacturing Principles A Case StudyLiju AlexNo ratings yet

- Strengthening the Operational Pillar: The Building Blocks of World-Class Production Planning and Inventory Control SystemsFrom EverandStrengthening the Operational Pillar: The Building Blocks of World-Class Production Planning and Inventory Control SystemsNo ratings yet

- How to Create Continuous Production Flow?: Toyota Production System ConceptsFrom EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Resume: Ansul P. Dulgaj Room No. 02 Opp. Ashapura BLDG, Email-2Document2 pagesResume: Ansul P. Dulgaj Room No. 02 Opp. Ashapura BLDG, Email-2Pravin SinghNo ratings yet

- Rural Marketing Strategies - HLLDocument95 pagesRural Marketing Strategies - HLLPravin Singh50% (2)

- Levi StraussDocument12 pagesLevi StraussPravin Singh50% (2)

- Strategies To Reduce The Harmful Use of AlcoholDocument2 pagesStrategies To Reduce The Harmful Use of AlcoholPravin SinghNo ratings yet

- Introduction To Operations ManagementDocument77 pagesIntroduction To Operations ManagementPravin SinghNo ratings yet

- Resume: Name: Periyaswami ArunachalamDocument1 pageResume: Name: Periyaswami ArunachalamPravin SinghNo ratings yet

- Status of Women in Indian SocietyDocument5 pagesStatus of Women in Indian SocietyPravin SinghNo ratings yet

- PDF - Study - How To Pay Your Course Fees PDFDocument3 pagesPDF - Study - How To Pay Your Course Fees PDFPrajakta TawdeNo ratings yet

- 8030 Series Wheel Tractors 8130 8230 8330 8430 8530 Replacement Parts GuideDocument3 pages8030 Series Wheel Tractors 8130 8230 8330 8430 8530 Replacement Parts GuideGeorge NetcaNo ratings yet

- Elitmus Syllabus and Question Paper PatternDocument5 pagesElitmus Syllabus and Question Paper PatternAbhishek MohanNo ratings yet

- Draft MOU UUM X UNRAM - International Partner 2023Document8 pagesDraft MOU UUM X UNRAM - International Partner 2023Mega Nisfa MakhrojaNo ratings yet

- Threat Hunting Through Email Headers - SQRRLDocument16 pagesThreat Hunting Through Email Headers - SQRRLSyeda Ashifa Ashrafi PapiaNo ratings yet

- Quality Test Bank 2Document16 pagesQuality Test Bank 2Behbehlynn100% (4)

- Additional Security Deposit For BESCOMDocument4 pagesAdditional Security Deposit For BESCOMBabuKumarNo ratings yet

- EVACS16 Installation ManualDocument17 pagesEVACS16 Installation ManualRonaldo RomeroNo ratings yet

- Clay BlockDocument20 pagesClay BlockNidhi MehtaNo ratings yet

- Loss of Containment Manual 2012 PDFDocument68 pagesLoss of Containment Manual 2012 PDFpetrolhead1No ratings yet

- Squeeze CastingDocument38 pagesSqueeze Castingjishnus100% (1)

- The Other Inconvenient Truth - Agriculture PDFDocument3 pagesThe Other Inconvenient Truth - Agriculture PDFTaís Presoto AlvarezNo ratings yet

- $RSQWUJADocument1 page$RSQWUJAJob Bank CanadaNo ratings yet

- 2nd Cedric Burl AmpDocument2 pages2nd Cedric Burl AmpCheryl LynnNo ratings yet

- Resources and DevelopmentDocument10 pagesResources and DevelopmentswitchangryNo ratings yet

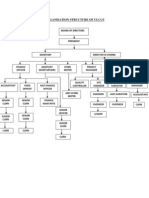

- Organisation Structure of Ulccs: Director in ChargeDocument1 pageOrganisation Structure of Ulccs: Director in ChargeMohamed RiyasNo ratings yet

- International Affairs 2022 Jan To December TopicWise PDF by AffairsCloud PDFDocument31 pagesInternational Affairs 2022 Jan To December TopicWise PDF by AffairsCloud PDFbatNo ratings yet

- HMT306 Food Processing and PreservationDocument431 pagesHMT306 Food Processing and Preservationgumnani.rewachandNo ratings yet

- LESSON 1 Quiz 1Document4 pagesLESSON 1 Quiz 1Carmen Florez100% (1)

- Checkpoint Science Past Papers 2008Document2 pagesCheckpoint Science Past Papers 2008Zindaba Shoko50% (2)

- Rand Func in WordDocument3 pagesRand Func in WordEngr Binish RazaNo ratings yet

- Fluid Mechanics - ProblemsDocument4 pagesFluid Mechanics - ProblemsClement Chima50% (2)

- Personalised Mobile Health and Fitness Apps: Lessons Learned From Myfitnesscompanion®Document11 pagesPersonalised Mobile Health and Fitness Apps: Lessons Learned From Myfitnesscompanion®sayed shahabuddin AdeebNo ratings yet

- VAWA Federalism One-PagerDocument2 pagesVAWA Federalism One-PagerThe National Task Force to End Sexual and Domestic ViolenceNo ratings yet

- 2021 Exam BramhastraDocument5,530 pages2021 Exam BramhastraRed VelvetNo ratings yet

- BA 501-Text AnalyticsDocument2 pagesBA 501-Text AnalyticsTanisha AgarwalNo ratings yet

- Computer Science #3Document356 pagesComputer Science #3Sean s Chipanga100% (1)