Professional Documents

Culture Documents

CT113030 Im

CT113030 Im

Uploaded by

Franklin LibreCopyright:

Available Formats

You might also like

- ASV 10 20 BrochureDocument8 pagesASV 10 20 BrochureThomas Duane DavidsonNo ratings yet

- On GLOBE VALVEDocument22 pagesOn GLOBE VALVEAditya AcharyaNo ratings yet

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocument1 pageMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441No ratings yet

- Sapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsDocument8 pagesSapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsAbdeldjalil AchourNo ratings yet

- Series: C80/C89 C70/C74Document12 pagesSeries: C80/C89 C70/C74Anupam MehraNo ratings yet

- Kunkle300 PDFDocument6 pagesKunkle300 PDFCastoriadisNo ratings yet

- Y Strainer kecleySA 7150 300Document2 pagesY Strainer kecleySA 7150 300kobyrtaczNo ratings yet

- Lead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersDocument2 pagesLead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersRockny2011No ratings yet

- Basket Strainer F85CS FabrotechDocument1 pageBasket Strainer F85CS FabrotechhugoheloNo ratings yet

- VIC 300 Butterfly ValvesDocument12 pagesVIC 300 Butterfly ValvesNtolo Ongene DimitriNo ratings yet

- Yarway Wye Type Pipeline StrainersDocument12 pagesYarway Wye Type Pipeline StrainersLuis CartageneaNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Knife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)Document2 pagesKnife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)juantamad02No ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Gate Valve Standard FeaturesDocument3 pagesGate Valve Standard Featuresعزت عبد المنعمNo ratings yet

- KEDDCO BinderDocument74 pagesKEDDCO BinderWillian FigueroaNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Series M Knife Gate ValveDocument11 pagesSeries M Knife Gate ValveRicardo MoralesNo ratings yet

- Butter Mueller 5bt520e0015wf00g1000Document2 pagesButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNo ratings yet

- Firelock Butterfly Valve: Series 705 With Weatherproof ActuatorDocument7 pagesFirelock Butterfly Valve: Series 705 With Weatherproof ActuatorDefy BbalNo ratings yet

- Valves Kvc07Document25 pagesValves Kvc07Dimas Anugrah MahardikaNo ratings yet

- Product Bulletin: Model Osg Ansi ProcessDocument6 pagesProduct Bulletin: Model Osg Ansi ProcessDomingo DíazNo ratings yet

- VCTDS 03384 enDocument8 pagesVCTDS 03384 enKrishnamoorthyNo ratings yet

- Catalogo KeckleyDocument3 pagesCatalogo KeckleyYGWHNo ratings yet

- Quick Sheet: API 602 Forged Steel Gate ValveDocument3 pagesQuick Sheet: API 602 Forged Steel Gate ValveNaresh ANo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- N, BNDocument1 pageN, BNmomenziNo ratings yet

- 350psi Swing Check Valve: General DescriptionDocument2 pages350psi Swing Check Valve: General DescriptionPedro Alberto Tello CNo ratings yet

- Bolted Bonet ValveDocument32 pagesBolted Bonet ValveRiza Ahmad Sofikul IrfanNo ratings yet

- KUKMC 0328 US - tcm106 37618Document15 pagesKUKMC 0328 US - tcm106 37618tuanhiena10No ratings yet

- VC D V Kea Kfa Kla Spira Trol Ti d413 03Document8 pagesVC D V Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiNo ratings yet

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 pagesBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNo ratings yet

- JCM 452 Stainless Tapping SleeveDocument3 pagesJCM 452 Stainless Tapping SleeveNgô Mạnh TiếnNo ratings yet

- 5TS-001A Bolting Torquing Quick GuideDocument2 pages5TS-001A Bolting Torquing Quick GuidehaddoucheNo ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- 10.11 1050 and 1060 BrochureDocument4 pages10.11 1050 and 1060 BrochureDariusz TaborNo ratings yet

- ASP SST Fittings DataCatalog-1013Document16 pagesASP SST Fittings DataCatalog-1013JMNo ratings yet

- 14.riser Check ValveDocument3 pages14.riser Check ValveJUAN AQUINONo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- 6 Body-Forms PDFDocument8 pages6 Body-Forms PDFsnamprogNo ratings yet

- Hyd Inc Swivel JointsDocument28 pagesHyd Inc Swivel Jointsfrancis_15inNo ratings yet

- Check Horizontal PDFDocument2 pagesCheck Horizontal PDFJorge CarionNo ratings yet

- CURC 01bDocument8 pagesCURC 01bmontsegranNo ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- 2022 1 PHF Catalogue - Page - 45Document1 page2022 1 PHF Catalogue - Page - 45lilama45-1No ratings yet

- Stainless EnstainlessDocument27 pagesStainless EnstainlessVinaya Almane DattathreyaNo ratings yet

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- CatalogoVCW EN Mai20Document11 pagesCatalogoVCW EN Mai20snri0da9No ratings yet

- USA Range - Piston Accumulators DatasheetDocument2 pagesUSA Range - Piston Accumulators DatasheetrinshonsanNo ratings yet

- CVC Steel FullDocument28 pagesCVC Steel FullSergio Bacca SantiagoNo ratings yet

- Product BrochureDocument16 pagesProduct Brochurevishnu300022No ratings yet

- LISTADO ACTUALIZADO AL 13-10 Listado de GasolinaDocument9 pagesLISTADO ACTUALIZADO AL 13-10 Listado de GasolinaFranklin LibreNo ratings yet

- CT114123 DRDocument1 pageCT114123 DRFranklin LibreNo ratings yet

- CT115579 ImDocument6 pagesCT115579 ImFranklin LibreNo ratings yet

- CT113015 ImDocument3 pagesCT113015 ImFranklin LibreNo ratings yet

- CT113004 DRDocument1 pageCT113004 DRFranklin LibreNo ratings yet

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- 0808 133 M200J 01Document125 pages0808 133 M200J 01Franklin LibreNo ratings yet

- Esquema Hidrostatico 895Document2 pagesEsquema Hidrostatico 895Carlos ParanhosNo ratings yet

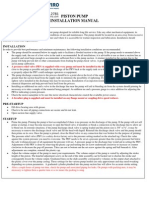

- A&F Pump Piston Pump Installation ManualDocument5 pagesA&F Pump Piston Pump Installation ManualPromagEnviro.com100% (1)

- Steer Gear 1Document40 pagesSteer Gear 1gilangpasekaNo ratings yet

- Example 1 Carnot Cycle PDFDocument3 pagesExample 1 Carnot Cycle PDFAbdullah AzizNo ratings yet

- Date Area Equipment Mech. Elect. C&I IsolationsDocument1 pageDate Area Equipment Mech. Elect. C&I IsolationsbhaskarNo ratings yet

- Coffee97 Coffee DeluxDocument3 pagesCoffee97 Coffee Deluxsasizzo78No ratings yet

- Esp Calculation Table (Ranjith)Document6 pagesEsp Calculation Table (Ranjith)RanjithNo ratings yet

- InsulationDocument5 pagesInsulationjaleelNo ratings yet

- The Basics of Air Compressor On A ShipDocument2 pagesThe Basics of Air Compressor On A Shipnagipa6555No ratings yet

- Product Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304Document16 pagesProduct Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304josecordova2014100% (1)

- 45 Export - Acetylene PlantDocument8 pages45 Export - Acetylene PlantBilel AzzouniNo ratings yet

- Gas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationDocument6 pagesGas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationscribdkhatnNo ratings yet

- Diagrama Bomba 9010B 2 de 2Document3 pagesDiagrama Bomba 9010B 2 de 2Comassur SA de CVNo ratings yet

- Refrigeration CircuitDocument32 pagesRefrigeration CircuitHassan Iftekhar Ahmed100% (1)

- Fan TestDocument10 pagesFan Testwhoelse_iNo ratings yet

- Spare Part ListDocument23 pagesSpare Part ListCarloAugentiNo ratings yet

- V CompressorDocument29 pagesV CompressorkeduseNo ratings yet

- Hdpe QuotationDocument3 pagesHdpe Quotationnachiketa99mithaiwalaNo ratings yet

- Fire Pump Proposal Summary: Project InformationDocument7 pagesFire Pump Proposal Summary: Project Informationmalex841007No ratings yet

- Plumbing Weekly Progress ReportDocument16 pagesPlumbing Weekly Progress ReportKevin John PaglinawanNo ratings yet

- Design / Selection of Brine Pump Design Condition: Type Centrifugal Capacity 0.44 Li/secDocument6 pagesDesign / Selection of Brine Pump Design Condition: Type Centrifugal Capacity 0.44 Li/secjomilanNo ratings yet

- Piping Material SpcificationDocument16 pagesPiping Material SpcificationMehdi NouriNo ratings yet

- Revision - Summary - 7T04 MP 00 TS 004 - Rev10Document10 pagesRevision - Summary - 7T04 MP 00 TS 004 - Rev10Cristi DemNo ratings yet

- NAF-Flex Wedge Gate Valves PN 16-100 FK 21.75 (2) GB NAF-Flex Wedge Gate ValvesDocument6 pagesNAF-Flex Wedge Gate Valves PN 16-100 FK 21.75 (2) GB NAF-Flex Wedge Gate ValvesNguyen KhaNo ratings yet

- VALVULA CHECK Dorot PDFDocument1 pageVALVULA CHECK Dorot PDFGustavo RomanNo ratings yet

- Refrigerant PumpDocument2 pagesRefrigerant PumpbarelihbNo ratings yet

- IWCF Principles & Procedures Test Paper (Answer)Document5 pagesIWCF Principles & Procedures Test Paper (Answer)andrzema100% (3)

- Exam On Pumps and Pipe NetworksDocument10 pagesExam On Pumps and Pipe Networksm_abdelgawadNo ratings yet

- Horizontal MultiStage Pump Data SheetDocument6 pagesHorizontal MultiStage Pump Data Sheetسمير البسيونىNo ratings yet

CT113030 Im

CT113030 Im

Uploaded by

Franklin LibreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CT113030 Im

CT113030 Im

Uploaded by

Franklin LibreCopyright:

Available Formats

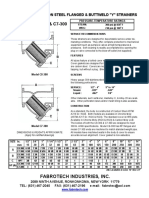

FA B R O T E C H I N D U S T R I E S, I N C .

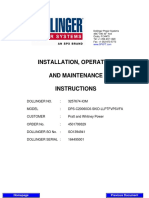

INSTALLATION, OPERATION AND MAINTENANCE

“Y” Strainers

WARNING

Individuals performing removal and disassembly should be provided with suitable protection from possibly hazardous liquids.

Before installing the “Y” strainer, be sure its pressure rating is correct for the system. If the end connections are threaded or de-

signed for soldering or brazing, be sure the piping is straight and not at an angle or offset. If the strainer has flanged ends be sure

the flanges of the connecting piping are square with the pipe so that no undue stresses are put on the strainer or piping when

tightening flange bolts. Tighten bolts in sequence crossing to opposites.

For maximum efficiency, a differential pressure gauge installed across the inlet and outlet will indicate pressure loss due to clogging

and may be used as a guide to determine when cleaning is required. If the strainer is equipped with a blow-down valve, open and

flush out until any sediment is removed. If the strainer is not fitted for blow-down cleaning, remove the cover (or cap) and clean

the screen. Re-install the screen in the strainer in the same position as before and tighten cover (or cap). Replace the gasket if

necessary.

Keeping a spare, clean screen will minimize shut down time.

SPARE PARTS

To order replacement screens or gaskets, which are the only items normally required, specify the following.

a) Size and model number of strainer or casting number as it appears on the body of the strainer.

b) Specify service. For example: water, steam, gas, air, oil. The working pressure and temperature of the system and

particle size to be strained out should also be specified.

2 0 8 9 N I N T H AV E N U E R O N K O N K O M A , N Y 1 1 7 7 9

P H O N E ( 6 3 1 ) 4 6 7 - 2 0 4 0 FA X ( 6 3 1 ) 4 6 7 - 2 1 9 6

Homepage Previous Document

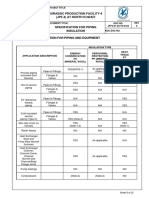

ENGINEERING SUBMITTAL DATA

600 LB. CAST STAINLESS STEEL FLANGED & BUTTWELD "Y" STRAINERS

PRESSURE-TEMPERATURE RATINGS

STEAM: 600 psi @ 1125o F

1440 psi @ 100o F

MODELS: S8-600 & S7-600 WOG:

SERVICE RECOMMENDATIONS

These strainers are designed to ensure complete protection to

mechanical equipment from the harmful effects of dirt, scale, etc.

The S8-600 is built for a long service life and designed to withstand

many different types of corrosive fluids at high pressures and

temperatures.

FEATURES

All sizes feature a bolted cover machined to receive the screen.

S8-600 are drilled in accordance with ANSI B16.5. Bolt holes are

either spot faced or flanges are back faced. Each unit is individually

hydrostatically tested. Ring Type Joints (RTJ) are available.

Standard gasket is Teflon, limited to 400o F.

SCREENS

Model S8-600 Heavy gauge 304 stainless steel screens are normally furnished in

the following perforations:

SERVICE: 1/2" - 4" 5" to 14"

Steam: .033" .045"

Liquid : .062" 1/8"

Other materials, such as Monel, Hastelloy C, & Alloy-20 are avail-

able. Other perforation sizes and/or mesh lining is also available.

CONSTRUCTION

Extremely rugged & durable bodies constructed from stock in type

316 stainless steel (ASTM A351, Grade CF8M). Other alloys are

available. All sizes contain generously proportioned screens with a

minimum capacity four times the corresponding pipe size. The

bodies of both the S8-600 & S7-600 are designed to meet 600 lb.

Model S7-600 ANSI specifications. Model S8-600 has RF flanges and model

S7-600 ends are machined to match schedule 80 pipe. All models

DIMENSIONS & WEIGHTS APPROXIMATE have machined seats in the body & cover which ensure accurate

(Apply for certified drawings) screen alignment.

SIZE in. 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3" 4" 5" 6" 8" 10" 12"

mm 15 20 25 32 40 50 65 80 100 125 150 200 250 300

S8-600 6 5/8 8 5/16 8 5/16 10 1/8 10 1/4 11 12 13 1/2 18 22 1/4 25 5/8 31 3/4 37 3/4 45 1/2

A

S7-600 6 5/8 8 5/16 8 5/16 10 1/8 10 1/4 11 12 13 1/2 18 22 1/4 25 5/8 31 3/4 37 3/4 45 1/8

S8-600 3 1/2 3 3/4 3 3/4 5 1/2 5 1/2 7 8 1/4 9 1/4 12 1/2 15 20 24 28 1/2 34 1/2

B

S7-600 3 1/2 3 3/4 3 3/4 5 1/2 5 1/2 7 8 1/4 9 1/4 12 1/2 15 20 24 28 1/2 34 1/2

C NPT 3/8 1/2 1/2 1/2 1/2 1 1 1 1/4 1 1/2 2 2 2 2 2

S8-600 6 12 1/4 13 19 27 39 60 75 160 260 360 635 1090 1315

WT (lb.)

S7-600 3 9 9 12 13 20 34 43 81 134 200 405 706 880

Also available in sizes 14" thru 24"

FABROTECH INDUSTRIES, INC.

2089 NINTH AVENUE, RONKONKOMA, NEW YORK 11779

TEL: (631) 467-2040 FAX: (631) 467-2196 e-mail: fabrotec@aol.com

www.fabrotech.com

Homepage Previous Document

You might also like

- ASV 10 20 BrochureDocument8 pagesASV 10 20 BrochureThomas Duane DavidsonNo ratings yet

- On GLOBE VALVEDocument22 pagesOn GLOBE VALVEAditya AcharyaNo ratings yet

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocument1 pageMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441No ratings yet

- Sapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsDocument8 pagesSapag: Sapag Series 8400 and 8500 Safety Relief Valves For API-526 Process ApplicationsAbdeldjalil AchourNo ratings yet

- Series: C80/C89 C70/C74Document12 pagesSeries: C80/C89 C70/C74Anupam MehraNo ratings yet

- Kunkle300 PDFDocument6 pagesKunkle300 PDFCastoriadisNo ratings yet

- Y Strainer kecleySA 7150 300Document2 pagesY Strainer kecleySA 7150 300kobyrtaczNo ratings yet

- Lead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersDocument2 pagesLead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersRockny2011No ratings yet

- Basket Strainer F85CS FabrotechDocument1 pageBasket Strainer F85CS FabrotechhugoheloNo ratings yet

- VIC 300 Butterfly ValvesDocument12 pagesVIC 300 Butterfly ValvesNtolo Ongene DimitriNo ratings yet

- Yarway Wye Type Pipeline StrainersDocument12 pagesYarway Wye Type Pipeline StrainersLuis CartageneaNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Knife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)Document2 pagesKnife Gate Valve LVC Figure 93 Stainless Steel Metal Seated - (PRATT)juantamad02No ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Gate Valve Standard FeaturesDocument3 pagesGate Valve Standard Featuresعزت عبد المنعمNo ratings yet

- KEDDCO BinderDocument74 pagesKEDDCO BinderWillian FigueroaNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Series M Knife Gate ValveDocument11 pagesSeries M Knife Gate ValveRicardo MoralesNo ratings yet

- Butter Mueller 5bt520e0015wf00g1000Document2 pagesButter Mueller 5bt520e0015wf00g1000Manusawin PinsongNo ratings yet

- Firelock Butterfly Valve: Series 705 With Weatherproof ActuatorDocument7 pagesFirelock Butterfly Valve: Series 705 With Weatherproof ActuatorDefy BbalNo ratings yet

- Valves Kvc07Document25 pagesValves Kvc07Dimas Anugrah MahardikaNo ratings yet

- Product Bulletin: Model Osg Ansi ProcessDocument6 pagesProduct Bulletin: Model Osg Ansi ProcessDomingo DíazNo ratings yet

- VCTDS 03384 enDocument8 pagesVCTDS 03384 enKrishnamoorthyNo ratings yet

- Catalogo KeckleyDocument3 pagesCatalogo KeckleyYGWHNo ratings yet

- Quick Sheet: API 602 Forged Steel Gate ValveDocument3 pagesQuick Sheet: API 602 Forged Steel Gate ValveNaresh ANo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- N, BNDocument1 pageN, BNmomenziNo ratings yet

- 350psi Swing Check Valve: General DescriptionDocument2 pages350psi Swing Check Valve: General DescriptionPedro Alberto Tello CNo ratings yet

- Bolted Bonet ValveDocument32 pagesBolted Bonet ValveRiza Ahmad Sofikul IrfanNo ratings yet

- KUKMC 0328 US - tcm106 37618Document15 pagesKUKMC 0328 US - tcm106 37618tuanhiena10No ratings yet

- VC D V Kea Kfa Kla Spira Trol Ti d413 03Document8 pagesVC D V Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiNo ratings yet

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 pagesBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNo ratings yet

- JCM 452 Stainless Tapping SleeveDocument3 pagesJCM 452 Stainless Tapping SleeveNgô Mạnh TiếnNo ratings yet

- 5TS-001A Bolting Torquing Quick GuideDocument2 pages5TS-001A Bolting Torquing Quick GuidehaddoucheNo ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- 10.11 1050 and 1060 BrochureDocument4 pages10.11 1050 and 1060 BrochureDariusz TaborNo ratings yet

- ASP SST Fittings DataCatalog-1013Document16 pagesASP SST Fittings DataCatalog-1013JMNo ratings yet

- 14.riser Check ValveDocument3 pages14.riser Check ValveJUAN AQUINONo ratings yet

- L&T Gate Globe Check Valves API 602Document12 pagesL&T Gate Globe Check Valves API 602Nilesh MistryNo ratings yet

- 6 Body-Forms PDFDocument8 pages6 Body-Forms PDFsnamprogNo ratings yet

- Hyd Inc Swivel JointsDocument28 pagesHyd Inc Swivel Jointsfrancis_15inNo ratings yet

- Check Horizontal PDFDocument2 pagesCheck Horizontal PDFJorge CarionNo ratings yet

- CURC 01bDocument8 pagesCURC 01bmontsegranNo ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- Catalog Mud Pump 25864Document24 pagesCatalog Mud Pump 25864agus100% (1)

- 2022 1 PHF Catalogue - Page - 45Document1 page2022 1 PHF Catalogue - Page - 45lilama45-1No ratings yet

- Stainless EnstainlessDocument27 pagesStainless EnstainlessVinaya Almane DattathreyaNo ratings yet

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- CatalogoVCW EN Mai20Document11 pagesCatalogoVCW EN Mai20snri0da9No ratings yet

- USA Range - Piston Accumulators DatasheetDocument2 pagesUSA Range - Piston Accumulators DatasheetrinshonsanNo ratings yet

- CVC Steel FullDocument28 pagesCVC Steel FullSergio Bacca SantiagoNo ratings yet

- Product BrochureDocument16 pagesProduct Brochurevishnu300022No ratings yet

- LISTADO ACTUALIZADO AL 13-10 Listado de GasolinaDocument9 pagesLISTADO ACTUALIZADO AL 13-10 Listado de GasolinaFranklin LibreNo ratings yet

- CT114123 DRDocument1 pageCT114123 DRFranklin LibreNo ratings yet

- CT115579 ImDocument6 pagesCT115579 ImFranklin LibreNo ratings yet

- CT113015 ImDocument3 pagesCT113015 ImFranklin LibreNo ratings yet

- CT113004 DRDocument1 pageCT113004 DRFranklin LibreNo ratings yet

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- 0808 133 M200J 01Document125 pages0808 133 M200J 01Franklin LibreNo ratings yet

- Esquema Hidrostatico 895Document2 pagesEsquema Hidrostatico 895Carlos ParanhosNo ratings yet

- A&F Pump Piston Pump Installation ManualDocument5 pagesA&F Pump Piston Pump Installation ManualPromagEnviro.com100% (1)

- Steer Gear 1Document40 pagesSteer Gear 1gilangpasekaNo ratings yet

- Example 1 Carnot Cycle PDFDocument3 pagesExample 1 Carnot Cycle PDFAbdullah AzizNo ratings yet

- Date Area Equipment Mech. Elect. C&I IsolationsDocument1 pageDate Area Equipment Mech. Elect. C&I IsolationsbhaskarNo ratings yet

- Coffee97 Coffee DeluxDocument3 pagesCoffee97 Coffee Deluxsasizzo78No ratings yet

- Esp Calculation Table (Ranjith)Document6 pagesEsp Calculation Table (Ranjith)RanjithNo ratings yet

- InsulationDocument5 pagesInsulationjaleelNo ratings yet

- The Basics of Air Compressor On A ShipDocument2 pagesThe Basics of Air Compressor On A Shipnagipa6555No ratings yet

- Product Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304Document16 pagesProduct Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304josecordova2014100% (1)

- 45 Export - Acetylene PlantDocument8 pages45 Export - Acetylene PlantBilel AzzouniNo ratings yet

- Gas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationDocument6 pagesGas Turbine-Compressor Unit For The Werne Natural Gas Compressor StationscribdkhatnNo ratings yet

- Diagrama Bomba 9010B 2 de 2Document3 pagesDiagrama Bomba 9010B 2 de 2Comassur SA de CVNo ratings yet

- Refrigeration CircuitDocument32 pagesRefrigeration CircuitHassan Iftekhar Ahmed100% (1)

- Fan TestDocument10 pagesFan Testwhoelse_iNo ratings yet

- Spare Part ListDocument23 pagesSpare Part ListCarloAugentiNo ratings yet

- V CompressorDocument29 pagesV CompressorkeduseNo ratings yet

- Hdpe QuotationDocument3 pagesHdpe Quotationnachiketa99mithaiwalaNo ratings yet

- Fire Pump Proposal Summary: Project InformationDocument7 pagesFire Pump Proposal Summary: Project Informationmalex841007No ratings yet

- Plumbing Weekly Progress ReportDocument16 pagesPlumbing Weekly Progress ReportKevin John PaglinawanNo ratings yet

- Design / Selection of Brine Pump Design Condition: Type Centrifugal Capacity 0.44 Li/secDocument6 pagesDesign / Selection of Brine Pump Design Condition: Type Centrifugal Capacity 0.44 Li/secjomilanNo ratings yet

- Piping Material SpcificationDocument16 pagesPiping Material SpcificationMehdi NouriNo ratings yet

- Revision - Summary - 7T04 MP 00 TS 004 - Rev10Document10 pagesRevision - Summary - 7T04 MP 00 TS 004 - Rev10Cristi DemNo ratings yet

- NAF-Flex Wedge Gate Valves PN 16-100 FK 21.75 (2) GB NAF-Flex Wedge Gate ValvesDocument6 pagesNAF-Flex Wedge Gate Valves PN 16-100 FK 21.75 (2) GB NAF-Flex Wedge Gate ValvesNguyen KhaNo ratings yet

- VALVULA CHECK Dorot PDFDocument1 pageVALVULA CHECK Dorot PDFGustavo RomanNo ratings yet

- Refrigerant PumpDocument2 pagesRefrigerant PumpbarelihbNo ratings yet

- IWCF Principles & Procedures Test Paper (Answer)Document5 pagesIWCF Principles & Procedures Test Paper (Answer)andrzema100% (3)

- Exam On Pumps and Pipe NetworksDocument10 pagesExam On Pumps and Pipe Networksm_abdelgawadNo ratings yet

- Horizontal MultiStage Pump Data SheetDocument6 pagesHorizontal MultiStage Pump Data Sheetسمير البسيونىNo ratings yet