Professional Documents

Culture Documents

PFMEA AIAG VDA Detection Rating PDF

PFMEA AIAG VDA Detection Rating PDF

Uploaded by

Ramdas PaithankarCopyright:

Available Formats

You might also like

- Case-Astra ZenecaDocument20 pagesCase-Astra Zenecaish june100% (1)

- Testing IBE R2Document644 pagesTesting IBE R2claudia veraNo ratings yet

- Detection Table - AIAG-VDA Process FMEADocument1 pageDetection Table - AIAG-VDA Process FMEARaajha MunibathiranNo ratings yet

- Table P3 For Detection RatingDocument2 pagesTable P3 For Detection RatingAhmad Bin Ismail KhanNo ratings yet

- The 7 Steps of Process-FMEA: Step 1: Planning and PreparationDocument2 pagesThe 7 Steps of Process-FMEA: Step 1: Planning and PreparationTarun PrabhakarNo ratings yet

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamNo ratings yet

- DETECCIONDocument2 pagesDETECCIONlaacostam93No ratings yet

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (6)

- Detection ScaleDocument1 pageDetection ScaleSergio LoayzaNo ratings yet

- Guided By: Prof. A. D. PatilDocument14 pagesGuided By: Prof. A. D. Patilshubham puranikNo ratings yet

- 100 Most Popular Software Testing TermsDocument8 pages100 Most Popular Software Testing TermssuketsomNo ratings yet

- 21st Century CGMPDocument13 pages21st Century CGMPVidya PasalkarNo ratings yet

- Error Proofing TechniquesDocument38 pagesError Proofing TechniquesDeepali ParmarNo ratings yet

- The 4 Components of ZDQDocument37 pagesThe 4 Components of ZDQMuhammad Gullraiz ChohanNo ratings yet

- Software Quality Assurance: Dynamic Testing-IDocument36 pagesSoftware Quality Assurance: Dynamic Testing-IPro HammadNo ratings yet

- Error-Proofing PDFDocument28 pagesError-Proofing PDFDanang WidoyokoNo ratings yet

- Error-Proofing PDFDocument28 pagesError-Proofing PDFR.BALASUBRAMANINo ratings yet

- Testing Processes MethodologyDocument14 pagesTesting Processes Methodologyapi-3770281No ratings yet

- Fy11 sh-22316-11 3-3 MistakeProofingDocument20 pagesFy11 sh-22316-11 3-3 MistakeProofingMani PathakNo ratings yet

- Understanding QA System in Pharma Industry - 23092020Document31 pagesUnderstanding QA System in Pharma Industry - 23092020Anggia Bia Amanda100% (1)

- DFMEArefcard PDFDocument2 pagesDFMEArefcard PDFIgor PNo ratings yet

- What Is Software Testing?: Testing of Mobile ApplicationDocument7 pagesWhat Is Software Testing?: Testing of Mobile ApplicationSaurav JamwalNo ratings yet

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 pagesFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluNo ratings yet

- Cleaning Validation For PharmaDocument8 pagesCleaning Validation For Pharmaanalistaaseguramiento1.bontalNo ratings yet

- Poka-Yoke: A Strategy For Performance ExcellenceDocument12 pagesPoka-Yoke: A Strategy For Performance ExcellenceIndranilNo ratings yet

- Statistical Quality ControlDocument78 pagesStatistical Quality ControlalmazwmbashiraNo ratings yet

- Cleaning Validation AlconoxDocument8 pagesCleaning Validation AlconoxEDGARNo ratings yet

- Istqb Section OneDocument39 pagesIstqb Section OneBrandon SteelNo ratings yet

- Static TestingDocument10 pagesStatic TestingRitiesh BhatiaNo ratings yet

- Discuss The Various Techniques Deployed in Fault Removal in Fault ToleranceDocument3 pagesDiscuss The Various Techniques Deployed in Fault Removal in Fault ToleranceEmmanuel John AbahNo ratings yet

- IATF 16949 Awareness Training-Terms OnlyDocument18 pagesIATF 16949 Awareness Training-Terms Onlysuresh kumar67% (3)

- Domain4 - Build The Test EnvironmentDocument73 pagesDomain4 - Build The Test Environmentapi-19934187No ratings yet

- Poka Yoke and BrainstormingDocument18 pagesPoka Yoke and Brainstormingananda wahyuNo ratings yet

- CS335 Testing LectureDocument64 pagesCS335 Testing LectureDoreen EmmanuelNo ratings yet

- 100 Most Popular Software Testing TermsDocument9 pages100 Most Popular Software Testing TermszoconNo ratings yet

- Touchless Testing PlatformDocument9 pagesTouchless Testing PlatformPrasanna KrishnaNo ratings yet

- Software mst-3Document25 pagesSoftware mst-3kalpitrawat16908No ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- Glossary Test TerminologyDocument8 pagesGlossary Test Terminologymgr810No ratings yet

- Poka YokeDocument17 pagesPoka YokePranav SharmaNo ratings yet

- 2024 - 05 - Objectives and Principles of Test AutomationDocument76 pages2024 - 05 - Objectives and Principles of Test AutomationMahammadali AbaszadaNo ratings yet

- Risk Based Approach To ValidationDocument6 pagesRisk Based Approach To ValidationAlex CristiNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- Manual TestingDocument4 pagesManual TestingAndreea LilianaNo ratings yet

- IEEE STDocument3 pagesIEEE STprithikamohankumar04No ratings yet

- OOSE Unit 4 NotesDocument17 pagesOOSE Unit 4 Notesrakshithaashok247No ratings yet

- Hybrid Model For Penetration TestingDocument8 pagesHybrid Model For Penetration TestinghappiestmindsNo ratings yet

- Six Sigma Analyze PhaseDocument12 pagesSix Sigma Analyze PhaseerinelNo ratings yet

- Chapter 2 What Is Software QualityDocument11 pagesChapter 2 What Is Software QualitytanzilaNo ratings yet

- "Failure Modes and Effect Analysis of S - Type Nozzle": A Project OnDocument15 pages"Failure Modes and Effect Analysis of S - Type Nozzle": A Project Onuujaval pavarNo ratings yet

- Istqb F.L. Glossary Chapter 2Document8 pagesIstqb F.L. Glossary Chapter 2karishma100% (1)

- 02 - Control of Non Corforming Product Sep13Document67 pages02 - Control of Non Corforming Product Sep13Mojtaba MousaviNo ratings yet

- Progress Report 3 PANKAJDocument5 pagesProgress Report 3 PANKAJWall HackNo ratings yet

- 7-Step Pocket GuideDocument2 pages7-Step Pocket Guidesutra01No ratings yet

- Unit Iv Testing: 4.1taxonomy of Software TestingDocument28 pagesUnit Iv Testing: 4.1taxonomy of Software TestingTanish PantNo ratings yet

- Delmia DPM M7 - Tool ValidationDocument59 pagesDelmia DPM M7 - Tool Validationkakaka22No ratings yet

- RAMS Optimum Inspection IntervalDocument8 pagesRAMS Optimum Inspection IntervalSrinivas PothulaNo ratings yet

- Testing Techniques For Software Validation: EmailDocument157 pagesTesting Techniques For Software Validation: EmailGarvit jethwaniNo ratings yet

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- Corporate ResponsibilityDocument1 pageCorporate ResponsibilityRamdas PaithankarNo ratings yet

- Capacity Analysis ReportDocument7 pagesCapacity Analysis ReportRamdas PaithankarNo ratings yet

- Quality Policy - 5.2Document1 pageQuality Policy - 5.2Ramdas Paithankar100% (1)

- Pareto Chart Excel TemplateDocument4 pagesPareto Chart Excel TemplateRamdas PaithankarNo ratings yet

- Organization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Document3 pagesOrganization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Ramdas PaithankarNo ratings yet

- Description Date: ShiftDocument5 pagesDescription Date: ShiftRamdas PaithankarNo ratings yet

- Machine Capability StudyDocument1 pageMachine Capability StudyRamdas PaithankarNo ratings yet

- Contingency Plan 6.1.2.3Document15 pagesContingency Plan 6.1.2.3Ramdas PaithankarNo ratings yet

- Record of Deviation PermitconncessionDocument1 pageRecord of Deviation PermitconncessionRamdas PaithankarNo ratings yet

- Context of Organization 4.1Document1 pageContext of Organization 4.1Ramdas PaithankarNo ratings yet

- Communication Matrix 7.4Document2 pagesCommunication Matrix 7.4Ramdas PaithankarNo ratings yet

- Interasted Parties Needs and Expactation 4.2Document3 pagesInterasted Parties Needs and Expactation 4.2Ramdas PaithankarNo ratings yet

- Sample Trial Report Blank FormatDocument1 pageSample Trial Report Blank FormatRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Occurrence Rating Table3 PDFDocument1 pagePFMEA AIAG VDA Occurrence Rating Table3 PDFRamdas PaithankarNo ratings yet

- Conductor Resistance Test Data1Document1 pageConductor Resistance Test Data1Ramdas PaithankarNo ratings yet

- 3517 4Document4 pages3517 4Ramdas PaithankarNo ratings yet

- Amendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringDocument1 pageAmendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Action Priority AP Table PDFDocument2 pagesPFMEA AIAG VDA Action Priority AP Table PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- List of Document Review FrequentlyDocument1 pageList of Document Review FrequentlyRamdas PaithankarNo ratings yet

- Covid 19 FmeaDocument2 pagesCovid 19 FmeaRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Foundry PDFDocument1 pagePFMEA AIAG VDA Filled Example Foundry PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Severity Rating PDFDocument1 pagePFMEA AIAG VDA Severity Rating PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Heading Hints PDFDocument1 pagePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNo ratings yet

- Gage Linearity and AccuracyDocument10 pagesGage Linearity and AccuracyRamdas PaithankarNo ratings yet

- IS 8394 - Ring Terminal STDDocument8 pagesIS 8394 - Ring Terminal STDRamdas PaithankarNo ratings yet

- Calibration History CardDocument1 pageCalibration History CardRamdas PaithankarNo ratings yet

- D5031 DTS0283 enDocument2 pagesD5031 DTS0283 enmbidNo ratings yet

- LogDocument14 pagesLogpwettyzey 06No ratings yet

- 200+ SEO FactorsDocument6 pages200+ SEO FactorsSony HasanNo ratings yet

- SL - No: No. of Thin Client Installed Server Working Yes / No No. of Thin Client Working HM Contact NumerDocument3 pagesSL - No: No. of Thin Client Installed Server Working Yes / No No. of Thin Client Working HM Contact NumerDeo Lalgudi100% (1)

- Comandos P TDocument3 pagesComandos P TcarlosfkNo ratings yet

- Exercise 1: Pizza Class Represents A Type of Pizza That Belongs To The Pizzeria's MenuDocument4 pagesExercise 1: Pizza Class Represents A Type of Pizza That Belongs To The Pizzeria's MenuNguena EstherNo ratings yet

- Octane ManualDocument47 pagesOctane ManualConcón QuemaoNo ratings yet

- DS Module4Document27 pagesDS Module4Sreekesh GiriNo ratings yet

- HNGGDocument12 pagesHNGGAgriyae JainNo ratings yet

- INF1002S+Lecture+Schedule+ +2022+DRAFT+v01Document11 pagesINF1002S+Lecture+Schedule+ +2022+DRAFT+v01khavisaniNo ratings yet

- Military Engineer ServicesDocument1 pageMilitary Engineer Servicestariq hossainNo ratings yet

- Computer Organization Chapter 8 Short NoteDocument31 pagesComputer Organization Chapter 8 Short NoteMeskatul Islam2100% (1)

- Lecture 1 - IntroductionDocument27 pagesLecture 1 - IntroductionQwekem 482No ratings yet

- Introduction To Software EngineeringDocument24 pagesIntroduction To Software EngineeringidontKnow99No ratings yet

- ABAP Environment in SAP BTPDocument21 pagesABAP Environment in SAP BTPJosé Roberto Vieira SalumNo ratings yet

- Building The Web HTML5 and CSS3Document107 pagesBuilding The Web HTML5 and CSS3Roshan Chunduri100% (1)

- 08GDMDocument7 pages08GDMMokbelNo ratings yet

- Sonar™ 8: (Windows XP, Windows Vista)Document22 pagesSonar™ 8: (Windows XP, Windows Vista)Andhang HabsoroNo ratings yet

- Workshop: Mixing Tee: ANSYS Fluent Getting StartedDocument39 pagesWorkshop: Mixing Tee: ANSYS Fluent Getting StartedSahil Jawa100% (1)

- Hardware vs. Software ParallelismDocument55 pagesHardware vs. Software ParallelismSajendra Kumar50% (2)

- MiniLab Series BrochureDocument16 pagesMiniLab Series BrochureAlexander Rodriguez SarmientoNo ratings yet

- Professional Practices: Assignment # 03Document4 pagesProfessional Practices: Assignment # 03ammarNo ratings yet

- Lecture 1: Catalan Numbers and Recurrence RelationsDocument6 pagesLecture 1: Catalan Numbers and Recurrence RelationsNameet JainNo ratings yet

- Binary Adder: A Full Adder CircuitDocument8 pagesBinary Adder: A Full Adder CircuitSejal KankriyaNo ratings yet

- 15-Day Challenge: Programming For EntertainmentDocument7 pages15-Day Challenge: Programming For Entertainmentapi-557631218No ratings yet

- BURNDY YGHC26C2 SpecsheetDocument2 pagesBURNDY YGHC26C2 SpecsheetGUSTAVO GARCESNo ratings yet

- ST Thomas School Question For ComputerDocument2 pagesST Thomas School Question For ComputerLionelkeneth12No ratings yet

- Human Centered Ai Ben Shneiderman Full ChapterDocument67 pagesHuman Centered Ai Ben Shneiderman Full Chaptersammy.parkes464100% (10)

PFMEA AIAG VDA Detection Rating PDF

PFMEA AIAG VDA Detection Rating PDF

Uploaded by

Ramdas PaithankarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFMEA AIAG VDA Detection Rating PDF

PFMEA AIAG VDA Detection Rating PDF

Uploaded by

Ramdas PaithankarCopyright:

Available Formats

Business Data Direction businessdatadirection@gmail.

com

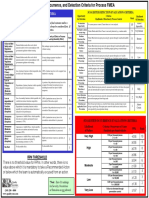

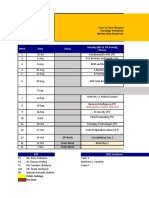

Detection potential (D) for the validation of the process design

Detection control rated according to detection method, maturity and opportunity for detection

DET Ability to Detection method maturity Opportunity for detection

No testing or inspection method has been

10 The failure mode will not or cannot be detected

established or is known

Very Low It is unlikely that the testing or inspection

9 method will detect the failure mode The failure mode is not easily detected through random or sporadic audits

Testing or inspection method has not human inspection (visual, tactile, audible), or use of manual gauging ( attribute or variable)

8

been proven to be effective and reliable that should detect the failure mode or failure cause

Low (i.e. plant has little or no experience with Machine based detection ( automated or semi automated with notification by light, buzzer,

7 method. Gauge R&R results marginal on etc.) or use of inspection equipment such as a coordinate measuring machine that should

comparable process or this application detect failure mode or failure cause.

Test or inspection method has been human inspection (visual, tactile, audible), or use of manual gauging ( attribute or variable)

6 proven to be effective and reliable (i.e that will detect the failure mode or failure cause (include product sample checks)

plant has experience with method; gauge

Moderate

R&R results are acceptable on Machine based detection (semi automated with notification by light, buzzer, etc.), or use of

5 comparable process or this application, inspection equipment such as coordinate measuring machine that will detect failure mode or

etc) failure cause (including product sample checks)

System has been proven to be effective Machine based automated detection method that will detect failure mode downstream,

and reliable (e.g. Plant has experience prevent further processing or system will identify the product as discrepant and allow it to

4 with method on identical process or this automatically move forward in the process until the designated reject unload area. Discrepant

application) gauge R&R result are product will be controlled by a robust system that will prevent outflow of the product from the

acceptable etc facility

Machine based automated detection method that will detect failure mode in station, prevent

further processing or system will identify the product as discrepant and allow it to

High

3 automatically move forward in the process until the designated reject unload area. Discrepant

product will be controlled by a robust system that will prevent outflow of the product from the

facility

Detection method has been proven

effective and reliable (e.g.. Plant has Machine based detection method that will detect the cause and prevent the failure mode

2

experience with method; error-proofing (discrepant part) from being produced

verification etc)

Failure mode cannot be physically produced as design or process or detection method proven to always detect the failure mode or

1 Very high

failure cause

Page | 1 of 1

You might also like

- Case-Astra ZenecaDocument20 pagesCase-Astra Zenecaish june100% (1)

- Testing IBE R2Document644 pagesTesting IBE R2claudia veraNo ratings yet

- Detection Table - AIAG-VDA Process FMEADocument1 pageDetection Table - AIAG-VDA Process FMEARaajha MunibathiranNo ratings yet

- Table P3 For Detection RatingDocument2 pagesTable P3 For Detection RatingAhmad Bin Ismail KhanNo ratings yet

- The 7 Steps of Process-FMEA: Step 1: Planning and PreparationDocument2 pagesThe 7 Steps of Process-FMEA: Step 1: Planning and PreparationTarun PrabhakarNo ratings yet

- Detection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionDocument1 pageDetection: Evaluation Criteria: Ref:As Per AIAG PFMEA Standards Ril/Pfmea/Annex-C Likelihood of DetectionaslamNo ratings yet

- DETECCIONDocument2 pagesDETECCIONlaacostam93No ratings yet

- PFMEA Reference Card PDFDocument2 pagesPFMEA Reference Card PDFRajesh Yadav100% (6)

- Detection ScaleDocument1 pageDetection ScaleSergio LoayzaNo ratings yet

- Guided By: Prof. A. D. PatilDocument14 pagesGuided By: Prof. A. D. Patilshubham puranikNo ratings yet

- 100 Most Popular Software Testing TermsDocument8 pages100 Most Popular Software Testing TermssuketsomNo ratings yet

- 21st Century CGMPDocument13 pages21st Century CGMPVidya PasalkarNo ratings yet

- Error Proofing TechniquesDocument38 pagesError Proofing TechniquesDeepali ParmarNo ratings yet

- The 4 Components of ZDQDocument37 pagesThe 4 Components of ZDQMuhammad Gullraiz ChohanNo ratings yet

- Software Quality Assurance: Dynamic Testing-IDocument36 pagesSoftware Quality Assurance: Dynamic Testing-IPro HammadNo ratings yet

- Error-Proofing PDFDocument28 pagesError-Proofing PDFDanang WidoyokoNo ratings yet

- Error-Proofing PDFDocument28 pagesError-Proofing PDFR.BALASUBRAMANINo ratings yet

- Testing Processes MethodologyDocument14 pagesTesting Processes Methodologyapi-3770281No ratings yet

- Fy11 sh-22316-11 3-3 MistakeProofingDocument20 pagesFy11 sh-22316-11 3-3 MistakeProofingMani PathakNo ratings yet

- Understanding QA System in Pharma Industry - 23092020Document31 pagesUnderstanding QA System in Pharma Industry - 23092020Anggia Bia Amanda100% (1)

- DFMEArefcard PDFDocument2 pagesDFMEArefcard PDFIgor PNo ratings yet

- What Is Software Testing?: Testing of Mobile ApplicationDocument7 pagesWhat Is Software Testing?: Testing of Mobile ApplicationSaurav JamwalNo ratings yet

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 pagesFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluNo ratings yet

- Cleaning Validation For PharmaDocument8 pagesCleaning Validation For Pharmaanalistaaseguramiento1.bontalNo ratings yet

- Poka-Yoke: A Strategy For Performance ExcellenceDocument12 pagesPoka-Yoke: A Strategy For Performance ExcellenceIndranilNo ratings yet

- Statistical Quality ControlDocument78 pagesStatistical Quality ControlalmazwmbashiraNo ratings yet

- Cleaning Validation AlconoxDocument8 pagesCleaning Validation AlconoxEDGARNo ratings yet

- Istqb Section OneDocument39 pagesIstqb Section OneBrandon SteelNo ratings yet

- Static TestingDocument10 pagesStatic TestingRitiesh BhatiaNo ratings yet

- Discuss The Various Techniques Deployed in Fault Removal in Fault ToleranceDocument3 pagesDiscuss The Various Techniques Deployed in Fault Removal in Fault ToleranceEmmanuel John AbahNo ratings yet

- IATF 16949 Awareness Training-Terms OnlyDocument18 pagesIATF 16949 Awareness Training-Terms Onlysuresh kumar67% (3)

- Domain4 - Build The Test EnvironmentDocument73 pagesDomain4 - Build The Test Environmentapi-19934187No ratings yet

- Poka Yoke and BrainstormingDocument18 pagesPoka Yoke and Brainstormingananda wahyuNo ratings yet

- CS335 Testing LectureDocument64 pagesCS335 Testing LectureDoreen EmmanuelNo ratings yet

- 100 Most Popular Software Testing TermsDocument9 pages100 Most Popular Software Testing TermszoconNo ratings yet

- Touchless Testing PlatformDocument9 pagesTouchless Testing PlatformPrasanna KrishnaNo ratings yet

- Software mst-3Document25 pagesSoftware mst-3kalpitrawat16908No ratings yet

- MeasureDocument51 pagesMeasureAshwani KumarNo ratings yet

- Glossary Test TerminologyDocument8 pagesGlossary Test Terminologymgr810No ratings yet

- Poka YokeDocument17 pagesPoka YokePranav SharmaNo ratings yet

- 2024 - 05 - Objectives and Principles of Test AutomationDocument76 pages2024 - 05 - Objectives and Principles of Test AutomationMahammadali AbaszadaNo ratings yet

- Risk Based Approach To ValidationDocument6 pagesRisk Based Approach To ValidationAlex CristiNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- Manual TestingDocument4 pagesManual TestingAndreea LilianaNo ratings yet

- IEEE STDocument3 pagesIEEE STprithikamohankumar04No ratings yet

- OOSE Unit 4 NotesDocument17 pagesOOSE Unit 4 Notesrakshithaashok247No ratings yet

- Hybrid Model For Penetration TestingDocument8 pagesHybrid Model For Penetration TestinghappiestmindsNo ratings yet

- Six Sigma Analyze PhaseDocument12 pagesSix Sigma Analyze PhaseerinelNo ratings yet

- Chapter 2 What Is Software QualityDocument11 pagesChapter 2 What Is Software QualitytanzilaNo ratings yet

- "Failure Modes and Effect Analysis of S - Type Nozzle": A Project OnDocument15 pages"Failure Modes and Effect Analysis of S - Type Nozzle": A Project Onuujaval pavarNo ratings yet

- Istqb F.L. Glossary Chapter 2Document8 pagesIstqb F.L. Glossary Chapter 2karishma100% (1)

- 02 - Control of Non Corforming Product Sep13Document67 pages02 - Control of Non Corforming Product Sep13Mojtaba MousaviNo ratings yet

- Progress Report 3 PANKAJDocument5 pagesProgress Report 3 PANKAJWall HackNo ratings yet

- 7-Step Pocket GuideDocument2 pages7-Step Pocket Guidesutra01No ratings yet

- Unit Iv Testing: 4.1taxonomy of Software TestingDocument28 pagesUnit Iv Testing: 4.1taxonomy of Software TestingTanish PantNo ratings yet

- Delmia DPM M7 - Tool ValidationDocument59 pagesDelmia DPM M7 - Tool Validationkakaka22No ratings yet

- RAMS Optimum Inspection IntervalDocument8 pagesRAMS Optimum Inspection IntervalSrinivas PothulaNo ratings yet

- Testing Techniques For Software Validation: EmailDocument157 pagesTesting Techniques For Software Validation: EmailGarvit jethwaniNo ratings yet

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- Corporate ResponsibilityDocument1 pageCorporate ResponsibilityRamdas PaithankarNo ratings yet

- Capacity Analysis ReportDocument7 pagesCapacity Analysis ReportRamdas PaithankarNo ratings yet

- Quality Policy - 5.2Document1 pageQuality Policy - 5.2Ramdas Paithankar100% (1)

- Pareto Chart Excel TemplateDocument4 pagesPareto Chart Excel TemplateRamdas PaithankarNo ratings yet

- Organization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Document3 pagesOrganization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Ramdas PaithankarNo ratings yet

- Description Date: ShiftDocument5 pagesDescription Date: ShiftRamdas PaithankarNo ratings yet

- Machine Capability StudyDocument1 pageMachine Capability StudyRamdas PaithankarNo ratings yet

- Contingency Plan 6.1.2.3Document15 pagesContingency Plan 6.1.2.3Ramdas PaithankarNo ratings yet

- Record of Deviation PermitconncessionDocument1 pageRecord of Deviation PermitconncessionRamdas PaithankarNo ratings yet

- Context of Organization 4.1Document1 pageContext of Organization 4.1Ramdas PaithankarNo ratings yet

- Communication Matrix 7.4Document2 pagesCommunication Matrix 7.4Ramdas PaithankarNo ratings yet

- Interasted Parties Needs and Expactation 4.2Document3 pagesInterasted Parties Needs and Expactation 4.2Ramdas PaithankarNo ratings yet

- Sample Trial Report Blank FormatDocument1 pageSample Trial Report Blank FormatRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Occurrence Rating Table3 PDFDocument1 pagePFMEA AIAG VDA Occurrence Rating Table3 PDFRamdas PaithankarNo ratings yet

- Conductor Resistance Test Data1Document1 pageConductor Resistance Test Data1Ramdas PaithankarNo ratings yet

- 3517 4Document4 pages3517 4Ramdas PaithankarNo ratings yet

- Amendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringDocument1 pageAmendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Action Priority AP Table PDFDocument2 pagesPFMEA AIAG VDA Action Priority AP Table PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- List of Document Review FrequentlyDocument1 pageList of Document Review FrequentlyRamdas PaithankarNo ratings yet

- Covid 19 FmeaDocument2 pagesCovid 19 FmeaRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Foundry PDFDocument1 pagePFMEA AIAG VDA Filled Example Foundry PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Severity Rating PDFDocument1 pagePFMEA AIAG VDA Severity Rating PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Heading Hints PDFDocument1 pagePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNo ratings yet

- Gage Linearity and AccuracyDocument10 pagesGage Linearity and AccuracyRamdas PaithankarNo ratings yet

- IS 8394 - Ring Terminal STDDocument8 pagesIS 8394 - Ring Terminal STDRamdas PaithankarNo ratings yet

- Calibration History CardDocument1 pageCalibration History CardRamdas PaithankarNo ratings yet

- D5031 DTS0283 enDocument2 pagesD5031 DTS0283 enmbidNo ratings yet

- LogDocument14 pagesLogpwettyzey 06No ratings yet

- 200+ SEO FactorsDocument6 pages200+ SEO FactorsSony HasanNo ratings yet

- SL - No: No. of Thin Client Installed Server Working Yes / No No. of Thin Client Working HM Contact NumerDocument3 pagesSL - No: No. of Thin Client Installed Server Working Yes / No No. of Thin Client Working HM Contact NumerDeo Lalgudi100% (1)

- Comandos P TDocument3 pagesComandos P TcarlosfkNo ratings yet

- Exercise 1: Pizza Class Represents A Type of Pizza That Belongs To The Pizzeria's MenuDocument4 pagesExercise 1: Pizza Class Represents A Type of Pizza That Belongs To The Pizzeria's MenuNguena EstherNo ratings yet

- Octane ManualDocument47 pagesOctane ManualConcón QuemaoNo ratings yet

- DS Module4Document27 pagesDS Module4Sreekesh GiriNo ratings yet

- HNGGDocument12 pagesHNGGAgriyae JainNo ratings yet

- INF1002S+Lecture+Schedule+ +2022+DRAFT+v01Document11 pagesINF1002S+Lecture+Schedule+ +2022+DRAFT+v01khavisaniNo ratings yet

- Military Engineer ServicesDocument1 pageMilitary Engineer Servicestariq hossainNo ratings yet

- Computer Organization Chapter 8 Short NoteDocument31 pagesComputer Organization Chapter 8 Short NoteMeskatul Islam2100% (1)

- Lecture 1 - IntroductionDocument27 pagesLecture 1 - IntroductionQwekem 482No ratings yet

- Introduction To Software EngineeringDocument24 pagesIntroduction To Software EngineeringidontKnow99No ratings yet

- ABAP Environment in SAP BTPDocument21 pagesABAP Environment in SAP BTPJosé Roberto Vieira SalumNo ratings yet

- Building The Web HTML5 and CSS3Document107 pagesBuilding The Web HTML5 and CSS3Roshan Chunduri100% (1)

- 08GDMDocument7 pages08GDMMokbelNo ratings yet

- Sonar™ 8: (Windows XP, Windows Vista)Document22 pagesSonar™ 8: (Windows XP, Windows Vista)Andhang HabsoroNo ratings yet

- Workshop: Mixing Tee: ANSYS Fluent Getting StartedDocument39 pagesWorkshop: Mixing Tee: ANSYS Fluent Getting StartedSahil Jawa100% (1)

- Hardware vs. Software ParallelismDocument55 pagesHardware vs. Software ParallelismSajendra Kumar50% (2)

- MiniLab Series BrochureDocument16 pagesMiniLab Series BrochureAlexander Rodriguez SarmientoNo ratings yet

- Professional Practices: Assignment # 03Document4 pagesProfessional Practices: Assignment # 03ammarNo ratings yet

- Lecture 1: Catalan Numbers and Recurrence RelationsDocument6 pagesLecture 1: Catalan Numbers and Recurrence RelationsNameet JainNo ratings yet

- Binary Adder: A Full Adder CircuitDocument8 pagesBinary Adder: A Full Adder CircuitSejal KankriyaNo ratings yet

- 15-Day Challenge: Programming For EntertainmentDocument7 pages15-Day Challenge: Programming For Entertainmentapi-557631218No ratings yet

- BURNDY YGHC26C2 SpecsheetDocument2 pagesBURNDY YGHC26C2 SpecsheetGUSTAVO GARCESNo ratings yet

- ST Thomas School Question For ComputerDocument2 pagesST Thomas School Question For ComputerLionelkeneth12No ratings yet

- Human Centered Ai Ben Shneiderman Full ChapterDocument67 pagesHuman Centered Ai Ben Shneiderman Full Chaptersammy.parkes464100% (10)