Professional Documents

Culture Documents

PFMEA AIAG VDA Occurrence Rating Table2 PDF

PFMEA AIAG VDA Occurrence Rating Table2 PDF

Uploaded by

Ramdas PaithankarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFMEA AIAG VDA Occurrence Rating Table2 PDF

PFMEA AIAG VDA Occurrence Rating Table2 PDF

Uploaded by

Ramdas PaithankarCopyright:

Available Formats

Business Data Direction businessdatadirection@gmail.

com

Occurrence potential (O) for the process

Potential Failure Causes rated according to the criteria below. Consider Prevention Controls when determining the best Occurrence

estimate, Occurrence is predictive qualitative rating made at the time of evaluation and may not reflect the actual occurrence. The

occurrence rating number is relative rating within the scope of FMEA (process being evaluated). For Prevention Controls with multiple

Occurrence Ratings, use the rating that best reflects the robustness of the control.

OCC Incidents per 100 item/vehicles Type of controls Prevention controls

10 >=100 per thousands 1/=1 in 10 None No prevention control.

9 50 per thousands 1 in 20

Prevention control will have little effect in preventing failure

Behavioral

cause

8 20 per thousands 1 in 50

7 10 per 1000 1 in 100

Prevention control somewhat effective in preventing failure

cause

6 2 per thousand 1 in 500

Behavioral or

technical

5 .5 per thousand 1 in 2000

Prevention control are effective in preventing failure cause

4 .1 per thousand 1 in 10000

3 .01 per thousand 1 in 100000 Best practices:

Prevention control are highly effective in preventing failure

Behavioral or

cause

2 <.001 per thousand 1 in 1000000 technical

Prevention control are extremely effective in preventing

failure cause from occurring due to design ( e.g. part

Failure is eliminated through prevention

1 Technical geometry) or process (e.g. fixture of tooling design). Intent of

control

prevention controls- failure mode cannot be physically

produced due to the failure cause.

Page | 1 of 1

You might also like

- Risk Assessment Example 1Document3 pagesRisk Assessment Example 1miptahul100% (3)

- Risk Assessment in HospitalDocument71 pagesRisk Assessment in HospitalHeba Hany100% (1)

- Pfmea Ranking TableDocument3 pagesPfmea Ranking TableKrunal Pandya100% (3)

- Final Year Project Report (Solar Cooker)Document31 pagesFinal Year Project Report (Solar Cooker)Deborshi Parasor100% (1)

- Honeywell Webinar QA Alarm Management WorkflowDocument9 pagesHoneywell Webinar QA Alarm Management Workflowfahim47No ratings yet

- Occurrence Table - AIAG-VDA Process FMEADocument3 pagesOccurrence Table - AIAG-VDA Process FMEARaajha MunibathiranNo ratings yet

- OccurrenceDocument1 pageOccurrenceBrenda GillNo ratings yet

- PFMEA AIAG VDA Occurrence Rating Table1 PDFDocument1 pagePFMEA AIAG VDA Occurrence Rating Table1 PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Occurrence Rating Table3 PDFDocument1 pagePFMEA AIAG VDA Occurrence Rating Table3 PDFRamdas PaithankarNo ratings yet

- SeverityDocument10 pagesSeverityVijayamalar AmruthalingamNo ratings yet

- Xfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument8 pagesXfmea Report Sample - Process FMEA: in Addition To This Summary, This Report Includes The Following Formssenzo scholar100% (1)

- PFMEA Ranking Table Rating Criteria Action GuidelineDocument10 pagesPFMEA Ranking Table Rating Criteria Action GuidelineEnrico Miguel AquinoNo ratings yet

- IEC 60601-1 Section 4.3 Essential Performance: Identify Low Level Failure Mode and Link It To Design OutputDocument3 pagesIEC 60601-1 Section 4.3 Essential Performance: Identify Low Level Failure Mode and Link It To Design Outputjingyong123No ratings yet

- OccuranceDocument1 pageOccuranceQuality VenusNo ratings yet

- ABB Alarm Management Fingerprint v1 19apr12Document8 pagesABB Alarm Management Fingerprint v1 19apr12Ahmed KhairyNo ratings yet

- SOD: Table SOD: Table: Failure Mode and Effects Analysis Failure Mode and Effects AnalysisDocument4 pagesSOD: Table SOD: Table: Failure Mode and Effects Analysis Failure Mode and Effects AnalysisGaurav NagpalNo ratings yet

- Pest Management Decision-Making: The Economic-Injury Level ConceptDocument2 pagesPest Management Decision-Making: The Economic-Injury Level ConceptharyadintNo ratings yet

- Taking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsDocument5 pagesTaking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsMuhammad SalmanNo ratings yet

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pages"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77No ratings yet

- Design and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Document19 pagesDesign and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Mohammed KassemNo ratings yet

- Alarm Management: Meet The Experts - Sept. 20/21., 2011Document38 pagesAlarm Management: Meet The Experts - Sept. 20/21., 2011ValterFélixJrCarvalhoNo ratings yet

- FEMEA Ranking TablesDocument3 pagesFEMEA Ranking TablesAhmed KsibiNo ratings yet

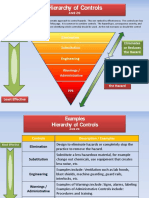

- Hierarchy of Risk Controls: Key LegislationDocument6 pagesHierarchy of Risk Controls: Key LegislationNaba majeadNo ratings yet

- Measuring Alarm System EffectivenessDocument2 pagesMeasuring Alarm System Effectivenessbilbil05No ratings yet

- WKEO SIF WorkSheetDocument66 pagesWKEO SIF WorkSheetheikal hajazieNo ratings yet

- Sevrity Reating Table Old & NewDocument26 pagesSevrity Reating Table Old & NewSibaram DasNo ratings yet

- Infographics Alarm-Management-Wonderware 082016Document1 pageInfographics Alarm-Management-Wonderware 082016sumankumar37No ratings yet

- 6 Mitig and Monitoring Jun08 TZDocument25 pages6 Mitig and Monitoring Jun08 TZcvbn bnNo ratings yet

- Risk Assessment Procedure Step Wise GuideDocument6 pagesRisk Assessment Procedure Step Wise GuidemostafaNo ratings yet

- Human Factors in AccidentsDocument7 pagesHuman Factors in Accidentsdafield.192No ratings yet

- JSA HEMP Well Services Pg01-05Document5 pagesJSA HEMP Well Services Pg01-05Ashok SureshNo ratings yet

- Bab 16Document11 pagesBab 1621013010069 MUHAMMAD NOVIAN GILANG RAMADHANNo ratings yet

- KT-ISMS-FR-05 Information Security Risk AssessmentDocument1 pageKT-ISMS-FR-05 Information Security Risk AssessmentAdil AbdulkhaderNo ratings yet

- Hierarchy of ControlsDocument2 pagesHierarchy of ControlsAbhash AryanNo ratings yet

- Hierarchy of Controls Web Version.Document2 pagesHierarchy of Controls Web Version.Anandhu100% (2)

- Scopy-Risk Assessment - ManagementDocument47 pagesScopy-Risk Assessment - ManagementnuwanNo ratings yet

- 10 Situational Awareness PDFDocument40 pages10 Situational Awareness PDFsyed muffassirNo ratings yet

- FMEA Ranking TableDocument4 pagesFMEA Ranking TableShyam KushanaNo ratings yet

- Risktec Solutions: Bowties - One Size Fits All?Document24 pagesRisktec Solutions: Bowties - One Size Fits All?paul_bright100% (1)

- PFMEA RankingDocument1 pagePFMEA RankingSachin KumbharNo ratings yet

- CH 2 4088 SaftyDocument32 pagesCH 2 4088 SaftyEsubalew BelayNo ratings yet

- How Plant Wellness Reduces Failure Rates and Maintenance CostsDocument4 pagesHow Plant Wellness Reduces Failure Rates and Maintenance CostsAlghurobaNo ratings yet

- Rotek Valves Risk Assessment - Process: If You Have Any Questions, Please Contact The ManagerDocument3 pagesRotek Valves Risk Assessment - Process: If You Have Any Questions, Please Contact The ManagerPieter BezuidenhoutNo ratings yet

- LOPA Tutorial: Figure 1. Layers of Protection Example VisualDocument11 pagesLOPA Tutorial: Figure 1. Layers of Protection Example VisualAbdelsalam ShihaNo ratings yet

- HTLWHS002 AT4A Risk Assessment Control 0521Document6 pagesHTLWHS002 AT4A Risk Assessment Control 0521Soumyanil BabiNo ratings yet

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- IT Governance Risk Register TemplateDocument3 pagesIT Governance Risk Register TemplateMohanNo ratings yet

- Tabla de Frecuencias TipicasDocument8 pagesTabla de Frecuencias TipicasÁngel Alberto Mathieu HanoNo ratings yet

- 0100 1042 PDFDocument112 pages0100 1042 PDFmiturraNo ratings yet

- Economics in LCMDocument36 pagesEconomics in LCMSn Carbonel100% (1)

- Exida Webinar Benchmarking Practices For The Use of Alarms As Safeguards and IPLs PDFDocument41 pagesExida Webinar Benchmarking Practices For The Use of Alarms As Safeguards and IPLs PDFSelvakumar JNo ratings yet

- Chapter 8Document19 pagesChapter 8Fazal KarimNo ratings yet

- +PFMEA Rating Scale GuidelinesDocument2 pages+PFMEA Rating Scale GuidelinesBalaji SNo ratings yet

- Alarm Shelving Exida Ebook PDFDocument26 pagesAlarm Shelving Exida Ebook PDFmilton100% (3)

- Bow Tie SafetyDocument15 pagesBow Tie SafetyAshish Mishra100% (1)

- Why We Need Effective Alarm Management White PaperDocument8 pagesWhy We Need Effective Alarm Management White PaperMaria Regina ReyesNo ratings yet

- SIL Determination-Mode of Operation PDFDocument6 pagesSIL Determination-Mode of Operation PDFchem_taNo ratings yet

- Infection Control Risk Assessment Tool 1208Document8 pagesInfection Control Risk Assessment Tool 1208Tribot ArwanaNo ratings yet

- Process Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaDocument4 pagesProcess Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaSelvakumaran Dhandapani100% (1)

- Plug The Holes in The Swiss Chesse Model - CEP - 20170946Document5 pagesPlug The Holes in The Swiss Chesse Model - CEP - 20170946gwinnruNo ratings yet

- Description Date: ShiftDocument5 pagesDescription Date: ShiftRamdas PaithankarNo ratings yet

- Quality Policy - 5.2Document1 pageQuality Policy - 5.2Ramdas Paithankar100% (1)

- Machine Capability StudyDocument1 pageMachine Capability StudyRamdas PaithankarNo ratings yet

- Organization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Document3 pagesOrganization Level - Internal & External Issues& Requirements of Interested Parties-New 11-11-17Ramdas PaithankarNo ratings yet

- Capacity Analysis ReportDocument7 pagesCapacity Analysis ReportRamdas PaithankarNo ratings yet

- Corporate ResponsibilityDocument1 pageCorporate ResponsibilityRamdas PaithankarNo ratings yet

- Interasted Parties Needs and Expactation 4.2Document3 pagesInterasted Parties Needs and Expactation 4.2Ramdas PaithankarNo ratings yet

- Context of Organization 4.1Document1 pageContext of Organization 4.1Ramdas PaithankarNo ratings yet

- Communication Matrix 7.4Document2 pagesCommunication Matrix 7.4Ramdas PaithankarNo ratings yet

- Contingency Plan 6.1.2.3Document15 pagesContingency Plan 6.1.2.3Ramdas PaithankarNo ratings yet

- Pareto Chart Excel TemplateDocument4 pagesPareto Chart Excel TemplateRamdas PaithankarNo ratings yet

- Sample Trial Report Blank FormatDocument1 pageSample Trial Report Blank FormatRamdas PaithankarNo ratings yet

- Record of Deviation PermitconncessionDocument1 pageRecord of Deviation PermitconncessionRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Foundry PDFDocument1 pagePFMEA AIAG VDA Filled Example Foundry PDFRamdas PaithankarNo ratings yet

- List of Document Review FrequentlyDocument1 pageList of Document Review FrequentlyRamdas PaithankarNo ratings yet

- 3517 4Document4 pages3517 4Ramdas PaithankarNo ratings yet

- Conductor Resistance Test Data1Document1 pageConductor Resistance Test Data1Ramdas PaithankarNo ratings yet

- PFMEA AIAG VDA Filled Example Assly PDFDocument1 pagePFMEA AIAG VDA Filled Example Assly PDFRamdas PaithankarNo ratings yet

- Covid 19 FmeaDocument2 pagesCovid 19 FmeaRamdas PaithankarNo ratings yet

- Gage Linearity and AccuracyDocument10 pagesGage Linearity and AccuracyRamdas PaithankarNo ratings yet

- Calibration History CardDocument1 pageCalibration History CardRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Severity Rating PDFDocument1 pagePFMEA AIAG VDA Severity Rating PDFRamdas PaithankarNo ratings yet

- Amendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringDocument1 pageAmendment No. 1 December 1980 IS: 8395 (Part I) - 1977 SPECIFICATION FOR Cable Terminations For Automobile WiringRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Heading Hints PDFDocument1 pagePFMEA AIAG VDA Heading Hints PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Action Priority AP Table PDFDocument2 pagesPFMEA AIAG VDA Action Priority AP Table PDFRamdas PaithankarNo ratings yet

- PFMEA AIAG VDA Occurrence Rating Table3 PDFDocument1 pagePFMEA AIAG VDA Occurrence Rating Table3 PDFRamdas PaithankarNo ratings yet

- IS 8394 - Ring Terminal STDDocument8 pagesIS 8394 - Ring Terminal STDRamdas PaithankarNo ratings yet

- Refinery Construcion Project KARBALA IRAQ 1609420219Document16 pagesRefinery Construcion Project KARBALA IRAQ 1609420219Clever RoseNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Darshan PanchalNo ratings yet

- Assembly - August 2017Document84 pagesAssembly - August 2017Varun KumarNo ratings yet

- 544-09 - Heat MGMTDocument22 pages544-09 - Heat MGMTHENIGUEDRINo ratings yet

- Syllabus Bs It MSC It Computer Science UosDocument10 pagesSyllabus Bs It MSC It Computer Science UosHamza Masood0% (1)

- Modeling and Analysis of Contingency AnaDocument25 pagesModeling and Analysis of Contingency AnaSatya Jagadeesh TatisettiNo ratings yet

- TCS - Mock Paper 1Document36 pagesTCS - Mock Paper 1CS2146Sakshi KhatkeNo ratings yet

- Cyber Attacks & Hacking: S. R. ShindeDocument70 pagesCyber Attacks & Hacking: S. R. ShindeAkshay GadeNo ratings yet

- A Complete Guide To Voice Over Internet ProtocolDocument11 pagesA Complete Guide To Voice Over Internet ProtocolChloe BeckhamNo ratings yet

- Nist Small Business Fundamentals July 2019Document48 pagesNist Small Business Fundamentals July 2019maria.procopovici.contractorNo ratings yet

- Assignment5 CLO3-SolDocument11 pagesAssignment5 CLO3-SolMuhammad AbdullahNo ratings yet

- Sentimental Analysis of Amazon Reviews Using NaiveDocument11 pagesSentimental Analysis of Amazon Reviews Using NaiveANJALI DEORENo ratings yet

- Transcript 8 - Histogram ExcelDocument1 pageTranscript 8 - Histogram ExcelRetno TriyaniNo ratings yet

- 3116 Block Head Bolt Hole Salvage GuideDocument15 pages3116 Block Head Bolt Hole Salvage GuideChrisdian FaraniNo ratings yet

- Question Chapter 6Document4 pagesQuestion Chapter 6umijannah1904No ratings yet

- MessagesDocument2 pagesMessageswai waiNo ratings yet

- UOP Horizontal Adsorber Unloading Loading SOPDocument17 pagesUOP Horizontal Adsorber Unloading Loading SOPGaurav GuptaNo ratings yet

- FeedDocument45 pagesFeedcristianNo ratings yet

- 2024 NEW PRICE FLYER (National)Document2 pages2024 NEW PRICE FLYER (National)chidieberendukweokpanNo ratings yet

- ABPM Quick StartDocument2 pagesABPM Quick StartMauricioDinizNo ratings yet

- PMM711S Unit 1Document48 pagesPMM711S Unit 1Laimi MutikishaNo ratings yet

- Chain Crosby® Grade 100Document1 pageChain Crosby® Grade 100CROSBYNo ratings yet

- UI Design Using InkscapeDocument31 pagesUI Design Using InkscapekumareshNo ratings yet

- Business Modeler IdeDocument1,120 pagesBusiness Modeler IdeSarvesh GhudusNo ratings yet

- Scheduling Concurrent Program in Oracle Apps - ErpschoolsDocument8 pagesScheduling Concurrent Program in Oracle Apps - ErpschoolsKhanBabaNo ratings yet

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaNo ratings yet

- Vande Bharat CaseDocument34 pagesVande Bharat CaseKLN CHUNo ratings yet

- ManualDocument482 pagesManualAri NugrohoNo ratings yet

- APsystems YC600 2019 10 ENDocument2 pagesAPsystems YC600 2019 10 ENCarlos BrancoNo ratings yet