Professional Documents

Culture Documents

Plaster Printed Finish TDS

Plaster Printed Finish TDS

Uploaded by

Omer TageldinCopyright:

Available Formats

You might also like

- Amalgam FailuresDocument16 pagesAmalgam Failuresrasagna reddyNo ratings yet

- Plaster Coarse Finish TDSDocument1 pagePlaster Coarse Finish TDSOmer TageldinNo ratings yet

- Plaster Stone Finish TDSDocument1 pagePlaster Stone Finish TDSOmer TageldinNo ratings yet

- Skin TDSDocument1 pageSkin TDSOmer TageldinNo ratings yet

- Cement Clay Plaster TDSDocument1 pageCement Clay Plaster TDSOmer TageldinNo ratings yet

- Technical Bulletin Plaste-Fix FinDocument2 pagesTechnical Bulletin Plaste-Fix FinVirah Sammy ChandraNo ratings yet

- Bostic - TDSDocument2 pagesBostic - TDSSatheesh KumarNo ratings yet

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Document5 pages4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808No ratings yet

- 0839 Sigmacryl SilkDocument2 pages0839 Sigmacryl SilkSyed AliNo ratings yet

- 4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5Document4 pages4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5yoxan25808No ratings yet

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Document5 pages8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808No ratings yet

- 0837 Sigma Profile Extra FineDocument2 pages0837 Sigma Profile Extra Fineمحمد عزتNo ratings yet

- Novo PRO Alkyd GlossyDocument1 pageNovo PRO Alkyd Glossywael barbaryNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Maxiseal Plus: Features / BenefitsDocument3 pagesMaxiseal Plus: Features / Benefitsannayya.chandrashekar Civil EngineerNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocument2 pagesConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNo ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- Bond Aid 100 - TDSDocument2 pagesBond Aid 100 - TDSAnoop ShankarNo ratings yet

- Capaland Plus TDSDocument2 pagesCapaland Plus TDSAnant JadhavNo ratings yet

- Nerolac Cement PuttyDocument2 pagesNerolac Cement PuttyNesiNo ratings yet

- Ready Mix Plaster: What Is MORTAR ?Document11 pagesReady Mix Plaster: What Is MORTAR ?nagesh raoNo ratings yet

- Plaster Binder: Product DescriptionDocument2 pagesPlaster Binder: Product DescriptionTAPANo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Sikalatex SuperDocument3 pagesSikalatex SuperAkash ChardeNo ratings yet

- Cemento PulidoDocument2 pagesCemento Pulidogeric1446No ratings yet

- Sikatop - 122Document3 pagesSikatop - 122YOSAFAT YUDHA GUNTORONo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- 0852 Sigma Acrylic Primer Sealer PDFDocument2 pages0852 Sigma Acrylic Primer Sealer PDFAhmed SakrNo ratings yet

- Sika Nigeria - Sika Grout 212 - V2Document3 pagesSika Nigeria - Sika Grout 212 - V2willy iremNo ratings yet

- Cemfair SmoothDocument2 pagesCemfair Smoothosama mohNo ratings yet

- Drybase Universal Mortar Datasheet PDFDocument2 pagesDrybase Universal Mortar Datasheet PDFdiribaNo ratings yet

- TDS - GypEX Silver PlasterDocument4 pagesTDS - GypEX Silver Plastersuyog kattelNo ratings yet

- Preserva PlusDocument3 pagesPreserva Plustiwari.onkarNo ratings yet

- Pinnacle Technical Dta Sheet Data SheetDocument3 pagesPinnacle Technical Dta Sheet Data SheetdubondsocialmediaNo ratings yet

- Ds Duralatex 1Document2 pagesDs Duralatex 1KeJeNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Gyproc Supreme 80 One Coat Gypsum PlasterDocument3 pagesGyproc Supreme 80 One Coat Gypsum PlasterSwapnil JadhavNo ratings yet

- Plast: Very Fast. Absolutely SmoothDocument2 pagesPlast: Very Fast. Absolutely Smoothsachinkarape4844100% (1)

- Technical Information ASSET DOC LOC 8749100Document3 pagesTechnical Information ASSET DOC LOC 8749100dongheep811No ratings yet

- PlasteringDocument15 pagesPlasteringMegha RajNo ratings yet

- Kilz Restoration Tds Canada Ce v3 FDocument2 pagesKilz Restoration Tds Canada Ce v3 FBM HướngNo ratings yet

- Dulux Trade Ecosure Plaster PrimerDocument5 pagesDulux Trade Ecosure Plaster PrimerEl Bekkari MohamedNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Slurry Bond: Liquid Polymer Modified High Strength AdhesiveDocument4 pagesSlurry Bond: Liquid Polymer Modified High Strength AdhesiveMahla Raj KumarNo ratings yet

- Davco Super TTB 998Document3 pagesDavco Super TTB 998JU SHUANGNo ratings yet

- Granite Polymer c2 - TdsDocument1 pageGranite Polymer c2 - TdsryanNo ratings yet

- Ornamental Sealer: Product InformationDocument4 pagesOrnamental Sealer: Product InformationGuruNo ratings yet

- 25 KG Gyproc Elite 100 One Coat Gypsum PlasterDocument3 pages25 KG Gyproc Elite 100 One Coat Gypsum Plastersyedaliabl2023No ratings yet

- E.MIX FinishDocument2 pagesE.MIX Finishsiti hanisahNo ratings yet

- Mirac Sealer ESDocument1 pageMirac Sealer ESChristinaNo ratings yet

- Consol CosmeticDocument2 pagesConsol Cosmeticotong geyongNo ratings yet

- Graphenstone TDS - MortarBase-Premium - 2018Document2 pagesGraphenstone TDS - MortarBase-Premium - 2018Nicholas ThengNo ratings yet

- Coverage:: Product DescriptionDocument2 pagesCoverage:: Product DescriptionAb KhawlhringNo ratings yet

- Sikaceram - 116 StandardDocument3 pagesSikaceram - 116 StandardMash-out VivA (www.VivA.com)No ratings yet

- Basf Mastertile 333 TdsDocument3 pagesBasf Mastertile 333 TdsdipinnediyaparambathNo ratings yet

- 01 - TDS PCI Primer GisogrundDocument4 pages01 - TDS PCI Primer GisogrundAlexi ALfred H. TagoNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- 9000 شهادة نظام إدارة الجودةDocument1 page9000 شهادة نظام إدارة الجودةOmer TageldinNo ratings yet

- شهادة التصنيف الائتماني AAADocument1 pageشهادة التصنيف الائتماني AAAOmer TageldinNo ratings yet

- معلومات تأهيل المختبرDocument1 pageمعلومات تأهيل المختبرOmer TageldinNo ratings yet

- الشهادة الموصى بها لوكالة تقييم حماية مستوى أمان الشبكة (New-Seal)Document1 pageالشهادة الموصى بها لوكالة تقييم حماية مستوى أمان الشبكة (New-Seal)Omer TageldinNo ratings yet

- شهادة تأهيل فريق تقييم المعلوماتDocument1 pageشهادة تأهيل فريق تقييم المعلوماتOmer TageldinNo ratings yet

- شهادة تأهيل فريق تقييم المعلومات PDFDocument1 pageشهادة تأهيل فريق تقييم المعلومات PDFOmer TageldinNo ratings yet

- شهادة معايرة أجهزة المختبرDocument1 pageشهادة معايرة أجهزة المختبرOmer TageldinNo ratings yet

- Skin TDSDocument1 pageSkin TDSOmer TageldinNo ratings yet

- Top Crete TDSDocument1 pageTop Crete TDSOmer TageldinNo ratings yet

- Plaster Coarse Finish TDSDocument1 pagePlaster Coarse Finish TDSOmer TageldinNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Cement Clay Plaster TDSDocument1 pageCement Clay Plaster TDSOmer TageldinNo ratings yet

- Plaster Stone Finish TDSDocument1 pagePlaster Stone Finish TDSOmer TageldinNo ratings yet

- إجراء المنح لمنتج الخرسانة جاهزة الخلط QMS-CR-10-08Document58 pagesإجراء المنح لمنتج الخرسانة جاهزة الخلط QMS-CR-10-08Omer TageldinNo ratings yet

- Integral Color TDSDocument2 pagesIntegral Color TDSOmer TageldinNo ratings yet

- Release Agent TDSDocument1 pageRelease Agent TDSOmer TageldinNo ratings yet

- Color Hardner TDSDocument2 pagesColor Hardner TDSOmer TageldinNo ratings yet

- Qic Invited Supplier Registration Process GuideDocument7 pagesQic Invited Supplier Registration Process GuideOmer TageldinNo ratings yet

- Whether Ordinance On Self-Denial of Nuclear Power Harmful To IndiaDocument55 pagesWhether Ordinance On Self-Denial of Nuclear Power Harmful To IndiabksubbaraoNo ratings yet

- James Joyce and The English ViceDocument14 pagesJames Joyce and The English Vicejanna100% (1)

- Sol-Gel Methods PDFDocument19 pagesSol-Gel Methods PDFDimitrios Tsiplakides100% (2)

- Technical Datasheet of SBRDocument13 pagesTechnical Datasheet of SBRKSPCB KalaburagiNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Definition of Biomedical Model of HealthDocument4 pagesDefinition of Biomedical Model of Healthتالیہ مرادNo ratings yet

- Chen 2021Document19 pagesChen 2021saka healthNo ratings yet

- Lefatshe La Botswana)Document21 pagesLefatshe La Botswana)nicNo ratings yet

- CDS57006 Bosch LSU 4.9 Sensor PDFDocument4 pagesCDS57006 Bosch LSU 4.9 Sensor PDFAnonymous K3FaYFlNo ratings yet

- BasuhTanganDenganBetul BIDocument1 pageBasuhTanganDenganBetul BIAdnan ShamsudinNo ratings yet

- PROLYMERDocument2 pagesPROLYMERFlavio GonzalezNo ratings yet

- Sudip Praposal - 1Document20 pagesSudip Praposal - 1Usha BbattaNo ratings yet

- Insurance LawDocument15 pagesInsurance LawShruti KambleNo ratings yet

- Nagpur Metro Region PlanDocument627 pagesNagpur Metro Region PlanReddycoke100% (1)

- Pembagian Distribusi Publikasi Peserta Poster IcprpDocument8 pagesPembagian Distribusi Publikasi Peserta Poster IcprpimaNo ratings yet

- 10.01.2011/EN FCI-Standard #149: Federation Cynologique Internationale (Aisbl)Document6 pages10.01.2011/EN FCI-Standard #149: Federation Cynologique Internationale (Aisbl)Domingos CunhaNo ratings yet

- MIDTERM 2020 For ASSESSMENTDocument4 pagesMIDTERM 2020 For ASSESSMENTDENNIS AFABLENo ratings yet

- H05V-K H07V-KDocument2 pagesH05V-K H07V-Ktwo travellerNo ratings yet

- Letter of Undertaking Letter Seggregation in ChargeDocument1 pageLetter of Undertaking Letter Seggregation in ChargeSijin SivankuttyNo ratings yet

- Mu350 1Document2 pagesMu350 1kresekjoy2No ratings yet

- Fact Sheet On The Death of Rey RiveraDocument4 pagesFact Sheet On The Death of Rey Riverahillarymitchell_5921No ratings yet

- Application - Cum - Declaration As To The Physical FitnessDocument2 pagesApplication - Cum - Declaration As To The Physical FitnessSunitha UrumbathNo ratings yet

- Conditioner Portatil Sams ClubDocument5 pagesConditioner Portatil Sams ClubJuan Carlos RodriguezNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- Overview of The Changing Family Pattern in Rural BangladeshDocument9 pagesOverview of The Changing Family Pattern in Rural BangladeshSadia Noor0% (1)

- Trouble ShootDocument10 pagesTrouble ShootFatima AbayonNo ratings yet

- CVDocument3 pagesCVshahbaz akramNo ratings yet

- Body Fat Content Worksheet (Male) - A5500Document1 pageBody Fat Content Worksheet (Male) - A5500JodyNo ratings yet

Plaster Printed Finish TDS

Plaster Printed Finish TDS

Uploaded by

Omer TageldinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plaster Printed Finish TDS

Plaster Printed Finish TDS

Uploaded by

Omer TageldinCopyright:

Available Formats

Plaster Printed Finish

DESCRIPTION: APPLICATION:

Plaster Printed Finish is a ready to use ▪ The surface should be clean and free from dust,

cementations decorative colored render, It’s a high paint and all lose particles. Dampen the surface

quality render coat, fast and easy to use, high before application.

durability. It consist of a mortar made up selected ▪ Mix the material with the same quantity of water

silica sand, Portland cement, pigments, additives to for each mix to avoid shading, 7-8 liter can be use.

increase impermeability and bonding strength. ▪ Apply the mix directly on a dampened substrate

on average thickness of 8.0 - 10mm by trowel.

▪ Carefully level and smooth the render, apply

ADVANTAGES: AmanCrete 300 Release Agent on the surface to

avoid sticking the material with the stamp

▪ Plaster Printed Finish is a pre-bagged high quality pattern.

render coat, fast and easy to use, it requires only ▪ Using rubber flexible mats, with the desired

addition of water on the site prior to use. pattern, start printing on the plaster on a constant

▪ Its practically crack free. way to achieve the desired look.

▪ Its water and weather resistant, it’s suitable to be ▪ After the render is set, wash out the excess

used in hot and humid weather as well as cold release with pressurized water and allow it to dry.

weather. ▪ Aman Super Sealer can be used on the top surface

▪ It can be used as finished plastering directly on to enhance the colour and give further protection.

block, bricks, or finished plastering, with high bond ▪ Do not apply the material if rain predicted.

strength on the substrate.

▪ It can be offered with a variety of colors and Pattern

to satisfy all tastes of clients.

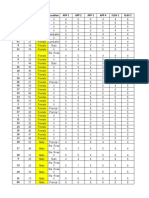

TECHNICAL PROPERTIES:

SHELF LIFE: Type of blinder Portland Cement

Under normal conditions and when kept dry, the shelf life of Printed Filler Selected Silica Sand of 1mm

Finish Plaster is 12 months from the manufacturing date. Inventory max

should be rotated. Dry Density 1.3 ± 0.1 kg./Ltr.

Wet Density 1.7 ± 0.1 kg/Ltr.

PACKAGING:

Flexural Strength 4.4 N/mm²

Plaster Printed Finish is available in 25 kg/bag.

Bonding Strength 1.4 N/mm²

Compressive Strength 12.1 N/mm²

COVERAGE:

Approximately 1.75 M²/bag at 8.0 mm average thickness.

GUARANTEE:

The information given in based of knowledge and performance of

the material. Every precaution took in the manufacturing of the

product and the responsibility is limited to the quality of supplies,

with no guarantee of results in the field, as AMANCRETE has no

control over site conditions or execution of work.

You might also like

- Amalgam FailuresDocument16 pagesAmalgam Failuresrasagna reddyNo ratings yet

- Plaster Coarse Finish TDSDocument1 pagePlaster Coarse Finish TDSOmer TageldinNo ratings yet

- Plaster Stone Finish TDSDocument1 pagePlaster Stone Finish TDSOmer TageldinNo ratings yet

- Skin TDSDocument1 pageSkin TDSOmer TageldinNo ratings yet

- Cement Clay Plaster TDSDocument1 pageCement Clay Plaster TDSOmer TageldinNo ratings yet

- Technical Bulletin Plaste-Fix FinDocument2 pagesTechnical Bulletin Plaste-Fix FinVirah Sammy ChandraNo ratings yet

- Bostic - TDSDocument2 pagesBostic - TDSSatheesh KumarNo ratings yet

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Document5 pages4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808No ratings yet

- 0839 Sigmacryl SilkDocument2 pages0839 Sigmacryl SilkSyed AliNo ratings yet

- 4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5Document4 pages4 Rockgrip 2 1 en Prep Plasterprimer 2020 Rev5yoxan25808No ratings yet

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Document5 pages8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808No ratings yet

- 0837 Sigma Profile Extra FineDocument2 pages0837 Sigma Profile Extra Fineمحمد عزتNo ratings yet

- Novo PRO Alkyd GlossyDocument1 pageNovo PRO Alkyd Glossywael barbaryNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Maxiseal Plus: Features / BenefitsDocument3 pagesMaxiseal Plus: Features / Benefitsannayya.chandrashekar Civil EngineerNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Consol Cosmetic: Polymer Modified Portland Cement CoatingDocument2 pagesConsol Cosmetic: Polymer Modified Portland Cement CoatingCiput MardiantoNo ratings yet

- Konsol PDFDocument2 pagesKonsol PDFCiput MardiantoNo ratings yet

- Bond Aid 100 - TDSDocument2 pagesBond Aid 100 - TDSAnoop ShankarNo ratings yet

- Capaland Plus TDSDocument2 pagesCapaland Plus TDSAnant JadhavNo ratings yet

- Nerolac Cement PuttyDocument2 pagesNerolac Cement PuttyNesiNo ratings yet

- Ready Mix Plaster: What Is MORTAR ?Document11 pagesReady Mix Plaster: What Is MORTAR ?nagesh raoNo ratings yet

- Plaster Binder: Product DescriptionDocument2 pagesPlaster Binder: Product DescriptionTAPANo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Sikalatex SuperDocument3 pagesSikalatex SuperAkash ChardeNo ratings yet

- Cemento PulidoDocument2 pagesCemento Pulidogeric1446No ratings yet

- Sikatop - 122Document3 pagesSikatop - 122YOSAFAT YUDHA GUNTORONo ratings yet

- Sikatop 107 Seal - Pds en PDFDocument3 pagesSikatop 107 Seal - Pds en PDFMarthinus Tonny PangemananNo ratings yet

- 0852 Sigma Acrylic Primer Sealer PDFDocument2 pages0852 Sigma Acrylic Primer Sealer PDFAhmed SakrNo ratings yet

- Sika Nigeria - Sika Grout 212 - V2Document3 pagesSika Nigeria - Sika Grout 212 - V2willy iremNo ratings yet

- Cemfair SmoothDocument2 pagesCemfair Smoothosama mohNo ratings yet

- Drybase Universal Mortar Datasheet PDFDocument2 pagesDrybase Universal Mortar Datasheet PDFdiribaNo ratings yet

- TDS - GypEX Silver PlasterDocument4 pagesTDS - GypEX Silver Plastersuyog kattelNo ratings yet

- Preserva PlusDocument3 pagesPreserva Plustiwari.onkarNo ratings yet

- Pinnacle Technical Dta Sheet Data SheetDocument3 pagesPinnacle Technical Dta Sheet Data SheetdubondsocialmediaNo ratings yet

- Ds Duralatex 1Document2 pagesDs Duralatex 1KeJeNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Gyproc Supreme 80 One Coat Gypsum PlasterDocument3 pagesGyproc Supreme 80 One Coat Gypsum PlasterSwapnil JadhavNo ratings yet

- Plast: Very Fast. Absolutely SmoothDocument2 pagesPlast: Very Fast. Absolutely Smoothsachinkarape4844100% (1)

- Technical Information ASSET DOC LOC 8749100Document3 pagesTechnical Information ASSET DOC LOC 8749100dongheep811No ratings yet

- PlasteringDocument15 pagesPlasteringMegha RajNo ratings yet

- Kilz Restoration Tds Canada Ce v3 FDocument2 pagesKilz Restoration Tds Canada Ce v3 FBM HướngNo ratings yet

- Dulux Trade Ecosure Plaster PrimerDocument5 pagesDulux Trade Ecosure Plaster PrimerEl Bekkari MohamedNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Slurry Bond: Liquid Polymer Modified High Strength AdhesiveDocument4 pagesSlurry Bond: Liquid Polymer Modified High Strength AdhesiveMahla Raj KumarNo ratings yet

- Davco Super TTB 998Document3 pagesDavco Super TTB 998JU SHUANGNo ratings yet

- Granite Polymer c2 - TdsDocument1 pageGranite Polymer c2 - TdsryanNo ratings yet

- Ornamental Sealer: Product InformationDocument4 pagesOrnamental Sealer: Product InformationGuruNo ratings yet

- 25 KG Gyproc Elite 100 One Coat Gypsum PlasterDocument3 pages25 KG Gyproc Elite 100 One Coat Gypsum Plastersyedaliabl2023No ratings yet

- E.MIX FinishDocument2 pagesE.MIX Finishsiti hanisahNo ratings yet

- Mirac Sealer ESDocument1 pageMirac Sealer ESChristinaNo ratings yet

- Consol CosmeticDocument2 pagesConsol Cosmeticotong geyongNo ratings yet

- Graphenstone TDS - MortarBase-Premium - 2018Document2 pagesGraphenstone TDS - MortarBase-Premium - 2018Nicholas ThengNo ratings yet

- Coverage:: Product DescriptionDocument2 pagesCoverage:: Product DescriptionAb KhawlhringNo ratings yet

- Sikaceram - 116 StandardDocument3 pagesSikaceram - 116 StandardMash-out VivA (www.VivA.com)No ratings yet

- Basf Mastertile 333 TdsDocument3 pagesBasf Mastertile 333 TdsdipinnediyaparambathNo ratings yet

- 01 - TDS PCI Primer GisogrundDocument4 pages01 - TDS PCI Primer GisogrundAlexi ALfred H. TagoNo ratings yet

- Bathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofFrom EverandBathtub and Shower Tray Repair: How to prevent remedials and make the repair future-proofNo ratings yet

- 9000 شهادة نظام إدارة الجودةDocument1 page9000 شهادة نظام إدارة الجودةOmer TageldinNo ratings yet

- شهادة التصنيف الائتماني AAADocument1 pageشهادة التصنيف الائتماني AAAOmer TageldinNo ratings yet

- معلومات تأهيل المختبرDocument1 pageمعلومات تأهيل المختبرOmer TageldinNo ratings yet

- الشهادة الموصى بها لوكالة تقييم حماية مستوى أمان الشبكة (New-Seal)Document1 pageالشهادة الموصى بها لوكالة تقييم حماية مستوى أمان الشبكة (New-Seal)Omer TageldinNo ratings yet

- شهادة تأهيل فريق تقييم المعلوماتDocument1 pageشهادة تأهيل فريق تقييم المعلوماتOmer TageldinNo ratings yet

- شهادة تأهيل فريق تقييم المعلومات PDFDocument1 pageشهادة تأهيل فريق تقييم المعلومات PDFOmer TageldinNo ratings yet

- شهادة معايرة أجهزة المختبرDocument1 pageشهادة معايرة أجهزة المختبرOmer TageldinNo ratings yet

- Skin TDSDocument1 pageSkin TDSOmer TageldinNo ratings yet

- Top Crete TDSDocument1 pageTop Crete TDSOmer TageldinNo ratings yet

- Plaster Coarse Finish TDSDocument1 pagePlaster Coarse Finish TDSOmer TageldinNo ratings yet

- Super Sealer TDSDocument2 pagesSuper Sealer TDSOmer TageldinNo ratings yet

- Cement Clay Plaster TDSDocument1 pageCement Clay Plaster TDSOmer TageldinNo ratings yet

- Plaster Stone Finish TDSDocument1 pagePlaster Stone Finish TDSOmer TageldinNo ratings yet

- إجراء المنح لمنتج الخرسانة جاهزة الخلط QMS-CR-10-08Document58 pagesإجراء المنح لمنتج الخرسانة جاهزة الخلط QMS-CR-10-08Omer TageldinNo ratings yet

- Integral Color TDSDocument2 pagesIntegral Color TDSOmer TageldinNo ratings yet

- Release Agent TDSDocument1 pageRelease Agent TDSOmer TageldinNo ratings yet

- Color Hardner TDSDocument2 pagesColor Hardner TDSOmer TageldinNo ratings yet

- Qic Invited Supplier Registration Process GuideDocument7 pagesQic Invited Supplier Registration Process GuideOmer TageldinNo ratings yet

- Whether Ordinance On Self-Denial of Nuclear Power Harmful To IndiaDocument55 pagesWhether Ordinance On Self-Denial of Nuclear Power Harmful To IndiabksubbaraoNo ratings yet

- James Joyce and The English ViceDocument14 pagesJames Joyce and The English Vicejanna100% (1)

- Sol-Gel Methods PDFDocument19 pagesSol-Gel Methods PDFDimitrios Tsiplakides100% (2)

- Technical Datasheet of SBRDocument13 pagesTechnical Datasheet of SBRKSPCB KalaburagiNo ratings yet

- User Analysis SampleDocument8 pagesUser Analysis Samplecece vergieNo ratings yet

- Definition of Biomedical Model of HealthDocument4 pagesDefinition of Biomedical Model of Healthتالیہ مرادNo ratings yet

- Chen 2021Document19 pagesChen 2021saka healthNo ratings yet

- Lefatshe La Botswana)Document21 pagesLefatshe La Botswana)nicNo ratings yet

- CDS57006 Bosch LSU 4.9 Sensor PDFDocument4 pagesCDS57006 Bosch LSU 4.9 Sensor PDFAnonymous K3FaYFlNo ratings yet

- BasuhTanganDenganBetul BIDocument1 pageBasuhTanganDenganBetul BIAdnan ShamsudinNo ratings yet

- PROLYMERDocument2 pagesPROLYMERFlavio GonzalezNo ratings yet

- Sudip Praposal - 1Document20 pagesSudip Praposal - 1Usha BbattaNo ratings yet

- Insurance LawDocument15 pagesInsurance LawShruti KambleNo ratings yet

- Nagpur Metro Region PlanDocument627 pagesNagpur Metro Region PlanReddycoke100% (1)

- Pembagian Distribusi Publikasi Peserta Poster IcprpDocument8 pagesPembagian Distribusi Publikasi Peserta Poster IcprpimaNo ratings yet

- 10.01.2011/EN FCI-Standard #149: Federation Cynologique Internationale (Aisbl)Document6 pages10.01.2011/EN FCI-Standard #149: Federation Cynologique Internationale (Aisbl)Domingos CunhaNo ratings yet

- MIDTERM 2020 For ASSESSMENTDocument4 pagesMIDTERM 2020 For ASSESSMENTDENNIS AFABLENo ratings yet

- H05V-K H07V-KDocument2 pagesH05V-K H07V-Ktwo travellerNo ratings yet

- Letter of Undertaking Letter Seggregation in ChargeDocument1 pageLetter of Undertaking Letter Seggregation in ChargeSijin SivankuttyNo ratings yet

- Mu350 1Document2 pagesMu350 1kresekjoy2No ratings yet

- Fact Sheet On The Death of Rey RiveraDocument4 pagesFact Sheet On The Death of Rey Riverahillarymitchell_5921No ratings yet

- Application - Cum - Declaration As To The Physical FitnessDocument2 pagesApplication - Cum - Declaration As To The Physical FitnessSunitha UrumbathNo ratings yet

- Conditioner Portatil Sams ClubDocument5 pagesConditioner Portatil Sams ClubJuan Carlos RodriguezNo ratings yet

- CPG - Management of AcneDocument97 pagesCPG - Management of Acneumiraihana1No ratings yet

- Overview of The Changing Family Pattern in Rural BangladeshDocument9 pagesOverview of The Changing Family Pattern in Rural BangladeshSadia Noor0% (1)

- Trouble ShootDocument10 pagesTrouble ShootFatima AbayonNo ratings yet

- CVDocument3 pagesCVshahbaz akramNo ratings yet

- Body Fat Content Worksheet (Male) - A5500Document1 pageBody Fat Content Worksheet (Male) - A5500JodyNo ratings yet