Professional Documents

Culture Documents

Electronic Circuitry For A Smart Spinning-Current Hall Plate With Low Offset

Electronic Circuitry For A Smart Spinning-Current Hall Plate With Low Offset

Uploaded by

George AcostaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronic Circuitry For A Smart Spinning-Current Hall Plate With Low Offset

Electronic Circuitry For A Smart Spinning-Current Hall Plate With Low Offset

Uploaded by

George AcostaCopyright:

Available Formats

Sensors and Actuators A, 25-27 (1991) 741-751 747

Electronic Circuitry for a Smart Spinning-current Hall Plate with Low Offset

P. J. A. MUNTER

Derft University of Technology, Electronic Instrumentation Laboratory, P.O. Box 5031, 2600 GA Delfr (The Netherlands)

Abstract of about 2 mT is obtained by the incorpora-

tion of two or four orthogonally coupled

The offset in silicon Hall plates is reduced Hall plates which are nested closely together

by multiple orthogonal switching of a single PI.

symmetrical spinning-current Hall plate. The However, silicon allows electronic cir-

offset virtually cancels out when the current cuitry to be merged on the same chip as

direction is made to spin with steps of n/8, the sensor, resulting in a so-called smart sen-

while the consecutively available Hall voltages sor. Now this smart sensor as a whole needs

are averaged over time. The novel 16contact to match the demands on sensitivity, offset,

spinning-current Hall plate shows less than etc.

50 PV ( 100 pT) residual offset. A combination In this paper first the spinning-current

of the spinning-current Hall plate and the offset-reduction method and some new re-

hybrid electronic circuitry obtains a 10 times sults are presented and secondly the hybrid

lower offset (at maximum 200 pT) when com- electronic circuitry for implementing this

pared to optimized commercially available method is discussed. The experimental re-

Hall plates without electronics. sults on the offset of a 16-contact spinning-

current Hall plate itself and on the offset

when the hybrid electronic circuitry is added

1. Introduction are given.

Over the past few decades, a great variety

of Hall plates made of different materials has 2. The Spinning-current Offset-reduction

been realized [ 11. The general design proce- Method

dure was always to improve the sensor by

selecting a material with a high mobility, A Hall plate is a thin resistive sheet of a

which determines the magnetic field sensitiv- high-mobility material with two pairs of

ity, and then to adjust the geometry until the diametrically opposed contacts. The bias cur-

characteristics of the sensor matched the de- rent which flows straight across the Hall

mands. plate is deflected by a magnetic field and a

Silicon can also be used to make Hall Hall voltage arises at the Hall contacts, see

plates which show a relatively low sensitivity Fig. 1:

and a high offset. The unknown offset in

silicon Hall plates is mainly caused by pack- VI-&(P) = S(q)Z,B + V,K(cp) (1)

age stress, which cannot be compensated with cp the direction of the current flow with

for in the factory because the stress appears respect to the crystal orientation, S the sensi-

to change with time and temperature. tivity, Z, the bias current, B the magnetic

Several offset-reduction methods have been induction and V,,(cp) the offset. The sensitiv-

proposed, none of which solved the offset ity is also q-dependent via the piezo-Hall

problem completely [ 1,2]. The lowest offset effect [3]. The sensitivity varies 2.5% at the

0924-4247/91/$3.50 0 Elsevier Sequoia/Printed in The Netherlands

748

which fulfils the sampling theorem, in which

the current is made to spin with steps of K/S

[5]. The current is forced straight across the

plate and the Hall voltage is measured at the

contact pair which is perpendicularly oriented

to the current flow. An integrator averages

the consecutively available Hall voltages. The

total Hall voltage is given by

t ttAt

Fig. 1. Orthogonal switching of a Hall plate to itself.

At time I the current flows downwards, and at time

f + At the current flows perpendicularly to the initial

current flow direction. The Hall voltage is measured at

the contact pair which is perpendicularly oriented to the

current flow.

= S’Z,B + V,,,(cp), Aso=2n/N (3)

most by the piezo-Hall effect when the cur- with Vr,, the residual offset, S’ the average

rent is made to spin [ 31 in the ( 110) plane of sensitivity and N = 16 for a 16-contact Hall

silicon. plate. The integration takes place over mul-

The offset in a Hall plate can be viewed as tiple full rotations of the current.

an imbalance of a Wheatstone bridge. The

geometrical errors cancel out completely

when the bridge is switched orthogonally to 3. The Electronic Implementation

itself. The influence of stress on the offset can

be modelled using piezoresistances. The offset The spinning-current offset-reduction

becomes [ 41 method requires electronic circuitry to be

V&(P) = added to the Hall plate. To examine the

concept, a hybrid circuit is built. First the

+++ +;))

(rc’(V operating principle and next the various cir-

cuit sections are discussed.

+;))x R

xcos(2(o-yl z

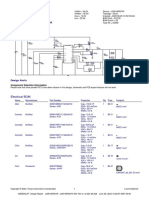

The block scheme of the circuit is given in

Fig. 2. The current flow is made to spin by a

Hall s

MOS multiplexer, while another MOS multi-

plexer selects the proper Hall-contact pair.

The consectively available Hall voltages are

with 11,and 71,the longitudinal and transverse amplified and an integrator averages out the

piezoresistive coefficients in the cp + n/4 cur- offset. The offset of the ‘chopper’ amplifier is

rent direction, X the stress and 0 the stress cancelled by reversing the bias current in the

orientation. The piezoresistance coefficients Hall plate while the input terminals of the

in (lOO)-oriented n-type silicon show a n/2 amplifier remain connected to the same Hall

periodicity and the stress shows a n: periodic- contacts and the output terminals are ex-

ity. The offset is the product of these two changed. The Hall voltage is treated as a

periodic functions and consists of n and n/3 differential signal to obtain a maximum

periodic terms. power supply rejection ratio. Noise minimiza-

Any periodic signal with the smallest pe- tion requires a bipolar amplifier input stage.

riod T should be sampled at least every A dual-slope integrator yields a low offset,

T, = T/2, according to Shannon’s sampling requires no calibration, uses only a small

theorem. Thus in our case the sampling rate amount of space on the chip and is commer-

becomes 7c/6. Using bipolar technology a cially available [6 and refs. therein]. The

symmetrical 16-contact Hall plate was made, earth’s magnetic field of about 30-40 PT

749

Fig. 3. Schematic diagram of the electronic circuitry for

the smart spinning-current Hall plate. The polarity

reverser which follows the amplifier is part of the

‘chopper’.

with N the number of contacts used and fret

(a) the rotation frequency of the current.

The spinning-current offset-reduction cir-

cuit is given in Fig. 3. The CM voltage at the

Hall contacts is cancelled by connecting one

Hall contact to the virtual ground and the

output of the opamp feedback loop to the

‘upper’ current contact [7]. When the direc-

tion of the current is made to spin, first all

(b) switches open and next the selected switches

Fig. 2. (a) Microphotograph of the 16-contact spin- are closed. During the switching sequence,

ning-current Hall plate. (b) Schematic diagram of the the voltage across the Hall plate is memo-

implementation of the spinning-current offset-reduction rized by the internal capacitance of the plate.

method.

The new Hall contacts are connected to the

Hall plate where the bias voltage across the

Hall plate is memorized. A large switching

results in a Hall voltage of about 100 PV peak results, which is proportional to any

(SIS = 0.5 V/T). The earth’s magnetic field de- resistive and capacitive asymmetries, where

termines the LSB of the integrator needed the resistive asymmetries include the Hall

and a 1Zbits plus 1 sign bit resolution covers plate’s offset. The integrator integrates the

all voltages up to the maximum initial offset peaks and a voltage appears at the output.

of 50 mV. The integration time is set by the The switching peaks are absent when the

quotient of the resolution and the reference direction of the current is reversed. The

frequency, fO, and has a minimum value of switching peaks cancel each other out when a

TCO”V = 4 ms (for 1Zbits and f0 = 1 MHz). proper switching sequence, that is cp from 0

The resolution (and consequently the conver- to x to ?r/2 to 31112,is used [S]. A better way

sion time) can be reduced by two to three bits to reduce these peaks is to short the input of

when the current is made to spin so that any the integrator during transients when the cur-

two consecutive Hall voltages have opposite rent is made to spin. Unfortunately, the sensi-

polarity, which results in a lower upper limit tivity is thus reduced proportional to the

of the dynamic range for the average input of duty-cycle (here 50%), which makes the offset

the integrator being almost zero. The current relatively twice as high. A high slew-rate am-

is made to spin with a maximum sampling plifier is needed to minimize the influence of

frequency the magnitude of the initial offset and the

magnetic field on the total offset and the

sensitivity respectively.

15op piezoresistance coefficients and arises when

the orientation of the legs of the Wheatstone

75wv

bridge is modified in such a way that they

0

give a better representation of the actual cur-

rent flow at these sectors of the Hall plate. A

virtually non-periodic offset of about 25 PV

is obtained when the current is made to spin

0 2n

with steps of n/8. The residual offset is non-

Current Orienta& v at I, = 5mA zero due to contributory factors, like the

(a) Peltier effect, which rotate with the current

1 OmV 15opv

like the magnetic field sensitivity and, there-

fore, are not cancelled out. The exact nature

of the residual offset can be extracted from

the bias current dependency (see Fig. 4(b)).

5mV 75p

The offset contribution of the hybrid cir-

cuitry can be evaluated using various Hall

plate models. The total Hall voltage at the

0 0 output of the integrator, with the offsetless

6 2.5

resistive Wheatstone bridge as Hall plate

Current I, (mA) at 4 = 0

(b)

model, shows solely the offset of the electronic

circuitry (see Fig. 5(a)). The total Hall voltage

Fig. 4. The offset of the spinning-current Hall plate

itself. The offset, the orthogonal offset and the residual

remains unchanged when a resistive bridge

offset after averaging over eight samples (a) as a func-

tion of the direction of the current and (b) as a function

of the bias current.

4. Experimental Results

First, the need for a 16-contact spinning-

current Hall plate for the optimal offset 2 4

reduction is confirmed. Secondly, the contri- Current I, (mA)

bution to the total offset of the hybrid cir- (a)

cuitry using orthogonal switching is discussed.

Finally, the possibility of merging the elec-

tronic circuitry and the Hall plate on one chip

is evaluated. A high-resolution digital multi-

meter with a multi-slope integrator input is

used as the integrator in the experiments.

The offset of the Hall plate itself clearly

shows a x-periodic term, while the n/3 peri-

odic term is significantly smaller (see Fig. 0 2 4

Current I, (mA)

4(a)). The two periodic terms are a result of

(W

the periodicity of the piezoresistance co-

efficients and the stress. The ortogonal offset Fig. 5. (a) The total offset of the smart Hall plate as a

function of the bias current. The dashed line is for a

at cp, which is the average of the offset at cp

resistive Wheatstone bridge with offset comparable to

and at q + 7~12,is non-zero and periodic. The that of the real Hall plate, given by the solid lines. (b)

periodicity of the orthogonal offset is believed The total equivalent magnetic field as a function of the

to be a function of the periodicity of the bias current.

with offset is used because its orthogonal 5. Conclusions

offset is zero. The total offset becomes depen-

dent on bias current and rotation frequency The spinning-current offset-reduction

when a real Hall plate is used. The bias current method reduces the offset significantly. The

dependency is a result of the non-zero orthog- Hall plate with hybrid circuit using single

onal offset voltage and of the finite slew-rate orthogonal switching shows less than 200 PT

of the amplifiers. The orthogonal offset re- equivalent offset, which is a result of the

mains the same, independent of the rotation residual offset of the Hall plate itself and of

frequency. At higher frequencies the width of the finite slew-rate of the amplifiers. The inte-

the pulses decreases, which increases the rela- gration time limits the bandwidth of the

tive importance of the slew-rate errors. Conse- smart Hall plate to about 1 kHz. This spin-

quently, the rotation frequency dependence of ning-current Hall plate with circuitry can be

the offset is proportional to the magnitude of integrated with BiCMOS technology, so that

the initial offset and, therefore, proportional we can expect that a single-chip smart spin-

to the stress in the package. ning-current Hall plate is feasible.

The equivalent magnetic field is defined as

Beg = V,,/(SI,) and is used to compare the Acknowledgements

offsets of different Hall plates (see Fig. 5(b)).

The maximum equivalent magnetic field is less The author is grateful to several people:

than 200 PT at I, = 4 mA, S’ = 110 V/A T and the members of Professor Huijsing’s group

fr,, = 4 kHz. This rotation frequency corre- for their help on the electronics and the mem-

sponds to a 1 kHz rotation frequency when all bers of the Delft Institute of MicroElectron-

16 different current flow directions are used. its and Submicron Technology (DIMES) for

In that case the contribution of the residual fabrication of the Hall plates. This work is

offset of the Hall plate itself is somewhat supported by the Delft University Fund.

smaller, (see Fig. 4(b)), while the number of

peaks over which it is integrated remains the

same. The equivalent offset is a factor of 10 References

smaller when compared to the offset of 2 mT

I H. P. Baltes and R. S. PopoviE, Integrated semicon-

in commercially available Hall plates [2]. Fi- ductor magnetic field sensors, Proc. IEEE, 74 (1986)

nally, a magnetic field of 50 mT is applied to 1107-1132.

test the dynamic range of the smart Hall plate 2 Improved Hall devices find new uses, Elecrron. Week,

for magnetic fields. The total Hall voltage 58 (1985) 59-61.

appears to be virtually independent of the 3 B. Halg, Piezo-Hall coefficients of n-type silicon, J.

Appl. Phys., 64 (1988) 276-282.

rotation frequency up to 1 kHz at minimum.

4 Y. Kanda et al., Silicon Hall-effect power IC’s for

Electronic circuitry can be merged on-chip brushless motors, IEEE Trans. Electron Devices, ED-

with a sensor when both can be made in the 29 (1982) 151-154.

same IC process and do not influence each 5 P. J. A. Munter, A low-offset spinning-current Hall

other thermally. The thermal influences of the plate, Sensors and Actuators, A21 -A23 (1990) 143-

electronic circuit on the sensor are the temper- 746.

6 B. J. Rodgers and C. R. Thurber, A monolithic +5

ature rise and gradient. The effect of a temper-

l/Zdigit BiMOS A/D converter, IEEE J. Solid-Stare

ature rise is negligible, since the spinning of Circuits, SSC-24 (1989) 617-626.

the current also reduces the thermal offset 7 K. Matsui et al., GaAs Hall generator application to

drift by about an order of magnitude. Exper- a current and watt meter, Proc. /st Sensor Symp.,

iments have shown that a homogeneous 0.5 K Japan, 1981, pp. 37-40.

thermal gradient across the Hall plates in- 8 P. J. A. Munter and S. Middelhoek, The electronic

circuitry for the low-offset spinning-current Hall

creases the offset by only 40 pV. Therefore, a plate, Proc. Third Int. Forum on ASK and Trans-

hybrid circuit is actually a reliable representa- ducer Technology, Banff, Alla., Canada, May 20-23

tion of an on-chip circuit. 1990, pp. lo!-112.

You might also like

- Epa 2010 Electrical GuideDocument43 pagesEpa 2010 Electrical Guidewilfredomolina83% (6)

- Hysteresis Curve of Transformer CoreDocument3 pagesHysteresis Curve of Transformer CoreErnesto Che50% (2)

- Water Meter DataDocument9 pagesWater Meter DataAjayNo ratings yet

- Aspects Related To Replacing HV Lines by HV Cables On Resonant Grid BehaviorDocument6 pagesAspects Related To Replacing HV Lines by HV Cables On Resonant Grid Behaviordeepak_27No ratings yet

- Vk5br Eh Dipole AntennaDocument12 pagesVk5br Eh Dipole AntennaInsafe El WakiliNo ratings yet

- LEP 4.4.04 Coil in The AC Circuit: Related TopicsDocument3 pagesLEP 4.4.04 Coil in The AC Circuit: Related Topicsnic.san1206No ratings yet

- Me-3115 2Document25 pagesMe-3115 2Amit PaulNo ratings yet

- Proposal of A Soft-Switching Single-PhaseDocument7 pagesProposal of A Soft-Switching Single-Phaseayie55No ratings yet

- Part HI of The Journal.) : TuckerDocument2 pagesPart HI of The Journal.) : TuckershirtquittersNo ratings yet

- Corbi No 2006Document7 pagesCorbi No 2006nadamopNo ratings yet

- Reciprocal Operation of Ultrasonic Transducers Experimental ResultsDocument4 pagesReciprocal Operation of Ultrasonic Transducers Experimental Resultsishi888No ratings yet

- Intro To Beam InstrumentationDocument38 pagesIntro To Beam InstrumentationDen BavisNo ratings yet

- PLK Vicwood K.T. Chong Sixth Form College 83' AL Physics: Essay Marking SchemeDocument7 pagesPLK Vicwood K.T. Chong Sixth Form College 83' AL Physics: Essay Marking Scheme林柄洲No ratings yet

- Rez 824Document15 pagesRez 824Quan LinhNo ratings yet

- An Introduction To The Hall EffectDocument19 pagesAn Introduction To The Hall EffectDdoremi DoremiNo ratings yet

- HumidityDocument7 pagesHumidityIbtehaj Tasfin RiasatNo ratings yet

- E 08e AUF Hall EffectDocument5 pagesE 08e AUF Hall EffectV. GrigorasNo ratings yet

- LEP 5.1.12 Electron Spin Resonance: Related Topics ProblemsDocument5 pagesLEP 5.1.12 Electron Spin Resonance: Related Topics ProblemsPedroNo ratings yet

- Models - Edecm.rotating Cylinder Hull CellDocument28 pagesModels - Edecm.rotating Cylinder Hull Cellkingsley peprahNo ratings yet

- LC Circuit - Wikipedia, The Free EncyclopediaDocument9 pagesLC Circuit - Wikipedia, The Free EncyclopediaAdrian TanaseNo ratings yet

- Broadband Rectenna Arrays For Randomly Polarized Incident WavesDocument4 pagesBroadband Rectenna Arrays For Randomly Polarized Incident WavesBruno SátiroNo ratings yet

- Hall EffectDocument10 pagesHall EffecttaruniisermNo ratings yet

- Tunneling Through A Controllable Vacuum Gap: Related ArticlesDocument4 pagesTunneling Through A Controllable Vacuum Gap: Related ArticlesSaeed MishalNo ratings yet

- Hartley OscillatorDocument3 pagesHartley OscillatorJunaid AleemNo ratings yet

- McDonald - Avalanche Degradation of HfeDocument8 pagesMcDonald - Avalanche Degradation of HfeChrisNo ratings yet

- Tunel Efect First PaperDocument4 pagesTunel Efect First PaperJose Pablo EstrellaNo ratings yet

- OutputDocument18 pagesOutputakterafuja7No ratings yet

- Damping Circuit Design For Ferroresonance in Floating Power SystemsDocument5 pagesDamping Circuit Design For Ferroresonance in Floating Power Systemssanela halidovicNo ratings yet

- Control Circuit Transients (General Electric) PDFDocument14 pagesControl Circuit Transients (General Electric) PDFtranhuutuongNo ratings yet

- Accircuit1 PartIDocument40 pagesAccircuit1 PartIriddhitadas9No ratings yet

- Pure Inductive Circuit AND L R Circuit: Nimisha Lonees K Ac Circuit-Electronics 2020-2021Document15 pagesPure Inductive Circuit AND L R Circuit: Nimisha Lonees K Ac Circuit-Electronics 2020-2021mahmoud yarahmadiNo ratings yet

- Fullll FinalDocument65 pagesFullll FinalAsif AliNo ratings yet

- 01451223Document28 pages01451223mentally_illNo ratings yet

- (2002) ShibuyaDocument6 pages(2002) ShibuyaAntônio Kaminski JúniorNo ratings yet

- Harmonic Oscillator ProjectDocument9 pagesHarmonic Oscillator Projectsvhanu4010No ratings yet

- Surge Propagation in Electrical SystemsDocument5 pagesSurge Propagation in Electrical SystemssamiNo ratings yet

- 06 2010 Lindberg ProceedingsNDES2010Document5 pages06 2010 Lindberg ProceedingsNDES2010Erik LindbergNo ratings yet

- Spatial Symmetry of Transduction Effects in Hall PlatesDocument4 pagesSpatial Symmetry of Transduction Effects in Hall PlatesGeorge AcostaNo ratings yet

- A Ac Air: Phase-Related Investigation of Corona inDocument8 pagesA Ac Air: Phase-Related Investigation of Corona inhkaruvathilNo ratings yet

- Hall EffectDocument10 pagesHall EffectGautam ChauhanNo ratings yet

- Helmoholtz CoilDocument8 pagesHelmoholtz CoilporfirioNo ratings yet

- Power/Ground Noise: Inductance EffectsDocument7 pagesPower/Ground Noise: Inductance EffectsRajniNo ratings yet

- A Study of Ferroresonance in Underground Distribution Network For 15mva, 33/11 KV Injection SubstationDocument9 pagesA Study of Ferroresonance in Underground Distribution Network For 15mva, 33/11 KV Injection SubstationMohammed AL-HejeriNo ratings yet

- Lab 6 Inductive ReactanceDocument7 pagesLab 6 Inductive ReactanceJn Guinto0% (1)

- PAPER 2003 03 en HV Shunt Reactor Secrets For Protection EngineersDocument30 pagesPAPER 2003 03 en HV Shunt Reactor Secrets For Protection Engineerslamugre20003506No ratings yet

- ABB HV Shunt ReactorDocument30 pagesABB HV Shunt Reactortkdrt2166100% (1)

- FE-Modelling of Induction Tool Responses: F Iii: GDocument4 pagesFE-Modelling of Induction Tool Responses: F Iii: GtomhowNo ratings yet

- Full Report Frequency Response and Switching of Bipolar TransistorsDocument8 pagesFull Report Frequency Response and Switching of Bipolar Transistorsarol_khaiNo ratings yet

- An LC CircuitDocument11 pagesAn LC CircuitHRM, BAPEXNo ratings yet

- Evaluation of Grounding Performance of Energized Substation by Ground Current MeasurementDocument4 pagesEvaluation of Grounding Performance of Energized Substation by Ground Current MeasurementjfriquelmeNo ratings yet

- High Performance Rogowski Current Transducers: W. F. Ray and C. R. HewsonDocument8 pagesHigh Performance Rogowski Current Transducers: W. F. Ray and C. R. HewsongovindarulNo ratings yet

- Electrical PropertiesDocument9 pagesElectrical Propertiesisratriha31No ratings yet

- ELE4111 Section 2aDocument27 pagesELE4111 Section 2asachinchunilallNo ratings yet

- Crystal OscillatorDocument26 pagesCrystal OscillatorSanjay Kumar Yadav100% (1)

- Glenn Halstead Brown, 1915-1995: Mary E. NeubertDocument3 pagesGlenn Halstead Brown, 1915-1995: Mary E. NeubertGeorge AcostaNo ratings yet

- US2840304Document37 pagesUS2840304George AcostaNo ratings yet

- MA102Document26 pagesMA102George AcostaNo ratings yet

- Poon1969 BDocument3 pagesPoon1969 BGeorge AcostaNo ratings yet

- An integrated front-end vertical hall magnetic sensor fabricated in 0.18 μm low-voltage CMOS technologyDocument8 pagesAn integrated front-end vertical hall magnetic sensor fabricated in 0.18 μm low-voltage CMOS technologyGeorge AcostaNo ratings yet

- US2700588Document8 pagesUS2700588George AcostaNo ratings yet

- Duff 1973Document7 pagesDuff 1973George AcostaNo ratings yet

- Kawanishi 2019Document27 pagesKawanishi 2019George AcostaNo ratings yet

- US2926005Document5 pagesUS2926005George AcostaNo ratings yet

- Schrank 1989Document3 pagesSchrank 1989George AcostaNo ratings yet

- UnclassifiedDocument56 pagesUnclassifiedGeorge AcostaNo ratings yet

- US767303Document4 pagesUS767303George AcostaNo ratings yet

- 1959 Pioneer Awards in Aeronautical and Navigational ElectronicsDocument7 pages1959 Pioneer Awards in Aeronautical and Navigational ElectronicsGeorge AcostaNo ratings yet

- US2846505Document5 pagesUS2846505George AcostaNo ratings yet

- US2228469Document4 pagesUS2228469George AcostaNo ratings yet

- Heise 1948Document7 pagesHeise 1948George AcostaNo ratings yet

- 10.1007@978 3 642 11682 78Document13 pages10.1007@978 3 642 11682 78George AcostaNo ratings yet

- An Air-Depolarized Primary Cell With Caustic Alkali Electrolyte.'Document9 pagesAn Air-Depolarized Primary Cell With Caustic Alkali Electrolyte.'George AcostaNo ratings yet

- Issue 49 1st Quarter of 08Document12 pagesIssue 49 1st Quarter of 08George AcostaNo ratings yet

- Walke Pravin 23Document125 pagesWalke Pravin 23George AcostaNo ratings yet

- MMMfrontDocument21 pagesMMMfrontGeorge AcostaNo ratings yet

- Daniel 1949Document6 pagesDaniel 1949George AcostaNo ratings yet

- Patre 12700Document7 pagesPatre 12700George AcostaNo ratings yet

- ACFrOgCZETY1N34f2srrkyR7JgrX4uSur7W4An MpSBkZiq2Us5 ZWkwcsaCvks8HGgRK8kpuFeq8pH9 wG9vwbHWwx74VfQl GbxKWpX50wp2CtiyjOU1HUvScSFKD3otsLYbmBbOJrBJX2Xu31Document3 pagesACFrOgCZETY1N34f2srrkyR7JgrX4uSur7W4An MpSBkZiq2Us5 ZWkwcsaCvks8HGgRK8kpuFeq8pH9 wG9vwbHWwx74VfQl GbxKWpX50wp2CtiyjOU1HUvScSFKD3otsLYbmBbOJrBJX2Xu31George AcostaNo ratings yet

- EP0095521B1Document8 pagesEP0095521B1George AcostaNo ratings yet

- US910Document3 pagesUS910George AcostaNo ratings yet

- Ep0061194b1 PDFDocument18 pagesEp0061194b1 PDFGeorge AcostaNo ratings yet

- Mauro 1894Document23 pagesMauro 1894George AcostaNo ratings yet

- US4530016Document25 pagesUS4530016George AcostaNo ratings yet

- Elias PeterDocument17 pagesElias PeterGeorge AcostaNo ratings yet

- Surge Test WhitepaperDocument13 pagesSurge Test WhitepaperMohamedHussein MohamedHusseinNo ratings yet

- ScienceeeDocument7 pagesScienceeeJaidyn LeeNo ratings yet

- Lichtmaschine BoschDocument23 pagesLichtmaschine BoschJames PonzoNo ratings yet

- APC Smart-UPS 3000VA LCD 230V: Part Number: SMT3000IDocument4 pagesAPC Smart-UPS 3000VA LCD 230V: Part Number: SMT3000IMateleNo ratings yet

- WBDesign138 - Load Transient-3Document11 pagesWBDesign138 - Load Transient-3bruno magalhãesNo ratings yet

- Second Quarter Tle 10Document3 pagesSecond Quarter Tle 10Ryan Erick Salvid LacernaNo ratings yet

- 8866 H1 Physics 2010 JC Prelims With AnsDocument705 pages8866 H1 Physics 2010 JC Prelims With AnsAlvinNo ratings yet

- ElecSteelsMagnAlloys Brochure enDocument52 pagesElecSteelsMagnAlloys Brochure enjmacarroNo ratings yet

- TP70P-211LC1T/ TP04P-20EXL1T Operation Manual TP70P-211LC1T/ TP04P-20EXL1TDocument85 pagesTP70P-211LC1T/ TP04P-20EXL1T Operation Manual TP70P-211LC1T/ TP04P-20EXL1TFrancisco HenriqueNo ratings yet

- Unit 4 Exam Notes Sheet PhysicsDocument2 pagesUnit 4 Exam Notes Sheet PhysicsBob BobNo ratings yet

- Ultrasil Polymer Housed Varistar Type U4 Surge Arrester For Systems Through 275 KV Iec 20 Ka Line Discharge Class 4 Catalog Ca235024enDocument12 pagesUltrasil Polymer Housed Varistar Type U4 Surge Arrester For Systems Through 275 KV Iec 20 Ka Line Discharge Class 4 Catalog Ca235024enMarlus DuarteNo ratings yet

- Snaa284a TI Analog Electronics Design To Improve Performance of Ultrasonic Gas Flow MeterDocument19 pagesSnaa284a TI Analog Electronics Design To Improve Performance of Ultrasonic Gas Flow MeterA N ArunkumarNo ratings yet

- Gas Insulated MV Circuit Breakers Up To: 40.5 KV 4000 A 50 KaDocument76 pagesGas Insulated MV Circuit Breakers Up To: 40.5 KV 4000 A 50 KaDevy MangimbaNo ratings yet

- Capacitive Voltage Transformer 040126Document4 pagesCapacitive Voltage Transformer 040126dharmendra.prp100% (6)

- RF Transmitter System: in Order To Activate The Nuclei So That They Emit A UsefulDocument8 pagesRF Transmitter System: in Order To Activate The Nuclei So That They Emit A UsefulNoor AyadNo ratings yet

- NTC71 5Document15 pagesNTC71 5Joao LucasNo ratings yet

- Tank TrucksDocument4 pagesTank Trucksram27_rajiNo ratings yet

- SL-V Series: Instruction ManualDocument10 pagesSL-V Series: Instruction ManualZuyeffNo ratings yet

- EE Lab 8 FinalDocument11 pagesEE Lab 8 FinalAbdullah TahirNo ratings yet

- Magnetic Properties of Materials PDFDocument31 pagesMagnetic Properties of Materials PDFPavan_yoyo100% (1)

- The Most Friendly Bench Instruments: Appa 200 Series VersameterDocument2 pagesThe Most Friendly Bench Instruments: Appa 200 Series Versametermarcelo zarateNo ratings yet

- Artikel 4Document8 pagesArtikel 4MiqbalNo ratings yet

- Physics 2 Quiz 2Document1 pagePhysics 2 Quiz 2Erica Rose GonzalesNo ratings yet

- RSE-SEE5 Circular1 2Document3 pagesRSE-SEE5 Circular1 2dD 16No ratings yet

- Use A Treadmill DC Drive Motor and PWM Speed ContrDocument12 pagesUse A Treadmill DC Drive Motor and PWM Speed ContrErmin FazlicNo ratings yet

- Challenges and Opportunities For Batteries of Electric VehiclesDocument5 pagesChallenges and Opportunities For Batteries of Electric VehiclesjubenrajNo ratings yet

- Model BETA 87A User Guide: Application and PlacementDocument12 pagesModel BETA 87A User Guide: Application and PlacementMHEP_DANIELNo ratings yet

- 57 byDocument2 pages57 byVlad RozmarinNo ratings yet