Professional Documents

Culture Documents

Electrostop

Electrostop

Uploaded by

tajman90Copyright:

Available Formats

You might also like

- Nursing Test 4 (NP Iii)Document16 pagesNursing Test 4 (NP Iii)Yuxin Liu100% (2)

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDocument15 pagesStudy The Effect of Acids and Bases On The Tensile Strength of A FibreHiaderKhokhawala75% (69)

- Method Statement For Cable Laying, Termination, TestingDocument10 pagesMethod Statement For Cable Laying, Termination, Testingahmedshah512No ratings yet

- Guide For Electric Motor Stator Winding Insulation Design, Testing and VPI Resin TreatmentDocument102 pagesGuide For Electric Motor Stator Winding Insulation Design, Testing and VPI Resin TreatmentAndrew Maverick50% (2)

- Raychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVDocument2 pagesRaychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVwael El-BegearmiNo ratings yet

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Document14 pagesEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNo ratings yet

- CCSI Duct Metallic 144F G655C Cable Spec Rev0 JakproDocument3 pagesCCSI Duct Metallic 144F G655C Cable Spec Rev0 JakproHABIB MUSTAQIM 10No ratings yet

- Butterfly Valves: Manufacturing Water Valves Industrial Valves Penstocks and Gates Radial Gates Special ApplicationsDocument19 pagesButterfly Valves: Manufacturing Water Valves Industrial Valves Penstocks and Gates Radial Gates Special ApplicationsHrudananda DalaiNo ratings yet

- ORCA - Universal Loose Tube Armoured CSTDocument1 pageORCA - Universal Loose Tube Armoured CSTMatteo Pio OlivieriNo ratings yet

- Training Presentation Elastimold ElsewedyDocument17 pagesTraining Presentation Elastimold Elsewedywael_mohamed_aliNo ratings yet

- GJ Strand Cable System Introduction (2015)Document41 pagesGJ Strand Cable System Introduction (2015)Sony JsdNo ratings yet

- CCSI - ADSS - 12F - G652D - Cable - Spec - Rev1 - Diskominfo Bogor - RevisiDocument2 pagesCCSI - ADSS - 12F - G652D - Cable - Spec - Rev1 - Diskominfo Bogor - RevisiAlvan umaraNo ratings yet

- Corrosion Protection Coatings For Buried In-PlaDocument11 pagesCorrosion Protection Coatings For Buried In-PlaElias EliasNo ratings yet

- Sealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsDocument2 pagesSealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsjohnnysNo ratings yet

- Corning CRN 24 ALTOS 24FDocument3 pagesCorning CRN 24 ALTOS 24FSosialNo ratings yet

- Product CatalogDocument17 pagesProduct CatalogPower TechNo ratings yet

- Altos Loose Tube, Gel-Free Cable: Features and BenefitsDocument3 pagesAltos Loose Tube, Gel-Free Cable: Features and BenefitsSosialNo ratings yet

- DBTS Megatron Catalogue-1Document40 pagesDBTS Megatron Catalogue-1KNS CSBNo ratings yet

- Ecmei Cat 2010Document42 pagesEcmei Cat 2010Nandy RizaldyNo ratings yet

- Elmex-Terminal Block CatalogDocument144 pagesElmex-Terminal Block CatalogHansen LaMessiah SaputraNo ratings yet

- Nexans - N2XSY 8 7 15 KV DNC ET 031b 1Document1 pageNexans - N2XSY 8 7 15 KV DNC ET 031b 1Joel Carhuancho NanaNo ratings yet

- K Series: User ManualDocument105 pagesK Series: User ManualCraig AdamsNo ratings yet

- 15001WR 04 (20151007)Document74 pages15001WR 04 (20151007)Enzo AscañoNo ratings yet

- Motor MomentsDocument4 pagesMotor Momentsgeorgel1980No ratings yet

- 3.EHVS 132 KV - EmpalmeDocument2 pages3.EHVS 132 KV - EmpalmepablodcabreraNo ratings yet

- K.2 Series: User ManualDocument23 pagesK.2 Series: User ManualRafael Angel Vidurrízaga MazuelosNo ratings yet

- Ms 02 36Document2 pagesMs 02 36bernardibayuNo ratings yet

- EPP-1496-3-09 DA1 Series IECDocument12 pagesEPP-1496-3-09 DA1 Series IECshemakkmkNo ratings yet

- (Paperhub Ir) 10 1109@pcicon 2003 1242604Document10 pages(Paperhub Ir) 10 1109@pcicon 2003 1242604Kolvin SenevirathnaNo ratings yet

- Technical Data and CatalogueDocument16 pagesTechnical Data and CatalogueHery MukhlisNo ratings yet

- KM Offshore Division Cable Earthing Installation ManualDocument28 pagesKM Offshore Division Cable Earthing Installation ManualkabjuniorNo ratings yet

- Technical Specification For Plastic-Insulated Low Voltage CablesDocument9 pagesTechnical Specification For Plastic-Insulated Low Voltage CablesrasoolNo ratings yet

- 2/2 Way Plunger-Solenoid Valve With Separating Diaphragm: Type 0117Document8 pages2/2 Way Plunger-Solenoid Valve With Separating Diaphragm: Type 0117Сергей КучаринNo ratings yet

- Datasheet Codeline Ecoline 40L30NDocument2 pagesDatasheet Codeline Ecoline 40L30NArmando Corral BlancoNo ratings yet

- PowerSafe OPzS - GeneralDocument2 pagesPowerSafe OPzS - GeneralWido BazanNo ratings yet

- Eng DS Epp-1865 1810Document4 pagesEng DS Epp-1865 1810Cbdtxd PcbtrNo ratings yet

- F00497en 02Document2 pagesF00497en 02csjijgosjoNo ratings yet

- Product Technical InformationDocument3 pagesProduct Technical Informationtedak2No ratings yet

- IPT ReviewDocument22 pagesIPT ReviewKshitija KalyankarNo ratings yet

- Ecia/Jedec Experimentation On Solderability Test PreconditioningDocument28 pagesEcia/Jedec Experimentation On Solderability Test PreconditioningesrisloNo ratings yet

- 1112impact of Petroleum Jelly On The Ageing of Telephone Wire FinalDocument6 pages1112impact of Petroleum Jelly On The Ageing of Telephone Wire FinalNavneet SinghNo ratings yet

- Motortech Salesflyer Champion Spark Plug Fb77wpcc 01.25.019 en 2018 07Document2 pagesMotortech Salesflyer Champion Spark Plug Fb77wpcc 01.25.019 en 2018 07RobertNo ratings yet

- Catalogue TD InsulatorsDocument24 pagesCatalogue TD InsulatorsmartinpellsNo ratings yet

- Udey Pyrocables - Instrumentation Cables Write-UpDocument14 pagesUdey Pyrocables - Instrumentation Cables Write-UpameyraneNo ratings yet

- Specification For 150kV AL 630sqmm CableDocument4 pagesSpecification For 150kV AL 630sqmm Cablebachtiar ramadhanNo ratings yet

- 2011-JAN ES-E SM-0128 US RevBDocument2 pages2011-JAN ES-E SM-0128 US RevBpclaptopsusNo ratings yet

- Cathodic Protection Drawings SP-1136Document4 pagesCathodic Protection Drawings SP-1136anuprajoshNo ratings yet

- PTP Support CatalogDocument199 pagesPTP Support CatalogIner GenNo ratings yet

- Siemens Flex CableDocument107 pagesSiemens Flex CableFateh TabaichountNo ratings yet

- Complete Tpo Roofing CatalogueDocument19 pagesComplete Tpo Roofing CatalogueAnastasia ErlitaNo ratings yet

- Astm E1974 - 1 (En)Document18 pagesAstm E1974 - 1 (En)Dinesh SaiNo ratings yet

- E 65 32 27 PDFDocument4 pagesE 65 32 27 PDFDhuvi LuvioNo ratings yet

- DDEControllerDocument13 pagesDDEControllercataNo ratings yet

- EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2Document47 pagesEE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2manoj kumarNo ratings yet

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06No ratings yet

- SPECTITE Inc Cat1Document12 pagesSPECTITE Inc Cat1Abraham100% (1)

- ECP Safe-T-Pull Remote (2019)Document2 pagesECP Safe-T-Pull Remote (2019)Guang ChenzNo ratings yet

- Sheet 1 of 8: Oleoducto Crudos PesadosDocument8 pagesSheet 1 of 8: Oleoducto Crudos PesadosVictor VillarrealNo ratings yet

- A Nexans Company: Catalogue 2009Document31 pagesA Nexans Company: Catalogue 2009Mosa Elnaid ElnaidNo ratings yet

- E-7 Electric Heat Trace PDFDocument15 pagesE-7 Electric Heat Trace PDFvikingNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Stones DevelopmentDocument52 pagesStones Developmenttajman90No ratings yet

- Hdpe Catalog Volume 1Document52 pagesHdpe Catalog Volume 1tajman90No ratings yet

- Access Guidline For Manual VavesDocument1 pageAccess Guidline For Manual Vavestajman90No ratings yet

- Eram Data Sheet 20 11 19Document2 pagesEram Data Sheet 20 11 19tajman90No ratings yet

- DocumentDocument3 pagesDocumenttajman90No ratings yet

- Product Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986Document38 pagesProduct Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986tajman90No ratings yet

- Prochind Monolithic Insulating Joints Pn40-100 enDocument1 pageProchind Monolithic Insulating Joints Pn40-100 entajman90No ratings yet

- Health, Safety, Environment and Quality Assurance Division Das Island DivisionDocument10 pagesHealth, Safety, Environment and Quality Assurance Division Das Island Divisiontajman90No ratings yet

- Fire Fighting PresentationDocument36 pagesFire Fighting Presentationtajman90No ratings yet

- Swc5-Ld: Specified PerformanceDocument1 pageSwc5-Ld: Specified PerformanceBenjamin MillerNo ratings yet

- Hood Design Sample Problems PDFDocument17 pagesHood Design Sample Problems PDFRiyazuddin MahamadNo ratings yet

- Case Study3-FitbitDocument11 pagesCase Study3-FitbitKwai Fong PANGNo ratings yet

- DocumentDocument4 pagesDocumentAngelica Jusay IbusNo ratings yet

- Behavioural Learning TheoriesDocument18 pagesBehavioural Learning TheoriesLouis SpencerNo ratings yet

- Auxiliary PowerDocument29 pagesAuxiliary PowerManoj UpadhyayNo ratings yet

- An Analysis On Maternity Benefit Laws of BangladeshDocument33 pagesAn Analysis On Maternity Benefit Laws of Bangladeshayesha.siddika.241No ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- The Ark Mythology: Philosophy and SkepticismDocument24 pagesThe Ark Mythology: Philosophy and SkepticismBrent SilbyNo ratings yet

- Pathogenesis & Prognosis LeukoplakiaDocument4 pagesPathogenesis & Prognosis LeukoplakiaSundhias LarashatiNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- Arcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Document1 pageArcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Felicia Cioaba100% (2)

- People v. PuedanDocument12 pagesPeople v. PuedanAlex FranciscoNo ratings yet

- MRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDocument12 pagesMRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDan RotariNo ratings yet

- Process and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21Document17 pagesProcess and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21schembriryanNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- ICU PendnatDocument8 pagesICU PendnatTH HMNo ratings yet

- Elecrolysis Cell DrawingDocument2 pagesElecrolysis Cell DrawingRimaNo ratings yet

- PROLYMERDocument2 pagesPROLYMERFlavio GonzalezNo ratings yet

- Engelhardt BioethicsDocument9 pagesEngelhardt BioethicsAaron Lee WiegmannNo ratings yet

- Perinatal Anxiety Screening ScaleDocument8 pagesPerinatal Anxiety Screening ScaleAprillia RNo ratings yet

- Bir Form 1600Document9 pagesBir Form 1600Vincent De GuzmanNo ratings yet

- Information Technology System Applicable To Nursing PracticeDocument56 pagesInformation Technology System Applicable To Nursing PracticeKristle Ann VillarealNo ratings yet

- DLL - Mapeh 3 - Q1 - W7Document5 pagesDLL - Mapeh 3 - Q1 - W7ADONNIS PESCASIONo ratings yet

- Instruction Manual: Power Meter T250Document20 pagesInstruction Manual: Power Meter T250Fersh ValderramashNo ratings yet

- RENOLD (Worm Gear - Models PH)Document60 pagesRENOLD (Worm Gear - Models PH)Rodrigo Leal GuzmanNo ratings yet

- Learning Challenges of Student Nurses in Virtual Learning QuestionnairesDocument8 pagesLearning Challenges of Student Nurses in Virtual Learning QuestionnairesJelaveil De VeraNo ratings yet

- IFR 150 GSM CoverallDocument4 pagesIFR 150 GSM CoverallBinay100% (1)

Electrostop

Electrostop

Uploaded by

tajman90Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrostop

Electrostop

Uploaded by

tajman90Copyright:

Available Formats

SD-ElectroStop-01-Rev.

0

Product Specification & Data

ElectroStop™ Rev. 00 Page 1 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

ELECTROSTOP™

MONOLITHIC ISOLATION JOINT

GPT QUALITY POLICY

We are committed to total quality customer satisfaction by:

• Driving continuous improvement in everything we do

• Exceeding our customer’s expectations

• Providing highest quality products

• Delivering on time

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

SD-ElectroStop-01-Rev.0

Product Specification & Data

ElectroStop™ Rev. 00 Page 2 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

1.0 PRODUCT OVERVIEW

1.1 PURPOSE

1.1.1 This purpose of this document is to describe the various parts of the manufacturing

process for ElectroStop™ Monolithic Isolation Joints.

1.2 SCOPE

1.2.1 This document covers the design, material and manufacturing standards for all NPS 2 - 24

ElectroStop™ Monolithic Isolation Joints manufactured at the GPT, Houston facility.

1.3 DEFINITIONS

ASTM - American Society for Testing Material

ANSI - American National Standards Institute

API - American Petroleum Institute

ASME - American Society of Mechanical Engineers

Cathodic Protection - A technique used to control the corrosion of a metal surface by making

it the cathode of an electrochemical cell.

Dielectric Fitting - A fitting having insulating parts or material that prohibits flow of electric

current.

Dielectric Strength - The maximum electrical field strength a non-conducting material can

withstand without breaking down.

Forged Steel Fittings - Solid pieces of steel are forced into fitting shapes under very high

temperature and pressure and then machined into final form

Galvanic Action - When two dissimilar metals are immersed in the same electrolytic solution

and connected electrically there is an interchange of atoms carrying an electric charge

between them. The anode metal with the higher electrode potential corrodes with the cathode

protected.

ISO 9000 - A series of five standards for developing a total quality management system.

Developed by the International Organization for Standardization.

ID - Inside diameter - the diameter of a pipe measured from the inside edges.

Insulation Resistance - The resistance to current leakage through the insulation materials.

Monolithic - consisting of or constituting a single unit.

NPS - Nominal Pipe Size - a North American set of standard sizes for pipes used for high or low

pressures and temperatures. Pipe size is specified with two non-dimensional numbers: a

nominal pipe size (NPS) for diameter based on inches, and a schedule (Sched. or Sch.) for

wall thickness.

OD- Outside Diameter - the diameter of a pipe measured from the outside edges.

SMLS - Seamless pipe

SPEC - Specification

STD - Standard

Schedule - Numbers assigned to different wall thicknesses of pipe (e.g.40, 80, 160)

Seamless Pipe - Pipe or tube formed by piercing a billet of steel and then rolling.

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

SD-ElectroStop-01-Rev.0

Product Specification & Data

ElectroStop™ Rev. 00 Page 3 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

Specified Minimum Yield Strength (SMYS) - the specified minimum yield strength for steel

pipe manufactured in accordance with a listed specification. It is an indication of the minimum

stress a pipe may experience that will cause plastic (permanent) deformation.

Thermosetting - A process in which a prepolymer in a soft solid or viscous state changes

irreversibly into an infusible, insoluble polymer network by curing.

Wall Thickness - The thickness of the pipe wall.

1.4 GENERAL DESCRIPTION

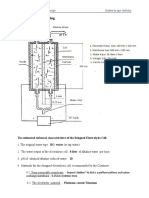

1.4.1 ElectroStop™ Monolithic Isolation Joints are used for electrical sectioning and improving

cathodic protection systems against corrosion of gas, water and petroleum pipelines. The

ElectroStop™ eliminates short circuits, field assembly and is less expensive than a

jointed flange with isolation gaskets. A high insulation resistance is assured by three

features: a) insulation gasket that prevents metal-to-metal contact across the joint, b)

internal cavities filled with a high dielectric strength compound, and c) internal and

external surfaces coated with non-conductive epoxy paint.

1. PIPE PUP A

2. RTV SEALANT

3. COLLAR

9 10

8 4. DIELECTRIC EPOXY RESIN

7 5. INSULATION RING

6. FLANGE A

6

7. O-RINGS

5

8. EPOXY COATING

4 9. FLANGE B

10. PIPE PUP B

3

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

SD-ElectroStop-01-Rev.0

Product Specification & Data

ElectroStop™ Rev. 00 Page 4 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

1.5 DESIGN & MANUFACTURING REQUIREMENTS

1.5.1 Monolithic isolation fittings shall be boltless and completely factory assembled in

accordance with the appropriate requirements of ASTM, API, DIN and BS codes. All

welds shall be butt weld construction. The dielectric isolation material shall be a

thermosetting fiberglass epoxy material. Sealing shall be by two static O-ring seals

housed machined grooves, fully protected from cavitation in full compliance with ASME

design codes. Interior and exterior coating shall be a two part epoxy with a thickness of

16 to 24 mils to within 2” of each end. Testing shall be Electrical (@5kv, 25 Mohm),

Hydraulic (@ 1.5 x O.P.) and Weld (Ultrasonic/Magnetic Particle).

1.6 MATERIAL SPECIFICATIONS

1.6.1 Pipe, Casting and Forging Specs

Specification Min. Tensile

Part Material Specification Size Range Type Grade SMYS (PSI)

Standard Strength (PSI)

A106 - This specification covers carbon steel

Pipe Carbon Steel ASTM NPS 2 - 4 SMLS B 35,000 60,000

pipe for high-temperature service.

API 5LX - This specification covers High test line PSL 1

Pipe Carbon Steel API NPS 6-24 X52 52,200 66,700

pipe. SMLS

API 5LX - This specification covers High test line PSL 2

Pipe Carbon Steel API NPS 6-24 X52 52,200 - 76,900 66,700 - 110,200

pipe. SMLS

A216 - This specification covers carbon steel

castings for Valves, flanges, fittings, or other

Castings Carbon Steel ASTM NPS 2 - 4 WCB 36,000 70,000 - 95,000

pressure-containing parts for high-temperature

service and of quality suitable for assembly w ith

A105 - This specification covers standards for

Forgings Carbon Steel ASTM forged carbon steel piping components, that is, NPS 6-24 A105 36,000 70,000

flanges, fittings, Valves, and similar parts, for

A694 - This specification covers forged or rolled

Forgings Carbon Steel ASTM steel pipe NPS 6-24 F52 52,000 66,000

flanges, forged fittings, valves, and parts

1.6.2 Isolation Gaskets - The dielectric insulation material shall be of glass reinforced epoxy

conforming to ASTM D709 Class IV.

1.6.3 O-rings – A 70 durometer Nitrile inner o-ring seal and a 75 durometer Viton outer o-ring

seal is the GPT standard. Other material may be selected upon customer request and

shall be conforming to an ASTM D2000 classification or equivalent material.

O-Ring Material Selection

ASTM

D1418 Elastomer Brief Summary

Designation

Nitrile has good mechanical properties and high wear resistance relative to

Buna-N

NBR other elastomers. Unless they are specially compounded, nitrile is not

(Nitrile)

resistant to weathering, sunlight and ozone.

Butadiene,

SBR is similar to natural rubber. SBR is mostly used in tires and seals for

SBR, BR Styrene

non-mineral oil based applications.

Butadiene

Butyl has a very low permeability rate making it a great seal under vacuum.

IIR Butyl

Butyl also has good electrical, shock dampening properties.

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

SD-ElectroStop-01-Rev.0

Product Specification & Data

ElectroStop™ Rev. 00 Page 5 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

Neoprene® exhibits good oil, ozone, weather, aging, refrigeration and

Chloroprene

CR chemical resistance. It also has good mechanical properties over a wide

(Neoprene®)

temperature range.

Ethylene Ethylene Propylene Copolymer has excellent resistance to phosphate ester

EPM, EPDM

Propylene fluids (Skydrol), brake fluids (glycol base), steam, weather, and ozone.

Responds very well with resistance to ozone, high temperatures, oxygen,

Fluorocarbon

FKM mineral oil, synthetic hydraulic fluids, fuels, aromatics and many organic

(Viton®)

solvents and chemicals. The universal O-ring.

Has excellent resistance to petroleum oils and fuels. Fluorosilicone has

FSI, FVMQ Fluorosilicone limited strength and abrasion resistance so it is generally recommended for

static applications only.

HNBR has excellent abrasion, compression set, tensile, and tear properties.

Hydrogenated

HNBR Unlike standard nitriles, HNBR resists ozone, sunlight, and other

Nitrile

atmospheric environments.

Natural

Natural Rubber / Isoprene has excellent dynamic properties. However, it

NR / IR Rubber /

does not do well with petroleum oils, sunlight and ozone.

Isoprene

Polyacrylate is used in applications such as transmissions or anything where

ACM Polyacrylate there is petroleum oils and high temperature. Highly resistant to ozone and

weathering.

Silicon exhibits great temperature range capabilities. Silicones also has good

Si, VMQ, MQ,

Silicone resistance to ozone, weather and is also a good insulator. However, it has

MQ, PVMQ

low tensile, tear and wear resistance.

1.6.4 Epoxy Fill – 90-3001 is a low viscosity, unfilled epoxy potting and encapsulating system

which forms a bubble free glass like finish when cured. This is a 100% solids resin system

that does not contain any solvents. Its low viscosity aids in filling voids and air pockets. In

addition, there is no filler settling with this system.

1.6.4.1 TYPICAL SPECIFICATIONS

Color Clear

Mix ratio, by volume 1:1

Mix ratio, by weight 100:83

Mix viscosity, @ 25C, cps 1,000

Pot life, 100 gram mass, @ 25C 20 minutes

Specific gravity, @ 25C 1.12

Hardness, Shore D 55-60

Tensile strength, psi 5,700

Thermal conductivity, btu·in/hr·ft2·F 3.0

Thermal expansion coefficient per C 50x10-6

Operating temperature C -50 to +150

Dielectric strength, volts/mil 558

Dielectric constant, 60 Hz 4.7

Dissipation factor, 60 Hz .034

Volume resistivity, ohm-cm 5.0x1015

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

SD-ElectroStop-01-Rev.0

Product Specification & Data

ElectroStop™ Rev. 00 Page 6 of 6

an EnPro Industries company Monolithic Isolation Joints Date Approved: 4/31/2014

1.6.5 RTV Sealant – A 100 percent silicone RTV rubber, neutral-cure sealant, Dow Corning

832 Multi-Surface Adhesive Sealant is non-corrosive and provides superior unprimed

adhesion, forming a flexible and long-lasting seal.

1.6.6 Epoxy Coating - The internal and external coating shall be a fusion-bonded epoxy resin.

The coating shall be applied, per manufacturer recommendations, the full length of each

steel pipe pup except for a 2” cut-back on both ends for welding.

GPT CONFIDENTIAL use pursuant to Company Procedures

THIS DOCUMENT IS UNCONTROLLED IF PRINTED

You might also like

- Nursing Test 4 (NP Iii)Document16 pagesNursing Test 4 (NP Iii)Yuxin Liu100% (2)

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDocument15 pagesStudy The Effect of Acids and Bases On The Tensile Strength of A FibreHiaderKhokhawala75% (69)

- Method Statement For Cable Laying, Termination, TestingDocument10 pagesMethod Statement For Cable Laying, Termination, Testingahmedshah512No ratings yet

- Guide For Electric Motor Stator Winding Insulation Design, Testing and VPI Resin TreatmentDocument102 pagesGuide For Electric Motor Stator Winding Insulation Design, Testing and VPI Resin TreatmentAndrew Maverick50% (2)

- Raychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVDocument2 pagesRaychem Inline and Shield-Break Joint EHVS For 123 KV Up To 170 KVwael El-BegearmiNo ratings yet

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Document14 pagesEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNo ratings yet

- CCSI Duct Metallic 144F G655C Cable Spec Rev0 JakproDocument3 pagesCCSI Duct Metallic 144F G655C Cable Spec Rev0 JakproHABIB MUSTAQIM 10No ratings yet

- Butterfly Valves: Manufacturing Water Valves Industrial Valves Penstocks and Gates Radial Gates Special ApplicationsDocument19 pagesButterfly Valves: Manufacturing Water Valves Industrial Valves Penstocks and Gates Radial Gates Special ApplicationsHrudananda DalaiNo ratings yet

- ORCA - Universal Loose Tube Armoured CSTDocument1 pageORCA - Universal Loose Tube Armoured CSTMatteo Pio OlivieriNo ratings yet

- Training Presentation Elastimold ElsewedyDocument17 pagesTraining Presentation Elastimold Elsewedywael_mohamed_aliNo ratings yet

- GJ Strand Cable System Introduction (2015)Document41 pagesGJ Strand Cable System Introduction (2015)Sony JsdNo ratings yet

- CCSI - ADSS - 12F - G652D - Cable - Spec - Rev1 - Diskominfo Bogor - RevisiDocument2 pagesCCSI - ADSS - 12F - G652D - Cable - Spec - Rev1 - Diskominfo Bogor - RevisiAlvan umaraNo ratings yet

- Corrosion Protection Coatings For Buried In-PlaDocument11 pagesCorrosion Protection Coatings For Buried In-PlaElias EliasNo ratings yet

- Sealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsDocument2 pagesSealed Receptacles With UTS Crimp Contacts For Bulkhead ApplicationsjohnnysNo ratings yet

- Corning CRN 24 ALTOS 24FDocument3 pagesCorning CRN 24 ALTOS 24FSosialNo ratings yet

- Product CatalogDocument17 pagesProduct CatalogPower TechNo ratings yet

- Altos Loose Tube, Gel-Free Cable: Features and BenefitsDocument3 pagesAltos Loose Tube, Gel-Free Cable: Features and BenefitsSosialNo ratings yet

- DBTS Megatron Catalogue-1Document40 pagesDBTS Megatron Catalogue-1KNS CSBNo ratings yet

- Ecmei Cat 2010Document42 pagesEcmei Cat 2010Nandy RizaldyNo ratings yet

- Elmex-Terminal Block CatalogDocument144 pagesElmex-Terminal Block CatalogHansen LaMessiah SaputraNo ratings yet

- Nexans - N2XSY 8 7 15 KV DNC ET 031b 1Document1 pageNexans - N2XSY 8 7 15 KV DNC ET 031b 1Joel Carhuancho NanaNo ratings yet

- K Series: User ManualDocument105 pagesK Series: User ManualCraig AdamsNo ratings yet

- 15001WR 04 (20151007)Document74 pages15001WR 04 (20151007)Enzo AscañoNo ratings yet

- Motor MomentsDocument4 pagesMotor Momentsgeorgel1980No ratings yet

- 3.EHVS 132 KV - EmpalmeDocument2 pages3.EHVS 132 KV - EmpalmepablodcabreraNo ratings yet

- K.2 Series: User ManualDocument23 pagesK.2 Series: User ManualRafael Angel Vidurrízaga MazuelosNo ratings yet

- Ms 02 36Document2 pagesMs 02 36bernardibayuNo ratings yet

- EPP-1496-3-09 DA1 Series IECDocument12 pagesEPP-1496-3-09 DA1 Series IECshemakkmkNo ratings yet

- (Paperhub Ir) 10 1109@pcicon 2003 1242604Document10 pages(Paperhub Ir) 10 1109@pcicon 2003 1242604Kolvin SenevirathnaNo ratings yet

- Technical Data and CatalogueDocument16 pagesTechnical Data and CatalogueHery MukhlisNo ratings yet

- KM Offshore Division Cable Earthing Installation ManualDocument28 pagesKM Offshore Division Cable Earthing Installation ManualkabjuniorNo ratings yet

- Technical Specification For Plastic-Insulated Low Voltage CablesDocument9 pagesTechnical Specification For Plastic-Insulated Low Voltage CablesrasoolNo ratings yet

- 2/2 Way Plunger-Solenoid Valve With Separating Diaphragm: Type 0117Document8 pages2/2 Way Plunger-Solenoid Valve With Separating Diaphragm: Type 0117Сергей КучаринNo ratings yet

- Datasheet Codeline Ecoline 40L30NDocument2 pagesDatasheet Codeline Ecoline 40L30NArmando Corral BlancoNo ratings yet

- PowerSafe OPzS - GeneralDocument2 pagesPowerSafe OPzS - GeneralWido BazanNo ratings yet

- Eng DS Epp-1865 1810Document4 pagesEng DS Epp-1865 1810Cbdtxd PcbtrNo ratings yet

- F00497en 02Document2 pagesF00497en 02csjijgosjoNo ratings yet

- Product Technical InformationDocument3 pagesProduct Technical Informationtedak2No ratings yet

- IPT ReviewDocument22 pagesIPT ReviewKshitija KalyankarNo ratings yet

- Ecia/Jedec Experimentation On Solderability Test PreconditioningDocument28 pagesEcia/Jedec Experimentation On Solderability Test PreconditioningesrisloNo ratings yet

- 1112impact of Petroleum Jelly On The Ageing of Telephone Wire FinalDocument6 pages1112impact of Petroleum Jelly On The Ageing of Telephone Wire FinalNavneet SinghNo ratings yet

- Motortech Salesflyer Champion Spark Plug Fb77wpcc 01.25.019 en 2018 07Document2 pagesMotortech Salesflyer Champion Spark Plug Fb77wpcc 01.25.019 en 2018 07RobertNo ratings yet

- Catalogue TD InsulatorsDocument24 pagesCatalogue TD InsulatorsmartinpellsNo ratings yet

- Udey Pyrocables - Instrumentation Cables Write-UpDocument14 pagesUdey Pyrocables - Instrumentation Cables Write-UpameyraneNo ratings yet

- Specification For 150kV AL 630sqmm CableDocument4 pagesSpecification For 150kV AL 630sqmm Cablebachtiar ramadhanNo ratings yet

- 2011-JAN ES-E SM-0128 US RevBDocument2 pages2011-JAN ES-E SM-0128 US RevBpclaptopsusNo ratings yet

- Cathodic Protection Drawings SP-1136Document4 pagesCathodic Protection Drawings SP-1136anuprajoshNo ratings yet

- PTP Support CatalogDocument199 pagesPTP Support CatalogIner GenNo ratings yet

- Siemens Flex CableDocument107 pagesSiemens Flex CableFateh TabaichountNo ratings yet

- Complete Tpo Roofing CatalogueDocument19 pagesComplete Tpo Roofing CatalogueAnastasia ErlitaNo ratings yet

- Astm E1974 - 1 (En)Document18 pagesAstm E1974 - 1 (En)Dinesh SaiNo ratings yet

- E 65 32 27 PDFDocument4 pagesE 65 32 27 PDFDhuvi LuvioNo ratings yet

- DDEControllerDocument13 pagesDDEControllercataNo ratings yet

- EE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2Document47 pagesEE8451, EE6303 Linear Integrated Circuits and Applications LICA - 2 Marks With Answers 2manoj kumarNo ratings yet

- 33& 11kv Terminations. KitsDocument9 pages33& 11kv Terminations. Kitsnvinodn06No ratings yet

- SPECTITE Inc Cat1Document12 pagesSPECTITE Inc Cat1Abraham100% (1)

- ECP Safe-T-Pull Remote (2019)Document2 pagesECP Safe-T-Pull Remote (2019)Guang ChenzNo ratings yet

- Sheet 1 of 8: Oleoducto Crudos PesadosDocument8 pagesSheet 1 of 8: Oleoducto Crudos PesadosVictor VillarrealNo ratings yet

- A Nexans Company: Catalogue 2009Document31 pagesA Nexans Company: Catalogue 2009Mosa Elnaid ElnaidNo ratings yet

- E-7 Electric Heat Trace PDFDocument15 pagesE-7 Electric Heat Trace PDFvikingNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Stones DevelopmentDocument52 pagesStones Developmenttajman90No ratings yet

- Hdpe Catalog Volume 1Document52 pagesHdpe Catalog Volume 1tajman90No ratings yet

- Access Guidline For Manual VavesDocument1 pageAccess Guidline For Manual Vavestajman90No ratings yet

- Eram Data Sheet 20 11 19Document2 pagesEram Data Sheet 20 11 19tajman90No ratings yet

- DocumentDocument3 pagesDocumenttajman90No ratings yet

- Product Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986Document38 pagesProduct Data Sheet Bettis G Series Pneumatic Double Acting Spring Return Actuator Torque Chart Metric en 1458986tajman90No ratings yet

- Prochind Monolithic Insulating Joints Pn40-100 enDocument1 pageProchind Monolithic Insulating Joints Pn40-100 entajman90No ratings yet

- Health, Safety, Environment and Quality Assurance Division Das Island DivisionDocument10 pagesHealth, Safety, Environment and Quality Assurance Division Das Island Divisiontajman90No ratings yet

- Fire Fighting PresentationDocument36 pagesFire Fighting Presentationtajman90No ratings yet

- Swc5-Ld: Specified PerformanceDocument1 pageSwc5-Ld: Specified PerformanceBenjamin MillerNo ratings yet

- Hood Design Sample Problems PDFDocument17 pagesHood Design Sample Problems PDFRiyazuddin MahamadNo ratings yet

- Case Study3-FitbitDocument11 pagesCase Study3-FitbitKwai Fong PANGNo ratings yet

- DocumentDocument4 pagesDocumentAngelica Jusay IbusNo ratings yet

- Behavioural Learning TheoriesDocument18 pagesBehavioural Learning TheoriesLouis SpencerNo ratings yet

- Auxiliary PowerDocument29 pagesAuxiliary PowerManoj UpadhyayNo ratings yet

- An Analysis On Maternity Benefit Laws of BangladeshDocument33 pagesAn Analysis On Maternity Benefit Laws of Bangladeshayesha.siddika.241No ratings yet

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- The Ark Mythology: Philosophy and SkepticismDocument24 pagesThe Ark Mythology: Philosophy and SkepticismBrent SilbyNo ratings yet

- Pathogenesis & Prognosis LeukoplakiaDocument4 pagesPathogenesis & Prognosis LeukoplakiaSundhias LarashatiNo ratings yet

- Pbl-Gin Urine Test (Feme)Document11 pagesPbl-Gin Urine Test (Feme)KarthigaRamanNo ratings yet

- Arcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Document1 pageArcelormittal Galati S.A. - Romania: Inspection Certificate 20564275 According To: en 10204/2004/3.1 Date: 26.11.2018Felicia Cioaba100% (2)

- People v. PuedanDocument12 pagesPeople v. PuedanAlex FranciscoNo ratings yet

- MRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDocument12 pagesMRXBOXAB-ECO (3 5) - AESW - MVHR For Wall MountingDan RotariNo ratings yet

- Process and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21Document17 pagesProcess and Material Specification: AIPI05-03-006 01-02-71 A1 FEB 01/21schembriryanNo ratings yet

- Autoclave - Kaizen ImperialDocument3 pagesAutoclave - Kaizen ImperialAnaThomasNo ratings yet

- ICU PendnatDocument8 pagesICU PendnatTH HMNo ratings yet

- Elecrolysis Cell DrawingDocument2 pagesElecrolysis Cell DrawingRimaNo ratings yet

- PROLYMERDocument2 pagesPROLYMERFlavio GonzalezNo ratings yet

- Engelhardt BioethicsDocument9 pagesEngelhardt BioethicsAaron Lee WiegmannNo ratings yet

- Perinatal Anxiety Screening ScaleDocument8 pagesPerinatal Anxiety Screening ScaleAprillia RNo ratings yet

- Bir Form 1600Document9 pagesBir Form 1600Vincent De GuzmanNo ratings yet

- Information Technology System Applicable To Nursing PracticeDocument56 pagesInformation Technology System Applicable To Nursing PracticeKristle Ann VillarealNo ratings yet

- DLL - Mapeh 3 - Q1 - W7Document5 pagesDLL - Mapeh 3 - Q1 - W7ADONNIS PESCASIONo ratings yet

- Instruction Manual: Power Meter T250Document20 pagesInstruction Manual: Power Meter T250Fersh ValderramashNo ratings yet

- RENOLD (Worm Gear - Models PH)Document60 pagesRENOLD (Worm Gear - Models PH)Rodrigo Leal GuzmanNo ratings yet

- Learning Challenges of Student Nurses in Virtual Learning QuestionnairesDocument8 pagesLearning Challenges of Student Nurses in Virtual Learning QuestionnairesJelaveil De VeraNo ratings yet

- IFR 150 GSM CoverallDocument4 pagesIFR 150 GSM CoverallBinay100% (1)