Professional Documents

Culture Documents

Mde 3116e

Mde 3116e

Uploaded by

Mark GilbreathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mde 3116e

Mde 3116e

Uploaded by

Mark GilbreathCopyright:

Available Formats

MDE-3116E

Distribution Box PA0306 Installation Instructions

November 2015

Introduction

Purpose

This manual provides installation instructions for the Distribution Box (D-Box)

PA0306XX20. The D-Box provides an interface between Gilbarco® consoles and controllers

with two-wire current loop and one of the following:

• Dispensing units

• CRIND® devices

Note: Current D-Boxes are available only with dual interface boards. Early D-Boxes were

available with single or dual interface boards.

IMPORTANT INFORMATION

Do not install this equipment unless you have proper training for installing equipment in a

hazardous location.

Intended Users

This manual is intended for Gilbarco trained and certified Authorized Service Contractors

(ASCs).

Table of Contents

Topic Page

Introduction 1

Important Safety Information 4

Overview 6

Preliminary Preparation 8

Installing D-Box 12

Appendix: Rewiring Transformer for Smaller Sites 15

Required Tools

Following tools are required for installing the D-Box:

• Drill

• Megger® Tester

• Phillips® Screwdriver

• Slotted-tip Screwdriver

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 1

Introduction

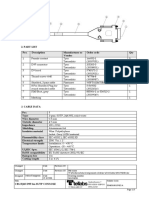

Parts List

PA03060020 D-Box

Following parts are required for installing the PA03060020 D-Box:

Item Description Part Number Quantity

1 Assembly, D-Box T19505-G3 1

2 Packing, D-Box PK0943 1

3 Kit, Documentation Package K94212-01 1

4 Cord, Set, Power 115 Voltage Alternate Current (VAC), Q11121-01 1

Plug/Receptacle

5 Assembly, Cable, Mass Terminal Assembly (MTA) R19263-G1 4

Pigtails

PA03061020 D-Box

Following parts required for installing the PA03061020 D-Box:

Item Description Part Number Quantity

1 Assembly, D-Box T19505-G4 1

2 Conformité Européenne (CE) Decal N23725 1

3 Packing, D-Box PK0943 1

4 Kit, Documentation Package K94212-01 1

5 Power Cord, 230 VAC, 3 Conductor, Right Angle Female Connector Q11736-02 1

6 Assembly, Cable MTA Pigtails R19263-G1 4

Required Reading

Read the safety information provided in “Important Safety Information” on page 4 before you

begin installation.

Read NFPA 30A and NFPA 70®

Before installing the equipment, read, understand, and follow:

• The National Electrical Code (NFPA 70)

• The Automotive and Marine Service Code (NFPA 30A)

• Any national, state, and local codes that apply

Failure to install the equipment in accordance with these codes may adversely affect the safe

use and operation of the equipment.

Related Documents

Document

Number Title GOLDSM Library

FE-321 Gilbarco STP Isolation Relay Box PA0287 120 VAC Engineering Diagrams

FE-363 Field Wiring Diagram Encore® 500/700 • Encore and Eclipse®

(M07555 Power Supply Only) • Encore and Eclipse Installers

• Engineering Diagrams

FE-364 Field Wiring Diagram Encore 300 • Encore and Eclipse

• Encore and Eclipse Installers

• Engineering Diagrams

Page 2 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Introduction

Document

Number Title GOLDSM Library

MDE-2530 Pump and Dispenser Installation Manual Footprint and Elevations

MDE-2531 Gilbarco Pump and Dispenser Start-Up and Service • Pump & Dispenser Start-Up

• Service Manual

MDE-2755 STP Control and Dispenser Isolation Relay Box • Advantage® and Legacy®

(PA0287) • Encore and Eclipse

• Encore and Eclipse Installers

MDE-3620 Point of Sale (POS) Systems Site Preparation Site Prep

Manual

MDE-3816 Passport® Hardware Start-up and Service Manual • Passport

• Service Manual

MDE-5083 Passport Hardware Start-up and Service Manual for Passport

PX60 Platform

Abbreviations and Acronyms

Term Description

ASC Authorized Service Contractors

AWG American Wire Gauge

CE Conformité Européenne

CRIND Card Reader in Dispenser

CSA Canadian Standards Association

D-Box Distribution Box

EDH Enhanced Dispenser Hub

ESD Electrostatic Discharge

GOLD Gilbarco Online Documentation

MTA Mass Terminal Assembly

NEC® National Electrical Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Administration

PCB Printed Circuit Board

POS Point of Sale

RFI Radio Frequency Interference

STP Submersible Turbine Pump

TAC Technical Assistance Center

TWI Two-wire Interface

UL® Underwriters Laboratories

UTP Unshielded Twisted-pair

VAC Voltage Alternate Current

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 3

Important Safety Information

Important Safety Information

Notes: 1) Save this Important Safety Information section Read the Manual

in a readily accessible location. Read, understand, and follow this manual and any other labels

or related materials supplied with this equipment. If you do not

2) Although DEF is non-flammable, Diesel is

understand a procedure, call the Technical Assistance Center

flammable. Therefore, for DEF cabinets that are

(TAC) at 1-800-743-7501. It is imperative to your safety and the

attached to Diesel dispensers, follow all the

safety of others to understand the procedures before beginning

notes in this section that pertain to flammable work.

fuels.

Follow the Regulations

This section introduces the hazards and safety precautions

Applicable information is available in National Fire Protection

associated with installing, inspecting, maintaining, or servicing

Association (NFPA) 30A; Code for Motor Fuel Dispensing

this product. Before performing any task on this product, read

Facilities and Repair Garages, NFPA 70; National Electrical

this safety information and the applicable sections in this

Code (NEC), Occupational Safety and Health Administration

manual, where additional hazards and safety precautions for

(OSHA) regulations and federal, state, and local codes. All

your task will be found. Fire, explosion, electrical shock, or

these regulations must be followed. Failure to install, inspect,

pressure release could occur and cause death or serious injury,

maintain, or service this equipment in accordance with these

if these safe service procedures are not followed.

codes, regulations, and standards may lead to legal citations

with penalties or affect the safe use and operation of the

Preliminary Precautions equipment.

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

Replacement Parts

trained or authorized individuals knowledgeable in the related

Use only genuine Gilbarco replacement parts and retrofit kits on

procedures should install, inspect, maintain, or service this

your pump/dispenser. Using parts other than genuine Gilbarco

equipment.

replacement parts could create a safety hazard and violate

local regulations.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate Safety Symbols and Warning Words

the switch or circuit breakers that shut off all power to all fueling This section provides important information about warning

equipment, dispensing devices, and Submerged Turbine symbols and boxes.

Pumps (STPs). Alert Symbol

! ! WARNING

The EMERGENCY STOP, ALL STOP, and This safety alert symbol is used in this manual and on

PUMP STOP buttons at the cashier’s station warning labels to alert you to a precaution which must be

WILL NOT shut off electrical power to the followed to prevent potential personal safety hazards. Obey

pump/dispenser. This means that even if you safety directives that follow this symbol to avoid possible injury

activate these stops, fuel may continue to flow or death.

uncontrolled. Signal Words

These signal words used in this manual and on warning labels

You must use the TOTAL ELECTRICAL tell you the seriousness of particular safety hazards. The

SHUT-OFF in the case of an emergency and not precautions below must be followed to prevent death, injury, or

the console’s ALL STOP and PUMP STOP or damage to the equipment:

similar keys. DANGER: Alerts you to a hazard or unsafe practice

! which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

Total Electrical Shut-Off Before Access ! that could result in death or serious injury.

Any procedure that requires access to electrical components or

CAUTION with Alert symbol: Designates a hazard or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

! unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard or

or circuit breaker before inspecting, installing, maintaining, or

unsafe practice which may result in property or

servicing Gilbarco equipment.

equipment damage.

Evacuating, Barricading, and Shutting Off

Any procedure that requires access to the pump/dispenser or Working With Fuels and Electrical Energy

STPs requires the following actions:

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

• An evacuation of all unauthorized persons and vehicles

dispenser or island.

from the work area

• Use of safety tape, cones, or barricades at the affected

DEF is non-flammable. Therefore, explosion and fire safety

unit(s)

warnings do not apply to DEF lines.

• A total electrical shut-off of the affected unit(s)

Page 4 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Important Safety Information

No Open Fire In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

Open flames from matches, lighters, welding torches, personnel:

or other sources can ignite fuels and their vapors. • Location of accident (for example, address, front/back of

No Sparks - No Smoking building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

Sparks from starting vehicles, starting, or using power tools, elderly)

burning cigarettes, cigars, or pipes can also ignite fuels and • Whether or not victim has received first aid (for example,

their vapors. Static electricity, including an electrostatic charge stopped bleeding by pressure, and so on)

on your body, can cause a spark sufficient to ignite fuel vapors. • Whether or not a victim has vomited (for example, if

Every time you get out of a vehicle, touch the metal of your swallowed or inhaled something, and so on)

vehicle, to discharge any electrostatic charge before you

approach the dispenser island. ! WARNING

Gasoline/DEF ingested may cause

Working Alone unconsciousness and burns to internal organs.

It is highly recommended that someone who is capable of Do not induce vomiting. Keep airway open.

rendering first aid be present during servicing. Familiarize Oxygen may be needed at scene. Seek medical

yourself with Cardiopulmonary Resuscitation (CPR) methods, if advice immediately.

you work with or around high voltages. This information is

available from the American Red Cross. Always advise the ! WARNING

station personnel about where you will be working, and caution

DEF generates ammonia gas at higher temperatures.

them not to activate power while you are working on the

When opening enclosed panels, allow the unit to air out to

equipment. Use the OSHA Lockout/Tagout procedures. If you

avoid breathing vapors.

are not familiar with this requirement, refer to this information in

If respiratory difficulties develop, move victim away from

the service manual and OSHA documentation.

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

Working With Electricity Safely

Ensure that you use safe and established practices in working ! WARNING

with electrical devices. Poorly wired devices may cause a fire,

explosion, or electrical shock. Ensure that grounding Gasoline inhaled may cause unconsciousness

connections are properly made. Take care that sealing devices and burns to lips, mouth, and lungs. Keep airway

and compounds are in place. Ensure that you do not pinch open. Seek medical advice immediately.

wires when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need ! WARNING

to understand and comply with this program completely to Gasoline/DEF spilled in eyes may cause burns to

ensure safety while the equipment is down. eye tissue. Irrigate eyes with water for

approximately 15 minutes. Seek medical advice

Hazardous Materials immediately.

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that ! WARNING

you clean hands after handling equipment. Do not place any

Gasoline/DEF spilled on skin may cause burns.

equipment in the mouth.

Wash area thoroughly with clear water.

Seek medical advice immediately.

! WARNING

The pump/dispenser contains a chemical known to the ! WARNING

State of California to cause cancer. DEF is mildly corrosive. Avoid contact with eyes, skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

! WARNING advice/recommended treatment if DEF spills into eyes.

The pump/dispenser contains a chemical known to the IMPORTANT: Oxygen may be needed at scene if gasoline has

State of California to cause birth defects or other been ingested or inhaled. Seek medical advice immediately.

reproductive harm. Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpected energization or

start-up of the machine(s) or equipment or release of stored

energy could cause injury to employees or personnel.

Lockout/Tagout applies to all mechanical, hydraulic, chemical,

or other energy, but does not cover electrical hazards.

Subpart S of 29 CFR Part 1910 - Electrical Hazards, 29 CFR

Part 1910.333 contains specific Lockout/Tagout provision for

electrical hazards.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 5

Overview

Overview

WARNING

Under no circumstances should a D-Box be used for normal operation with the cover

removed. The cover protects personnel and the environment from potential safety

hazards associated with electronic circuitry.

CAUTION

When the D-Box is used at smaller sites (two-wire runs less than 100 feet with few

fueling positions), components on the boards may fail. Refer to “Appendix: Rewiring

Transformer for Smaller Sites” on page 15 for modifications to rework the D-Box to avoid

this issue.

The D-Box provides an interface between Gilbarco consoles and controllers with Two-wire

Interface (TWI) current loop and dispensing units, and CRIND devices. The distribution

board(s) are fixed at 45 mA interface to the controller and are set standard at 45 mA output to

dispensing units or CRIND devices. Additional field jumper settings are provided to select

30 mA for other non-Gilbarco Underwriters Laboratories (UL)-listed dispensers.

Note: Interface cables between the D-Box and the console/controller are not included with the

D-Box, and must be ordered separately. Refer to “TWI (Current Loop)” on page 10 for

proper length and type of cable required. Two pieces each of these cables are supplied

with Passport systems.

The D-Box houses the power supply transformer and a removable tray with up to two Printed

Circuit Boards (PCB). Each PCB contains a power supply, an opto-coupled current loop

interface, eight dispenser current loops, and automatic isolation circuitry.

Two four-channel MTA connectors are provided for each circuit board for field wiring (see

Figure 4 on page 14).

The Passport Enhanced Dispenser Hub [EDH (PA0403 or PA0415)] requires this D-Box. For

wiring connections, see Figure 3 on page 13.

There are eight individual current data loops for dispensing units on each distribution board.

The two boards installed in a D-Box can be configured as either of the following:

• Two separate inputs with each input controlling eight data loops.

• One input controlling 16 data loops.

Page 6 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Overview

Each data loop has both current regulation and automatic isolation circuitry. The dispenser

data-loop drivers operate from an unregulated 12 VDC supply at 45 mA for Gilbarco

dispensers and CRIND devices, or 30 mA for other non-Gilbarco UL-listed dispensers

selected by jump jacks on board (for wiring connections, see Figure 3 on page 13).

Notes: 1) Each distribution board must be dedicated for use with Gilbarco 45 mA dispensing

units, CRIND devices, or 30 mA for other non-Gilbarco UL-listed dispensers.

No mixing of differing current loop equipment on a distribution board is allowed.

2) Connect only one dispenser or CRIND to any one data-loop channel. The wiring

distance between the D-Box and dispensers is not to exceed 2600 feet (5200 feet of

total wire), and requires twisted-pair stranded 14 American Wire Gauge (AWG) wire.

Daisy chaining is not allowed with this unit. Shielded wire is not recommended for

dispensers.

Model Number Breakdown

Figure 1 shows the model number breakdown of the D-Box.

Figure 1: PA0306XXXX Model Number Breakdown

PA0306XXXX

Data Input: 0 - Two-wire Input

Number of PCBs:

1 - 1 PCB (8 loops)

2 - 2 PCBs (16 loops)

Graphics/Housing: 0 - USA/Canada

1 - Europe

Source Voltage: 1 - 230 VAC 50/60 Hz

0 - 115 VAC 50/60 Hz

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 7

Preliminary Preparation

Specifications

Following tables list the physical, electrical, and operating environmental details of the

D-Box:

Model Number - PA0306XXXX

Dimensions

Height 7 - 13/16 inches

Width 16 - 9/32 inches

Depth 5 - 15/32 inches

Weight 5 lbs.

Dedicated Isolated Ground Receptacle

USA/Canada 115 VAC nominal, 50/60 Hz

International 230 VAC nominal, 50/60 Hz

Current

0.5 amp at 115 VAC

0.25 amp at 230 VAC

Operating Environment

Minimum Temperature +32 °F (0 °C)

Maximum Temperature +130 °F (+55 °C)

Humidity 5 - 95% Rh (non-condensing)

Preliminary Preparation

Unpacking Equipment

When the equipment arrives at the installation site, each unit should be unpacked and

inspected for possible shipping damage. If damage is evident, it must be reported to the carrier.

Shipping damage is not covered under Gilbarco’s warranty policy. After visual inspection,

place the unit back in its shipping carton to prevent undue exposure to the elements, and store

indoors until ready for installation.

Basic Site Criteria

Installation of the D-Box must be in accordance with the NEC NFPA 70, the Automotive and

Marine Service Station Code NFPA 30A, and any state or local electrical requirements.

For Canadian installations, use the Canadian Electrical Code CSA C22.2.

The site must be equipped with electric service allowing compliance with all installation

requirements of a complete fueling system.

Page 8 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Preliminary Preparation

An enclosed weather-protected structure must be located on the site for housing the D-Box.

Room ambient temperature or weather-protected containment structure temperature must not

exceed 130 °F (55 °C). This maximum temperature is allowed only if the equipment is

allowed free air flow.

Megger testing of field wiring must be completed prior to connecting wires to the D-Box.

The data cabling between the D-Box and the system controller must be kept separate from all

other power and control lines.

Physical Placement

Locate the D-Box in an area not subjected to extreme temperature variations (the D-Box is not

weather proof). Refer to “Operating Environment” on page 8. The ambient temperature must

remain relatively constant. Do not install the D-Box in a position subject to direct sunlight. If

conditions so dictate, provide a suitable sunscreen.

The PA0306 D-Box is suitable for use over hazardous locations. The box must be installed at

least 18 inches above the floor. Locate the D-Box in an area which minimizes the possibility of

liquids being spilled onto it.

Allow several inches clearance on the left side of the D-Box for the AC power cord. Allow

2 inches clearance above the box for removing the cover.

Electrical Wiring Requirements

The receptacle providing power to the D-Box must be a properly installed isolated ground

receptacle (Hubbell® #IG5261 or equivalent). This type receptacle is easily identified by its

bright orange color and by the triangle embossed into the face of the outlet. The green

grounding screw must be attached to the grounding conductor.

• All electrical wiring must conform to NEC and local wiring codes, as well as the criteria in

this manual and MDE-3620 Point of Sale (POS) Systems Site Preparation Manual.

• One conduit from the breaker panel to the D-Box location is required. The conduit must

contain three 14 AWG wires: 115 VAC hot, neutral, and ground; or 230 VAC L1, L2, and

Ground. Do not use the electrical conduit to provide earth ground.

• The circuit powering the D-Box must not power other devices. This circuit must not share

a conduit with wiring for devices drawing high amperage (compressor, freezer, and so on)

or devices that are sources of Radio Frequency Interference [RFI (TV, microwave,

intercom, etc.)].

• The AC outlet must be within 6 feet of the D-Box (see Figure 2 on page 10). Do not use

extension cords.

Note: The box and associated wiring must not be located closer than 12 inches to an

electronically noisy device, such as a variable speed Submersible Turbine Pump

(STP) controller or associated wiring.

• The receptacle is to be installed in accordance with MDE-3620 Point of Sale (POS)

Systems Site Preparation Manual.

Note: For 230 VAC operation, a 9-foot detachable line cord is provided. It is the

customer’s responsibility to supply a plug for the cord that meets local electrical

codes and UL requirements.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 9

Preliminary Preparation

Figure 2: Interface Cabling Between D-Box and Controller

Console/Controller

Cables

Line Cord (Q11121-01)

at 115 VAC

1-inch conduit knock-outs (3) are

provided for field wiring.

Line Cord

Q11736-02

230 VAC

Q11736-02 (User to supply proper plug for 230 VAC)

Note: Isolated Receptacle - User to supply proper receptacle to meet local electrical code requirements. The

receptacle providing power to the PA0306 must be a properly isolated ground receptacle (Hubbell #IG 5261

or the equivalent). The green grounding screw must be attached to the grounding conductor.

Passport System

Use the cables listed in the following table to connect the D-Box direct to the two-wire loop

ports:

TWI (Current Loop)

Cable Part Number Cable Length (in feet)

Q13850-03 3

Q13850-06 6

Q13850-10 10

Q13850-15 15

Q13850-25 25

Q13850-50 50

Q13850-100 100

Q13850-150 150

Q13850-200 200

Page 10 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Preliminary Preparation

Data Cabling Requirements

For the correct controller to the D-Box data cable, refer to “TWI (Current Loop)” on page 10.

Neatly install all cables so that they are protected from damage or accidental disconnection.

Route the cables along a wall or under a counter and secure with cable-ties or suitable cable

clamps.

Do not route data wires over fluorescent light, compressor wiring, etc., nor within 12 inches of

electronically noisy devices, such as variable speed STP controllers or associated wiring.

Use a 9-pin D-Sub receptacle to 8-pin Modular Jack Gender Mender (Q13180-11) to convert

the Transac System 1000™ console 9-pin plug D-Sub on underside panel to modular jack

receptacle to connect the cables above. That can also be used for pre-existing sites on end of

molded D-Sub cable if that cable must remain due to difficult prior installation.

Field Wiring for Data Cables

Use the following modular jack parts for field wiring:

Number Description

Q13241-01 In-line 8-pin modular jack receptacle to receptacle coupling.

Q13241-02 Wall-mount single 8-pin modular jack receptacle to field wiring.

Q13241-05 3-way splitter

Note: Use 14 AWG stranded or solid wire between wall receptacles.

Field Wiring Requirements

A wiring trough is required in the vicinity of the D-Box for terminating the conduit runs from

the dispensers. Three 1-inch knockouts are provided on the bottom of the D-Box for running

conduit between the box and the wiring trough.

Use 14 AWG stranded twisted-pair wire for data wires to Gilbarco dispensing equipment.

Leave plenty of wire exposed as a service loop in the wiring trough. 16 inches of exposed wire

is needed inside the D-Box.

Note: In the main conduit, for communications use only twisted-pair, two-wire data pairs. Do

not use shielded wire.

Unshielded Twisted-pair (UTP) wire is required for two-wire communication wiring for new

installations. Previously wired stations may continue to use tested existing non-twisted pair

wiring that has been tested for short circuits and continuity and passed. However, twisted pair

wiring is recommended for existing wired stations known to have communications problems

between the console and dispensers.

When pulling wires, be careful to avoid damage to the insulation.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 11

Installing D-Box

Installing D-Box

To install the D-Box, proceed as follows:

1 Loosen the two screws on the bottom-front of the D-Box and lift the cover.

2 Carefully remove and discard any packing material from the D-Box.

3 Disconnect the cable from the distribution board(s) at P101. Disconnect the wiring pigtails

from P106 and P107 (for wiring connections, see Figure 3 on page 13).

CAUTION

Working on PCBs without connecting to a ground or discharging static can damage

electronic parts. Use a properly grounded Electrostatic Discharge (ESD) wrist strap and

store parts in antistatic storage bags.

4 Slide the distribution board mounting plate up and out of the D-Box and remove the boards

avoiding unnecessary damage to the components when mounting the box.

5 Mount the D-Box to the wall, and ensure to:

• allow clearance on the left side to connect the AC cable.

• allow clearance above the D-Box so that the cover can be removed.

• mount the D-Box within 6 feet of the AC outlet.

6 Install the conduit for data wires between the wiring trough and the D-Box. Pull data wires up

into the D-Box leaving 16 inches of wire inside the D-Box. This allows for easy installation of

the wiring pigtails.

7 Connect the data wires to the pigtails (see Figure 4 on page 14).

8 Replace the distribution board mounting plate. Reconnect P101, P106, and P107 (for wiring

connections, see Figure 3 on page 13) as required to the board(s).

9 Connect the data cable(s) to the 8-pin modular jack connectors.

10 Verify that the jumper settings are set correctly for your configuration (for wiring connections,

see Figure 3 on page 13).

11 Plug in the AC power cord.

12 Change the jump jacks (JP1 through JP8) one at a time to the NORMAL position (for wiring

connections, see Figure 3 on page 13). Verify operation of the card readers and/or dispensing

units.

13 Replace the D-Box cover and secure with screws.

Page 12 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Installing D-Box

D-Box Wiring

Figure 3 shows the D-Box board layout with dispenser connections.

Figure 3: D-Box Board Layout

Wire Nut to Field Wiring Wire Nut to Field Wiring

P101-P106-P107

To Transformer To Dispensers To Dispensers To Dispensers To Dispensers

P106

P106

P107

P107

P101

JP4-JP3-JP2-JP1

JP7-JP6-JP5-JP8

R19262-G1

JP12

J103 J103

To Controller To Controller

Board 1 Board 2

JP13B JP11B

TP1 TP3 JP10 JP9

JP13A JP11A

Dual Board Configuration (T19547)

Board 1 Board 2

Description Jumper Settings Jumper Settings

2 boards, 1 input, 16 loops interface to all TWI consoles/controllers. JP13A – In JP13B – In

JP11B – In JP11A – In

JP12 – In JP12 – In

2 boards, 2 inputs, 8 loops interface to all TWI consoles/controllers. JP13B – In JP13B – In

JP11B – In JP11B –In

JP12 – In JP12 – In

2 boards, 1 input, 16 loops, 30 mA for Non-Gilbarco UL Listed JP13A – In JP13B – In

dispensers. Interfaces to 45 mA controllers. JP11B – In JP11A – In

JP10 – In JP10 – In

2 boards, 2 inputs, 8 loops, 30 mA for Non-Gilbarco UL Listed dispensers. JP13B – In JP13B – In

Interfaces to 45 mA controllers. JP11B – In JP11B – In

JP10 – In JP10 – In

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 13

Installing D-Box

Figure 4: Field Wiring to MTA Pigtails

Cut and strip supplied loops for desired number of

field connections.

Note: If unused pigtail loops are cut, the exposed

ends must be capped with wire nuts.

Wire Nuts

14 AWG Field Wiring

R19263 Pigtail Cable Assembly

Page 14 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Appendix: Rewiring Transformer for Smaller Sites

Appendix: Rewiring Transformer for Smaller Sites

For smaller sites (two-wire wiring runs less than 100 feet) with few fueling positions,

transistors Q21 through Q28 may overheat. In those cases, proceed as follows:

WARNING

Do NOT attempt to rewire the transformer with power applied.

Follow the lockout/tagout procedures in “Important Safety Information” on page 4.

Accessing Transformer

To access the transformer for rewiring, proceed as follows:

1 Turn off the breaker associated with the dedicated receptacle supplying power to the D-Box

and lockout/tagout.

2 Unplug the power cord from the dedicated outlet.

3 Unplug the power cord from the D-Box.

4 Remove the D-Box cover.

5 Disconnect dispenser-loop wiring, POS cables, and transformer power from the D-Box

boards.

6 Remove the board tray to expose the transformer.

7 Remove the shield that surrounds the transformer.

8 Remove the transformer from the mounting studs.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 15

Appendix: Rewiring Transformer for Smaller Sites

Rewiring Transformer

To rewire the transformer, proceed as follows:

1 Remove the loop-back (see Figure 5) from the side of the transformer opposite the wiring

going to the AC receptacle (see Figure 6).

Figure 5: Removing Loop-back Connection

Figure 6: AC Receptacle Wiring

To the AC

receptacle no

modifications

needed

Page 16 MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

Appendix: Rewiring Transformer for Smaller Sites

2 Remove one secondary connection from the top of the transformer and move that secondary

connection to the contact from where the loop-back was removed in step 1 on page 16

(see Figure 7).

Figure 7: Moving Secondary Connection

3 Remove the loop-back connection and discard it (see Figure 8).

Figure 8: Removing Loop-back Connection

Returning Transformer to Service

To return the transformer to service, proceeds as follows:

1 Reinstall the transformer onto its studs and reassemble the transformer shield and D-Box

board tray.

2 Reinstall the AC power cord to the D-Box.

3 Plug the AC cord back into the isolated and dedicated receptacle.

4 Remove the lockout/tagout tags.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015 Page 17

Appendix: Rewiring Transformer for Smaller Sites

5 Apply power by turning on the associated circuit breaker.

6 Take voltage readings between the TP1 (+12UN) and TP3 (GND) pins on each of the boards

(for wiring connections, see Figure 3 on page 13).

7 Verify that the voltage readings are between 11 and 12 VDC.

8 Reinstall the D-Box cover.

WARNING

Do NOT operate the D-Box without a cover or with ventilation holes drilled in the cover.

If any holes have been drilled in the cover or fans installed, or if the cover was removed

and discarded, you must replace the cover. Do not reinstall any fans.

9 Verify that there is proper communication between the dispensers/pumps and console.

The Advantage® Series, CRIND®, Encore®, Eclipse®, Gilbarco®, Legacy®, and Passport® are registered trademarks of Gilbarco Inc.

System 1000™ is a trademark of Gilbarco Inc. GOLDSM is a service mark of Gilbarco Inc. Hubbell® is a registered trademark of Hubbell Inc.

Megger® is a registered trademark of Megger Limited. NEC® and NFPA 70® are registered trademarks of the National Fire Protection

Association. Phillips® is a registered trademark of the Phillips Screw Company. UL® is a registered trademark of Underwriters Laboratories Inc.

© 2015 Gilbarco Inc.

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone (336) 547-5000 · http://www.gilbarco.com · Printed in the U.S.A.

MDE-3116E Distribution Box PA0306 Installation Instructions · November 2015

You might also like

- Conveyor Belt Commissioning ProcedureDocument7 pagesConveyor Belt Commissioning Procedurevvijaybhan100% (6)

- Gilbarco ElectricalWiringDocument16 pagesGilbarco ElectricalWiringmrzeeusa75% (4)

- Autopilot NP2015/2025: Type 102 - 886 NG001Document105 pagesAutopilot NP2015/2025: Type 102 - 886 NG001Alexey Plekhanov100% (1)

- GUE Fundamentals Workbook ImperialDocument70 pagesGUE Fundamentals Workbook Imperialonlydlonly100% (1)

- Sharp cd-sw340 PDFDocument92 pagesSharp cd-sw340 PDFAbel GaunaNo ratings yet

- SONY - KDL-32-37-40-46-55EX505 Chassis - AZ1-L - SM PDFDocument64 pagesSONY - KDL-32-37-40-46-55EX505 Chassis - AZ1-L - SM PDFAnselmo Baturite100% (2)

- 275-103-044 Installation Guide REV BDocument14 pages275-103-044 Installation Guide REV BJohan MonguaNo ratings yet

- N2XY IEC 60502-1 XLPE PVC 0.6/1kV Cable: Application StandardsDocument5 pagesN2XY IEC 60502-1 XLPE PVC 0.6/1kV Cable: Application StandardsSaravana Kumar Senthil KumarNo ratings yet

- BOM-speeduino v0.4.3 Compatible PCB For m40 Rev1.0Document1 pageBOM-speeduino v0.4.3 Compatible PCB For m40 Rev1.0Randol Rafael Reyes Rodriguez50% (2)

- Mde 3882BDocument20 pagesMde 3882BBasel Hilal HaiderNo ratings yet

- Gillbarco ProtocolDocument10 pagesGillbarco ProtocolAlejandro BarajasNo ratings yet

- Mde 4709aDocument8 pagesMde 4709awotanelNo ratings yet

- AP-0622 Access Point: Installation GuideDocument40 pagesAP-0622 Access Point: Installation Guidejan3623No ratings yet

- 128 I NuviinstallDocument7 pages128 I Nuviinstallgeorge e.bayNo ratings yet

- Mde 4351aDocument26 pagesMde 4351ahusam haiderNo ratings yet

- Delta InverterDocument122 pagesDelta InverterNurwikan AdiwinotoNo ratings yet

- PDFDocument43 pagesPDFMaya TesNo ratings yet

- NGS-D320: Service ManualDocument20 pagesNGS-D320: Service ManualChristian MuñozNo ratings yet

- HP LJ M525 Enterprise 500 - Parts - CatalogDocument33 pagesHP LJ M525 Enterprise 500 - Parts - CatalogFuciu FlorinNo ratings yet

- In-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101Document18 pagesIn-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101creative BrandwiseNo ratings yet

- Bu0600 6076002 en 4022 Desk 1Document264 pagesBu0600 6076002 en 4022 Desk 1olivier.bigouretNo ratings yet

- Operation Manual: E/P Regulator ITV1000, IT 2000, ITV3000 SeriesDocument10 pagesOperation Manual: E/P Regulator ITV1000, IT 2000, ITV3000 SeriesNARAYAN SINHANo ratings yet

- Service Manual: CD-MPX880Document88 pagesService Manual: CD-MPX880Radj MohanNo ratings yet

- TB 412-21-247 (2021.11.24)Document10 pagesTB 412-21-247 (2021.11.24)yu gangNo ratings yet

- Atlas Copco T3W ManualDocument1,147 pagesAtlas Copco T3W ManualwalkercadillacNo ratings yet

- Bellingham Stanley Refractometer Adp 440 Plus Manual 001Document87 pagesBellingham Stanley Refractometer Adp 440 Plus Manual 001Dao Quang AiNo ratings yet

- Avionic Cooling Fan - Installation - ManualDocument2 pagesAvionic Cooling Fan - Installation - ManualDade SobarnaNo ratings yet

- Tda 6110 XJDocument60 pagesTda 6110 XJniki georgievNo ratings yet

- 5 Manual RepairDocument432 pages5 Manual Repairbannet100% (1)

- ACS580-04 Quick Installation ManualDocument102 pagesACS580-04 Quick Installation ManualByron NyashaNo ratings yet

- Manual Sony TV ServiceDocument67 pagesManual Sony TV ServiceMarcelo VasconcelosNo ratings yet

- KS Series: User ManualDocument23 pagesKS Series: User ManualbachstradNo ratings yet

- Rehs2362 02Document24 pagesRehs2362 02zekaNo ratings yet

- LCD TV Service Manual: Konka Group Co, LTDDocument18 pagesLCD TV Service Manual: Konka Group Co, LTDOliver Arenas Jones FENo ratings yet

- CGC 400 Quick Start Guide 4189340849 UK - 2013.12.13Document10 pagesCGC 400 Quick Start Guide 4189340849 UK - 2013.12.13Thiago GarciaNo ratings yet

- Intellivue Patient MonitorDocument30 pagesIntellivue Patient MonitorystloveNo ratings yet

- Synapsis Radar Service and Installation Manual: 4277DOC020302 Edition: 17.FEB.2015Document3 pagesSynapsis Radar Service and Installation Manual: 4277DOC020302 Edition: 17.FEB.2015yohanes andrianNo ratings yet

- 2XX-IP: Ethernet Interface OptionDocument12 pages2XX-IP: Ethernet Interface OptionDidik SudarsonoNo ratings yet

- Pioneer pdp-503cmx Mxe PDFDocument167 pagesPioneer pdp-503cmx Mxe PDFTheojt100% (1)

- Service Manual: DEH-2450FDocument63 pagesService Manual: DEH-2450Fmarco agudeloNo ratings yet

- ACS550 User ManualDocument320 pagesACS550 User Manualsolutionbriigh1No ratings yet

- REHS9792 - Installation Procedure For Excitation Modules 10 and 15 (4467) PDFDocument10 pagesREHS9792 - Installation Procedure For Excitation Modules 10 and 15 (4467) PDFHafid AnwarNo ratings yet

- 33-210B.PD SF6 Single Pressure Outdoor Power Circuit Breaker PDFDocument289 pages33-210B.PD SF6 Single Pressure Outdoor Power Circuit Breaker PDFakhilNo ratings yet

- Quick Start Guide: Network Fabric Switch Package ContentsDocument12 pagesQuick Start Guide: Network Fabric Switch Package ContentsAnton Popov (EvilTheCat)No ratings yet

- 4100/4120-Series Vesda Interface Cards Installation InstructionsDocument20 pages4100/4120-Series Vesda Interface Cards Installation InstructionsLeoNo ratings yet

- Opc-Vg1-Tl: T-Link Interface Card For FRENIC-VGDocument8 pagesOpc-Vg1-Tl: T-Link Interface Card For FRENIC-VGiqdam94No ratings yet

- Acesso Tellabs PDFDocument3 pagesAcesso Tellabs PDFadilson1231975No ratings yet

- MUL - ACS880-04 - R10 - R11 - QIG - E - A4 - drwA33AXD50000009366Document92 pagesMUL - ACS880-04 - R10 - R11 - QIG - E - A4 - drwA33AXD50000009366rammu2001No ratings yet

- Quick Start Guide: Niagara 2825Document16 pagesQuick Start Guide: Niagara 2825m_homossaniNo ratings yet

- Pioneer Pdp-504pu Pe Pro-504pu SM (ET)Document100 pagesPioneer Pdp-504pu Pe Pro-504pu SM (ET)huchka_jumpNo ratings yet

- Autopilot Interface Unit: Deklin Technologies IncDocument24 pagesAutopilot Interface Unit: Deklin Technologies Incraphael EliasNo ratings yet

- 520-qs001 - En-E Configuracion Basica PDFDocument38 pages520-qs001 - En-E Configuracion Basica PDFluis.chuquimiaNo ratings yet

- Idcgroupsliteraturedocumentsqs520 Qs001 en e PDFDocument38 pagesIdcgroupsliteraturedocumentsqs520 Qs001 en e PDFCody KeiferNo ratings yet

- Document: Installation Instructions Part: 4100-6103, 4007-9804 DCAI Cards Product: 4100ES, 4007ESDocument8 pagesDocument: Installation Instructions Part: 4100-6103, 4007-9804 DCAI Cards Product: 4100ES, 4007ESmsaabNo ratings yet

- EST3 Installation SheetsDocument180 pagesEST3 Installation SheetsGió Bốn Mùa100% (1)

- 78512471Document43 pages78512471RonaldNo ratings yet

- John Deere Bpf10173 Installation InstructionsDocument20 pagesJohn Deere Bpf10173 Installation InstructionsFerNo ratings yet

- Nha18534 enDocument45 pagesNha18534 enYaswanth AkasamNo ratings yet

- Lemur ManualDocument79 pagesLemur ManualtpsniNo ratings yet

- Ts5a23157 q1Document30 pagesTs5a23157 q1wanshibo1992No ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Guide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)From EverandGuide to the IET Wiring Regulations: IET Wiring Regulations (BS 7671:2008 incorporating Amendment No 1:2011)Rating: 4 out of 5 stars4/5 (2)

- NEMA 23 1.8° Hybrid Stepper Motor CatalogDocument2 pagesNEMA 23 1.8° Hybrid Stepper Motor CatalogThành DuongNo ratings yet

- DTAC Charging System ProceduresDocument2 pagesDTAC Charging System ProceduresGerald BoyNo ratings yet

- 330 SeriesDocument4 pages330 SeriesRodolfoMarínNo ratings yet

- Micrometer HeadsDocument44 pagesMicrometer HeadsHamdan Rusli HabibiNo ratings yet

- Servicemanual - Panasonic - KV s4065cl, KV s4065cw, KV s4065cwcn, KV sS4085cl, KV s4085cw, KV s4085cwcn - s1Document14 pagesServicemanual - Panasonic - KV s4065cl, KV s4065cw, KV s4065cwcn, KV sS4085cl, KV s4085cw, KV s4085cwcn - s1Ralf KöhlerNo ratings yet

- High-Tech Range: MRR1 - Multifunctional Generator Rotor Protection RelayDocument16 pagesHigh-Tech Range: MRR1 - Multifunctional Generator Rotor Protection RelayAnandSreeNo ratings yet

- 07 Dividing Head of A MillingDocument8 pages07 Dividing Head of A MillingkabbirhossainNo ratings yet

- Mass Airflow SensorsDocument6 pagesMass Airflow SensorsRosu AndreiNo ratings yet

- ECOTEC CPU CatalogDocument13 pagesECOTEC CPU CatalogFiras omNo ratings yet

- Neca 420-2014Document34 pagesNeca 420-2014dougyuNo ratings yet

- UIC-568 Jumper Cable PDFDocument12 pagesUIC-568 Jumper Cable PDFaksNo ratings yet

- Slimline+ R5Document14 pagesSlimline+ R5benghoe77No ratings yet

- Usb DevsDocument381 pagesUsb DevsIonut Baciu100% (1)

- Bahrain Regulation For Electrical InstallationDocument81 pagesBahrain Regulation For Electrical InstallationNarayanan Nair57% (7)

- Non Return Valves: Jeevan Bhar Ka Saath..Document2 pagesNon Return Valves: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- Pages From All Drawings - Bid SetDocument2 pagesPages From All Drawings - Bid SetbilalNo ratings yet

- 814K PDFDocument31 pages814K PDFgilmer flores mamaniNo ratings yet

- Laser Lamps: Flash Lamps and Arc Lamps: Table of Parameters For Continuous Wave LampsDocument21 pagesLaser Lamps: Flash Lamps and Arc Lamps: Table of Parameters For Continuous Wave LampsMatias Canton100% (1)

- Dgca Module 12 Part 03 PDFDocument22 pagesDgca Module 12 Part 03 PDFAdrian Lau100% (1)

- High Beam FSB-200SDocument4 pagesHigh Beam FSB-200SSANTONo ratings yet

- Service SpecificationsDocument47 pagesService SpecificationsXuân VinhNo ratings yet

- Pulsatron Series A Plus Tech Sheet-1Document2 pagesPulsatron Series A Plus Tech Sheet-1sugiantoNo ratings yet

- D046 D049 Eu V1.31Document119 pagesD046 D049 Eu V1.31andykoglerNo ratings yet

- V1 T1 Loadcenters and Circuit Breakers Ca08100002eDocument105 pagesV1 T1 Loadcenters and Circuit Breakers Ca08100002eomarlgonzNo ratings yet

- Busch Instruction Manual RA 0165 0305 D en 0870524629 D0007Document32 pagesBusch Instruction Manual RA 0165 0305 D en 0870524629 D0007Franco bucciarelliNo ratings yet