Professional Documents

Culture Documents

Spirax Sarco's Steam Trap Range: Thermodynamic

Spirax Sarco's Steam Trap Range: Thermodynamic

Uploaded by

BinhvvCopyright:

Available Formats

You might also like

- 6T40 Manual PDFDocument10 pages6T40 Manual PDFJesus Teodoro Mendoza Guerra100% (3)

- Dynatech T56 Repair Capabilities ListDocument6 pagesDynatech T56 Repair Capabilities ListrizkyNo ratings yet

- Peugeot 406 Owners Manual 2003Document84 pagesPeugeot 406 Owners Manual 2003husni103180% (15)

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocument6 pagesDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- High Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Document24 pagesHigh Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Wong DaNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewSekson JunsukplukNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewHayder HusseinNo ratings yet

- Spirax Trap Review GST - 33 PDFDocument22 pagesSpirax Trap Review GST - 33 PDFFrank UrsNo ratings yet

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocument8 pagesSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNo ratings yet

- Comparison Flowtite Vs DI, CCP and RCCPDocument6 pagesComparison Flowtite Vs DI, CCP and RCCPnaseer lateeNo ratings yet

- DRS CatalogueDocument12 pagesDRS CatalogueDMA ASIANo ratings yet

- Accumulators Low ResDocument1 pageAccumulators Low ResbdepeverelliNo ratings yet

- Heat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016Document29 pagesHeat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016svishnuvNo ratings yet

- 1316 EKN Hotwater Edition3Document11 pages1316 EKN Hotwater Edition3AhmedRamadanNo ratings yet

- Data Sheets Bulletin Control Valves HP Turbine Bypass Valve Model 115 CHP Sempell en en 2723428 PDFDocument8 pagesData Sheets Bulletin Control Valves HP Turbine Bypass Valve Model 115 CHP Sempell en en 2723428 PDFmagnsNo ratings yet

- Crescograph SolutionDocument18 pagesCrescograph SolutionIvy LeeNo ratings yet

- d75kx Specification Sheet EnglishDocument4 pagesd75kx Specification Sheet EnglishPedro ArancibiaNo ratings yet

- 296 Balt Evaporative CondensersDocument20 pages296 Balt Evaporative CondensersJohnnybacsiNo ratings yet

- ACTUADORDocument4 pagesACTUADORkholymmNo ratings yet

- Chemical Industry BrochureDocument6 pagesChemical Industry BrochureFrank HigueraNo ratings yet

- Ram Sons Viet MachinesDocument38 pagesRam Sons Viet MachinesDeepanNo ratings yet

- Final - Steam Engineering - Product - Portfolio-5-14Document10 pagesFinal - Steam Engineering - Product - Portfolio-5-14angga rizkiNo ratings yet

- Ayvaz Steam Traps BookDocument79 pagesAyvaz Steam Traps BookgideonolinyoNo ratings yet

- FTI Finish Thompson DB SP MSDB Series Pumps BrochureDocument12 pagesFTI Finish Thompson DB SP MSDB Series Pumps BrochureLê Hoàng GiangNo ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- Aquamist Pump BrochureDocument4 pagesAquamist Pump BrochureJuanHernandezNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceVEZZ RIDE25No ratings yet

- STL DatasheetDocument16 pagesSTL DatasheetCarlos Miguel Barrena TorresNo ratings yet

- 2240 1312 EKN Steelwelded Edition3 en 0607Document7 pages2240 1312 EKN Steelwelded Edition3 en 0607AhmedRamadanNo ratings yet

- Steam Traps - TypesDocument3 pagesSteam Traps - Typesrenji_danny100% (1)

- Vahterus-Intercambiador de Placas-PsheDocument3 pagesVahterus-Intercambiador de Placas-PshepxpingenieriaNo ratings yet

- 2235 1314 EKN Hardrubber Edition3 en 0607Document7 pages2235 1314 EKN Hardrubber Edition3 en 0607AhmedRamadanNo ratings yet

- Chiller Cutsheet M702 M802Document1 pageChiller Cutsheet M702 M802GamalpageNo ratings yet

- CECO Sethco Model P90Document4 pagesCECO Sethco Model P90marcoNo ratings yet

- 1315 EKN Hotwater Steelwelded Edition3 enDocument7 pages1315 EKN Hotwater Steelwelded Edition3 enAhmedRamadanNo ratings yet

- 2/2-Way Solenoid Valve: Type 253Document4 pages2/2-Way Solenoid Valve: Type 253Francisco Mones RuizNo ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- Parker Filtration Group - GSF (July 2016)Document28 pagesParker Filtration Group - GSF (July 2016)Shibu ThomasNo ratings yet

- SH 60 TD enDocument98 pagesSH 60 TD enCésar David Pedroza DíazNo ratings yet

- Data Sheets L M Replaceable Polymer Liner Knife Gate Valves Clarkson en en 5196090Document8 pagesData Sheets L M Replaceable Polymer Liner Knife Gate Valves Clarkson en en 5196090Samuel WeberNo ratings yet

- 09hermetically Sealed OilDocument2 pages09hermetically Sealed OiljuliancansenNo ratings yet

- Parker 441 HoseDocument2 pagesParker 441 HoseRajpal SharmaNo ratings yet

- D75KSDocument4 pagesD75KSA LettristeNo ratings yet

- ActuatorDocument8 pagesActuatorMuhammed Ali PisuwalaNo ratings yet

- No-Skive: Tough Cover Compact HoseDocument2 pagesNo-Skive: Tough Cover Compact HoseleonardoNo ratings yet

- Evaporative CondensersDocument20 pagesEvaporative CondensersAl Musabbir LeeonNo ratings yet

- Crompton DC MotorsDocument6 pagesCrompton DC MotorsAzed-dine BoughmarNo ratings yet

- SMD Axially Split Casing, Double Suction PumpDocument8 pagesSMD Axially Split Casing, Double Suction PumpdonestebNo ratings yet

- Bauma ATS Stage - V AGCOpdfDocument3 pagesBauma ATS Stage - V AGCOpdfNicolas WangNo ratings yet

- Catalogo CeaDocument2 pagesCatalogo CeaSergio ZegarraNo ratings yet

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- CEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZDocument48 pagesCEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZValbertNo ratings yet

- Bharat Bijlee Power TransformerDocument24 pagesBharat Bijlee Power Transformerchirag100% (1)

- MP2010 345 Product Brochure S Series RevEDocument2 pagesMP2010 345 Product Brochure S Series RevEJackNo ratings yet

- Secador de Aire Sullair SR 500Document16 pagesSecador de Aire Sullair SR 500Darwin Santamaría CalderónNo ratings yet

- Sandvik d55sp Specification Sheet EnglishDocument4 pagesSandvik d55sp Specification Sheet EnglishSheree PeoplesNo ratings yet

- GD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWDocument8 pagesGD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWgheantikaNo ratings yet

- Purgadores de VaporDocument6 pagesPurgadores de VaporPaulo CostaNo ratings yet

- Brochure Isolation Valves Product Overview en en 5253576Document36 pagesBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNo ratings yet

- Thorburn Flex Powergen2012Document4 pagesThorburn Flex Powergen2012Raja Syahmarizal Raja BaharuddinNo ratings yet

- Butterfly Valve CatalogDocument18 pagesButterfly Valve Catalogyash100% (1)

- Steam Trapping OverviewDocument1 pageSteam Trapping OverviewBinhvvNo ratings yet

- TAKAMI Instruction Manual TDCVDocument9 pagesTAKAMI Instruction Manual TDCVBinhvvNo ratings yet

- An Introduction To Steam TrapsDocument1 pageAn Introduction To Steam TrapsBinhvvNo ratings yet

- Zhongquan Valve CertDocument1 pageZhongquan Valve CertBinhvvNo ratings yet

- SMC AN SilencerDocument1 pageSMC AN SilencerBinhvvNo ratings yet

- Make Your Steam System Safe, Efficient and Sustainable: How Can Spirax Sarco Help You?Document1 pageMake Your Steam System Safe, Efficient and Sustainable: How Can Spirax Sarco Help You?BinhvvNo ratings yet

- SLS - Series Level SwitchDocument3 pagesSLS - Series Level SwitchBinhvvNo ratings yet

- 1 3 13certificateDocument1 page1 3 13certificateBinhvvNo ratings yet

- tmm55 InclinometerDocument3 pagestmm55 InclinometerBinhvvNo ratings yet

- Metertalk Ultrasonic Flowmeter 3Document1 pageMetertalk Ultrasonic Flowmeter 3BinhvvNo ratings yet

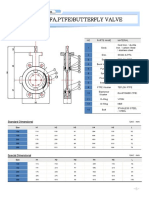

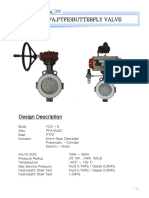

- 내산 (Pfa,Ptfe) Butterfly Valve: Standard DimensionalDocument1 page내산 (Pfa,Ptfe) Butterfly Valve: Standard DimensionalBinhvvNo ratings yet

- Feida Valve CertDocument1 pageFeida Valve CertBinhvvNo ratings yet

- HC Valve 5 PDFDocument1 pageHC Valve 5 PDFBinhvvNo ratings yet

- 내산 (Pfa,Ptfe) Butterfly Valve: Han Chang Industry Co.,LtdDocument1 page내산 (Pfa,Ptfe) Butterfly Valve: Han Chang Industry Co.,LtdBinhvvNo ratings yet

- Bg20016-Catalog + DrawingDocument9 pagesBg20016-Catalog + DrawingBinhvvNo ratings yet

- HC ValveDocument1 pageHC ValveBinhvvNo ratings yet

- GML 209 NJ GB1 LED 24 Grey - TechdataDocument3 pagesGML 209 NJ GB1 LED 24 Grey - TechdataBinhvvNo ratings yet

- Catalog VikorDocument16 pagesCatalog VikorBinhvvNo ratings yet

- Technical Features: Equivalents of Burgmann MG SeriesDocument2 pagesTechnical Features: Equivalents of Burgmann MG SeriesBinhvvNo ratings yet

- Series ALLUB RUVDocument2 pagesSeries ALLUB RUVBinhvvNo ratings yet

- Feed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataBinhvvNo ratings yet

- ATEX Marking Electrical Equipment Ex PDFDocument1 pageATEX Marking Electrical Equipment Ex PDFBinhvvNo ratings yet

- Water/oil Coolers Series CSW 8: CiesseDocument4 pagesWater/oil Coolers Series CSW 8: CiesseBinhvvNo ratings yet

- K23Document8 pagesK23BinhvvNo ratings yet

- Schneider Cam Switch 4 Poles 20ADocument1 pageSchneider Cam Switch 4 Poles 20ABinhvvNo ratings yet

- Weidmuller 1282250000-Cat1-W-EnDocument32 pagesWeidmuller 1282250000-Cat1-W-EnBinhvvNo ratings yet

- Data Sheet: SAK Series Sakk 4Document4 pagesData Sheet: SAK Series Sakk 4BinhvvNo ratings yet

- Course Objectives and OutcomesDocument2 pagesCourse Objectives and OutcomesHarjit Singh MangatNo ratings yet

- Glenda Melanie Lub - ChartDocument7 pagesGlenda Melanie Lub - ChartAndrei ZahaNo ratings yet

- Shaft Design and Detailing Recommendations - Pile DetailingDocument3 pagesShaft Design and Detailing Recommendations - Pile DetailingNoli PaladNo ratings yet

- Hedland Variable Area Flow Meters and Flow Switches Brochure Vam-br-00714-EnDocument8 pagesHedland Variable Area Flow Meters and Flow Switches Brochure Vam-br-00714-EnRosendo RizoNo ratings yet

- VW 01M Transmission 65535 ErrorDocument6 pagesVW 01M Transmission 65535 ErrorRashaad Sheik100% (1)

- GUASCOR dipticoING 1800Document4 pagesGUASCOR dipticoING 1800Juan RamónNo ratings yet

- Oncology, Gardiac, GI Design ReportDocument72 pagesOncology, Gardiac, GI Design ReportEng. Ayenew ZewdieNo ratings yet

- Aircraft Loading and Structural LayoutDocument626 pagesAircraft Loading and Structural LayoutUroš Roštan100% (1)

- Airbus 30 A300 A310 Ice and RainDocument48 pagesAirbus 30 A300 A310 Ice and RainElijah Paul Merto100% (2)

- DIN EN 10130 - February - 1999Document13 pagesDIN EN 10130 - February - 1999dpfloresNo ratings yet

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 pagesSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekNo ratings yet

- Exam in Engine Management 1Document3 pagesExam in Engine Management 1Jhezel Mae Alfaro Aquino100% (1)

- Ficha Tecnica - Backing RingDocument1 pageFicha Tecnica - Backing RingFernando Rocca VillalobosNo ratings yet

- Lecture 3-Column DesignDocument95 pagesLecture 3-Column DesignRuben Ooi100% (1)

- Si RSUQ AYMDocument456 pagesSi RSUQ AYMTaofik Muarifin100% (1)

- BMS Excel List PointDocument8 pagesBMS Excel List PointfghabboonNo ratings yet

- BradleyDocument247 pagesBradleythomas duncan eelesNo ratings yet

- Manual de Taller ET 300Document165 pagesManual de Taller ET 300yisusyisus0% (1)

- Room Air Conditioners - SpecificationDocument58 pagesRoom Air Conditioners - SpecificationAbhishek SrivastvaNo ratings yet

- AASHTO LRFD 8th Steel Design ChangeDocument8 pagesAASHTO LRFD 8th Steel Design ChangetsuregiNo ratings yet

- Thermal EnergyDocument30 pagesThermal EnergyKella OrtegaNo ratings yet

- Arc Blow LogoDocument3 pagesArc Blow Logoأحمد حسنNo ratings yet

- Air or Gas Driven Injectors: Description ApplicationsDocument8 pagesAir or Gas Driven Injectors: Description ApplicationsEyo Etim0% (1)

- Air Comp. BasicsDocument33 pagesAir Comp. Basicskisan singhNo ratings yet

- SLON-GATHMGNO000-PIP-LST-PHR-2002-00 - MTO Piping Material Menggala North GS - Rev 0A3 - DA CommentDocument13 pagesSLON-GATHMGNO000-PIP-LST-PHR-2002-00 - MTO Piping Material Menggala North GS - Rev 0A3 - DA CommentDheska AgungwNo ratings yet

- Data Sheet For Carbon Steel Piping MaterialsDocument14 pagesData Sheet For Carbon Steel Piping MaterialsNoor AnterNo ratings yet

- ASTM A789 Stainless Steel TubingDocument6 pagesASTM A789 Stainless Steel TubingPlinio PazosNo ratings yet

Spirax Sarco's Steam Trap Range: Thermodynamic

Spirax Sarco's Steam Trap Range: Thermodynamic

Uploaded by

BinhvvOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spirax Sarco's Steam Trap Range: Thermodynamic

Spirax Sarco's Steam Trap Range: Thermodynamic

Uploaded by

BinhvvCopyright:

Available Formats

s t e a m t r a p p i n g

Spirax Sarco’s steam trap range

Steam trap

Thermodynamic Mechanical Thermostatic

operation

Thermodynamic Ball float Inverted Balanced Bimetallic

bucket pressure

Steam trap

types

• Robust design

• High capacity

giving excellent • High capacity

resistance to • Excellent

• Robust

waterhammer and air venting

design

vibration capabilities • Utilises sensible heat in the condensate,

• Near reducing flash steam losses, which saves

Main • Inexpensive • Continuous

continuous energy

discharge of

features • Positive discharge discharge of

• Excellent air venting properties for quick

condensate for

with tight shut-off condensate

maximum heat start-up

• Discharge transfer • Minimal

condensate close back-up of

• Will not back-up

to steam saturation condensate

with condensate

temperature

• Mains drainage

and all tracing • Temperature/

applications • Temperature/ pressure

• Where condensate back-up can be

pressure controlled

Typical • Some process tolerated or is required in order to remove

controlled applications

applications applications with applications with with

excess enthalpy, e.g. non-critical tracing

light loads such as fluctuating loads fluctuating

small presses and loads

cylinders

DN8 – DN25 DN15 – DN100 DN15 – DN50 DN8 – DN25 DN8 – DN100

Size (¼”– 1”) (½" – 4") (½" – 2") (¼"– 1") (¼"– 4")

Maximum PN100 and PN40 and

PN250 ASME 900 ASME Class 600

body rating ASME Class 600 ASME Class 300

Maximum

operating 250 bar g 80 bar g 110 bar g 32 bar g 70 bar g

pressure

You might also like

- 6T40 Manual PDFDocument10 pages6T40 Manual PDFJesus Teodoro Mendoza Guerra100% (3)

- Dynatech T56 Repair Capabilities ListDocument6 pagesDynatech T56 Repair Capabilities ListrizkyNo ratings yet

- Peugeot 406 Owners Manual 2003Document84 pagesPeugeot 406 Owners Manual 2003husni103180% (15)

- DVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L IDocument6 pagesDVMX. Between-Bearings, Multistage, Axially Split Pump. API-610,10th Edition ISO M A R E L L Imiguel hernandezNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- High Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Document24 pagesHigh Performance Pumps: Rotary Lobe / Gear Pumps 120 450 92 3,400,000Wong DaNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewSekson JunsukplukNo ratings yet

- Steam Trapping OverviewDocument22 pagesSteam Trapping OverviewHayder HusseinNo ratings yet

- Spirax Trap Review GST - 33 PDFDocument22 pagesSpirax Trap Review GST - 33 PDFFrank UrsNo ratings yet

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocument8 pagesSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNo ratings yet

- Comparison Flowtite Vs DI, CCP and RCCPDocument6 pagesComparison Flowtite Vs DI, CCP and RCCPnaseer lateeNo ratings yet

- DRS CatalogueDocument12 pagesDRS CatalogueDMA ASIANo ratings yet

- Accumulators Low ResDocument1 pageAccumulators Low ResbdepeverelliNo ratings yet

- Heat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016Document29 pagesHeat Pipe Vapor Chamber Heat Sink Design Guidelines Thermal Live 2016svishnuvNo ratings yet

- 1316 EKN Hotwater Edition3Document11 pages1316 EKN Hotwater Edition3AhmedRamadanNo ratings yet

- Data Sheets Bulletin Control Valves HP Turbine Bypass Valve Model 115 CHP Sempell en en 2723428 PDFDocument8 pagesData Sheets Bulletin Control Valves HP Turbine Bypass Valve Model 115 CHP Sempell en en 2723428 PDFmagnsNo ratings yet

- Crescograph SolutionDocument18 pagesCrescograph SolutionIvy LeeNo ratings yet

- d75kx Specification Sheet EnglishDocument4 pagesd75kx Specification Sheet EnglishPedro ArancibiaNo ratings yet

- 296 Balt Evaporative CondensersDocument20 pages296 Balt Evaporative CondensersJohnnybacsiNo ratings yet

- ACTUADORDocument4 pagesACTUADORkholymmNo ratings yet

- Chemical Industry BrochureDocument6 pagesChemical Industry BrochureFrank HigueraNo ratings yet

- Ram Sons Viet MachinesDocument38 pagesRam Sons Viet MachinesDeepanNo ratings yet

- Final - Steam Engineering - Product - Portfolio-5-14Document10 pagesFinal - Steam Engineering - Product - Portfolio-5-14angga rizkiNo ratings yet

- Ayvaz Steam Traps BookDocument79 pagesAyvaz Steam Traps BookgideonolinyoNo ratings yet

- FTI Finish Thompson DB SP MSDB Series Pumps BrochureDocument12 pagesFTI Finish Thompson DB SP MSDB Series Pumps BrochureLê Hoàng GiangNo ratings yet

- May Nen IntermechDocument2 pagesMay Nen IntermechUchiha SaitamaNo ratings yet

- Aquamist Pump BrochureDocument4 pagesAquamist Pump BrochureJuanHernandezNo ratings yet

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDocument6 pagesMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceVEZZ RIDE25No ratings yet

- STL DatasheetDocument16 pagesSTL DatasheetCarlos Miguel Barrena TorresNo ratings yet

- 2240 1312 EKN Steelwelded Edition3 en 0607Document7 pages2240 1312 EKN Steelwelded Edition3 en 0607AhmedRamadanNo ratings yet

- Steam Traps - TypesDocument3 pagesSteam Traps - Typesrenji_danny100% (1)

- Vahterus-Intercambiador de Placas-PsheDocument3 pagesVahterus-Intercambiador de Placas-PshepxpingenieriaNo ratings yet

- 2235 1314 EKN Hardrubber Edition3 en 0607Document7 pages2235 1314 EKN Hardrubber Edition3 en 0607AhmedRamadanNo ratings yet

- Chiller Cutsheet M702 M802Document1 pageChiller Cutsheet M702 M802GamalpageNo ratings yet

- CECO Sethco Model P90Document4 pagesCECO Sethco Model P90marcoNo ratings yet

- 1315 EKN Hotwater Steelwelded Edition3 enDocument7 pages1315 EKN Hotwater Steelwelded Edition3 enAhmedRamadanNo ratings yet

- 2/2-Way Solenoid Valve: Type 253Document4 pages2/2-Way Solenoid Valve: Type 253Francisco Mones RuizNo ratings yet

- Description Materials: Cast Iron For Horizontal InstallationDocument2 pagesDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNo ratings yet

- Parker Filtration Group - GSF (July 2016)Document28 pagesParker Filtration Group - GSF (July 2016)Shibu ThomasNo ratings yet

- SH 60 TD enDocument98 pagesSH 60 TD enCésar David Pedroza DíazNo ratings yet

- Data Sheets L M Replaceable Polymer Liner Knife Gate Valves Clarkson en en 5196090Document8 pagesData Sheets L M Replaceable Polymer Liner Knife Gate Valves Clarkson en en 5196090Samuel WeberNo ratings yet

- 09hermetically Sealed OilDocument2 pages09hermetically Sealed OiljuliancansenNo ratings yet

- Parker 441 HoseDocument2 pagesParker 441 HoseRajpal SharmaNo ratings yet

- D75KSDocument4 pagesD75KSA LettristeNo ratings yet

- ActuatorDocument8 pagesActuatorMuhammed Ali PisuwalaNo ratings yet

- No-Skive: Tough Cover Compact HoseDocument2 pagesNo-Skive: Tough Cover Compact HoseleonardoNo ratings yet

- Evaporative CondensersDocument20 pagesEvaporative CondensersAl Musabbir LeeonNo ratings yet

- Crompton DC MotorsDocument6 pagesCrompton DC MotorsAzed-dine BoughmarNo ratings yet

- SMD Axially Split Casing, Double Suction PumpDocument8 pagesSMD Axially Split Casing, Double Suction PumpdonestebNo ratings yet

- Bauma ATS Stage - V AGCOpdfDocument3 pagesBauma ATS Stage - V AGCOpdfNicolas WangNo ratings yet

- Catalogo CeaDocument2 pagesCatalogo CeaSergio ZegarraNo ratings yet

- Sero Prospekt SRZ eDocument8 pagesSero Prospekt SRZ esdafas dfNo ratings yet

- CEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZDocument48 pagesCEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZValbertNo ratings yet

- Bharat Bijlee Power TransformerDocument24 pagesBharat Bijlee Power Transformerchirag100% (1)

- MP2010 345 Product Brochure S Series RevEDocument2 pagesMP2010 345 Product Brochure S Series RevEJackNo ratings yet

- Secador de Aire Sullair SR 500Document16 pagesSecador de Aire Sullair SR 500Darwin Santamaría CalderónNo ratings yet

- Sandvik d55sp Specification Sheet EnglishDocument4 pagesSandvik d55sp Specification Sheet EnglishSheree PeoplesNo ratings yet

- GD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWDocument8 pagesGD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWgheantikaNo ratings yet

- Purgadores de VaporDocument6 pagesPurgadores de VaporPaulo CostaNo ratings yet

- Brochure Isolation Valves Product Overview en en 5253576Document36 pagesBrochure Isolation Valves Product Overview en en 5253576Muthu Kumar RNo ratings yet

- Thorburn Flex Powergen2012Document4 pagesThorburn Flex Powergen2012Raja Syahmarizal Raja BaharuddinNo ratings yet

- Butterfly Valve CatalogDocument18 pagesButterfly Valve Catalogyash100% (1)

- Steam Trapping OverviewDocument1 pageSteam Trapping OverviewBinhvvNo ratings yet

- TAKAMI Instruction Manual TDCVDocument9 pagesTAKAMI Instruction Manual TDCVBinhvvNo ratings yet

- An Introduction To Steam TrapsDocument1 pageAn Introduction To Steam TrapsBinhvvNo ratings yet

- Zhongquan Valve CertDocument1 pageZhongquan Valve CertBinhvvNo ratings yet

- SMC AN SilencerDocument1 pageSMC AN SilencerBinhvvNo ratings yet

- Make Your Steam System Safe, Efficient and Sustainable: How Can Spirax Sarco Help You?Document1 pageMake Your Steam System Safe, Efficient and Sustainable: How Can Spirax Sarco Help You?BinhvvNo ratings yet

- SLS - Series Level SwitchDocument3 pagesSLS - Series Level SwitchBinhvvNo ratings yet

- 1 3 13certificateDocument1 page1 3 13certificateBinhvvNo ratings yet

- tmm55 InclinometerDocument3 pagestmm55 InclinometerBinhvvNo ratings yet

- Metertalk Ultrasonic Flowmeter 3Document1 pageMetertalk Ultrasonic Flowmeter 3BinhvvNo ratings yet

- 내산 (Pfa,Ptfe) Butterfly Valve: Standard DimensionalDocument1 page내산 (Pfa,Ptfe) Butterfly Valve: Standard DimensionalBinhvvNo ratings yet

- Feida Valve CertDocument1 pageFeida Valve CertBinhvvNo ratings yet

- HC Valve 5 PDFDocument1 pageHC Valve 5 PDFBinhvvNo ratings yet

- 내산 (Pfa,Ptfe) Butterfly Valve: Han Chang Industry Co.,LtdDocument1 page내산 (Pfa,Ptfe) Butterfly Valve: Han Chang Industry Co.,LtdBinhvvNo ratings yet

- Bg20016-Catalog + DrawingDocument9 pagesBg20016-Catalog + DrawingBinhvvNo ratings yet

- HC ValveDocument1 pageHC ValveBinhvvNo ratings yet

- GML 209 NJ GB1 LED 24 Grey - TechdataDocument3 pagesGML 209 NJ GB1 LED 24 Grey - TechdataBinhvvNo ratings yet

- Catalog VikorDocument16 pagesCatalog VikorBinhvvNo ratings yet

- Technical Features: Equivalents of Burgmann MG SeriesDocument2 pagesTechnical Features: Equivalents of Burgmann MG SeriesBinhvvNo ratings yet

- Series ALLUB RUVDocument2 pagesSeries ALLUB RUVBinhvvNo ratings yet

- Feed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataBinhvvNo ratings yet

- ATEX Marking Electrical Equipment Ex PDFDocument1 pageATEX Marking Electrical Equipment Ex PDFBinhvvNo ratings yet

- Water/oil Coolers Series CSW 8: CiesseDocument4 pagesWater/oil Coolers Series CSW 8: CiesseBinhvvNo ratings yet

- K23Document8 pagesK23BinhvvNo ratings yet

- Schneider Cam Switch 4 Poles 20ADocument1 pageSchneider Cam Switch 4 Poles 20ABinhvvNo ratings yet

- Weidmuller 1282250000-Cat1-W-EnDocument32 pagesWeidmuller 1282250000-Cat1-W-EnBinhvvNo ratings yet

- Data Sheet: SAK Series Sakk 4Document4 pagesData Sheet: SAK Series Sakk 4BinhvvNo ratings yet

- Course Objectives and OutcomesDocument2 pagesCourse Objectives and OutcomesHarjit Singh MangatNo ratings yet

- Glenda Melanie Lub - ChartDocument7 pagesGlenda Melanie Lub - ChartAndrei ZahaNo ratings yet

- Shaft Design and Detailing Recommendations - Pile DetailingDocument3 pagesShaft Design and Detailing Recommendations - Pile DetailingNoli PaladNo ratings yet

- Hedland Variable Area Flow Meters and Flow Switches Brochure Vam-br-00714-EnDocument8 pagesHedland Variable Area Flow Meters and Flow Switches Brochure Vam-br-00714-EnRosendo RizoNo ratings yet

- VW 01M Transmission 65535 ErrorDocument6 pagesVW 01M Transmission 65535 ErrorRashaad Sheik100% (1)

- GUASCOR dipticoING 1800Document4 pagesGUASCOR dipticoING 1800Juan RamónNo ratings yet

- Oncology, Gardiac, GI Design ReportDocument72 pagesOncology, Gardiac, GI Design ReportEng. Ayenew ZewdieNo ratings yet

- Aircraft Loading and Structural LayoutDocument626 pagesAircraft Loading and Structural LayoutUroš Roštan100% (1)

- Airbus 30 A300 A310 Ice and RainDocument48 pagesAirbus 30 A300 A310 Ice and RainElijah Paul Merto100% (2)

- DIN EN 10130 - February - 1999Document13 pagesDIN EN 10130 - February - 1999dpfloresNo ratings yet

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 pagesSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekNo ratings yet

- Exam in Engine Management 1Document3 pagesExam in Engine Management 1Jhezel Mae Alfaro Aquino100% (1)

- Ficha Tecnica - Backing RingDocument1 pageFicha Tecnica - Backing RingFernando Rocca VillalobosNo ratings yet

- Lecture 3-Column DesignDocument95 pagesLecture 3-Column DesignRuben Ooi100% (1)

- Si RSUQ AYMDocument456 pagesSi RSUQ AYMTaofik Muarifin100% (1)

- BMS Excel List PointDocument8 pagesBMS Excel List PointfghabboonNo ratings yet

- BradleyDocument247 pagesBradleythomas duncan eelesNo ratings yet

- Manual de Taller ET 300Document165 pagesManual de Taller ET 300yisusyisus0% (1)

- Room Air Conditioners - SpecificationDocument58 pagesRoom Air Conditioners - SpecificationAbhishek SrivastvaNo ratings yet

- AASHTO LRFD 8th Steel Design ChangeDocument8 pagesAASHTO LRFD 8th Steel Design ChangetsuregiNo ratings yet

- Thermal EnergyDocument30 pagesThermal EnergyKella OrtegaNo ratings yet

- Arc Blow LogoDocument3 pagesArc Blow Logoأحمد حسنNo ratings yet

- Air or Gas Driven Injectors: Description ApplicationsDocument8 pagesAir or Gas Driven Injectors: Description ApplicationsEyo Etim0% (1)

- Air Comp. BasicsDocument33 pagesAir Comp. Basicskisan singhNo ratings yet

- SLON-GATHMGNO000-PIP-LST-PHR-2002-00 - MTO Piping Material Menggala North GS - Rev 0A3 - DA CommentDocument13 pagesSLON-GATHMGNO000-PIP-LST-PHR-2002-00 - MTO Piping Material Menggala North GS - Rev 0A3 - DA CommentDheska AgungwNo ratings yet

- Data Sheet For Carbon Steel Piping MaterialsDocument14 pagesData Sheet For Carbon Steel Piping MaterialsNoor AnterNo ratings yet

- ASTM A789 Stainless Steel TubingDocument6 pagesASTM A789 Stainless Steel TubingPlinio PazosNo ratings yet