Professional Documents

Culture Documents

SR-3173 Crimping Instruction Steel Part REV.1

SR-3173 Crimping Instruction Steel Part REV.1

Uploaded by

Mian HananOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SR-3173 Crimping Instruction Steel Part REV.1

SR-3173 Crimping Instruction Steel Part REV.1

Uploaded by

Mian HananCopyright:

Available Formats

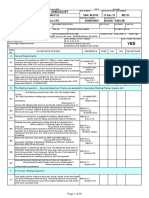

Dok No/Doc No : BGR/T-18

CRIMPING METHOD FOR SITE Sayfa/Page No : 1 /4

INSTALLATION of SR–3173 (Steel Part)

PROJECT 500kV HARDWARE PROJECTS FOR

NTDC

CUSTOMER REF. No. 3217(R)-4M

ŞA-RA REF. No. PK/NAT/14/50/1757

APROVED POSE NAMES/DWG No. SR-3173

CONTENT OF MODIFICATIONS

REV ESTABLISHED CHECKED APPROVED DESCRIPTION

01 Sertaç EROL Cem DAGTEKIN M.YAŞAYAN

Design Engineer Q.S Manager 30/09/2019

HAZIRLAYAN/Prepared ONAY/Approval Haz.Tarih/Origin Date: 30/09/2019

Hakkı Işık ARIDENİZ Cem DAGTEKIN Rev.Tarih/Rev.Date 03/10/2019

Quality Control Engineer Q.S Manager Yürürlülük/Effective Date : 30/09/2019

. Revizyon/Rev. No : 01

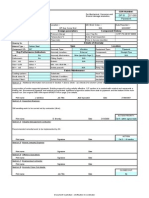

Dok No/Doc No : BGR/T-18

CRIMPING METHOD FOR SITE Sayfa/Page No : 2 /4

INSTALLATION of SR–3173 (Steel Part)

1- PURPOSE

This Instruction defines to obtaining the compression and inspection method of mid

span joint as per Technical Drawings (SR-3173) to be installed at site, conforming to

500kV HARDWARE PROJECTS FOR NTDC according to following requirements.

2 - APPLICATION

it covers mid span joint (SR-3173) to be compressed at the customer site installation

after ex-works.

3- METHOD FOR CRIMPING

3.1) Supply, all necessary equipment identified regarding compression process

according to the method statement in the installation site.

3.2) Automatic compression and its die equipment are to be used clean and well

maintained.

3.3) Cut the aluminum layers at the steel without the steel core (Picture:1)

Picture:1

3.4 ) Steel core length for SR–3173 as 138 mm (+2-0)

3.5) Slide the long aluminum tube on the conductor, turning towards the wiring direction

HAZIRLAYAN/Prepared ONAY/Approval Haz.Tarih/Origin Date: 30/09/2019

Hakkı Işık ARIDENİZ Cem DAGTEKIN Rev.Tarih/Rev.Date 03/10/2019

Quality Control Engineer Q.S Manager Yürürlülük/Effective Date : 30/09/2019

. Revizyon/Rev. No : 01

Dok No/Doc No : BGR/T-18

CRIMPING METHOD FOR SITE Sayfa/Page No : 3 /4

INSTALLATION of SR–3173 (Steel Part)

3.6) Select and insert to die of (Picture 2) to the compression machine SR–3173 for

steel part

Picture : 2 (Compression die for SR-3173 steel part)

Note: Dies with size 19.5 to 19.6 mm give better visual appearance to the completed

mid span joint.

3.7) Never rotate the position until last step of crimping operation at site floor.

Picture : 3

HAZIRLAYAN/Prepared ONAY/Approval Haz.Tarih/Origin Date: 30/09/2019

Hakkı Işık ARIDENİZ Cem DAGTEKIN Rev.Tarih/Rev.Date 03/10/2019

Quality Control Engineer Q.S Manager Yürürlülük/Effective Date : 30/09/2019

. Revizyon/Rev. No : 01

Dok No/Doc No : BGR/T-18

CRIMPING METHOD FOR SITE Sayfa/Page No : 4 /4

INSTALLATION of SR–3173 (Steel Part)

Stage of Crimping Operations (For Steel Part)

3.9) Start compression from each direction. (Please, see picture: 3)

4.0) 2nd crimping should be started before L/3 level of 1st crimping length.

4.1) Apply this method through the Each Crimping step should be continued till end

location accordingly.

Note: Compression data shown in the technical drawing SR-3173

4.2) Crimped steel part sample have been indicated and shown in Pictures No: 4

Picture: 4

4.2) Check and measure the crimping distance with caliper. According to the

crimping direction (picture 3)

4.3) Crimping distance (for steel part) should be conformed according to

technical drawings SR–3173

HAZIRLAYAN/Prepared ONAY/Approval Haz.Tarih/Origin Date: 30/09/2019

Hakkı Işık ARIDENİZ Cem DAGTEKIN Rev.Tarih/Rev.Date 03/10/2019

Quality Control Engineer Q.S Manager Yürürlülük/Effective Date : 30/09/2019

. Revizyon/Rev. No : 01

You might also like

- Gantrex NA Catalog March 2019Document240 pagesGantrex NA Catalog March 2019fostbarr100% (1)

- 31) Method Statement For Shaft WorksDocument3 pages31) Method Statement For Shaft WorksNikhil Manjrekar0% (2)

- User Design Spec - Rev1Document5 pagesUser Design Spec - Rev1John NashNo ratings yet

- Method Statement For Rebar InstallationDocument4 pagesMethod Statement For Rebar InstallationPaul Ladjar100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Renewable Energy Potentials in Saudi ArabiaDocument27 pagesRenewable Energy Potentials in Saudi Arabiam_mukbel8752No ratings yet

- Passive Fire Protection Testing & CertificationDocument9 pagesPassive Fire Protection Testing & CertificationVikas Kumar Pathak100% (1)

- SR-3089.S Crimping Instruction Alm. Part REV.2Document5 pagesSR-3089.S Crimping Instruction Alm. Part REV.2Mian HananNo ratings yet

- Technical Specification Carbon Steel Heat Exchangers: Project No: 338033Document14 pagesTechnical Specification Carbon Steel Heat Exchangers: Project No: 338033jdgh1986No ratings yet

- Technical Specification Stainless Steel Heat Exchangers: Project No: 338033Document13 pagesTechnical Specification Stainless Steel Heat Exchangers: Project No: 338033jdgh1986No ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Welding Repair ProcedureDocument4 pagesWelding Repair ProcedureRiky SumantriNo ratings yet

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduNo ratings yet

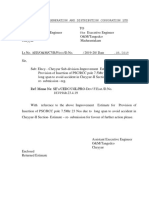

- HV Projects Department-South Civil & Electromehcanical Projects DivisionDocument1 pageHV Projects Department-South Civil & Electromehcanical Projects DivisionALI ASGHARNo ratings yet

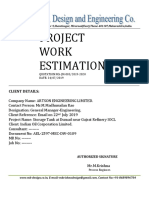

- Project Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaDocument6 pagesProject Work Estimation: Mumbai Office: C-62/204, Sector-9, Shantinagar, Miraroad (East), Thane-401107, Maharashtra, IndiaAmul AmnajeNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- 1042238180-2141571394-RT Request Co1Document1 page1042238180-2141571394-RT Request Co1iankulehNo ratings yet

- 2.procedure For Fabrication and ErectionDocument13 pages2.procedure For Fabrication and Erectionanon_106345234100% (2)

- MYMYDocument1 pageMYMYExplore the world TodayNo ratings yet

- (Customer) (CS-2019-026 - EN) Aluminum Radiators IntroductionDocument1 page(Customer) (CS-2019-026 - EN) Aluminum Radiators IntroductionXuân Quang PhạmNo ratings yet

- DT-PL-5223-2629-DT-16.03.2023 (TS-047-REV-01) CommentedDocument77 pagesDT-PL-5223-2629-DT-16.03.2023 (TS-047-REV-01) Commentedhazem badawyNo ratings yet

- AP-GSME-PL-CAL-001 Pipeline Wall Thickness Calculation Rev.ADocument18 pagesAP-GSME-PL-CAL-001 Pipeline Wall Thickness Calculation Rev.AgamadraftNo ratings yet

- CS HARDWARE TS-SA-193-P-222051-R0 (Commented)Document1 pageCS HARDWARE TS-SA-193-P-222051-R0 (Commented)PRADEEP GAIKWADNo ratings yet

- Factory BuildingDocument19 pagesFactory BuildingDr Ganesh Kame (Dr Kame)No ratings yet

- HV Projects Department-South Civil & Electromehcanical Projects DivisionDocument1 pageHV Projects Department-South Civil & Electromehcanical Projects DivisionALI ASGHARNo ratings yet

- 17 185 DCR 64Document2 pages17 185 DCR 64Agni DuttaNo ratings yet

- 23 9 2019 RequiredDocument1 page23 9 2019 RequirednidhisasidharanNo ratings yet

- Method Statement of Casting (Manhole and Chamber) (Rev C0)Document20 pagesMethod Statement of Casting (Manhole and Chamber) (Rev C0)Isam GhawadrehNo ratings yet

- B2020 TDC PP 003 - Pipes - R2Document2 pagesB2020 TDC PP 003 - Pipes - R2Ramalingam PrabhakaranNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- Fabrication Method For HSM 2 ProjectDocument14 pagesFabrication Method For HSM 2 ProjectMikiRoniWijayaNo ratings yet

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pages7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresNo ratings yet

- Peil-Ces-Cs-Btg-Bc-06 (SH-4) - Rev-3Document8 pagesPeil-Ces-Cs-Btg-Bc-06 (SH-4) - Rev-3Smart ShivaNo ratings yet

- Painting Procedure ManufactureDocument14 pagesPainting Procedure ManufactureAgung Haryono, Amd, ST, MTNo ratings yet

- CDR 07-055Document4 pagesCDR 07-055diaccessltd_17172961No ratings yet

- AMS2303 - Steel Cleanliness, Aircraft Quality PDFDocument14 pagesAMS2303 - Steel Cleanliness, Aircraft Quality PDFRATHNAKUMARANo ratings yet

- RFI TempleteDocument6 pagesRFI TempleteAshadi Amir100% (1)

- Test Report: 23 First Lok Yang RoadDocument3 pagesTest Report: 23 First Lok Yang RoadshahruziNo ratings yet

- Attention: Project Details:: Work Inspection RequestDocument1 pageAttention: Project Details:: Work Inspection Requestkpastrano.rtqccNo ratings yet

- AP-GSME-PL-CAL-002 Pipeline Road Crossing Calculation Rev.ADocument24 pagesAP-GSME-PL-CAL-002 Pipeline Road Crossing Calculation Rev.AgamadraftNo ratings yet

- Test Report - Metallography: Customer Name& AddressDocument1 pageTest Report - Metallography: Customer Name& AddressP NAVEEN KUMARNo ratings yet

- G SM PPLT Pip 805Document12 pagesG SM PPLT Pip 805rokan123No ratings yet

- 02 ACSR ZEBRA ConductorDocument37 pages02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Fabrication - Assembly & ErectionDocument83 pagesFabrication - Assembly & ErectionRengga Andryastama100% (2)

- 338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFDocument9 pages338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFjdgh1986No ratings yet

- 26071-100-VSC-NP1-00001 - 001 Radiographic Examination Procedure-2Document30 pages26071-100-VSC-NP1-00001 - 001 Radiographic Examination Procedure-2Dwi Agung AriyonoNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- Fitting AHU and PumpDocument7 pagesFitting AHU and PumpJf OngNo ratings yet

- 028120-SPL-002 CRA Lined Carbon Steel Linepipe (Rev. C)Document13 pages028120-SPL-002 CRA Lined Carbon Steel Linepipe (Rev. C)Rokan PipelineNo ratings yet

- CC-SP-3013 - 3049 - PL40 190: Primer Breemo Red OxideDocument1 pageCC-SP-3013 - 3049 - PL40 190: Primer Breemo Red OxideAhmed LepdaNo ratings yet

- Milnadu Generation and Distribution Corporation LTDDocument1 pageMilnadu Generation and Distribution Corporation LTDparameswarikumarNo ratings yet

- LABORATORY TEST CIVIL ENGINEERING TESTING ACCREDITATION ScheduleDocument33 pagesLABORATORY TEST CIVIL ENGINEERING TESTING ACCREDITATION Schedulejuli_rad100% (2)

- Attention: Project Details:: Work Inspection RequestDocument1 pageAttention: Project Details:: Work Inspection Requestkpastrano.rtqccNo ratings yet

- Method Statement, ITP & Riskassesment For AAC Block & Bricks WorksDocument31 pagesMethod Statement, ITP & Riskassesment For AAC Block & Bricks WorksFozan GhotiaNo ratings yet

- 08572-Trht-Ms-Ppfm003-A06-004 - D General Arrangement Drawing Lean Amine Surge TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-004 - D General Arrangement Drawing Lean Amine Surge TankSamer ArousNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument7 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheettuanphamNo ratings yet

- Site Instruction No.3Document1 pageSite Instruction No.3Babini mbolaNo ratings yet

- S-00-1360-002 Rev 1 (Piping Material Specification)Document53 pagesS-00-1360-002 Rev 1 (Piping Material Specification)ajmain100% (1)

- ArduinoPortentaEdgeControl CircuitDocument8 pagesArduinoPortentaEdgeControl Circuitgodwinraj123No ratings yet

- Techspecs fx180 240 EngDocument2 pagesTechspecs fx180 240 EngmjgosslerNo ratings yet

- Et200s Im151-3 PN ManualDocument56 pagesEt200s Im151-3 PN ManualrafaelfbbNo ratings yet

- Hilti Firestop Application Handbook 2017 A4 14Document36 pagesHilti Firestop Application Handbook 2017 A4 14dexterbox1No ratings yet

- MV RelaysDocument1 pageMV Relaysyadav_sctNo ratings yet

- Ultra Station DatasheetDocument4 pagesUltra Station Datasheetbubo28No ratings yet

- Autocad Mechanical 2007 Product DetailDocument9 pagesAutocad Mechanical 2007 Product DetailpetereidNo ratings yet

- Aerodrome Inspector HandbookDocument131 pagesAerodrome Inspector HandbookciucamiNo ratings yet

- 2 DSHK-DTDocument2 pages2 DSHK-DTRama Aji Al HakimNo ratings yet

- Catálogo Caterpillar - Motores e GeradoresDocument106 pagesCatálogo Caterpillar - Motores e GeradoresFranciele GomesNo ratings yet

- Prodelin 1251Document2 pagesProdelin 1251Marcos Della MeaNo ratings yet

- Analysis and Design of Space FramDocument16 pagesAnalysis and Design of Space FramDuaa Nairat67% (3)

- Integrated Hydraulic Rock Drill and Splitter BrochureDocument14 pagesIntegrated Hydraulic Rock Drill and Splitter Brochureمصطفي جودهNo ratings yet

- Consumer Buying Behaviour MBADocument115 pagesConsumer Buying Behaviour MBAmail_ankitkr40% (5)

- ECOCEMDocument24 pagesECOCEMoneakshayNo ratings yet

- Stress Corrosion Cracking - A Caustic ExperienceDocument3 pagesStress Corrosion Cracking - A Caustic Experienceramadoss_alwar7307No ratings yet

- Equations: Hvac Equations, Data, and Rules of ThumbDocument21 pagesEquations: Hvac Equations, Data, and Rules of ThumbzodedNo ratings yet

- Advanced Training Institute, DGT, MSDE, Mumbai - MCQ Test 4 - POT / ETDocument4 pagesAdvanced Training Institute, DGT, MSDE, Mumbai - MCQ Test 4 - POT / ETpriyanka lariyaNo ratings yet

- Electrical Engineering Question Paper-II: - Kirchoff's LossDocument25 pagesElectrical Engineering Question Paper-II: - Kirchoff's LossbasavarajNo ratings yet

- Ir2530 2525 2520-SM-E Rev7Document395 pagesIr2530 2525 2520-SM-E Rev7Gabriel VoicuNo ratings yet

- RX8200 Configuration PacksDocument7 pagesRX8200 Configuration PacksevvnNo ratings yet

- Hadfield MN SteelDocument16 pagesHadfield MN SteelX048Anshul JumoreNo ratings yet

- ITOTEC - 115Z - Operation Manual (Applied)Document88 pagesITOTEC - 115Z - Operation Manual (Applied)18-424 Ganesh KotaNo ratings yet

- 16.1 Application For Supply / Additional Load / Shifting / Extension of Services / Change of Name / Changeover of SupplyDocument3 pages16.1 Application For Supply / Additional Load / Shifting / Extension of Services / Change of Name / Changeover of SupplypraschNo ratings yet

- PCC41NG2 Series Component Cleanliness Cabinet: FeaturesDocument2 pagesPCC41NG2 Series Component Cleanliness Cabinet: FeaturesSamNo ratings yet

- 2015 - Poirier E.A. Et Al - Measuring The Impact of BIM On Labor Productivity in A Small Specialty Contracting Enterprise PDFDocument11 pages2015 - Poirier E.A. Et Al - Measuring The Impact of BIM On Labor Productivity in A Small Specialty Contracting Enterprise PDFKaueTKNo ratings yet