Professional Documents

Culture Documents

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Uploaded by

JAY AGRAWALCopyright:

Available Formats

You might also like

- 5.5.1 PracticeDocument12 pages5.5.1 PracticeSid MathurNo ratings yet

- Master of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: EnglishDocument4 pagesMaster of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: Englishmuhammad adnanNo ratings yet

- Material Science EngineDocument5 pagesMaterial Science EngineJohn_AdaNo ratings yet

- Electives - 2nd Sem 2013-14Document3 pagesElectives - 2nd Sem 2013-14Rohit LadNo ratings yet

- Free Download Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques Silberschmidt Full Chapter PDFDocument51 pagesFree Download Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques Silberschmidt Full Chapter PDFdebra.mchone833100% (28)

- ModernMaterials Ghosh Kumar ViswanathanDocument2 pagesModernMaterials Ghosh Kumar ViswanathanHamed hussain S HanifiNo ratings yet

- 18me34 MSDocument173 pages18me34 MSArjun AjoozNo ratings yet

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- The Mechanical Properties of Biomaterials: BIOM9561Document9 pagesThe Mechanical Properties of Biomaterials: BIOM9561vodounnouNo ratings yet

- Materials Science and Engineering - Stanford UniversityDocument22 pagesMaterials Science and Engineering - Stanford Universityteerth_brahmbhattNo ratings yet

- Outreach Pamphlet RCCDocument2 pagesOutreach Pamphlet RCCnarayananx5No ratings yet

- MS Program in Materials Science and EngineeringDocument76 pagesMS Program in Materials Science and EngineeringMuhammad SalmanNo ratings yet

- ME8381STRENGTHOF Materials Notes Hand NotesDocument60 pagesME8381STRENGTHOF Materials Notes Hand NoteselabalajiNo ratings yet

- Materials Sceince and TechnologyDocument18 pagesMaterials Sceince and TechnologyRajareddyDuddekuntaNo ratings yet

- PHD Programme in Mechanical EngineeringDocument7 pagesPHD Programme in Mechanical EngineeringAshok BodaNo ratings yet

- Amema 2023Document4 pagesAmema 2023BRajesh ReddyNo ratings yet

- IOP Conference Series Materials Science and Engineering Bristol Vol 1133, Iss. 1 (Apr 2021) - DOI 10.1088 1757 OutDocument6 pagesIOP Conference Series Materials Science and Engineering Bristol Vol 1133, Iss. 1 (Apr 2021) - DOI 10.1088 1757 OutfalmubaddelNo ratings yet

- Dialog - Undergraduate Program Metalurgy & Material EngineeringDocument5 pagesDialog - Undergraduate Program Metalurgy & Material EngineeringAlfa DamaNo ratings yet

- Report On BiodieselDocument95 pagesReport On Biodieselsumanth kumar gaddamNo ratings yet

- Material Science and EngineeringDocument2 pagesMaterial Science and Engineering3m3hNo ratings yet

- CHL MFC STCWGE Mar2024 v2Document2 pagesCHL MFC STCWGE Mar2024 v2hodcivilssmietNo ratings yet

- MSM Lab Manual - 2021-22Document61 pagesMSM Lab Manual - 2021-22Divyaraj VaghelaNo ratings yet

- 6032 PDFDocument191 pages6032 PDFMuhammad KashifNo ratings yet

- Chemical Engineering Past Present and FutureDocument2 pagesChemical Engineering Past Present and FutureArinjayKumarNo ratings yet

- SWOT Analysis - Kinetic ArchitectureDocument9 pagesSWOT Analysis - Kinetic ArchitectureVinay GoyalNo ratings yet

- Project Proposal (Vibration Engineering)Document15 pagesProject Proposal (Vibration Engineering)Yhan Sombilon100% (1)

- Letter of MotivationDocument2 pagesLetter of MotivationSajib Chandra RoyNo ratings yet

- OutlineDocument4 pagesOutlineRajib BaruaNo ratings yet

- Nanotechnology For Structural ApplicationDocument42 pagesNanotechnology For Structural ApplicationThisari MunmullaNo ratings yet

- Materials 14 00029 v21Document23 pagesMaterials 14 00029 v21Jesús de Vicente y OlivaNo ratings yet

- Natonial Conference 2016-02 (Innovative Trends in Mechanical Engineering)Document16 pagesNatonial Conference 2016-02 (Innovative Trends in Mechanical Engineering)Ravichandran GNo ratings yet

- Study PlanDocument5 pagesStudy PlanFawad AhmadNo ratings yet

- Principles of Cement and Concrete Composites: Natt MakulDocument209 pagesPrinciples of Cement and Concrete Composites: Natt MakulGilart A C KerrNo ratings yet

- A Synopsis On "Synthesis and Characterization of Composite Material For Biomedical Application" Submitted ToDocument14 pagesA Synopsis On "Synthesis and Characterization of Composite Material For Biomedical Application" Submitted ToAtul JainNo ratings yet

- 1 s2.0 S2238785419319714 MainDocument18 pages1 s2.0 S2238785419319714 MainRio ArrayNo ratings yet

- Quagliotti MSMNMetrologyAPMT PDFDocument201 pagesQuagliotti MSMNMetrologyAPMT PDFDiana Alejandra Bermudez FajardoNo ratings yet

- Materials Lab 28072023Document38 pagesMaterials Lab 28072023ShemelsNo ratings yet

- Master of Science eTH in Mechanical EngineeringDocument4 pagesMaster of Science eTH in Mechanical EngineeringAhmed TariqNo ratings yet

- Chandigarh University - ApplicationDocument9 pagesChandigarh University - ApplicationNaval Koralkar Chemical Engg. Dept.No ratings yet

- Brochure GIAN-Design of AnchorsDocument2 pagesBrochure GIAN-Design of Anchorsrehanmaaz100% (1)

- Failure of Metals II FatigueDocument24 pagesFailure of Metals II Fatigueandremuniz150No ratings yet

- Prediction of Microstructural Evolution During Hot Forging: Fei Chen, Zhenshan Cui, and Jun ChenDocument21 pagesPrediction of Microstructural Evolution During Hot Forging: Fei Chen, Zhenshan Cui, and Jun Chen임학진No ratings yet

- 2018 2019UndergraduateEnglishTaughtCoursesDocument40 pages2018 2019UndergraduateEnglishTaughtCoursesmalu accountNo ratings yet

- 18ME32Document59 pages18ME32Pratham J TudoorNo ratings yet

- Seismic Structural EngineeringDocument11 pagesSeismic Structural EngineeringMuhammad AbubakarNo ratings yet

- Advanced Material Chemistry Digital NotesDocument82 pagesAdvanced Material Chemistry Digital Notesharshitjoshi200417No ratings yet

- Pengantar Material TeknikDocument50 pagesPengantar Material TeknikbledsoeNo ratings yet

- CV of Dr. Md. Arifuzzaman NUS PDFDocument5 pagesCV of Dr. Md. Arifuzzaman NUS PDFMd Arifuzzaman ArifNo ratings yet

- Computational Nanomechanics of Materials: Wing Kam Liu, Sukky Jun, and Dong QianDocument27 pagesComputational Nanomechanics of Materials: Wing Kam Liu, Sukky Jun, and Dong QianQaisNo ratings yet

- Full Download Book Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials PDFDocument36 pagesFull Download Book Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials PDFdoris.perrin870100% (25)

- Metallurgical EngineeringDocument1 pageMetallurgical EngineeringP PNo ratings yet

- Design, Fabrication, and Mechanics of 3DDocument3 pagesDesign, Fabrication, and Mechanics of 3Dtharindu jayasingheNo ratings yet

- Study ProposalDocument2 pagesStudy ProposalRamsha KanwalNo ratings yet

- Muet Prospectus 14-Batch 2013-14Document124 pagesMuet Prospectus 14-Batch 2013-14Bilal NaveedNo ratings yet

- Mme 312 AssignmentDocument5 pagesMme 312 AssignmentFaruqNo ratings yet

- Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials Xianfeng Zhang Full Download ChapterDocument51 pagesShock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials Xianfeng Zhang Full Download Chapterrita.aadland779100% (9)

- Higher Education and Research in Foreign From IndiaDocument37 pagesHigher Education and Research in Foreign From IndiaJagmohan DixitNo ratings yet

- MTech PHD Admission Brochure MSME IITHyderabad 2018Document7 pagesMTech PHD Admission Brochure MSME IITHyderabad 2018Anonymous I3IUcziNo ratings yet

- Materials Forming and Machining: Research and DevelopmentFrom EverandMaterials Forming and Machining: Research and DevelopmentRating: 3 out of 5 stars3/5 (1)

- Microforming Technology: Theory, Simulation and PracticeFrom EverandMicroforming Technology: Theory, Simulation and PracticeRating: 5 out of 5 stars5/5 (1)

- Coursera FDPMEYK6VC75Document1 pageCoursera FDPMEYK6VC75JAY AGRAWALNo ratings yet

- Svnit - JNFDocument2 pagesSvnit - JNFJAY AGRAWALNo ratings yet

- Coursera RQY89J9KQB2HDocument1 pageCoursera RQY89J9KQB2HJAY AGRAWALNo ratings yet

- I10010799S20Document6 pagesI10010799S20JAY AGRAWALNo ratings yet

- Daily Activity Report Day 1Document4 pagesDaily Activity Report Day 1Muhammad ZakiNo ratings yet

- Safety Data Sheet: March 22, 2017Document10 pagesSafety Data Sheet: March 22, 2017Gonzalo tobonNo ratings yet

- Effect of Formation Route On The Mechanical Properties of The Polyethersulfone CompositesDocument11 pagesEffect of Formation Route On The Mechanical Properties of The Polyethersulfone CompositesOumeyma HamlauiNo ratings yet

- Experimental Investigation On Four Stroke Catalyst Coated Si EngineDocument8 pagesExperimental Investigation On Four Stroke Catalyst Coated Si EngineNaveenprabhu VNo ratings yet

- A Study of Scrap Rubber Devulcanization and PDFDocument216 pagesA Study of Scrap Rubber Devulcanization and PDFalfiharadisNo ratings yet

- Chapter 1 Environment Monthly TestDocument5 pagesChapter 1 Environment Monthly TestCandleNo ratings yet

- Geo 11 Lesson02 Part 1Document18 pagesGeo 11 Lesson02 Part 1Joverose Manalo VillamorNo ratings yet

- SMB 104 Introduction 1Document29 pagesSMB 104 Introduction 1Shem Peter Mutua MutuiriNo ratings yet

- Sist en Iso 7346 2 1998Document9 pagesSist en Iso 7346 2 1998Dave ManimbenNo ratings yet

- CSDS Stopaq FAST GRE V3Document2 pagesCSDS Stopaq FAST GRE V3AndyNo ratings yet

- Reference Material: Chapter 10.4 (PG 248) of JMH Physics Chapter 8 of MHRDocument19 pagesReference Material: Chapter 10.4 (PG 248) of JMH Physics Chapter 8 of MHRzachariaNo ratings yet

- Binay: Model Li-600 Led-Based Aviation Obstruction LightDocument2 pagesBinay: Model Li-600 Led-Based Aviation Obstruction Lightamit1003_kumarNo ratings yet

- BS-Mechanical Engineering MSU-IITDocument1 pageBS-Mechanical Engineering MSU-IITnaseb.haliNo ratings yet

- 3-FDS Lactose - Pharma - Flowlac ALPAVITDocument4 pages3-FDS Lactose - Pharma - Flowlac ALPAVITMourad BenkNo ratings yet

- Heat Transfer - A Practical Approach - Yunus A. CengelDocument873 pagesHeat Transfer - A Practical Approach - Yunus A. Cengelvinodkonatham70371% (7)

- Compilation Mole Concept Web PagesDocument80 pagesCompilation Mole Concept Web Pagesngah lidwineNo ratings yet

- Methanol Production and Use PDFDocument347 pagesMethanol Production and Use PDFRazleen Rashidi100% (5)

- NETZSCH Steam Jet Mill S-Jet eDocument20 pagesNETZSCH Steam Jet Mill S-Jet ejojibaNo ratings yet

- 5989 2727enDocument10 pages5989 2727enNguyen Manh HungNo ratings yet

- Physics 80 Imp Questions PdfsDocument7 pagesPhysics 80 Imp Questions PdfsM4 PrinceNo ratings yet

- Zinc Acrylate - KansaiDocument9 pagesZinc Acrylate - KansaiApni SafitriNo ratings yet

- Röhr MMA TIG WSME 200 WSME 250 Welder Instruction Manual MinDocument45 pagesRöhr MMA TIG WSME 200 WSME 250 Welder Instruction Manual Minaajj ajsgNo ratings yet

- Chemical BondingDocument274 pagesChemical BondingSafwan AliNo ratings yet

- Material Safety Data Sheet: 1. IdentificationDocument9 pagesMaterial Safety Data Sheet: 1. IdentificationsandeepNo ratings yet

- Fdocuments - in Chemistry Project Space ChemistryDocument22 pagesFdocuments - in Chemistry Project Space ChemistryLip UtNo ratings yet

- Electron Configuration Review WorksheetDocument6 pagesElectron Configuration Review WorksheetDanielle HopkinsNo ratings yet

- Etd. It1 2021-2022 OddDocument1 pageEtd. It1 2021-2022 Oddmmk.mech59No ratings yet

- Introduction To Chemical Reactions-Acid and BasesDocument13 pagesIntroduction To Chemical Reactions-Acid and BasesJenelyn Ponce AguiloNo ratings yet

- R 410a Si PDFDocument20 pagesR 410a Si PDFMarin Munteanu0% (1)

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Uploaded by

JAY AGRAWALOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Gian Course - Svnit - Spain - 30 Jan - 03 Feb 2023 - VDK

Uploaded by

JAY AGRAWALCopyright:

Available Formats

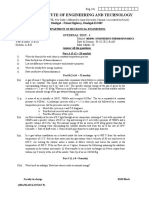

Microstructural control and advanced metallurgical characterization: Application

to thermomechanical processing, welding and severe plastic deformation

(Course code: 191033L03)

(30 January – 03 February 2023)

Overview

Metallurgical science contains disparate time and length scales spanning years to

femtoseconds and meters to angstroms in accordance with research investigations and problem

of interest. It is well known that characteristic length (in terms of distance but also of time)

governs most of the metallurgical phenomena. Particularly, the microstructure control of the

materials has strong influence on fundamental mechanical properties such as toughness,

strength, hardness, ductility, corrosion resistance, wear resistance, etc. which are useful in

structural applications. On the other hand, grain refinement, grain structure during solidification,

inhomogeneities and phase transformations (where time scale plays a major role) are significant

metallurgical aspects affecting mechanical properties in welding applications. It is important to

analyze microstructure/nanostructure by advanced characterization techniques like SEM, EDS,

XRD, TEM and EBSD in order to understand properly the correlation between properties and

ultrafine microestructures. Hence, it is essential to enhance research potential by providing

insightful view by field experts to the research community in accordance with proposed course.

The aim of this course is to provide fundamental understandings of various

microstructure controlling mechanisms in metals for structural applications. Emphasis is

given on promoting grain refinement up to ultrafine and nanometric grain sizes by a)

thermomechanical processing, b) microstructural changes during welding, and c) severe

plastic deformation processes, aiming to improve properties of interest for structural

applications. In this sense, metallurgy and solidification of the weldments are important

aspects to understand the science behind weldments.

Few glimpses of microstructural features obtained through SEM, TEM, OM and EDS

Theoretical conceptualization will be beneficial in grasping the basic understanding of

microstructural characterisation techniques. Faculties, research scholars and industrial persons

will be able to understand and apply it to their respective research areas. Outcomes in terms of

basic learnings about material characterization techniques will be applicable to material

development and materials’ processing to solve current industrial challenges.

Objectives:

The primary objectives of the course are as follows:

i) Exposing participants to the need and significance of microstructure control in

structural applications.

ii) Building in confidence and capability amongst the participants for grain refinement

in regard to mechanical properties for ultrafine and nanometric grain sizes.

iii) Providing exposure to different thermomechanical processing in terms of grain

refinement by dynamic recrystallization, plus modelling, simulation and testing.

iv) Enhancing the capability of the participants to summarize fundamentals on grain

structure, inhomogeneities and phase transformation to welding applications.

v) Providing exposure to severe plastic deformation processes with their applications

including future trends.

vi) Providing exposure to classical and advanced characterization techniques for

observing microstructural alterations.

Course Duration: 30 January – 03 February 2023

Total contact hours: Minimum 20 (Including lectures and hands-on)

information The number of participants for the course will be limited to 50.

Modules Significance and need of metallurgical considerations in structural applications.

Importance of grain refinement in regard to mechanical properties.

Overview of microstructural control in structural applications.

Hall-Petch inversion, mechanical properties for ultrafine/nanometric grain sizes.

Thermomechanical processing: Dynamic recrystallization; modelling and

simulation; testing.

Welding metallurgy: Grain structure in weld pool during solidification - Growth,

control and microstructure refinement; welding inhomogeneities and

microstructural studies of welding defects; phase transformation theory to

welding - Introduction and applications.

Severe plastic deformation processes: Equal channel angular pressure and high

pressure torsion, other processes, application to welding (friction stir welding),

future trends.

Interpretation of micrographs and industrial case studies related to metallurgical

characterization.

Mechanical behavior of metals with nanometric grain sizes.

Future trends for research and opportunities in material science/welding

applications

You should You are designer, manager, executive, engineer, technician, researcher,

scientist, etc. from industries, government organizations including R&D

attend if… laboratories.

You are faculty from reputed technical institutions.

You are PG student and research scholar, etc.

Course fee Industry/Govt./Research organizations: Rs. 3,500/-

Faculty/staff from academic institutions: Rs. 3,500/-

Research scholar/Student: Rs. 2,500/-

Additional 18% GST as per Govt. of India norms is applicable on the course

fee. The course fee covers the course materials, access to all the sessions,

tutorials, laboratory usage, and refreshments/working lunch between the course

sessions. The interested participants will be provided single/shared

accommodation in the Institute guest house/student hostel on self-payment basis,

subjected to availability.

The Faculty

Dr. Jose Maria Cabrera Marrero, born at Santa

Cruz de Tenerife, Canary Islands, Spain in 1964.

He has been a Professor of Metallurgy at the

Polytechnic University of Catalonia (UPC), Spain

since 1996 and is currently a University Professor

(“Chair”) in the Department of Materials Science

and Engineering of the UPC, a position he has held

since 2008.

He was secretary of the department for 10 years,

and deputy vice director of the same and

responsible for the doctoral program for another 10

years. He is currently Director of the CIM UPC

Foundation.

He has been the recipient of a research training grant (1992-1995) and a

postdoctoral fellowship (1995-1996) from the Generalitat de Catalunya.

He has carried out research stays at various universities like, McGill University

Montreal, National Polytechnic Institute of Mexico City (1995 and 1996, where he

obtained an appointment as a visiting professor), Federal University of Sao Carlos

Brazil (2012), Materials Research Institute of the UNAM Mexico (2017).

He has made a sabbatical stay at the Institute of Research in Materials and

Metallurgy of the Michoacan University of San Nicolas de Hidalgo, Morelia for 12

months (September 2019-August 2020), financed by CONACyT.

He has participated in more than 70 research projects (leading 50) both competitive

public funding (responsible for four CICYT projects, a PETRI, an ALFA network,

member of a CYTED project, leader of three European RCFS projects and

participant in two others), and in projects with companies (including two large

projects funded by the CENIT program).

His area of knowledge is oriented to the characterization of the plastic behavior,

mainly at high temperature, of metallic materials. It is basically in this area that

Professor Cabrera has made his greatest contributions, especially by offering a

universal constitutive equation that explains the hot creep curves of practically

all types of metallic materials.

He has given lectures, talks and courses at universities, institutes and industries in

France, England, Germany, Belgium, Greece, Russia, Mexico, Argentina,

Colombia, Chile, Venezuela and Brazil. Course

He has published more than 250 scientific papers and presented more than 400

communications in conferences, congresses, plenary talks.

coordinator:

He has also supervised 17 PhD students.

Dr. Vivek D. Kalyankar

For more details visit: https://orcid.org/0000-0001-8417-1736 Scopus Author ID:

Assistant Professor

35271381300

Department of

Mechanical Engineering

Dr. Vivek Kalyankar is presently serving as Assistant

S. V. National Institute

Professor in the Department of Mechanical Engineering at

of Technology,

S. V. National Institute of Technology (SVNIT), Surat,

Surat – 395007, Gujarat

Gujarat, India, which is an Institution of National

Importance of Govt. of India. He is having around 20

Phone: 9510828842,

years of professional experience which involves the blend

0261-2201934

of academics, research, and industry experience. His

E-mail:

research interest mainly includes the weldability of vivekkalyankar@yahoo.co.in

advanced grades of materials and surface engineering vkalyankar@med.svnit.ac.in

with high temperature applications. ...............................................

He was instrumental in developing an advanced welding laboratory in the

department which consists of state of the art research facilities highlighted with the

availabilty of plasma transferred arc welding set up, Servo-electro mechanical creep

testing machine set up, etc. Apart from handling several funded projects, he

developed good networks with surrounding industries of the field and involved in

attempting various industry-based projects through research on their ongoing

materials. He is a co-author of more that 35 International articles and also acting as

a reviewer to various reputed International Journals. He is a recipient of the ‘Young

Engineer Award in Mechanical Engineering Discipline’ in 2014-2015 given by

Institution of Engineers (India). For more details visit: https://orcid.org/0000-0002-

7141-3705 Scopus Author ID: 55279804400

Registration process

Step 1: One Time Web (Portal) Registration

The candidates are advised to visit GIAN Website using the link:

https://gian.iitkgp.ac.in/GREGN/index and create Login User ID and Password. Fill up the

blank registration form and do web registration by paying Rs. 500 online through Net

Banking/Debit/Credit Card. This provides the candidate with life-time registration of the GIAN

portal to enroll in any number of the GIAN courses offered. Those candidates, who have

already enrolled at the GIAN portal, need not register again.

Step 2: Course Registration (Through GIAN Portal)

Log in to the GIAN portal with the user ID and Password created. Click on “Course

Registration” option given at the top of the registration form. Select the Course titled

‘Microstructural control and advanced metallurgical characterization: Application to

thermomechanical processing, welding and severe plastic deformation’ (Course code:

191033L03) from the list and click on ‘Save’ option. Confirm your registration by Clicking on

‘Confirm Course’

Step 3: Course fee payment

After registration on GIAN portal, the course fee is to be paid online in the account of SVNIT

Surat, the details of which are given below:

Course Fee

Industry/Govt./Research organizations: Rs. 3,500 (+ 18% GST)

Faculty/staff from academic institutions: Rs. 3,500 (+ 18% GST)

Research scholar/Student: Rs. 2,500 (+ 18% GST)

Account Details Scan code:

Bank: State Bank of India

Name: Director, SVNIT-CCE

Account Number: 37030749143

IFSC Code: SBIN0003320

MCIR Code: 395002012

The participants should pay registration fee through online mode (NEFT/IMPS/SCAN & PAY)

and fill in the transaction ID/details in the Google Form using the link given in Step-4.

Step-4:

After online payment of course fee, fill the google form Registration link given below:

https://forms.gle/XuKLwTxZU8CDGc92A

You will receive the final confirmation of participants from the course coordinator after few

days of completion of all steps.

_________________________________________________________________________

You might also like

- 5.5.1 PracticeDocument12 pages5.5.1 PracticeSid MathurNo ratings yet

- Master of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: EnglishDocument4 pagesMaster of Science in Sustainable Materials Engineering: 120 Ects Credits - Language: Englishmuhammad adnanNo ratings yet

- Material Science EngineDocument5 pagesMaterial Science EngineJohn_AdaNo ratings yet

- Electives - 2nd Sem 2013-14Document3 pagesElectives - 2nd Sem 2013-14Rohit LadNo ratings yet

- Free Download Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques Silberschmidt Full Chapter PDFDocument51 pagesFree Download Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques Silberschmidt Full Chapter PDFdebra.mchone833100% (28)

- ModernMaterials Ghosh Kumar ViswanathanDocument2 pagesModernMaterials Ghosh Kumar ViswanathanHamed hussain S HanifiNo ratings yet

- 18me34 MSDocument173 pages18me34 MSArjun AjoozNo ratings yet

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- The Mechanical Properties of Biomaterials: BIOM9561Document9 pagesThe Mechanical Properties of Biomaterials: BIOM9561vodounnouNo ratings yet

- Materials Science and Engineering - Stanford UniversityDocument22 pagesMaterials Science and Engineering - Stanford Universityteerth_brahmbhattNo ratings yet

- Outreach Pamphlet RCCDocument2 pagesOutreach Pamphlet RCCnarayananx5No ratings yet

- MS Program in Materials Science and EngineeringDocument76 pagesMS Program in Materials Science and EngineeringMuhammad SalmanNo ratings yet

- ME8381STRENGTHOF Materials Notes Hand NotesDocument60 pagesME8381STRENGTHOF Materials Notes Hand NoteselabalajiNo ratings yet

- Materials Sceince and TechnologyDocument18 pagesMaterials Sceince and TechnologyRajareddyDuddekuntaNo ratings yet

- PHD Programme in Mechanical EngineeringDocument7 pagesPHD Programme in Mechanical EngineeringAshok BodaNo ratings yet

- Amema 2023Document4 pagesAmema 2023BRajesh ReddyNo ratings yet

- IOP Conference Series Materials Science and Engineering Bristol Vol 1133, Iss. 1 (Apr 2021) - DOI 10.1088 1757 OutDocument6 pagesIOP Conference Series Materials Science and Engineering Bristol Vol 1133, Iss. 1 (Apr 2021) - DOI 10.1088 1757 OutfalmubaddelNo ratings yet

- Dialog - Undergraduate Program Metalurgy & Material EngineeringDocument5 pagesDialog - Undergraduate Program Metalurgy & Material EngineeringAlfa DamaNo ratings yet

- Report On BiodieselDocument95 pagesReport On Biodieselsumanth kumar gaddamNo ratings yet

- Material Science and EngineeringDocument2 pagesMaterial Science and Engineering3m3hNo ratings yet

- CHL MFC STCWGE Mar2024 v2Document2 pagesCHL MFC STCWGE Mar2024 v2hodcivilssmietNo ratings yet

- MSM Lab Manual - 2021-22Document61 pagesMSM Lab Manual - 2021-22Divyaraj VaghelaNo ratings yet

- 6032 PDFDocument191 pages6032 PDFMuhammad KashifNo ratings yet

- Chemical Engineering Past Present and FutureDocument2 pagesChemical Engineering Past Present and FutureArinjayKumarNo ratings yet

- SWOT Analysis - Kinetic ArchitectureDocument9 pagesSWOT Analysis - Kinetic ArchitectureVinay GoyalNo ratings yet

- Project Proposal (Vibration Engineering)Document15 pagesProject Proposal (Vibration Engineering)Yhan Sombilon100% (1)

- Letter of MotivationDocument2 pagesLetter of MotivationSajib Chandra RoyNo ratings yet

- OutlineDocument4 pagesOutlineRajib BaruaNo ratings yet

- Nanotechnology For Structural ApplicationDocument42 pagesNanotechnology For Structural ApplicationThisari MunmullaNo ratings yet

- Materials 14 00029 v21Document23 pagesMaterials 14 00029 v21Jesús de Vicente y OlivaNo ratings yet

- Natonial Conference 2016-02 (Innovative Trends in Mechanical Engineering)Document16 pagesNatonial Conference 2016-02 (Innovative Trends in Mechanical Engineering)Ravichandran GNo ratings yet

- Study PlanDocument5 pagesStudy PlanFawad AhmadNo ratings yet

- Principles of Cement and Concrete Composites: Natt MakulDocument209 pagesPrinciples of Cement and Concrete Composites: Natt MakulGilart A C KerrNo ratings yet

- A Synopsis On "Synthesis and Characterization of Composite Material For Biomedical Application" Submitted ToDocument14 pagesA Synopsis On "Synthesis and Characterization of Composite Material For Biomedical Application" Submitted ToAtul JainNo ratings yet

- 1 s2.0 S2238785419319714 MainDocument18 pages1 s2.0 S2238785419319714 MainRio ArrayNo ratings yet

- Quagliotti MSMNMetrologyAPMT PDFDocument201 pagesQuagliotti MSMNMetrologyAPMT PDFDiana Alejandra Bermudez FajardoNo ratings yet

- Materials Lab 28072023Document38 pagesMaterials Lab 28072023ShemelsNo ratings yet

- Master of Science eTH in Mechanical EngineeringDocument4 pagesMaster of Science eTH in Mechanical EngineeringAhmed TariqNo ratings yet

- Chandigarh University - ApplicationDocument9 pagesChandigarh University - ApplicationNaval Koralkar Chemical Engg. Dept.No ratings yet

- Brochure GIAN-Design of AnchorsDocument2 pagesBrochure GIAN-Design of Anchorsrehanmaaz100% (1)

- Failure of Metals II FatigueDocument24 pagesFailure of Metals II Fatigueandremuniz150No ratings yet

- Prediction of Microstructural Evolution During Hot Forging: Fei Chen, Zhenshan Cui, and Jun ChenDocument21 pagesPrediction of Microstructural Evolution During Hot Forging: Fei Chen, Zhenshan Cui, and Jun Chen임학진No ratings yet

- 2018 2019UndergraduateEnglishTaughtCoursesDocument40 pages2018 2019UndergraduateEnglishTaughtCoursesmalu accountNo ratings yet

- 18ME32Document59 pages18ME32Pratham J TudoorNo ratings yet

- Seismic Structural EngineeringDocument11 pagesSeismic Structural EngineeringMuhammad AbubakarNo ratings yet

- Advanced Material Chemistry Digital NotesDocument82 pagesAdvanced Material Chemistry Digital Notesharshitjoshi200417No ratings yet

- Pengantar Material TeknikDocument50 pagesPengantar Material TeknikbledsoeNo ratings yet

- CV of Dr. Md. Arifuzzaman NUS PDFDocument5 pagesCV of Dr. Md. Arifuzzaman NUS PDFMd Arifuzzaman ArifNo ratings yet

- Computational Nanomechanics of Materials: Wing Kam Liu, Sukky Jun, and Dong QianDocument27 pagesComputational Nanomechanics of Materials: Wing Kam Liu, Sukky Jun, and Dong QianQaisNo ratings yet

- Full Download Book Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials PDFDocument36 pagesFull Download Book Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials PDFdoris.perrin870100% (25)

- Metallurgical EngineeringDocument1 pageMetallurgical EngineeringP PNo ratings yet

- Design, Fabrication, and Mechanics of 3DDocument3 pagesDesign, Fabrication, and Mechanics of 3Dtharindu jayasingheNo ratings yet

- Study ProposalDocument2 pagesStudy ProposalRamsha KanwalNo ratings yet

- Muet Prospectus 14-Batch 2013-14Document124 pagesMuet Prospectus 14-Batch 2013-14Bilal NaveedNo ratings yet

- Mme 312 AssignmentDocument5 pagesMme 312 AssignmentFaruqNo ratings yet

- Shock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials Xianfeng Zhang Full Download ChapterDocument51 pagesShock Compression and Chemical Reaction of Multifunctional Energetic Structural Materials Xianfeng Zhang Full Download Chapterrita.aadland779100% (9)

- Higher Education and Research in Foreign From IndiaDocument37 pagesHigher Education and Research in Foreign From IndiaJagmohan DixitNo ratings yet

- MTech PHD Admission Brochure MSME IITHyderabad 2018Document7 pagesMTech PHD Admission Brochure MSME IITHyderabad 2018Anonymous I3IUcziNo ratings yet

- Materials Forming and Machining: Research and DevelopmentFrom EverandMaterials Forming and Machining: Research and DevelopmentRating: 3 out of 5 stars3/5 (1)

- Microforming Technology: Theory, Simulation and PracticeFrom EverandMicroforming Technology: Theory, Simulation and PracticeRating: 5 out of 5 stars5/5 (1)

- Coursera FDPMEYK6VC75Document1 pageCoursera FDPMEYK6VC75JAY AGRAWALNo ratings yet

- Svnit - JNFDocument2 pagesSvnit - JNFJAY AGRAWALNo ratings yet

- Coursera RQY89J9KQB2HDocument1 pageCoursera RQY89J9KQB2HJAY AGRAWALNo ratings yet

- I10010799S20Document6 pagesI10010799S20JAY AGRAWALNo ratings yet

- Daily Activity Report Day 1Document4 pagesDaily Activity Report Day 1Muhammad ZakiNo ratings yet

- Safety Data Sheet: March 22, 2017Document10 pagesSafety Data Sheet: March 22, 2017Gonzalo tobonNo ratings yet

- Effect of Formation Route On The Mechanical Properties of The Polyethersulfone CompositesDocument11 pagesEffect of Formation Route On The Mechanical Properties of The Polyethersulfone CompositesOumeyma HamlauiNo ratings yet

- Experimental Investigation On Four Stroke Catalyst Coated Si EngineDocument8 pagesExperimental Investigation On Four Stroke Catalyst Coated Si EngineNaveenprabhu VNo ratings yet

- A Study of Scrap Rubber Devulcanization and PDFDocument216 pagesA Study of Scrap Rubber Devulcanization and PDFalfiharadisNo ratings yet

- Chapter 1 Environment Monthly TestDocument5 pagesChapter 1 Environment Monthly TestCandleNo ratings yet

- Geo 11 Lesson02 Part 1Document18 pagesGeo 11 Lesson02 Part 1Joverose Manalo VillamorNo ratings yet

- SMB 104 Introduction 1Document29 pagesSMB 104 Introduction 1Shem Peter Mutua MutuiriNo ratings yet

- Sist en Iso 7346 2 1998Document9 pagesSist en Iso 7346 2 1998Dave ManimbenNo ratings yet

- CSDS Stopaq FAST GRE V3Document2 pagesCSDS Stopaq FAST GRE V3AndyNo ratings yet

- Reference Material: Chapter 10.4 (PG 248) of JMH Physics Chapter 8 of MHRDocument19 pagesReference Material: Chapter 10.4 (PG 248) of JMH Physics Chapter 8 of MHRzachariaNo ratings yet

- Binay: Model Li-600 Led-Based Aviation Obstruction LightDocument2 pagesBinay: Model Li-600 Led-Based Aviation Obstruction Lightamit1003_kumarNo ratings yet

- BS-Mechanical Engineering MSU-IITDocument1 pageBS-Mechanical Engineering MSU-IITnaseb.haliNo ratings yet

- 3-FDS Lactose - Pharma - Flowlac ALPAVITDocument4 pages3-FDS Lactose - Pharma - Flowlac ALPAVITMourad BenkNo ratings yet

- Heat Transfer - A Practical Approach - Yunus A. CengelDocument873 pagesHeat Transfer - A Practical Approach - Yunus A. Cengelvinodkonatham70371% (7)

- Compilation Mole Concept Web PagesDocument80 pagesCompilation Mole Concept Web Pagesngah lidwineNo ratings yet

- Methanol Production and Use PDFDocument347 pagesMethanol Production and Use PDFRazleen Rashidi100% (5)

- NETZSCH Steam Jet Mill S-Jet eDocument20 pagesNETZSCH Steam Jet Mill S-Jet ejojibaNo ratings yet

- 5989 2727enDocument10 pages5989 2727enNguyen Manh HungNo ratings yet

- Physics 80 Imp Questions PdfsDocument7 pagesPhysics 80 Imp Questions PdfsM4 PrinceNo ratings yet

- Zinc Acrylate - KansaiDocument9 pagesZinc Acrylate - KansaiApni SafitriNo ratings yet

- Röhr MMA TIG WSME 200 WSME 250 Welder Instruction Manual MinDocument45 pagesRöhr MMA TIG WSME 200 WSME 250 Welder Instruction Manual Minaajj ajsgNo ratings yet

- Chemical BondingDocument274 pagesChemical BondingSafwan AliNo ratings yet

- Material Safety Data Sheet: 1. IdentificationDocument9 pagesMaterial Safety Data Sheet: 1. IdentificationsandeepNo ratings yet

- Fdocuments - in Chemistry Project Space ChemistryDocument22 pagesFdocuments - in Chemistry Project Space ChemistryLip UtNo ratings yet

- Electron Configuration Review WorksheetDocument6 pagesElectron Configuration Review WorksheetDanielle HopkinsNo ratings yet

- Etd. It1 2021-2022 OddDocument1 pageEtd. It1 2021-2022 Oddmmk.mech59No ratings yet

- Introduction To Chemical Reactions-Acid and BasesDocument13 pagesIntroduction To Chemical Reactions-Acid and BasesJenelyn Ponce AguiloNo ratings yet

- R 410a Si PDFDocument20 pagesR 410a Si PDFMarin Munteanu0% (1)