Professional Documents

Culture Documents

Prem Project Report PLC Final Traffic - 1

Prem Project Report PLC Final Traffic - 1

Uploaded by

Mohammed FazalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prem Project Report PLC Final Traffic - 1

Prem Project Report PLC Final Traffic - 1

Uploaded by

Mohammed FazalCopyright:

Available Formats

Controlling of Traffic signal light using PLC 2022-23

ABSTRACT

Control Engineering has evolved over time. In the past humans were the main methods

for controlling a system. More recently electricity has been used for control and early electrical

control was based on relays. These relays allow power to be switched on and off without a

mechanical switch. It is common to use relays to make simple logical control decisions. The

development of low cost computer has brought the most recent revolution, the Programmable

Logic Controller (PLC). The arrival of the PLC began in the 1970s and has become the most

common choice for manufacturing controls. PLCs have been gaining popularity on the factory

floor and will probably remain predominant for some time to come.

PLCs are most certain for all mechanical engineers. Students studying in this stream

have to acquire a basic knowledge about automation. Recently, Board of Technical Education

(DTE) prescribed “Elements of Automation” course for 4th semester students’ in new C20

curriculum. In this regard, to make laboratory setup for junior friends, an attempt is made to

design and fabricate student friendly and safe PLC kits is undertaken. This project helps to

understand the automation concepts by easily by designing any conceived automation idea and

downloading to PLC. "Elevator Model" is also designed and fabricated to interface with PLCs.

Students can individually program and download any logic to control elevator model according

his conceived logic.

In this kits, latest and industry 2.0 recommended Allen Bradley's Micro820 PLC is

used. Most common programming method, Ladder Logic is used to program the PLC. Most

recent push buttons, sensors, motors, relay, solenoids and displays are used to make the models

more realistic

DME SJEP Govt. Polytechnic Bangalore - 560001 1

Controlling of Traffic signal light using PLC 2022-23

ACNOWLEDGEMENTS

We have great pleasure in expressing our deep sense of gratitude to this institution,

which as provided us an opportunity to do the project in the college and also facilities for doing

it.

We are grateful to Smt, GAYATHRI V Principal, and Sri, HARISH KUMAR S V,

Head of Mechanical Engineering Department, for their inspiration and help for doing this

project.

We whole heatedly thank all staff members of Mechanical Engineering Department for

their suggestions and support.

We thank staff member of Government Polytechnic, Holenarasipura for extending their

support to fabricate PLC trainer kit frame.

Last but the least, we also thank all those who have been directly or indirectly involved

in the completion of our project.

DME SJEP Govt. Polytechnic Bangalore - 560001 2

Controlling of Traffic signal light using PLC 2022-23

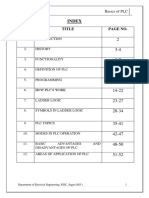

CONTENTS

Chapter 1: Introduction to Programmable Logic Controller Page No

1.1 Introduction 01-05

1.2 History 06-07

1.3 Components of PLC 07-08

1.4 Basic Structure of Programmable Logic Controller 09-09

1.5 Input/ Output 10-10

1.6 Input/ Output Processing 11-12

1.7 Ladder Logic 12-19

1.8 Timer, Internal Relay and Counters 19-24

1.9 Manufacturing and Assembly Process 25-25

1.10 Merits and Demerits of Automation 25-27

Chapter 2: Design and Implementation of a PLC Trainer Workstation 28-34

2.1 Structure of PLC Trainer Workstation 28-29

2.2 Aluminum Frame 29-31

2.3 Programmable Logic Controller (PLC) 31-32

2.4 PLC Programming Software 33-33

2.5 Power Supply 34-34

Chapter 3: Fabrication of traffic light signal model 35-44

3.1 Introduction 36-38

3.2 Structure of Traffic light signal model 39-42

3.3 Traffic light signal ladder diagram 42-44

Chapter 4: Estimation and Costing 45-47

4.1 Estimation and Costing 46-47

Chapter 5: Conclusions 48-49

References 50-50

DME SJEP Govt. Polytechnic Bangalore - 560001 3

Controlling of Traffic signal light using PLC 2022-23

CHAPTER 1

INTRODUCTION TO PROGRAMMABLE LOGIC

CONTROLLERS

DME SJEP Govt. Polytechnic Bangalore - 560001 4

Controlling of Traffic signal light using PLC 2022-23

CHAPTER 1:

PROGRAMMABLE LOGIC CONTROLLER

1.1 INTRODUCTION:

A programmable logic controller, PLC, or programmable controller is a small computer

used for automation of real-world processes, such as control of machinery on factory assembly

lines. The PLC usually uses a microprocessor. The program can often control complex

sequencing and is written by skilled engineers. The program is stored in battery-backed memory

and/or EEPROMs.

PLCs differ from normal computers by its special input/output arrangements. These

connect the PLC to sensors and actuators. PLCs read limit switches, dual-level devices,

temperature indicators and the positions of complex positioning systems. Some even use

machine vision. On the actuator side, PLCs drive any kind of electric motor, pneumatic or

hydraulic cylinders or diaphragms, magnetic relays or solenoids. The input/output arrangements

may be built into a simple PLC, or the PLC may have external I/O modules attached to a

proprietary computer network that plugs into the PLC.

PLCs were invented as less expensive replacements for older automated systems that would use

hundreds or thousands of relays and cam timers. Often, a single PLC can be programmed to

replace thousands of relays. Programmable controllers were initially adopted by the automotive

manufacturing industry, where software revision replaced the re-wiring of hard- wired control

panels.

The functionality of the PLC has evolved over the years to include typical relay control,

sophisticated motion control, process control, Distributed Control Systems and complex

networking.

The earliest PLCs expressed all decision making logic in simple ladder logic inspired

from the electrical connection diagrams. The electricians were quite able to trace out circuit

problems with schematic diagrams using ladder logic. This was chosen mainly to reduce the

apprehension of the existing technicians.

DME SJEP Govt. Polytechnic Bangalore - 560001 5

Controlling of Traffic signal light using PLC 2022-23

1.2 HISTORY:

The PLC was invested in response to the needs of the American automotive

industry. Before the PLC, control, sequencing, and safety interlock logic for

manufacturing automobiles and trucks was accomplished using relays, timers and

dedicated closed-loop controllers. The process for updating such facilities for the yearly

model changeover was very time consuming and expensive, as the relay systems

needed to be rewired by skilled electricians. In 1968 GM Hydromantic (the automatic

transmission division of General Motors) issued a request for proposal for an

electronic replacement for hard-wired relay systems.

The winning proposal came from Bedford Associates of Bedford, Massachusetts.

Tech first PLC, designated the 084 because it was Bedford Associates eighty-fourth

project, was the result. Bedford Associates started a new company dedicated to

developing, manufacturing, selling, and servicing this new product: Modicon, which

stood for Modular Digital Controller. Dick Morley is considered to be the “father” of the

PLC. The Modicon brand was sold in 1977 to Gould Electronics, and later acquired by

German Company AEG and then by Schneider Electric, the current owner.

One of the very first 084 models build is now on display at Modicon’s

headquarters in North Andover, Massachusetts. It was presented to Modicon by GM,

when the unit was retired from nearly twenty years of uninterrupted service.

The first PLC systems evolved from conventional computers in the late 1960’s

and early1970’s these first PLCs were installed primarily in automotive plants.

Traditionally, the auto plants had to be shut down for up to a month at model changeover

time. The early PLCs were used along with other new automation techniques to shorten

the change over time. The PLC keyboard reprogramming procedure replaced the rewiring

of a panel full of wires, relays, times, and other components. The new PLCs helped reduce

change over time to a matter of a few days. With the adventure of the microprocessor

these devices have become very powerful in recent years. Both the personal computers

DME SJEP Govt. Polytechnic Bangalore - 560001 6

Controlling of Traffic signal light using PLC 2022-23

and PLCs are now used in manufacturing systems. Personal computers and PLC are based

upon microprocessor and these are used for similar type tasks on the shop floor.

Personal computers are generally designed for business used with control a

secondary function and for these personal computers normally it requires additional

interface software and hardware however various stand-alone personal computers are

become available that do have necessary construction to withstand rigors (sense of

coldness with concentration of skin) and demand of the factory environment. This PLCs

are designed for control of equipment of process in an industry environment which

requires high temperature, humidity variation and so on. The PLCs are designed in such

a way that PLC devices are directly connected to machines and industry plant. PLC

doesn’t require a monitor but it has the ability to have several types of peripheral devices

connected to view the status of program that it is running.

1.3 COMPONENTS OF THE PLC:

The basic components of the PLC are as follows:

Input module

Output module

Processor

Memory

Power supply

Programming device

DME SJEP Govt. Polytechnic Bangalore - 560001 7

Controlling of Traffic signal light using PLC 2022-23

Figure 1.1: Basic elements of PLC.

The input module and output module are the connections to the industrial process

that in to be controlled. The inputs to the controller are signals from limit switches,

pushbuttons, sensors, and other devices. The outputs from the controller in order to operate

motors, valves, and other devices required to actuate the process.

The processor is the central processing unit (CPU) of the programmable controller.

It executes the various logic and sequencing functions. The processor is similar in its

construction to those used in personal computers and microprocessor very other data-

processing equipment. Tied to the CPU is the PLC memory, which contains the program

of logic, sequencing, and other input/output operations.

The memory for a programmable logic controller is specified in the same way as

for a computer, and may range from 1k to over 48 k of storage capacity. A power supply

of 115V ac is specially used to drive the PLC even though the components of the industrial

process that are regulated may have a higher voltage and power rating than the controller

itself.

DME SJEP Govt. Polytechnic Bangalore - 560001 8

Controlling of Traffic signal light using PLC 2022-23

1.4 BASIC STRUCTURE OF PLC:

The following fig shows the internal structure of PLC. It consists of CPU, memory,

input, and output module. PLC hardware, as in case of almost all of–days microcomputer

systems is based on a bus system. The term bus refers to the path’s or number of electrical

links and it is divided into address such as

1) The Data Bus

2) The Address Bus

The bus is a group of parallel lines. Data bus is an electrical path that connects the

CPU, memory, and other hardware devices on the other board.

Figure 1.2: Architecture of PLC

The Address bus is a set of wires, which is similar to the data bus, but it connects

only the CPU and the memory, and all it carries are memory address. A bus system carries

information and data to from the CPU main memory and input and output module. All the

operations and processes controlled by CPU within the PLC, the software which is the

user program written by PLC user, user programs are usually installed in RAM. A random

memory where they can be easily modified. Control bus or lines are required to activate

the correct bus station either as a transmitter or sender.

DME SJEP Govt. Polytechnic Bangalore - 560001 9

Controlling of Traffic signal light using PLC 2022-23

1.5 PLC CONNECTIONS:

When a process is controlled by a PLC it uses inputs from sensors to make decisions

and update outputs to drive actuators, as shown in Figure. The process is real process that

will change over time. Actuators will drive the system to new states (or modes of

operation). This means that the sensors available limit the controller, if an input is not

available the controller will have no way to detect a condition.

The control loop is a continuous cycle of the PLC reading inputs, solving the ladder

logic, and then changing the outputs. Like any computer this does not happen instantly.

Figure shows the basic operation cycle of a PLC. When power is turned on initially the

PLC does a quick sanity check to ensure that the hardware is working properly. If there is

a problem the PLC will halt and indicate there is an error. For example, if the PLC backup

battery is low and power was lost, the memory will be corrupt and this will result in a fault.

If the PLC passes the sanity check it will then scan (read) all the inputs. After the inputs

values are stored in memory the ladder logic will be scanned (Solved) using the stored

values – not the current values. This is one to prevent logic problems when inputs change

during the ladder logic scans. When the ladder logic scan is complete the outputs will be

scanned the output values will be changed. After this the system goes back to do a sanity

check, and the loop continues indefinitely. Unlike normal computers, the entire program

will be run every scan. A typical time for each of the stages is in the order of milliseconds.

DME SJEP Govt. Polytechnic Bangalore - 560001 10

Controlling of Traffic signal light using PLC 2022-23

1.6 INPUT AND OUTPUT:

The input/output unit provides the interface between the system and the outside

world. Programs are entered into the input/output unit from a panel, which can vary from

small keyboards with liquid crystal displays to those using a visual display unit (VDU)

with keyboard. Alternatively the programs can be entered into the system by means of a

link to a personal computer which is loaded with an appropriate software package.

Figure 1.4: The PLC Scan Cycle

The input/output channels provide signal conditioning and isolation functions so

that sensors and actuators can be generally directly connected to them without the need

for other circuitry. Common input voltages are 5V and 24V.

Common output voltages are 24V and 240V. Outputs are specified as being of

relay type, transistor type or Triac type. With the relay type, the signal from the PLC

output is used to operate a relay and so is able to switch currents of the order of few

amperes in an external circuit.

DME SJEP Govt. Polytechnic Bangalore - 560001 11

Controlling of Traffic signal light using PLC 2022-23

The relay isolates the PLC from the external circuit and can be used for both AC

and DC switching. Relays are relatively slow to operate. The transistor type of output

uses a transistor to switch current through the external circuit. This gives a faster

switching action. The transistor output is only for DC switching. Triac outputs can be

used to control external loads, which are connected to the AC power supply only. Opt

isolators are again used to provide isolation.

1.7 INPUT AND OUTPUT PROCESSING:

Basically ladder programming is used with PLCs. The ladder program consists of

individual rungs containing one output instruction and one or more input instructions. The

rungs could specify the state of switches.

For instance, the switch A and switch B inputs are tested; if switch A and switch B

are both closed then a solenoid, the output is enabled.

1) The following ladder program sequences carried out by means of PLC are:

2) Scan the program inputs with first rung of the ladder diagram.

3) With Ladder program inputs logically solve its operation.

4) Set or rest of the output for rung.

5) Until the end of the ladder program in every sequence it moves on to the next

rung and repeats the operations a, b, c.

When a ladder program is executed, every time each rung of the ladder diagram is

scanned to process the scanning of input/output data. The following two methods are to

be considered.

• Continuous updating

• Mass input or output copying

DME SJEP Govt. Polytechnic Bangalore - 560001 12

Controlling of Traffic signal light using PLC 2022-23

CONTINUOUS UPDATING:

The operating cycle of a PLC that consists of program scan and input/output scan,

the data associated with external outputs are transferred from the output data file to the

output terminals. Their data is updated during the previous scan of the ladder program and

also the input and output scan where, the inputs are scanned to determine their state and

associated ON/OFF states. During the program scan the updated status of the external

input device are applied to the ladder program. The CPU processes all the instructions in

the ascending rung order in the ladder programs scan that moves from one instruction to

the next instructions through all the rungs of the ladder program.

MASS INPUT OF OUTPUT COPYING:

Whenever updating continuously for each input there should be a delay of 3ms in

time. When we compare for many inputs and output depending upon the length of the

program the time taken will be considerably more. As updating time is much more, to

overcome this and to permit execution of program, temporary memory is used to store the

data and RAM is used as a buffer (Temporary). When each program cycle starts the

microprocessor scans all the inputs with their status and the copies into the I/O addresses

in RAM.

The stored data in RAM are used during every next step which the PLC execute

the program and then stores the result of the execution for subsequent use and at the end

the PLC always updates the status of the outputs.

DME SJEP Govt. Polytechnic Bangalore - 560001 13

Controlling of Traffic signal light using PLC 2022-23

LADDER LOGIC INPUTS:

PLC inputs are easily represented in ladder logic. In Figure there are three types of

inputs shown. The first two is normally open and normally closed inputs. The III

(immediate Input) function allows inputs to be read after the input scan, while the ladder

logic is being scanned. This allows ladder logic to examine input values more often than

once every cycle.

Figure 1.5: Ladder Logic Inputs

Normally open and active input will close the contact and allow power to flow.

Normally closed, power flows when the input is not open. In ladder logic there are multiple

types of outputs, but these are not cons available on all PLCs. Some of the outputs will be

externally connected to device the PLC, but it is also possible to use internal memory

locations in the PLC. Six outputs are shown in Figure. The first is a normal output, when

energized the will turn on, and energize an output. The circle with a diagonal line through

is an on output. When initially energized the output will turn off. This type of output is not

available all PLC types. When initially energized the OSR (One Shot Relay) instruction

will for one scan, but then be off for all scans after, until it is turned off. The L (latch

unlatch) instructions can be used to lock outputs on. When an L output is energized output

will turn on indefinitely, even when the output coil is de-energized. The only are turned off

DME SJEP Govt. Polytechnic Bangalore - 560001 14

Controlling of Traffic signal light using PLC 2022-23

using a U output. The last instruction is the IOT (Immediate that will allow outputs to be

updated without having to wait for the ladder logic’s completed.

Figure 1.6: Latch and Unlatch Coils

When power is applied (on) the output x is activated for the left output, but turn off

for the output on the right.

LADDER LOGIC:

PLC had to be maintainable by technicians and electrical personnel. To support

this programming language of Ladder Logic was developed. Ladder Logic is based on

the relay and contact symbols technicians were used to through wiring diagrams of

electrical control panels. Until recently there has been no formal programming standard

for PLC‟s. The introduction of the IEC 61131 Standard in 1998 provides a more formal

approach to coding. PLC Manufacturers have so far been slow on the uptake of the

standard with partial implementation. The Search Eng. article IEC 61131-3, a Standard

for PLC Software by R.W.Lewis provide standard an introduction to the documentation

for early PLC Programs was either non-existent or very poor, just providing simple

addressing or basic comments, making large programs difficult to follow. This has been

greatly improved with the development of PLC Programming Packages.

DME SJEP Govt. Polytechnic Bangalore - 560001 15

Controlling of Traffic signal light using PLC 2022-23

Figure 1.7: Basic ladder logic concept

Modern control systems still include relays, but these are rarely used for logic. A

relay is a simple device that uses a magnetic field to control a switch, as pictured in

figure when a voltage is applied to the input coil, the resulting current creates a magnetic

field. The magnetic field pulls a metal switch (or reed) towards it and the contacts touch,

closing the switch. The contact that closes when the coil is energized is called normally

open.

The normally closed contacts touch when the input coil is not energized. Relays

are normally drawn in schematic form using a circle to represent the input coil. The

output contacts are shown with two parallel lines. Normally open contacts are shown as

two lines, and will be open (non-conducting) when the input is not energized. Normally

closed contacts are shown with two lines with a diagonal line through them. When the

coil is not energized the normally closed contacts will be closed.

Relays are used to let one power source close a switch for another (often-high

current) power source, while keeping them isolated. An example of a relay in a simple

control application is shown in Figure. In this system the first relay on the left is used as

normally closed, and will allow current to flow until a voltage is applied to the input A.

The second relay is normally open and will not allow current to flow until a voltage is

applied to the input B. If current is flowing through the first two relays then current will

flow through the coil in the third relay, and close the switch for output C. This circuit

would normally be drawn in the ladder logic form. This can be read logically as C will be

ON.

DME SJEP Govt. Polytechnic Bangalore - 560001 16

Controlling of Traffic signal light using PLC 2022-23

Figure 1.8: Simple Relay

Figure 1.9: Simple Relay Controller

The example in Figure does not show the entire control system, but only the logic.

When we consider a PLC there are inputs, outputs, and the logic. Above figure shows a

more complete representation of the PLC. Here there are two inputs from push buttons.

We can imagine the inputs as activating 24V DC relay coils in the PLC. This in turn drives

an output relay that switches 115V AC that will turn on a light. Note, in actual PLCs inputs

DME SJEP Govt. Polytechnic Bangalore - 560001 17

Controlling of Traffic signal light using PLC 2022-23

are never relays, but outputs are often relays. The ladder logic in the PLC is actually a

computer program that the user can enter and change. Notice that both of the inputs push

buttons are normally open, but the ladder logic inside the PLC has one normally open

contact.

PROGRAMMING:

Early PLCs, up to the mid-1980s, were programmed using proprietary

programming panels or special-purpose programming terminals, which often had

dedicated function keys representing the various logical elements of PLC programs.

Programs were stored on cassette tape cartridges. Facilities for printing and documentation

were very minimal due to lack of memory capacity. More recently, PLC programs are

typically written in a special application on a personal computer then downloaded by a

direct-connection cable or over a network to the PLC. The very oldest PLCs used non-

volatile Magnetic core memory but now the program is stored in the PLC either in battery-

backed-up RAM or some other non-volatile flash memory.

Early PLCs were designed to be used by electricians who would learn PLC

programming on the job. These PLCs were programmed in “ladder logic”, which strongly

resembles schematic diagram of relay logic. Modern PLCs can be programmed in a variety

of ways, from ladder logic to more traditional programming languages such as BASIC

and C. Another method is State Logic, a Very High Level Programming Language

designed to program PLCs based on State Transition Diagrams.

Recently, the International standard IEC 61131-3 has become popular. IEC 61131-

3 currently defines five programming languages for programmable control systems:

FBD (Function block diagram), LD (Ladder diagram), ST (Structured text, similar to the

Pascal programming language, IL (Instruction list, similar to assembly language) and SFC

(sequential function chart). These techniques emphasize logical organization of operations.

DME SJEP Govt. Polytechnic Bangalore - 560001 18

Controlling of Traffic signal light using PLC 2022-23

While the fundamental concepts of PLC programming are common to all

manufacturers, differences in I/O addressing, memory organization and instruction set

mean that PLC programs are never perfectly interchangeable between different makers.

Even within the same product line of a single manufacturer, different models may not be

directly compatible.

1.8 REGISTERS TIMER, INTERNAL RELAY AND COUNTERS

Within the PLC CPU registers are found in to location. The microprocessor has

internal Registers most of which are not directly accessible by the user. These registers (4,

8, 16 or 32 bits wide depending on the microprocessor) help the control and arithmetic

and logic units within the processor to carry out their tasks. Accumulator register, data

Registers, index registers condition, code registers, scratch pad registers and instruction

register work to temporarily store data, which in turn is used to facilitate the carrying out

of programmed functions.

In addition to their internal registers, the CPU‟s Rams also contains slots that are

designated to hold variable information. These locations, or address, become external

registers there can be a mere handful of such registers or hundreds depending on the size

of the CPU and complexity of the user program.

Each bit locations in a register contains of course, either 1 or Q O. in addition on

many models you can print on the register contents on a typed keyboard various numbering

system are possible for reading register contents or printing them out. Depending on PLC

capabilities. You may choose to print register valve based on one or more different

numbering systems for E.g.: one model allows you to choose between 1-Decimal 2-Binary

3-Hex, or 4-Ascii other possibilities are actual and special codes unique to the system being

used. Still other PLCs are contained to displaying or printing in only on numbering system

usually decimal systems.

DME SJEP Govt. Polytechnic Bangalore - 560001 19

Controlling of Traffic signal light using PLC 2022-23

There are functions of five key registers are

1) Holding register

2) Input register (single and group)

3) Output registers (Single and group)

4) Operate to temporarily store data for microprocessor manipulation

PLC TIMER FUNCTIONS:

A single –input timer called a no retentive timer is used in some PLCs. Eg:

Energizing IN001 causes the timer to run for 4 seconds. At the end of 4 seconds the output

goes on. When the input is de-energized the output goes off and the timer resets to 0. If

the input IN001 is turned off during the internal (E.g.: after 2.7 seconds) the timer resets

to 0. In this case the output would not have turned on.

There are disadvantages of the single- input type timer that are overcome by the

multiple input timer. There is 3 type of formats for PLC timers.

1) Block format

2) Coil format with separate enable 4 reset

3) Coil format

The black format includes the enabled reset line. Which allows the timer to run

when energized? When de-energized, the timer is kept at O or reset to 0. The upper line

causes the timer to run when the time is enabled. When enabled the timer runs as long or

the run input is energized. If Two other timer functions are including in some PLCs. Time

delay on 4-time delay off there are 3 states in a timing cycle.

1) The initial or reset state

2) The state during timing 4

3) The state after timing is complete

DME SJEP Govt. Polytechnic Bangalore - 560001 20

Controlling of Traffic signal light using PLC 2022-23

Figure 1.10: TON Timer Logic diagram

A system of “X‟ for on 4 „0‟ for off is normally used. The examples illustrate this

convention. In some system as 1 is used instead of an x to indicate contract closed.

EXAMPLES OF TIMER FUNCTION INDUSTRIAL APPLICATION

Some commonly used timer functions are

1) On delay output B comes on at a specific set time after output A is turned on. When

A is turned off B also goes off.

2) Off delay. Both A and B have been turned on at the sometime. Both are in

operation. When A is turned off, B remains on for a specific set time period before

going off.

3) Limited on time A and B go on at the same time B goes off after specific set time

period but A remains on.

4) Repeat cycling, An output pulses on and quickly off at a constant pre-set time into

5) On-shot operation, output B goes on for a specified time after output A is turned

on. Output B will run for its specified time interval even if A is turned off during

the B timing interval.

DME SJEP Govt. Polytechnic Bangalore - 560001 21

Controlling of Traffic signal light using PLC 2022-23

6) Alternate on 4 off two outputs. An E.g. of this timing. Application is two alternately

flashing signal lights. The time on for each of the two lights may be the same or

the two times could be set to different intervals.

7) Multiple on delay 2 different event start at different time intervals after an initial

starting time reference point. Multiple off delay 2 different functions remain on for

two different time intervals after a process is turned off.

8) Interval time within a cycle e we may require that an output come on 7.5 seconds.

After system start up remain on for 4 seconds and then go off 4 stay off. The

interval would then be repeated only after the system is shut off and then turned

back on.

PLC COUNTER

A counter is a PLC instruction that either increments (counts up) or decrements

(counts down) an integer number value when prompted by the transition of a bit from 0

to 1 (“false” to “true”).

Counter instructions come in three basic types:

1) up counters

2) down counters

3) Up/down counters

Both “up” and “down” counter instructions have single inputs for triggering

counts, whereas “up/down” counters have two trigger inputs: one to make the counter

increment and one to make the counter decrement.

PLC Counter Instructions

To illustrate the use of a counter instruction, we will analyze a PLC-based system

designed to count objects as they pass down a conveyor belt:

DME SJEP Govt. Polytechnic Bangalore - 560001 22

Controlling of Traffic signal light using PLC 2022-23

Figure 1.11: PLC Counter Illustration

In this system, a continuous (unbroken) light beam causes the light sensor to close

its output contact, energizing discrete channel IN4. When an object on the conveyor belt

interrupts the light beam from source to sensor, the sensor’s contact opens, interrupting

power to input IN4.A push-button switch connected to activate discrete input IN5 when

pressed will serve as a manual “reset” of the count value. An indicator lamp connected to

one of the discrete output channels will serve as an in indicator of when the object count

value has exceeded some pre-set limit. We will now analyze a simple Ladder Diagram

program designed to increment a counter instruction each time the light beam breaks.

DME SJEP Govt. Polytechnic Bangalore - 560001 23

Controlling of Traffic signal light using PLC 2022-23

Figure 1.12: PLC Counter in ladder logic

This particular counter instruction (CTU)is an incrementing counter which, means

it counts "up" with each off-to on transition input to its "CU" input. The normally-closed

virtual contact (IN sensor object) is typically held in the "open" state when the light beam

is continuous, by virtue of the fact the sensor holds that discrete input channel energized

while the beam is continuous. When the beam I broken by a passing object on the conveyor

belt, the input channel de-energizes, causing the virtual contact IN sensor object to "dose"

and send virtual power to the "CU" input of the counter instruction. This increments the

counter just as the leading edge of the object breaks the beam. The second input of the

counter instruction box ("R") is the reset input, receiving virtual power from the contact IN

switch reset whenever the reset pushbutton pressed. If this input is activated, the counter

immediately resets its current value (CV) to zero.

DME SJEP Govt. Polytechnic Bangalore - 560001 24

Controlling of Traffic signal light using PLC 2022-23

1.9 MANUFACTURING AND ASSEMBLY PROCESS

PLC‟s is used to automate manufacturing and assembly process. By “process”, we

mean step-by-step procedure where by a product is manufactured and assembled. It is the

responsibility of the Product Engineering (PE) department to plan for the manufacture of

new or modified products. According to Rehg and Kraebber, in their book. manufacturing,

2nd ed., the plan has seven elements.

1) Process planning.

2) Production machine programming.

3) Tool and fixture Engineering.

4) Work and production standard

5) Process planning.

6) Production machine programming.

7) Tool and fixture Engineering.

1.10 MERITS AND DEMERITS OF PLCS

Merits:

1) Flexibility: - In the past, each different electronically controlled production machine

required its own controller, 15 machines might require 15 different controllers. Now

it is possible to use just one model of a PLC to run any one of the 15 machines.

Furthermore, you would probably need fewer than 15 controllers, because one PLC

can easily run many machines.

2) Lower Cost: - Increased technology makes it possible to condense more functions into

smaller and less expensive packages. Now you can purchase a PLC with numerous

relays, times, and controllers, a sequencer, and other functions for under a hundred

dollars.

DME SJEP Govt. Polytechnic Bangalore - 560001 25

Controlling of Traffic signal light using PLC 2022-23

3) Visual Observation: - In advanced PLC systems, an operator message can be

programmed for Control of Traffic Signal Lights by Using PLC reach possible

malfunction. The malfunction description appears on the screen when the malfunction

is detected by the PLC logic.

4) Speed of Operation: - Relays can take an unacceptable amount of time to actuate. The

operational speed for the PLC program is very fast. The speed for the PLC logic

operation is determined by scan time, which is a matter of milliseconds

5) Ladder or Boolean Programming Method: - The PLC programming can be

accomplished in the ladder mode by an electrician or technician. Alternatively, a PLC

programmer who works in digital or Boolean control systems can also easily perform

PLC programming.

6) Reliability and Maintainability: - Solid-state devices are more reliable, in general, than

mechanical systems or relays and timers. The PLC is made of solid-state components

with very high reliability rates. Consequently, the control system maintenance costs

are low and down time are minimal.

7) Ease of changes by Reprogramming: - Since the PLC can be reprogrammed quickly,

mixed production processing can be accomplished.

8) Security: - A PLC program change cannot be made unless the PLC is properly

unlocked and programmed. Relay panels tend to undergo undocumented changes.

People on late shifts do not always record panel alterations made when the office area

is locked up for the night.

DME SJEP Govt. Polytechnic Bangalore - 560001 26

Controlling of Traffic signal light using PLC 2022-23

Demerits

1) Newer Technology: - It is difficult to change the thinking of some personnel from

ladders and relays to the PLC computer concept.

2) Fixed Program Applications: - Some applications are single function application. It

does not pay to use a PLC that includes multiple programming capabilities if they

are not needed.

3) Environmental Considerations: - Certain process environments, such as high heat

and vibration, interfere with the electronic devices in PLCs, which limit their use.

4) Fail-safe Operation: - In relay systems, the stop button electrically di connects the

circuit if the power fails, the system stops. Furthermore, the relay system does not

automatically restart when power is restored.

5) 5 Fixed Circuit Operation: - If the circuit in operation is never altered, a fixed

control system might be less costly than a PLC. The PLC is most effective when

periodic changes in operation are made.

DME SJEP Govt. Polytechnic Bangalore - 560001 27

Controlling of Traffic signal light using PLC 2022-23

CHAPTER 2

DESIGN AND IMPLEMENTATION OF PLC TRAINER

WORKSTATIONS

DME SJEP Govt. Polytechnic Bangalore - 560001 28

Controlling of Traffic signal light using PLC 2022-23

2.1 STRUCTURE OF PLC TRAINER WORKSTATION

PLC workstations are fabricated using 40x40 aluminum profile. Five PLC

workstations are made in one frame. Each workstation is consisting of independent PLC

and computer having separate power connections. Acrylic panels designed and fabricated

using laser engraving and cutting machines to accommodate power supply switches, push

buttons, PLC, output indicators etc. Allen-Bradley Micro 820 PLCs are used. Connected

Components Workbench (CCW) version 13 software is used for designing and downing

the ladder program for PLC

2.2 ALUMINUM FRAME

Seven 4040 aluminum profile of each 6m length is used for fabrication of frame.

Each workstation is having width of 4 feet to ensure the comfortable accommodation for

PLC, computer and other power supply unit and input-output components. Frame initially

designed using “Item online CAD”, which helps in designing and preparing the components

requirement for fabrication of frame. L-cl frame. MPs, rubber vacuum feet, 8mm T-nuts

and screws are used for the F

Figure 2.1: PLC Trainer Work Station

DME SJEP Govt. Polytechnic Bangalore - 560001 29

Controlling of Traffic signal light using PLC 2022-23

Panel Board drawing is prepared using Solid Edge software as shown in figure

2.2. Red lines in the figure shows the slot cutting areas and blue lines are for engraving.

At most care is taken accommodate all the mountings on the panel board for

easy accessibility and understanding. Then the CAD drawings DXF format is sent for

cutting and engraving on the 5mm thick acrylic sheet.

Figure 2.2: Solid Edge Drawing for Acrylic Panel Board

DME SJEP Govt. Polytechnic Bangalore - 560001 30

Controlling of Traffic signal light using PLC 2022-23

Figure 2.3: Acrylic Panel Board prepared using Laser engraver and cutter

Figure 2.3 shows finished acrylic panel sheet. From the sketch it clear seen that all

the interfacing and mounting provisions are made in the panel board

2.3. PROGRAMMABLE LOGIC CONTROLLER (PLC)

Each work station has Allen-Bradley Micro 820 PLC. Totally five PLC are used in

this project. The AB PLC model having catalogue number 2080-LC20-20QBB is used here.

This Micro820 series PLC has 20 point (12 IOs) Micro PLC is specifically designed for

small standalone machines and remote automation projects with embedded Ethernet and

serial ports. It has a Controller, 12 24V DC Inputs, 4 configurable analogue input with

thermistor voltage reference out, 7 24V DC Source Output, 1 Analog Output, Embedded

Ethernet Port and RS- 232/485 non-isolated Serial port, Embedded RTC, Micro-SD Card

support, 2 Plug-In slots.

DME SJEP Govt. Polytechnic Bangalore - 560001 31

Controlling of Traffic signal light using PLC 2022-23

Figure 2.4: Allen-Bradley Micro 820 PLC

It can function as a RTU (remote terminal unit) for remote machines with support

for Modbus RTU and TCP. It has embedded support for 4 thermistor temperature inputs

for use as a DDC (direct digital controller) for Building Management Systems.

The Micro820 supports an embedded micro-SD slot that can be used for storing

large amounts of data that normally cannot fit into memory for applications that require

data log and recipe. All files are stored in CSV text format for easy viewing and editing.

The micro-SD card is also used for backing up and restoring the program, which can be

used for duplicating the program in several machines.

DME SJEP Govt. Polytechnic Bangalore - 560001 32

Controlling of Traffic signal light using PLC 2022-23

2.4. PLC PROGRAMMING SOFTWARE

Connected Components Workbench software (CCW) is developed by Rockwell

Automation. CCW Version 13 is used in this project. This software has following

features

• Easy to configure – Single software package reduces initial machine development time

and cost

• Easy to program – Simplify programming process with sample code and user-defined

function blocks

• Easy to visualize – Reference Micro800 controller variables directly when creating

HMI tags Connected Components Workbench design and configuration software

offers controller programming, device configuration, and integration with HMI editor.

Figure 2.5: CCW version 13 Software

DME SJEP Govt. Polytechnic Bangalore - 560001 33

Controlling of Traffic signal light using PLC 2022-23

2.5 POWER SUPPLY

Each work station has independent power supply. 24 volts 5 amps DC power

Supply is used is shown in fig 2.6. Two separate DPST switches are used for PLC and

other components of the workstation.

Figure 2.6: 24 Volts 5 amps DC SMPS

DME SJEP Govt. Polytechnic Bangalore - 560001 34

Controlling of Traffic signal light using PLC 2022-23

CHAPTER 3

FABRICATION OF THE TRAFFIC LIGHT SIGNAL MODEL

DME SJEP Govt. Polytechnic Bangalore - 560001 35

Controlling of Traffic signal light using PLC 2022-23

INTRODUCTION

Traffic signals control vehicle and pedestrian traffic by assigning priorities to

various traffic movements to influence traffic flow. Properly designed, located and

maintained traffic signals have one or more of these advantages:

• Provide for orderly movement of traffic;

• Increase traffic-handling capacity of an intersection;

• Reduce frequency and severity of certain types of crashes, especially right-angle

collisions;

• Provide for continuous movement of traffic at a definite speed along a given route;

• Interrupt heavy traffic at intervals to permit other vehicles or pedestrians to cross.

Traffic signals are not a solution for all traffic problems at intersections, and

unwarranted signals can adversely affect the safety and efficiency of traffic by causing

one or more of the following:

• Excessive delay;

• Increased traffic congestion, air pollution and fuel consumption;

• Disobedience of signals;

• Increased use of less-adequate streets to avoid traffic signals;

• Increased frequency of crashes, especially rear-end collisions.

Traffic signals are designed to ensure an orderly flow of traffic, provide an

opportunity for pedestrians or vehicles to cross an intersection and help reduce the number

of conflicts between vehicles entering intersections from different directions. Following are

indications of traffic light.

DME SJEP Govt. Polytechnic Bangalore - 560001 36

Controlling of Traffic signal light using PLC 2022-23

Red A red signal means “STOP”.

Yellow A yellow signal light means “CAUTION”, the red signal is about to

appear.

Green A green light means “GO”.

3.2 Structure of Traffic Light signal model

Figure 8.1: Traffic Interaction Point

The main aim in designing and developing of the Traffic Signal is to reduce the

waiting time of each lane of the cars and also to maximize the total number of cars that can

cross an intersection. The Intelligent Traffic Signal Control System consists of two

important parts. The first part is the PLC controller and second part is hardware. These

usually comprise of red, yellow, and green lights.

DME SJEP Govt. Polytechnic Bangalore - 560001 37

Controlling of Traffic signal light using PLC 2022-23

Logic Description:

Two-way traffic interaction is considered for designing the traffic light for the given

location. When the START push button is pressed sequence shown in Table 8.1 takes place.

When START button is not pressed or the STOP button is pressed the yellow light on both

direction (SOUTH and EAST) will flash continuously until the START button is ON.

Table 3. 1 Traffic Light sequence in East and south Directions.

Components required

Sl No Component Specification Quantity

name

1 POWER SUPPLY

2 PLC 1

3 INDICATORS 6

4 ALUMINIUM

FRAME

5 BANANA PINS 8

FEMALE

DME SJEP Govt. Polytechnic Bangalore - 560001 38

Controlling of Traffic signal light using PLC 2022-23

ALUMINIUM FRAME:

BANANA PINS FEMALE:

DME SJEP Govt. Polytechnic Bangalore - 560001 39

Controlling of Traffic signal light using PLC 2022-23

INDICATORS :

Ladder diagram:

Rung 1 Diagram: Start the main switch of traffic signal by pressing START button and

switch off by using STOP button

DME SJEP Govt. Polytechnic Bangalore - 560001 40

Controlling of Traffic signal light using PLC 2022-23

Rung 2 Diagram: To run timer for YELLOW 1

Rung 3 Diagram: To turn on YELLOW 1 and turn it OFF

Rung 4 Diagram: To turn on GREEN 1 timer after YELLOW 1light turns OFF

DME SJEP Govt. Polytechnic Bangalore - 560001 41

Controlling of Traffic signal light using PLC 2022-23

Rung 5 Diagram: To turn on GREEN 1 light and turn it OFF

Rung 6 Diagram: To run YELLOW 2 timer after the GREEN 1 timer

Rung 7 Diagram: To turn on YELLOW 2 and turn it OFF

DME SJEP Govt. Polytechnic Bangalore - 560001 42

Controlling of Traffic signal light using PLC 2022-23

Rung 8 Diagram: To run the timer for GREEN 2 after YELLOW 2 timer

Rung 9 Diagram: To turn on GREEN 1 and turn it OFF

Rung 10 Diagram: To turn on RED 1 after GREEN 1 turn OFF

DME SJEP Govt. Polytechnic Bangalore - 560001 43

Controlling of Traffic signal light using PLC 2022-23

Rung 11 Diagram: To turn on RED 2 along with YELLOW 1 and turn it off with GREEN 1

Result: A Two way traffic signal light is designed and tested successfully.

DME SJEP Govt. Polytechnic Bangalore - 560001 44

Controlling of Traffic signal light using PLC 2022-23

CHAPTER 4

ESTIMATION AND COSTING

DME SJEP Govt. Polytechnic Bangalore - 560001 45

Controlling of Traffic signal light using PLC 2022-23

EASTIMATION AND COASTING

On Estimating this project, we get the idea of the cost of the project and hence its

feasibility can determinate i.e., whether the project could be taken up within the funds

available or not. Estimation gives an idea of time required for the completion of the work.

costing its provides a tool for price fixations as well as price control costing can be

help the make decisions about tariff protection, and it can also offer information relating to

wage. A final advantage of costing is that it helps us within to make decisions about wages.

DME SJEP Govt. Polytechnic Bangalore - 560001 46

Controlling of Traffic signal light using PLC 2022-23

ESTIMATION AND COSTING TABLE:

Sl No

Particulars Quantity Rate Amount

1 4040 Aluminum Profile 48 meters 430 20640

2 2020 Aluminum Profile 6 meters 160 960

3 2040 Aluminum profile 6 meters 300 1800

4 Slot filling Beading 60 meters 18 1080

5 L clamps 70 28 1960

6 T-Nuts & Bolts 140 12 1680

7 Aluminum Fixture for 2020 & 2040 and others 3168

8 Leveling Pad 10 100 1000

9 Transportation(Aluminum Profiles) VRL 3840

10 Acrylic Panel-5mm thick 5 2200 11000

11 Power Supply 24 Volt, 5 amps 5 650 3250

12 PLC –Micro 820 5 11500 57500

13 Banana Pins Female 250 8 2000

14 3mm LED with Holder 250 2 500

15 Proximity Sensors 250 10 2500

16 Molex 24 Pin Connectors 250 10 2500

17 Terminal Connector 20 10 200

18 DPST switches 10 20 200

19 Digital Voltmeter & Ammeter 5 250 1250

20 Indicators 20 50 1000

21 DC Motor 1 200 200

22 ACP sheet 8x4 1 85/sq ft 2720

140 /sq Ft

23 WPVC Sheet 8X4 1 4480

Miscellaneous 5000

Grand Tot Rs. 1,30,428

DME SJEP Govt. Polytechnic Bangalore - 560001 47

Controlling of Traffic signal light using PLC 2022-23

Chapter 5

CONCLUSION

DME SJEP Govt. Polytechnic Bangalore - 560001 48

Controlling of Traffic signal light using PLC 2022-23

CONCLUSIONS

This PLC Trainer kit is an experimental platform, by using this ladder logics

programs can be checked. This equipment is specially built for teaching and student

community. Following are the some of the important from the project work.

1. Helps in understanding the PLC interfacing

2. Helps in understanding the Lift/Elevator programming.

3. Kit is modular and can be connected to any application.

4. Ladder programming helps to develop complex logic programs with ease.

5. Wherever needed sensors can be used instead of limit switch.

conclusions drawn

DME SJEP Govt. Polytechnic Bangalore - 560001 49

Controlling of Traffic signal light using PLC 2022-23

REFERENCE

1. Programmable logic Controllers By W. BOLTON

2. Digital electronics By FLYOD

3. Exploring PLC with applications By PRADEEP KUMAR SRIVATSAVA

4. Automation, Production systems and Computer Integrated Manufacturing By

MIKELL

5. GROOVER

6. Sensors Hand book-SABRIE SOLOMAN-MC-GRAW HILL publications

7. Hand book of Modern Sensors” Physics, Designs and Applications- JACOB

FRADEN- Springer Publications

8. Electric Motors and Drives BY AUSTIN HUGHES and BILL DRURY

DME SJEP Govt. Polytechnic Bangalore - 560001 50

You might also like

- PLC Full BookDocument112 pagesPLC Full BookDilip Patel100% (2)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- 05Document42 pages05tt_aljobory3911No ratings yet

- ch-1 Petruzella PDFDocument16 pagesch-1 Petruzella PDFozzaapriodede100% (1)

- A Project Report On: "PLC Based Elevator Control System"Document28 pagesA Project Report On: "PLC Based Elevator Control System"Sapna KumariNo ratings yet

- Project PLCDocument12 pagesProject PLCmajumderabhijit85No ratings yet

- Industrial Training Report: Sri.B.SharanappaDocument40 pagesIndustrial Training Report: Sri.B.SharanappaKollu dhruvaNo ratings yet

- Final Year Project Report FainalllllDocument45 pagesFinal Year Project Report Fainalllllanon_76743611No ratings yet

- Study and Implementation of Programmable Logic ControllerDocument39 pagesStudy and Implementation of Programmable Logic ControlleroxygenmonitoringiotNo ratings yet

- Index: S. NO. Title Page NoDocument52 pagesIndex: S. NO. Title Page NoBasant VishwakarmaNo ratings yet

- PLC Based Car Parking Guidance SystemDocument42 pagesPLC Based Car Parking Guidance Systemramsj100% (2)

- Overview of Mecon LimitedDocument5 pagesOverview of Mecon LimitedMd Irfan AhmadNo ratings yet

- PLCDocument56 pagesPLCFelix Lee Kah NgieNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- "Plc-Scada": Bachelor of Technology in Electronics & Communication EngineeringDocument50 pages"Plc-Scada": Bachelor of Technology in Electronics & Communication EngineeringluvnshaadiNo ratings yet

- Embedded PLC Implementation Using ARMDocument5 pagesEmbedded PLC Implementation Using ARMsnehagoyankaNo ratings yet

- Industrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeDocument35 pagesIndustrial Training: Submitted For Partial Fulfillment of Award of B.Tech DegreeNeha DhanukaNo ratings yet

- PLC SCADA Training ReportDocument37 pagesPLC SCADA Training ReportAarif HussainNo ratings yet

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- Control Engineering Lab Semester: Winter 2021 Session: FALL 2018Document5 pagesControl Engineering Lab Semester: Winter 2021 Session: FALL 2018abdullah anwarNo ratings yet

- Summer Training Report On PLC and Scada11Document31 pagesSummer Training Report On PLC and Scada11Sahil SamotraNo ratings yet

- Chapter 1 Introduction To PLCDocument43 pagesChapter 1 Introduction To PLCSri Sarat ChandraNo ratings yet

- Programmable Logic ControllerDocument4 pagesProgrammable Logic ControllerBlack PigeonNo ratings yet

- Internship 3Document38 pagesInternship 3S K B COMPUTERSNo ratings yet

- PLC SCADARishavReportDocument34 pagesPLC SCADARishavReportMohammad ZobeidiNo ratings yet

- Programmable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferDocument41 pagesProgrammable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferAbhishek SinghNo ratings yet

- PLC Scada Training ReportDocument31 pagesPLC Scada Training ReportÄkshãy SaçhånNo ratings yet

- Report AcknowledgmentDocument45 pagesReport Acknowledgmentrajubhati41No ratings yet

- PLC 1Document9 pagesPLC 1عبدالسلام الهبوبNo ratings yet

- Raghu ReportDocument42 pagesRaghu ReportTyrone MichaelsNo ratings yet

- PLC & SCADA Training ReportDocument44 pagesPLC & SCADA Training Reportneeraj meena100% (2)

- Programable Logic ControllerDocument24 pagesProgramable Logic Controllersatyajit_manna_2No ratings yet

- Industrial Training EditedDocument30 pagesIndustrial Training Editedit's ND GamingNo ratings yet

- E 448 ContentDocument101 pagesE 448 ContentPhyuphwaykyaw PhyuphwayNo ratings yet

- Mini Project ReportDocument5 pagesMini Project ReportKavissh BNo ratings yet

- I M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseDocument5 pagesI M C T P L C C: Ntegration OF Otion Ontrol Echnologies Into A Rogrammable Ogic Ontrols OurseGoran MiljkovicNo ratings yet

- Syeda HusnaDocument31 pagesSyeda HusnaSyeda HusnaNo ratings yet

- Sipsudeep 151129115245 Lva1 App6891Document33 pagesSipsudeep 151129115245 Lva1 App6891Gaurav SharmaNo ratings yet

- Automation Summer Training ReportDocument45 pagesAutomation Summer Training ReportLaxman GautamNo ratings yet

- Design and Implementation of A PLC Trainer WorkstationDocument7 pagesDesign and Implementation of A PLC Trainer WorkstationJohn nery barriosNo ratings yet

- Ei8761 Industrial Automation Lab Manual PDFDocument77 pagesEi8761 Industrial Automation Lab Manual PDFSoumik gamingNo ratings yet

- Burhan 2012Document5 pagesBurhan 2012Anthony BarrónNo ratings yet

- Fom MicroprojectDocument9 pagesFom MicroprojectPRABHAVATI TANAJI DESHMUKH100% (1)

- Chapter 2Document68 pagesChapter 2Niño AntoninoNo ratings yet

- MCT-319 IA 2010 Lab Manual 1Document4 pagesMCT-319 IA 2010 Lab Manual 1junaid chNo ratings yet

- PLC Programming FileDocument33 pagesPLC Programming FileRahul kumarNo ratings yet

- PLC1 ADocument71 pagesPLC1 ASymon Justine SañoNo ratings yet

- Seminar ReportDocument18 pagesSeminar ReportAnkitha TheresNo ratings yet

- (IDR) PLC Operation and Maintenance (TUGINO) (INDONESIA) (Online Learning) (May 2022) IkaDocument6 pages(IDR) PLC Operation and Maintenance (TUGINO) (INDONESIA) (Online Learning) (May 2022) Ikamochn2585No ratings yet

- Automation of Water Tube Boiler Electrical ThesisDocument53 pagesAutomation of Water Tube Boiler Electrical ThesisMuhammadIrfanNo ratings yet

- Programmable Logic: PLC ControllerDocument10 pagesProgrammable Logic: PLC ControllerAppu BhattNo ratings yet

- PLC Industrial Training FileDocument22 pagesPLC Industrial Training FileROHIT MishraNo ratings yet

- Pratyush Priyansh Summer Training ReportDocument45 pagesPratyush Priyansh Summer Training ReportDark VoidNo ratings yet

- Synopsis of Summer Training HemantDocument6 pagesSynopsis of Summer Training HemantAnkit KumarNo ratings yet

- Modified Graduation ProjectDocument37 pagesModified Graduation ProjectSagar G ReddyNo ratings yet

- A Summary of PLCDocument2 pagesA Summary of PLCHoàng Minh ChíNo ratings yet

- National Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byDocument31 pagesNational Institute of Technology, Kurukshetra Haryana: Submitted To Submitted byÄkshãy SaçhånNo ratings yet

- Automated Process Control Through Programmable Logic Controller (PLC) For National Economic DevelopmentDocument9 pagesAutomated Process Control Through Programmable Logic Controller (PLC) For National Economic DevelopmentZamfirMarianNo ratings yet

- LEC 03 PROGRAMMABLE LOGIC CONTROLLER - Engr, M, Rafay KhanDocument13 pagesLEC 03 PROGRAMMABLE LOGIC CONTROLLER - Engr, M, Rafay KhanShaahrozz Ali KhanNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- MCD4710 Week3 Sample Test SolDocument8 pagesMCD4710 Week3 Sample Test SolVionnie TanNo ratings yet

- Untitled17 - Jupyter NotebookDocument2 pagesUntitled17 - Jupyter NotebookjackmekaNo ratings yet

- T.Y.B.Sc. (Cyber and Digital Science) - 01092022Document53 pagesT.Y.B.Sc. (Cyber and Digital Science) - 01092022RohittitansinghNo ratings yet

- Labview FpgaDocument3 pagesLabview FpgaSanwal SaleemNo ratings yet

- Parking Analysis (Procedure) - Traffic Engineering Laboratory - Civil Engineering - IIT Bombay Virtual LabDocument2 pagesParking Analysis (Procedure) - Traffic Engineering Laboratory - Civil Engineering - IIT Bombay Virtual Labadeewijaya32No ratings yet

- R18 B.Tech 3-2 CSE SyllabusDocument26 pagesR18 B.Tech 3-2 CSE SyllabusNishanth NishiNo ratings yet

- Analog VLSI Design: Technology TrendsDocument31 pagesAnalog VLSI Design: Technology TrendsSathyaNarasimmanTiagarajNo ratings yet

- Database Management Reference ManualDocument251 pagesDatabase Management Reference ManualCủa Trần VănNo ratings yet

- Programation Deuxieme Annee - OdtDocument4 pagesProgramation Deuxieme Annee - OdtMiguel Clovis KamNo ratings yet

- CTR 8500-8300 3.0 ISIS Config July2015 260-668256-011Document47 pagesCTR 8500-8300 3.0 ISIS Config July2015 260-668256-011BwaiNo ratings yet

- Ubuntu 16.04 Wont Shutdown RestartDocument4 pagesUbuntu 16.04 Wont Shutdown RestartRobinson CruzoeNo ratings yet

- Virtual Guided Labs - Getting Started With vSAN 6.7 PDFDocument24 pagesVirtual Guided Labs - Getting Started With vSAN 6.7 PDFMario TabuadaNo ratings yet

- Network Function Virtualization: State-Of-The-Art and Research ChallengesDocument28 pagesNetwork Function Virtualization: State-Of-The-Art and Research ChallengesYoonjeong HaNo ratings yet

- (PDF) Nokia 3110c SchematicDocument4 pages(PDF) Nokia 3110c SchematicMulyanaNo ratings yet

- A Short Manual For Use From The Command Line: Jump ToDocument11 pagesA Short Manual For Use From The Command Line: Jump ToAnanth IyengarNo ratings yet

- CF-19 BIOS Update ManualDocument3 pagesCF-19 BIOS Update ManualAnonymous V9fdC6No ratings yet

- Data Analytics and Visualization of TwitterSpam DatasetDocument5 pagesData Analytics and Visualization of TwitterSpam DatasetGloria AumaNo ratings yet

- Latitude 7000 Series Technical GuidebookDocument31 pagesLatitude 7000 Series Technical GuidebookJenNo ratings yet

- 2.1.1.5 Packet Tracer - Create A Simple Network Using Packet TracerDocument6 pages2.1.1.5 Packet Tracer - Create A Simple Network Using Packet TracerGrandmaster MeowNo ratings yet

- STG8000Document73 pagesSTG8000Lucas PereiraNo ratings yet

- ONW310600 IManager M2000 V200R013 Topology Management ISSDocument33 pagesONW310600 IManager M2000 V200R013 Topology Management ISSneomadrid70No ratings yet

- Quick Reference Card OpenStage 15 SIPDocument2 pagesQuick Reference Card OpenStage 15 SIPRodrigo MontesNo ratings yet

- HP Commercial January 2021 Pricelist Version 2.0Document69 pagesHP Commercial January 2021 Pricelist Version 2.0Vinodh MNo ratings yet

- Comparison Table VxLAN Vs OTVDocument3 pagesComparison Table VxLAN Vs OTVNguyen LeNo ratings yet

- CAD Help Center - Step by Step Installation Process of Catia V6R2009 x64 Bit On Windows XP x64 BitDocument10 pagesCAD Help Center - Step by Step Installation Process of Catia V6R2009 x64 Bit On Windows XP x64 BitSarath Babu NagarajanNo ratings yet

- Management Information System CIADocument8 pagesManagement Information System CIARatik RebelloNo ratings yet

- A Self Checking Reed Solomon Encoder Design and AnalysisDocument9 pagesA Self Checking Reed Solomon Encoder Design and AnalysisRAJKUMAR SAMIKKANNUNo ratings yet

- Ebook Comptia Network Certification All in One Exam Guide Seventh Edition Exam N10 007 PDF Full Chapter PDFDocument67 pagesEbook Comptia Network Certification All in One Exam Guide Seventh Edition Exam N10 007 PDF Full Chapter PDFclara.hem799100% (35)

- Asus Teresa r1.1 SchematicsDocument58 pagesAsus Teresa r1.1 SchematicsАнтон ФедоровNo ratings yet