Professional Documents

Culture Documents

Improving Matrix Acidizing White Paper

Improving Matrix Acidizing White Paper

Uploaded by

Mustafa AlrikabiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Improving Matrix Acidizing White Paper

Improving Matrix Acidizing White Paper

Uploaded by

Mustafa AlrikabiCopyright:

Available Formats

Technical Overview

Improving Matrix Acidizing optimisation by

Autonomous flow diverter

Introduction formation pore network near wellbore or to remove

Acidizing is commonly performed on wells to remove plugging in the perforation. In carbonate formation, matrix

damage and reduce skin to maximize productivity and acidizing works by forming conductive channels called

recovery. Acidizing enhancement technique is still a highly worm holes through the formation rock.

preferred method of damage removal/stimulation adopted There are three type of matrix treatments:

for sandstone and carbonate reservoir dating as far back as

– Near wellbore stimulation – within 2ft to 3ft of the wellbore

the nineteenth century. A proper acid design program is

critical to success of these types of treatments. However, – Intermediate matrix stimulation – within 3ft to 6ft of the

proper placement technique carries the same importance as wellbore

the acid design. Using a new placement technique, the – Extended matrix acidizing – further than 6ft from

entire planned completion interval can be acidizing at wellbore and use large volume

sufficient injection rates without exceeding the formation

ability to accept fluid below the fracture gradient. When Ideally, when acid is pumped into zones of variable

acid is pumped into damaged reservoir for damage permeability, it will distribute equally into all zones.

removal/stimulation, distorted inflow of acid into formation However, in general, acid preferentially flows into path of

occurs caused by preferentially traveling into highly least resistance which is the high permeability regions over

permeability regions over low permeability regions or into low permeability regions as shown in Figure 1.

the path of least resistance. If acid is not effectively diverted

in formation with high permeability/fracture anisotropy,

some treated zones may become acid sinks while other

zones are left with inadequate acid stimulation.

Acidizing Challenge

Reservoir and wellbores are interconnected by pores in the Figure 1. Acid preferentially flows into least resistance path.

formation. The flow of fluids through these pores is often

restricted because of permeability damage in the near

wellbore formation caused by drilling fluid invasion, When acid is flow into high permeability/fracture zones

cementing and completion operation that reduce the compared to low permeability zone, consequently the

physical size of pore throats or block the pore space causing damage in the high permeability zones will be removed at

impairment to the reservoir permeability that often-called higher rate hence the skin is drastically reduced. Such a

formation damage. distorted flow results into over-threating a high

permeability zone leading to poor zonal coverage as shown

Acid treatment falls into three general categories: in Figure 2. In this case, the low permeability zone is poorly

– Wellbore cleanout – remove debris that block pore space treated with acid resulting in poor production recovery. The

during installation high permeability zone could also lead to excessive flow

contribution that resulting in water or gas conning.

– Matrix acidizing – pump below formation pressure

– Fracture acidizing – pump above formation pressure

Wellbore cleanout is processed to clean the tubular and

wellbore with acid to clear out debris that block the pore

space due to drilling operation. Matrix acidizing is an acid

treatment injection at matrix pressure and staying below

formation fracture pressure. In sandstone formation, it is

used to remove or dissolve acid removable damage in the Figure 2. Over threating a high permeability zone resulting in poor

distribution to low permeability zone.

FloFuse acidizing technique

Acid diverter is one of the acidizing techniques that could

be used to distribute acid in well. The choice of diverter

method depends on its applicability, well characteristic and

reservoir property. However, existing method need a

mechanical isolation device to temporary straddle the Figure 6. Higher pressure drop indicate higher flowrate at fracture zone

fracture zone and this often associated with high cost and cause the FloFuse stop flowing to “fuse zone”.

more operation time. Limited entry liner is another

diversion technique that been adopted in long horizontal Once the effected flofuse “fuse”, it will increase the well

well. The limited entry is achieved by proportioning the head pressure to indicate a particular zone have completed

number of perforations according to the thickness of the acidizing and the need of reduction of flowrate. The “fuse”

pay zone. However, this technique has significant challenge process will keep continue as a new zone increase in

if fracture location is unknows as it unable to isolate the permeability as shown in Figure 7 and 8.

fracture zone.

FloFuse is an autonomous acid divertor device which is

biased open valve which enables acid injection at normal

distributed rates. The Flofuse is mounted into the basepipe

or screen section and required zone isolation to distribute

the outflow of the acid as shown in Figure 3. The placement

of the flofuse could be simulate in modelling to show equal

distribution of acid as shown in Figure 4. Figure 7. FloFuse stop flowing to next “fuse zone” as the permeability

increase cause fuse and distribute acids to other zone.

Figure 3. FloFuse placement in a well.

Figure 8. FloFuse stop flowing to most “fuse zone” as the permeability

increase cause fuse and distribute acids to other zone.

When all the zone has been given the desired amount of

acids treatments and become very permeable zones. All

flofuse will be in choke/shut in position as shown in Figure

9. The fuse effect could be observed with rapid increase in

Figure 4. Equal distribution of acid at initial stage. well head pressure that indicate all zone have been acidize

at optimum rate without over threating any of the zone.

If the acid is injected into fracture of high permeability zone, This technique will also avoid any excessive use of acid.

the acid will preferentially flow at higher flowrate that will Figure 10 shows a optimization modelling example

exceeded the ‘trigger rate’ and choke the valve. Once the between wellhead pressure and injection rate to shows

FloFuse is triggered, outflow is highly constrained into the injection process.

‘fused’ zone enabling acid injection to be diverted into the

other compartments as shown in Figure 5. The fuse zone could

be indicate with higher pressure drop due to higher flow rate

at fracture zone cause the FloFuse stop flowing to “fuse zone”

as shown in Figure 6.

Figure 9. FloFuse stop flowing to all the “fuse zone” as all the zone being

threated.

The FloFuse is fully reversable and the valve will re-set if

injection is stop and differential pressure across the valve

Figure 5. FloFuse stop flowing to “fuse zone” as the permeability increase cause

fuse and distribute acids to another zone. decrease. The acidizing process could be repeated if further

acid treatment is desire and the rate become sufficiently

distributed again.

Figure 10. FloFuse optimisation modelling

FloFuse device

The target normal operating rates and degree of outflow

control and trigger rates and can be varied by application.

Figure 11 show the cross section and key features of the

valve in open position.

Figure 13. FloFuse mounted in screen housing

Summary

Acidizing of sandstone and carbonate reservoir is a

comment practice to ensure high productivity by removing

the near wellbore damage. A new autonomous acid

stimulation device, FloFuse is developed to choke back the

acid injection treatment into natural/induced fractures and

mitigate the disproportional injection of acid into the

Figure 11. Flofuse construction in open position fracture/high permeability zone. Flofuse device improved

acidizing treatment efficiency by autonomously shut in the

If the formation have fracture or high permeability, the injection into fracture zone and divert the flow to another

injection rate into that compartment will increase. The untreated zone. Flofuse stop over threated to high

resultant increased pressure drop through the nozzle acts permeability area or fracture reduce the waste of acid and

against the spring until the flow area between the seal face improved the economic of acidizing. Optimization of

and the nozzle becomes restricted and the valve triggers to Flofuse acid treatment design have been simulated in

the fused position restricting the outflow into that reservoir modelling.

compartment as shown in Figure 12.

Figure 12. Flofuse in close position, main nozzle slide to sealing face

Under normal operating conditions injection outflow passes

through the main nozzle and into the formation. In case sand

control is needed, the outflow will be injected into the

housing and through the screen as required as shown in

Figure 13.

©2019 Tendeka. All rights reserved. www.tendeka.com

TDK-WP-IMA-0919

You might also like

- LZ 5941SDocument1 pageLZ 5941SphamthuyhaNo ratings yet

- Nitrogen FoamsDocument24 pagesNitrogen Foamsquespues100% (2)

- JPME Volume 17 Issue 1 Pages 54-58Document5 pagesJPME Volume 17 Issue 1 Pages 54-58afzal7No ratings yet

- Polymer Flooding TanjungDocument19 pagesPolymer Flooding TanjungYogia WirahandhikaNo ratings yet

- SPE 59771 Matrix Acidizing in Gas Wells: O. Fadele, SPE, D. Zhu, SPE, A. D. Hill, SPE, The University of Texas at AustinDocument8 pagesSPE 59771 Matrix Acidizing in Gas Wells: O. Fadele, SPE, D. Zhu, SPE, A. D. Hill, SPE, The University of Texas at AustinBolsec14No ratings yet

- Acidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingDocument2 pagesAcidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingEbrahim SoleimaniNo ratings yet

- Section 13 PerforatingDocument5 pagesSection 13 PerforatingaistopNo ratings yet

- 10 - Hole CleaningDocument5 pages10 - Hole CleaningFarouq EngNo ratings yet

- Bottom Hole Completion TechniquesDocument9 pagesBottom Hole Completion Techniquesakshitppe11No ratings yet

- Production Ii PDFDocument235 pagesProduction Ii PDFADARSH KUMARNo ratings yet

- Spe 183465 MSDocument10 pagesSpe 183465 MSkumar abhishek singhNo ratings yet

- Belkin 2005Document7 pagesBelkin 2005Wail KebbabiNo ratings yet

- FoamsymptomsDocument2 pagesFoamsymptomsRemeras TartagalNo ratings yet

- Bazin Et Al., 1999: Reservoir CompletionDocument1 pageBazin Et Al., 1999: Reservoir CompletionRaed fouadNo ratings yet

- SPE 86559 Stabilizing Wellbores in Unconsolidated, Clay-Laden FormationsDocument16 pagesSPE 86559 Stabilizing Wellbores in Unconsolidated, Clay-Laden Formationsmohamadi42No ratings yet

- SPE 137268 The Development and Application of A Novel Free-Damage Fracturing Fluid (PH 2)Document8 pagesSPE 137268 The Development and Application of A Novel Free-Damage Fracturing Fluid (PH 2)Ricardo Zapien RamirezNo ratings yet

- WST - Formation Damage Part 2Document30 pagesWST - Formation Damage Part 2NorNo ratings yet

- Thank You For Specifying That This Concept Is Related To Matrix AcidizingDocument1 pageThank You For Specifying That This Concept Is Related To Matrix AcidizingibrahimNo ratings yet

- Acidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingDocument2 pagesAcidizing Concepts-Matrix vs. Fracture Acidizing: George E. KingRamanamurthy PalliNo ratings yet

- Foam FloodingDocument36 pagesFoam FloodingWaleed Barakat MariaNo ratings yet

- Well - Stimulation PpoDocument6 pagesWell - Stimulation PponikhilnemnaniNo ratings yet

- Formation Damage and The Components of SkinDocument45 pagesFormation Damage and The Components of SkinBrian OmbogoNo ratings yet

- Solvent-Free Consolidation System Controls Proppant FlowbackDocument2 pagesSolvent-Free Consolidation System Controls Proppant Flowbackkumar abhishek singhNo ratings yet

- Slope Stabilisation Using LimeDocument8 pagesSlope Stabilisation Using LimeMohammadreza HarirsazNo ratings yet

- WST - Formation Damage Part 1Document31 pagesWST - Formation Damage Part 1NorNo ratings yet

- Effect of PH On Interfacial Films and Stability of Crude Oil-Water EmulsionsDocument10 pagesEffect of PH On Interfacial Films and Stability of Crude Oil-Water EmulsionsZakiyah Kamto IrfinNo ratings yet

- Effect of Foams Used During Carbonate Acidizing: M.G. Bernadlner, K.E. Thompson, H.S. FoglerDocument7 pagesEffect of Foams Used During Carbonate Acidizing: M.G. Bernadlner, K.E. Thompson, H.S. FoglerBolsec14No ratings yet

- Speidoe: Speidoe 92 Gel Placement in Heterogeneous Systems With CrossflowDocument18 pagesSpeidoe: Speidoe 92 Gel Placement in Heterogeneous Systems With CrossflowBình Trần100% (1)

- Acid FracturingDocument5 pagesAcid FracturingShamit RathiNo ratings yet

- 8.0 Feasibility of Passive Site RemediationDocument16 pages8.0 Feasibility of Passive Site RemediationTATATAHERNo ratings yet

- SPE 82273 Gas Assisted Acidizing of Carbonate Formations: R R SLNDocument12 pagesSPE 82273 Gas Assisted Acidizing of Carbonate Formations: R R SLNabbas1368No ratings yet

- SPE 0514 0032 JPT Matrix Acidizing Innovation SurpassesDocument4 pagesSPE 0514 0032 JPT Matrix Acidizing Innovation SurpassesTrần Hoàng ChươngNo ratings yet

- General Nature of Expansive SoilsDocument5 pagesGeneral Nature of Expansive Soilshaithamsaeed هيثم حازم سعيدNo ratings yet

- POG15 - FCA 2020 Paper Peru 2015Document10 pagesPOG15 - FCA 2020 Paper Peru 2015damianNo ratings yet

- SPE 127827 Combining Stimulation and Water Control in High-Water-Cut WellsDocument10 pagesSPE 127827 Combining Stimulation and Water Control in High-Water-Cut WellsNavneet SinghNo ratings yet

- Rim-Flo ClarifiersDocument8 pagesRim-Flo ClarifiersRamkiNo ratings yet

- Dke78 Ch13Document39 pagesDke78 Ch13Hồ ThắngNo ratings yet

- Acid Fracturing - Petrowiki, 2015Document4 pagesAcid Fracturing - Petrowiki, 2015Aliz ReNo ratings yet

- SPE 100456 Field Application of Emulsified Scale Inhibitor Treatment To Mitigate Calcium Carbonate Scale in Horizontal WellsDocument9 pagesSPE 100456 Field Application of Emulsified Scale Inhibitor Treatment To Mitigate Calcium Carbonate Scale in Horizontal WellsAbed Alftah AgabNo ratings yet

- 2530 Floatables 2530 A.: Approved by Standard Methods Committee, 2010. Editorial Revisions, 2011Document4 pages2530 Floatables 2530 A.: Approved by Standard Methods Committee, 2010. Editorial Revisions, 2011Gloria JimenzNo ratings yet

- OTC28267-MS Experience With SCON - WA Case StudiesDocument10 pagesOTC28267-MS Experience With SCON - WA Case StudiesLekan OdedeyiNo ratings yet

- Evonik Defoamers PDFDocument16 pagesEvonik Defoamers PDFmazen jamal100% (1)

- Energies 14 01148 v3Document11 pagesEnergies 14 01148 v3quy tran xuanNo ratings yet

- Entrainment Issues in Vacuum ColumnDocument10 pagesEntrainment Issues in Vacuum Columnvinay26guptaNo ratings yet

- Acid Stimulation - Steven Salgado, Bryan Perez, Luis Hinojosa.Document22 pagesAcid Stimulation - Steven Salgado, Bryan Perez, Luis Hinojosa.Steven SalgadoNo ratings yet

- Large Scale Mixer Settlers DesignDocument8 pagesLarge Scale Mixer Settlers DesignRodrigo GarcíaNo ratings yet

- Distinguished Author Series: Matrix AcidizingDocument15 pagesDistinguished Author Series: Matrix AcidizingGabyNo ratings yet

- Basics of Reverse Osmosis PrincipleDocument6 pagesBasics of Reverse Osmosis Principlezerocool86No ratings yet

- Matrix Stimulation of Water Disposal Wells Using Viscoelastic Surfactant-Based Acid SPE 88588Document10 pagesMatrix Stimulation of Water Disposal Wells Using Viscoelastic Surfactant-Based Acid SPE 88588Israel Arias GonzálezNo ratings yet

- When Nameplate Is Not EnoughDocument9 pagesWhen Nameplate Is Not Enoughgreenisin100% (1)

- Mass Transfer Ass 2 BakhtawarDocument7 pagesMass Transfer Ass 2 BakhtawarHasieb Alam KhanNo ratings yet

- Liquid Jet EductorsDocument4 pagesLiquid Jet EductorsCookiemon100% (1)

- Foaming in Fractionation ColumnsDocument7 pagesFoaming in Fractionation ColumnsmehdiNo ratings yet

- 10 - Emulsions and Foams - 1992 - Introduction To Colloid and Surface ChemistryDocument15 pages10 - Emulsions and Foams - 1992 - Introduction To Colloid and Surface ChemistryAZUCENANo ratings yet

- IADC World Drilling 2003Document12 pagesIADC World Drilling 2003gplese0No ratings yet

- Dry Gas Tech For Red WaterDocument3 pagesDry Gas Tech For Red WaterEduardo LopesNo ratings yet

- Pilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricDocument5 pagesPilot-Plant Development Ofthe Foam Distribution Process For Production OF Wet-Process PhosphoricIngrid ContrerasNo ratings yet

- What Is A CompletionDocument44 pagesWhat Is A CompletionMustafa AlrikabiNo ratings yet

- Hydrow I PKR-Tech SheetDocument53 pagesHydrow I PKR-Tech SheetMustafa AlrikabiNo ratings yet

- Naufal CVDocument2 pagesNaufal CVMustafa AlrikabiNo ratings yet

- 2022 2023 Doha British School Parent School CalendarDocument1 page2022 2023 Doha British School Parent School CalendarMustafa AlrikabiNo ratings yet

- SR 12 11684 - Materials - Selection - Guideline - For - Producer - and - Injector - Wells (2) - SignedDocument61 pagesSR 12 11684 - Materials - Selection - Guideline - For - Producer - and - Injector - Wells (2) - SignedMustafa AlrikabiNo ratings yet

- P264 Subpump ExerciseDocument26 pagesP264 Subpump ExerciseMustafa AlrikabiNo ratings yet

- 2022 JP Grand Cherokee FA5p39ubi07v9hnbqvffldk7fvanDocument13 pages2022 JP Grand Cherokee FA5p39ubi07v9hnbqvffldk7fvanMustafa AlrikabiNo ratings yet

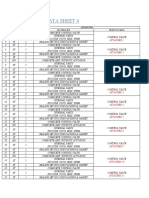

- Data Analysis Steps 456Document18 pagesData Analysis Steps 456Mustafa AlrikabiNo ratings yet

- ???? ?????? ????? ?????Document11 pages???? ?????? ????? ?????Mustafa AlrikabiNo ratings yet

- Oil Well ConstructionDocument35 pagesOil Well ConstructionMustafa AlrikabiNo ratings yet

- Completion Design - Session 1Document38 pagesCompletion Design - Session 1Mustafa AlrikabiNo ratings yet

- Sizing Sheet 149960Document23 pagesSizing Sheet 149960Mustafa AlrikabiNo ratings yet

- Sand Production Lecture 1Document20 pagesSand Production Lecture 1Mustafa AlrikabiNo ratings yet

- 08-01 CompletionDocument31 pages08-01 CompletionMustafa AlrikabiNo ratings yet

- 06-05 Chemical StimulationDocument99 pages06-05 Chemical StimulationMustafa AlrikabiNo ratings yet

- Ninth Grade Physical Science Students' Achievements in Math Using A Modeling Physical Science CurriculumDocument18 pagesNinth Grade Physical Science Students' Achievements in Math Using A Modeling Physical Science CurriculumDavid GiraldoNo ratings yet

- Date Sheet For The MA MSC Part II Annual Examination 2022 To Be Held 69830Document4 pagesDate Sheet For The MA MSC Part II Annual Examination 2022 To Be Held 69830Khushbakhat BilalNo ratings yet

- Gauss Jacobi Method v.2Document6 pagesGauss Jacobi Method v.2NUCUP Marco V.No ratings yet

- Math Test 2 DR - EhsanDocument9 pagesMath Test 2 DR - EhsanNərmin ŞahverdiyevaNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- MEMS IMU For AHRS ApplicationsDocument7 pagesMEMS IMU For AHRS ApplicationsFrank FrunkNo ratings yet

- Elements of DanceDocument4 pagesElements of DanceMich ValenciaNo ratings yet

- Problems Sheet 4: Hermite Polynomials (Solutions) : 2. The EquationDocument2 pagesProblems Sheet 4: Hermite Polynomials (Solutions) : 2. The Equationghouti ghoutiNo ratings yet

- Study Guide For Laboratory Technician: Human Resources Southern California Edison CompanyDocument12 pagesStudy Guide For Laboratory Technician: Human Resources Southern California Edison CompanyAjoy PaulNo ratings yet

- TOEFL Insight 1 - StructureDocument7 pagesTOEFL Insight 1 - StructureRimaNo ratings yet

- 3-Dimensioning Tolerancing FitsDocument36 pages3-Dimensioning Tolerancing FitsthelearningaceNo ratings yet

- Lecture - 4 Crystal Structure - IIDocument16 pagesLecture - 4 Crystal Structure - IIHarshini SNo ratings yet

- Code History and Ultimate Strength Design PDFDocument17 pagesCode History and Ultimate Strength Design PDFAfrizal Rif AnNizarNo ratings yet

- Rotating Trolley With Lead Screw Mechanism: International Journal On Emerging TechnologiesDocument3 pagesRotating Trolley With Lead Screw Mechanism: International Journal On Emerging TechnologiesTeam LegendsNo ratings yet

- Lessonsections-24 2Document11 pagesLessonsections-24 2Ghazi DallyNo ratings yet

- Photovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerDocument12 pagesPhotovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerHocine AbdelhakNo ratings yet

- General Education 900 Questions With Answer KeyDocument44 pagesGeneral Education 900 Questions With Answer KeyKd CancinoNo ratings yet

- Statistics Notes Part 1Document26 pagesStatistics Notes Part 1Lukong LouisNo ratings yet

- Batuan 2Document23 pagesBatuan 2Dewi ShafiraNo ratings yet

- Chapter 12 Thermodynamics PDFDocument94 pagesChapter 12 Thermodynamics PDFNitish MehraNo ratings yet

- DP Type LTDocument3 pagesDP Type LTRahul ChandrawarNo ratings yet

- AF12 Chapter 5 SolutionsDocument111 pagesAF12 Chapter 5 SolutionssupremeNo ratings yet

- BS 8666Document23 pagesBS 8666Joshua David RomeroNo ratings yet

- Inverted T Bent Caps RetrofittingDocument286 pagesInverted T Bent Caps RetrofittingHrprudential ConsultantNo ratings yet

- Basic ChemistryDocument15 pagesBasic ChemistryNurharis MunandarNo ratings yet

- Illustrative Worked Examples: Worked Example No. Title of Worked Example: Centrifugal Force On Continuous Bridge PierDocument1 pageIllustrative Worked Examples: Worked Example No. Title of Worked Example: Centrifugal Force On Continuous Bridge Pierjatin singlaNo ratings yet

- Turki Al-Anina, FM-3, S09Document15 pagesTurki Al-Anina, FM-3, S09xKrA1tosNo ratings yet

- XTRACT Fall2012 Manual PDFDocument15 pagesXTRACT Fall2012 Manual PDFJuan Pablo PeñalosaNo ratings yet

- Activities of NDT, AECD, BAEC, 20-21Document26 pagesActivities of NDT, AECD, BAEC, 20-21Fatin IshraqueNo ratings yet