Professional Documents

Culture Documents

02.03.2020 F-22 Weekly - Engine - Machinery Rep.

02.03.2020 F-22 Weekly - Engine - Machinery Rep.

Uploaded by

Sharapov Mechanic (Все просто)0 ratings0% found this document useful (0 votes)

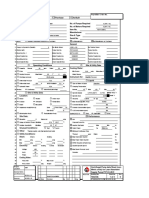

12 views1 pageThis document provides a weekly machinery engine report for the MV Breb Courageous. It includes operating parameters for the main engine such as RPM, temperature readings, fuel and lube oil consumption. Cylinder performance data like exhaust gas temperatures and fuel pump positions are reported. Maintenance tasks completed include installing new batteries, cleaning filters and separators, greasing pumps and fans, and repairing equipment. The chief engineer signed off on the report.

Original Description:

Weekly engine machinery presentation

Original Title

02.03.2020 F-22 Weekly_Engine_Machinery rep.

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a weekly machinery engine report for the MV Breb Courageous. It includes operating parameters for the main engine such as RPM, temperature readings, fuel and lube oil consumption. Cylinder performance data like exhaust gas temperatures and fuel pump positions are reported. Maintenance tasks completed include installing new batteries, cleaning filters and separators, greasing pumps and fans, and repairing equipment. The chief engineer signed off on the report.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views1 page02.03.2020 F-22 Weekly - Engine - Machinery Rep.

02.03.2020 F-22 Weekly - Engine - Machinery Rep.

Uploaded by

Sharapov Mechanic (Все просто)This document provides a weekly machinery engine report for the MV Breb Courageous. It includes operating parameters for the main engine such as RPM, temperature readings, fuel and lube oil consumption. Cylinder performance data like exhaust gas temperatures and fuel pump positions are reported. Maintenance tasks completed include installing new batteries, cleaning filters and separators, greasing pumps and fans, and repairing equipment. The chief engineer signed off on the report.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

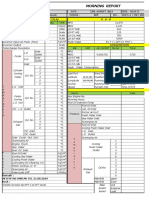

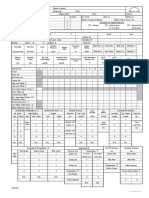

Weekly & Machinery Engine Report F-22

-For 4- Stroke Engines only- Revision 1-2020

(to be completed during sailing only!!)

MV : BREB COURAGEOUS

Week No. 10 Date: 02,03,2020

Main Eng.-Type: MAK 6M32C FW Consumpt: total 1.80 t/d

G.O Consumpt: t/d

RPM: 590 Prop.-Pitch: 74.0 % F.O Consumpt: M/E 10.40 t/d

F.O Consumpt: A/E t/d

Eng.-Room Temp.: 28 °C Engine load 69 % Boiler: t/d

Exhaust Gas Temp. before T.C. 520 °C Sea W.-Temp.: 18 °C

Exh. Gas Temp. behind T.C.: 369 °C Wind: 3 Bft

Speed: 12.0 kn

Rev. Turbo Charger: 28000 rpm Sea: 1 m Wind

Cyl. 1 Cyl. 2 Cyl. 3 Cyl. 4 Cyl. 5 Cyl. 6 Cyl. 7 Cyl. 8 Cyl. 9

Exh. gas temp. Cyl. M.E. 415 415 426 425 408 409

Exh. gas temp. Cyl. E.C.R. 411 413 422 422 404 406

Fuel pp. rack pos. 37 37 37 35 38 37

Ignition pressure (mean) 160 158 158 156 158 156

Compress. pressure

Big end bearing / oilsplash temp 66 64 65 65 66 66

Main Bearing Temperature

ME Parameters Heavy/Light Fuel Oil

T water engine inlet H.T 82 °C P fuel before M.E. 5.7 bar

T water engine outlet H.T 85 °C T fuel before M.E. 104 °C

P water before engine H.T 4.5 bar Viscosity of fuel at M.E 13 cst.

T water LT 30 °C IFO-380

Fuel type/grade/Sulphur 0,5%mm cst @ 50°C

P water LT 3.4 bar Daily Luboil Consumption

P water SW 3.0 bar Main Engine 50 ltr/d

Evaporator production 7.50 t/d Aux. Gen. 1/ 2/ 3 ltr/d

Water in oil test M/E Luboil < 0,02 % Emerg. Gen. ltr/d

P Charge air bef./ aft cooler 2.1 bar Stern Tube ltr/d

T Charge air bef./ aft cooler 167 43 °C Lube oil Stock

P differential air cooler (taken fr U-pipe) 50 mmWC Main engine L.O. 7000 Ltr

P lube oil before engine 4.8 bar Auxilary diesel L.O. 370 Ltr

T lube oil engine inlet 60 °C Running hours

T lube oil engine outlet 76 °C Main Engine 47421 total

P lube oil Gear box 3.8 bar Generator 1/ 2/ 3 32369 29791 total

T lube oil Gear box 35.0 °C Emerg. Gen. 253 total

P oil CPP unit 54.0 bar Compressor 1/ 2/ 3 11374 4871 h/d

T oil CPP unit 38.0 °C Work air Compressor 7556 h/d

T Stern Tube 56.0 °C Boiler Burner 4471 h/d

Shaft Generator 160.0 kW LO Separator M/E 67388 h 98 °C

Shaft Earth Volt 20.0 mV

Cooling water Treatment HT LT LO Separator A/E n/a h °C

PH (potentia hydrogenia) 9.5 10.0 HFO 1 Separator 23901 h 98 °C

Inhabitor Concentration 20 40 HFO 2 Separator 20448 h 98 °C

Chlorid / ppm 1620 1800 GO Separator 11291 h 30.00 °C

Boiler additional parameters

Alkalinity / ppm 190 Intake Air Temp. T.C. 28 °C

Conductivity / ppm 1662 T Charge air cooler H.T. inlet 85 °C

Condensate ph 10.0 T Charge air cooler H.T. outlet 87 °C

Thermaloil T Charge air cooler L.T. inlet 33 °C

Pressure/ Temperature N/A bar / °C T Charge air cooler L.T. outlet 35 °C

Sludge Fuel oil net. Specific energy 42 MJ/kg

Capacity / Total on board 35.8 4.2 m³ L.O. TBN 30

Bilge Water

Capacity / Total on board 5.2 1.2 m³

Main jobs / repairs carried out:

Install new batery on GMDSS bridge 24v. Free fall boat. Clean MDO purifier.

Maintenance Shaft Earthing device. Change oil and oil filters in DG 1. Change Bilge cargo hold sensor 2 AFT PS

Grease all pump and Fans. Install new projectors Top deck and wings.

Change batter on UPS for ER k-chief comp. No2. Clean ME duplex fuel filter. Renew el conection box for bow thruster fan motor.

Valve clearance on AE No1. Repair Slack wire safety switch hoisting and luffting winches on crain No2

Safety day. Cleaning and paint in ER. Clean sea side filter on LT cooler 1

Signed by: Stepanov M Name Chief engineer on board since : 9/1/2019 date: 02,03,2020

You might also like

- Data Kalibrasi Injection Pump Forklift MitsubishiDocument3 pagesData Kalibrasi Injection Pump Forklift Mitsubishinarama100% (1)

- Cat C4.4-110 De110e3 enDocument1 pageCat C4.4-110 De110e3 enEdwin Enrique Osorio100% (1)

- Fiber FilmDocument4 pagesFiber FilmDavid GarciaNo ratings yet

- MAN Biogas EngineDocument16 pagesMAN Biogas EngineMuhammad rizkiNo ratings yet

- Main Engine DetailDocument9 pagesMain Engine DetailRashid Mahmood JaatNo ratings yet

- Main Engine (Akasaka-6Uec37La) R - O - B: 22th. AUGUST 2019 469 233/ S-2 / VIII / 2019Document4 pagesMain Engine (Akasaka-6Uec37La) R - O - B: 22th. AUGUST 2019 469 233/ S-2 / VIII / 2019Mardi Santoso T/09No ratings yet

- SD220P - Sne - 2024 04 23 22 56 03Document6 pagesSD220P - Sne - 2024 04 23 22 56 03josue.zepeda0304No ratings yet

- TAD 1630 GE: Genset Engine - Gen PacDocument2 pagesTAD 1630 GE: Genset Engine - Gen PacselfyNo ratings yet

- T3 ME Performance Record Jan TemplateDocument5 pagesT3 ME Performance Record Jan TemplateMuhd Khir RazaniNo ratings yet

- E0834 E302 Natural Gas - GBDocument24 pagesE0834 E302 Natural Gas - GBvalvotecnicaNo ratings yet

- SD40P - Sne 2024 04 23 22 01 57Document6 pagesSD40P - Sne 2024 04 23 22 01 57josue.zepeda0304No ratings yet

- Volvo Tad1632Document2 pagesVolvo Tad1632Pakito-sanNo ratings yet

- Man E2876e312Document9 pagesMan E2876e312Oscar BarraganNo ratings yet

- C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesC Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- Service Performance ME-BDocument2 pagesService Performance ME-BValeriy DomashenkoNo ratings yet

- FG40-50 Engine SpecificationDocument5 pagesFG40-50 Engine SpecificationHai DuyNo ratings yet

- Press-T G Ts0038uk03Document20 pagesPress-T G Ts0038uk03Berhanu GebreyohannesNo ratings yet

- Tmi 24Document6 pagesTmi 24Anthony graciano leyvaNo ratings yet

- Service Performance ME-BDocument2 pagesService Performance ME-BThusitha DalpathaduNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Алексей ГавриловNo ratings yet

- Perkins 1506A E88TAG3 250kVADocument3 pagesPerkins 1506A E88TAG3 250kVAMohamed AbdElhamedNo ratings yet

- Motordatenblatt MTU 20V4000G63L 1Document2 pagesMotordatenblatt MTU 20V4000G63L 1JeevaganNo ratings yet

- Test Specification Data: Test Spec Number: Engine Serial Number: 67Z00776 Engine Model: Combustion: AspirationDocument3 pagesTest Specification Data: Test Spec Number: Engine Serial Number: 67Z00776 Engine Model: Combustion: AspirationDhrubajyoti BoraNo ratings yet

- JMS-320 GS NL (1065kw)Document4 pagesJMS-320 GS NL (1065kw)Dexterous EngineeringNo ratings yet

- GJ Ev GZ 1.8i 84-88Document1 pageGJ Ev GZ 1.8i 84-88Manuel IzquierdoNo ratings yet

- Pumpdesign Report: Pump ParametersDocument7 pagesPumpdesign Report: Pump Parameterscristian fernando garnicaNo ratings yet

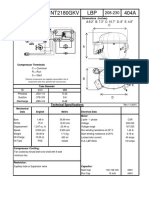

- NT2180GKV2 923MD04Document2 pagesNT2180GKV2 923MD04Christian DelgadoNo ratings yet

- MGS2800B (2.500 - 2.750 kVA)Document4 pagesMGS2800B (2.500 - 2.750 kVA)kesitiNo ratings yet

- JMS 420 GS-N.L: Technical SpecificationDocument4 pagesJMS 420 GS-N.L: Technical SpecificationАлександр ПедашNo ratings yet

- c13 EspecificacionesDocument3 pagesc13 EspecificacionesEDSON JONATHAN SALINAS AYALA100% (1)

- Acceptance Test Protocol: MAN Diesel & TurboDocument25 pagesAcceptance Test Protocol: MAN Diesel & TurboManretyNo ratings yet

- Performance Observations Plate 70603-40 Page 1 (2) : SuhvvDocument2 pagesPerformance Observations Plate 70603-40 Page 1 (2) : SuhvvMax MaksNo ratings yet

- Deutz, TBG 616 K (323 - 700 KW)Document4 pagesDeutz, TBG 616 K (323 - 700 KW)Dexterous EngineeringNo ratings yet

- Service Performance MEDocument2 pagesService Performance METhusitha DalpathaduNo ratings yet

- Weekly Learning Summary-10052019-Yandi 燕迪Document14 pagesWeekly Learning Summary-10052019-Yandi 燕迪Hamka PutraNo ratings yet

- Y4110Zld Engine Technical Data SheetDocument2 pagesY4110Zld Engine Technical Data SheetValeriyNo ratings yet

- Me Performance ReportDocument1 pageMe Performance ReportgioNo ratings yet

- B - N67 TE5: 202 KW (1500 RPM) - 217 KW (1800 RPM)Document4 pagesB - N67 TE5: 202 KW (1500 RPM) - 217 KW (1800 RPM)Ricardo MarmoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document7 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- 362214Document59 pages362214Anderson BombistaNo ratings yet

- Vehicle Identification: Notes Specified Value Measured ValueDocument5 pagesVehicle Identification: Notes Specified Value Measured ValueПан ТелемонNo ratings yet

- Sea Sovereign: Test Specification and Protocol FOR Fuel Oil SystemDocument4 pagesSea Sovereign: Test Specification and Protocol FOR Fuel Oil SystemPT INDORAD MEGA BINTANGNo ratings yet

- Engine Expt 4Document8 pagesEngine Expt 4aashiquear100% (3)

- C100 Service Training Manual: Engine Repair (2.4L DOHC)Document30 pagesC100 Service Training Manual: Engine Repair (2.4L DOHC)DangLuyenNo ratings yet

- Generators Mitsubishi mgs2000bDocument4 pagesGenerators Mitsubishi mgs2000bhungNo ratings yet

- Engine Performance Query Manager 24 HDocument4 pagesEngine Performance Query Manager 24 HTyler GoodwinNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document3 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)LIONN TESTE2021No ratings yet

- AD - 803 - Mariner 320 - en 2020Document11 pagesAD - 803 - Mariner 320 - en 2020Carlos Cesar Silva FilhoNo ratings yet

- N67 TE2F: 1/ GeneralDocument3 pagesN67 TE2F: 1/ General林哲弘100% (1)

- LogbookDocument1 pageLogbooksmrahman17323No ratings yet

- Motordatenblatt MTU 12V4000G63 PDFDocument2 pagesMotordatenblatt MTU 12V4000G63 PDFTaz UddinNo ratings yet

- JMS 416 GS-N.LDocument4 pagesJMS 416 GS-N.Lemamul613No ratings yet

- WSHP 120 KBTH - LH - 220V3ph - STD - Tstat - Technical Data SheetDocument2 pagesWSHP 120 KBTH - LH - 220V3ph - STD - Tstat - Technical Data SheetAilefo DelimaNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- R2 00 MGS2800HV (50Hz 10kV)Document4 pagesR2 00 MGS2800HV (50Hz 10kV)luat1983No ratings yet

- 4AD158TI/4AD222TI Marine Generator EngineDocument1 page4AD158TI/4AD222TI Marine Generator EngineElton FloresNo ratings yet

- Test Specification Data: Test Spec Number: Engine Serial Number: MCW00001 Engine Model: Combustion: AspirationDocument4 pagesTest Specification Data: Test Spec Number: Engine Serial Number: MCW00001 Engine Model: Combustion: AspirationMaimun maimunNo ratings yet

- Cummins C275D5 - Datasheet 250kva 275kvaDocument3 pagesCummins C275D5 - Datasheet 250kva 275kvalam101185No ratings yet

- Generator Set Data Sheet: 440kVA Standby at 50HzDocument3 pagesGenerator Set Data Sheet: 440kVA Standby at 50HzDheoiNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Module 11. PCB FailureDocument19 pagesModule 11. PCB FailureSharapov Mechanic (Все просто)100% (1)

- MODULE 12. Batteries (Jogesh)Document26 pagesMODULE 12. Batteries (Jogesh)Sharapov Mechanic (Все просто)No ratings yet

- MODULE 13. Low Voltage Electrical EquipmentDocument15 pagesMODULE 13. Low Voltage Electrical EquipmentSharapov Mechanic (Все просто)No ratings yet

- EG Black Out Test JRCSDocument14 pagesEG Black Out Test JRCSSharapov Mechanic (Все просто)100% (1)

- MODULE 6 Distribution of Electric PowerDocument54 pagesMODULE 6 Distribution of Electric PowerSharapov Mechanic (Все просто)100% (2)

- Module 6a. MCCBDocument19 pagesModule 6a. MCCBSharapov Mechanic (Все просто)100% (1)

- History of Energy in Pakistan - Time Line - DAWNDocument5 pagesHistory of Energy in Pakistan - Time Line - DAWNMuhammad JahangirNo ratings yet

- Makalah Akhir Pressure MaintenanceDocument13 pagesMakalah Akhir Pressure MaintenanceBarbara_LFCNo ratings yet

- City Cement SaudiDocument5 pagesCity Cement SaudijagrutNo ratings yet

- CS WHP BoDDocument86 pagesCS WHP BoDHua Tien DungNo ratings yet

- RepairManual NEF M100 M150 P3D32N003E Mar06Document172 pagesRepairManual NEF M100 M150 P3D32N003E Mar06manuel segovia100% (1)

- Intercooler - WikipediaDocument6 pagesIntercooler - Wikipediashapoor_pouladiNo ratings yet

- Wiring Diagram FH, NH: GroupDocument110 pagesWiring Diagram FH, NH: GroupStefan AslamNo ratings yet

- Toyota Starlet 4K 1983Document20 pagesToyota Starlet 4K 1983David Emmanuel Turcios CarrilloNo ratings yet

- Turbocharger and SuperchargerDocument13 pagesTurbocharger and Superchargernishantdubey11830% (1)

- Service at A Glance Maintenance Intervals: EngineDocument1 pageService at A Glance Maintenance Intervals: EngineDadangNo ratings yet

- Group 5Document72 pagesGroup 5Rifah TasniaNo ratings yet

- Thermax 1Document53 pagesThermax 1Miera MoreNo ratings yet

- SPE-7494-PA Economic Evaluation of Cycling Gas Condensate ReDocument8 pagesSPE-7494-PA Economic Evaluation of Cycling Gas Condensate ReMiguel Angel GonzalesNo ratings yet

- Vaillant 007472 Ecotec Boiler Range 06072015 Print Ready PDF Final Version Low Res SM 1Document72 pagesVaillant 007472 Ecotec Boiler Range 06072015 Print Ready PDF Final Version Low Res SM 1nicehornetNo ratings yet

- Nodia and Company: Gate Solved Paper Aerospace Engineering 2007Document16 pagesNodia and Company: Gate Solved Paper Aerospace Engineering 2007likhith saiNo ratings yet

- VolvoPenta 4.3gi User ManualDocument96 pagesVolvoPenta 4.3gi User ManualDilbert007100% (1)

- Motobombas GodwinDocument12 pagesMotobombas GodwinmuahdibNo ratings yet

- Hydradrive EsiteDocument12 pagesHydradrive EsiteMakeNo ratings yet

- NANO-REX Lubricant AdditiveDocument8 pagesNANO-REX Lubricant AdditiveProject Sales CorpNo ratings yet

- Bang TSKT Hd120Document9 pagesBang TSKT Hd120donhuy100% (1)

- PT6A 25SBindex CGA PDFDocument20 pagesPT6A 25SBindex CGA PDFandresNo ratings yet

- 103 JamnagarDocument2 pages103 JamnagarseehariNo ratings yet

- Engineer'S Specification Fuel Oil Day Tank 1.0 1.1Document4 pagesEngineer'S Specification Fuel Oil Day Tank 1.0 1.1Ladapo OladipupoNo ratings yet

- Back-Pressure Tests On. Gas-Condensate Wells: As - OndeisateDocument9 pagesBack-Pressure Tests On. Gas-Condensate Wells: As - OndeisateAura Cristina Villafañe GeraldinoNo ratings yet

- Diploma Mechanical Engg 4th SemDocument2 pagesDiploma Mechanical Engg 4th SemShravani SalunkheNo ratings yet

- Parlour Pellet ManualDocument29 pagesParlour Pellet ManualAmândio PintoNo ratings yet

- Nigel Gee - Izar Pentamaran ConceptDocument14 pagesNigel Gee - Izar Pentamaran ConceptrmdowlandNo ratings yet

- Lec 2Document11 pagesLec 2Omar SafwatNo ratings yet

- Engine Expert ManualDocument37 pagesEngine Expert ManualEktidustu CheleNo ratings yet