Professional Documents

Culture Documents

Bolts and Power Screws - Long

Bolts and Power Screws - Long

Uploaded by

Ameeh TorionCopyright:

Available Formats

You might also like

- Propeller and Propfan: NoiseDocument64 pagesPropeller and Propfan: NoiseWouterr GNo ratings yet

- Versaworks ManualDocument36 pagesVersaworks ManualMartinNo ratings yet

- GPRP Pro Setup and Tuning Guide PDFDocument46 pagesGPRP Pro Setup and Tuning Guide PDFmohnaserNo ratings yet

- EMF Assignment1Document5 pagesEMF Assignment1Ahtasham ArshadNo ratings yet

- Budgeting Exercise 03Document7 pagesBudgeting Exercise 03ERIK ACEVEDO ESCOBEDONo ratings yet

- Instructions For Paper Submission of Form FDA 2541eDocument41 pagesInstructions For Paper Submission of Form FDA 2541eVân Nguyễn Trương TuyếtNo ratings yet

- Block Port v1Document14 pagesBlock Port v1Ariel OneCHEENo ratings yet

- Example of Spot Speed StudyDocument9 pagesExample of Spot Speed StudySivaruban FrancisNo ratings yet

- ROVHYDocument77 pagesROVHYXyriz Paz EstrelladoNo ratings yet

- Tilak Slides PDFDocument72 pagesTilak Slides PDFDarsh MenonNo ratings yet

- Linear Actuator-ThomsonDocument168 pagesLinear Actuator-ThomsonANTON NEAGUNo ratings yet

- OptistructDocument85 pagesOptistructSahithyananda ShashidharNo ratings yet

- Small Scale Wind Tunnel Testing of Model PropellersDocument10 pagesSmall Scale Wind Tunnel Testing of Model PropellersClaus WehmannNo ratings yet

- Effective Bulk Modulus PHD Thesis PDFDocument177 pagesEffective Bulk Modulus PHD Thesis PDFDizzixxNo ratings yet

- Computational Modelling For Cavitation and Tip Vortex FlowsDocument115 pagesComputational Modelling For Cavitation and Tip Vortex FlowsQianZHNo ratings yet

- NECS 0202T-0612T Technical BulletinDocument42 pagesNECS 0202T-0612T Technical BulletinVictor AANo ratings yet

- DissertationDocument82 pagesDissertationCoCoNo ratings yet

- DACO Occupational Safety ManualDocument47 pagesDACO Occupational Safety Manualabdullah shafeiNo ratings yet

- Icar Institute ProfileDocument214 pagesIcar Institute ProfilerakeshalleNo ratings yet

- Updated List of Approved ART Clinics04082021Document72 pagesUpdated List of Approved ART Clinics04082021ChandanNo ratings yet

- Asaan Movers Thesis 7.0Document65 pagesAsaan Movers Thesis 7.0Qasim KhanNo ratings yet

- Optimizing Gear Ratio Selection For Lap Performance: Vehicle ModelsDocument9 pagesOptimizing Gear Ratio Selection For Lap Performance: Vehicle ModelsRITESH RATHORENo ratings yet

- Camd Manual18me36a FinalDocument44 pagesCamd Manual18me36a FinalDANISH ME-18-40No ratings yet

- Unit 1 - IntroductionDocument33 pagesUnit 1 - IntroductionRavi KantNo ratings yet

- RPP 2021 - Project Guidelines and Work PackagesDocument25 pagesRPP 2021 - Project Guidelines and Work PackagespintuNo ratings yet

- 1 s2.0 S0029801822002840 MainDocument13 pages1 s2.0 S0029801822002840 Main刘五六No ratings yet

- RADIOSS 2017 Tutorials and ExamplesDocument947 pagesRADIOSS 2017 Tutorials and ExamplesRanjit PatilNo ratings yet

- Grammar - Reported SpeechDocument18 pagesGrammar - Reported SpeechArpithaNo ratings yet

- Alex 123 EditedDocument90 pagesAlex 123 EditedabeNo ratings yet

- DR Ganesh Patil Medical StatisticsDocument77 pagesDR Ganesh Patil Medical StatisticsKaushal PatelNo ratings yet

- Hindustan TimesDocument20 pagesHindustan TimesRavindra Varma PvsNo ratings yet

- John ResearchDocument109 pagesJohn ResearchJo NipseyNo ratings yet

- Biochemistry Summary NotesDocument98 pagesBiochemistry Summary NotesPatricia EspirituNo ratings yet

- Bài tập tự động hóa sản xuất - 0001-0001Document1 pageBài tập tự động hóa sản xuất - 0001-0001Minh NhậtNo ratings yet

- Design Final ProjectDocument41 pagesDesign Final ProjectmagnifcoNo ratings yet

- WAVE Tutorial 001Document46 pagesWAVE Tutorial 001Premkumarr SanthanammNo ratings yet

- A Review On Planning, Configurations, Modeling and Optimization Techniques of Hybrid Renewable Energy Systems For Off Grid ApplicationsDocument21 pagesA Review On Planning, Configurations, Modeling and Optimization Techniques of Hybrid Renewable Energy Systems For Off Grid Applicationsel_ruso__83100% (1)

- Optimal Baffle DesignDocument16 pagesOptimal Baffle DesignJustine HauptNo ratings yet

- CS2252 NotesDocument196 pagesCS2252 NotesANBALAGHI DaddyNo ratings yet

- Nara Bassinet Maintenance ManualDocument46 pagesNara Bassinet Maintenance ManualAnonymous KiraNo ratings yet

- ROBOTICS. Application Manual PROFINET Controller - DeviceDocument88 pagesROBOTICS. Application Manual PROFINET Controller - DevicebNo ratings yet

- Lecture 7Document12 pagesLecture 7MohamedNo ratings yet

- Technical Specifications: Hydraulic Mining ShovelDocument10 pagesTechnical Specifications: Hydraulic Mining ShovelOrso OsvaldNo ratings yet

- DURBIN MEDICAL SUPPLY CATALOGUE Consumables and General SuppliesDocument22 pagesDURBIN MEDICAL SUPPLY CATALOGUE Consumables and General SuppliesAlexander Kwaitota100% (1)

- Novak Thesis 2019Document132 pagesNovak Thesis 2019Hossein MalekinejadNo ratings yet

- Digital-Alternate ChannelDocument146 pagesDigital-Alternate ChannelBhaskar GarimellaNo ratings yet

- Military TechDocument15 pagesMilitary TechAbel TayeNo ratings yet

- Jeecs 20 3 0310021Document16 pagesJeecs 20 3 0310021rosca raulNo ratings yet

- ECSS E 30part5.1a (2april2002) PDFDocument72 pagesECSS E 30part5.1a (2april2002) PDFAndreeNo ratings yet

- Bearing LifetimeDocument164 pagesBearing LifetimeOscar Orlando CuervoNo ratings yet

- Andersson-Valves Contribution To System DampingDocument25 pagesAndersson-Valves Contribution To System Dampingsivaraman jaganathanNo ratings yet

- Drag Force in Flow Over A Body Full ReportDocument25 pagesDrag Force in Flow Over A Body Full Reportfaruq haziqNo ratings yet

- Material Drive Control Systems For Wheel LoadersDocument20 pagesMaterial Drive Control Systems For Wheel LoadersJerson T. Altovar100% (1)

- DFM SK DFM DFM I Operation ManualDocument105 pagesDFM SK DFM DFM I Operation ManualBrion Bara IndonesiaNo ratings yet

- Infineon EPS User ManualDocument42 pagesInfineon EPS User Manualacmilan4eva1899No ratings yet

- Main Ngoài Ngáng DceDocument16 pagesMain Ngoài Ngáng DceCao LanNo ratings yet

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque ValuesJadon TheophilusNo ratings yet

- Automobile ModuleiiDocument96 pagesAutomobile ModuleiinameNo ratings yet

- Eme PDFDocument7 pagesEme PDFprathaNo ratings yet

- Bolts (Screws) and Nuts: External Thread Internal ThreadDocument8 pagesBolts (Screws) and Nuts: External Thread Internal ThreadLanugan, Jenkhen B.No ratings yet

- TORION - Progress Report #1Document5 pagesTORION - Progress Report #1Ameeh TorionNo ratings yet

- ConEngg TorionDocument1 pageConEngg TorionAmeeh TorionNo ratings yet

- Quiz I - PumpsDocument1 pageQuiz I - PumpsAmeeh TorionNo ratings yet

- Quiz 2Document1 pageQuiz 2Ameeh TorionNo ratings yet

- Lesson 2 - Principles of ThermodynamicsDocument10 pagesLesson 2 - Principles of ThermodynamicsAmeeh TorionNo ratings yet

- ConeggDocument1 pageConeggAmeeh TorionNo ratings yet

- Vacuum Cooling For The Food IndustryDocument11 pagesVacuum Cooling For The Food IndustryAmeeh TorionNo ratings yet

- Shaft Design LongDocument5 pagesShaft Design LongAmeeh TorionNo ratings yet

- RA 115350 MECHANICAL ENGINEER Rosales Pangasinan 8 2022 With RemindersDocument24 pagesRA 115350 MECHANICAL ENGINEER Rosales Pangasinan 8 2022 With RemindersAmeeh TorionNo ratings yet

- Bonus Rules and CalcuDocument7 pagesBonus Rules and CalcuAmeeh TorionNo ratings yet

- Improvement of The Vacuum Cooling System For Biodiesel ProductionDocument7 pagesImprovement of The Vacuum Cooling System For Biodiesel ProductionAmeeh TorionNo ratings yet

- Friction Clutches - LongDocument4 pagesFriction Clutches - LongAmeeh TorionNo ratings yet

- Constants and ConversionsDocument32 pagesConstants and ConversionsAmeeh TorionNo ratings yet

- Brake Design - LongDocument3 pagesBrake Design - LongAmeeh TorionNo ratings yet

- Leaf Spring - LongDocument2 pagesLeaf Spring - LongAmeeh TorionNo ratings yet

- Synthes ScrewsDocument4 pagesSynthes ScrewsviolentmidnightNo ratings yet

- Manual Thread Cutting - Course - Technique For Manual Working of Materials. Trainees' Handbook of Lessons - 7Document7 pagesManual Thread Cutting - Course - Technique For Manual Working of Materials. Trainees' Handbook of Lessons - 7Henrique MarquesNo ratings yet

- US Wall Chart REV 06 2011Document2 pagesUS Wall Chart REV 06 20111DB7Li51Q2cZMNo ratings yet

- Valve Assy, Control, P - N Yy30v00036f1Document3 pagesValve Assy, Control, P - N Yy30v00036f1刘奇雄No ratings yet

- Meritor TP9613P Wheel Stud ID ChartDocument40 pagesMeritor TP9613P Wheel Stud ID ChartScottNo ratings yet

- FAIDocument14 pagesFAIalejandroruiz020697No ratings yet

- The Car Tools Vocabulary (I)Document6 pagesThe Car Tools Vocabulary (I)Abdi AvalosNo ratings yet

- Tapping Procedures: MACH 112: Cutting Tools & MeasurementDocument14 pagesTapping Procedures: MACH 112: Cutting Tools & MeasurementG. Dancer GhNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument3 pagesMaryland Metrics - Thread Data ChartsbalaNo ratings yet

- Fastbind EliteXT SPDocument16 pagesFastbind EliteXT SPLidograf Used Printing MachinesNo ratings yet

- Whitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)Document2 pagesWhitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)aldoNo ratings yet

- Catalogo de Equipos de Medicion de Roscas 2Document27 pagesCatalogo de Equipos de Medicion de Roscas 2HERNANDO CASTILLONo ratings yet

- All in One MC 50 (2023)Document98 pagesAll in One MC 50 (2023)YashuNo ratings yet

- Metric Thread Size Chart: Product TableDocument5 pagesMetric Thread Size Chart: Product TableAan KurniawanNo ratings yet

- Machinery's Handbook 28 Edition - WHITWORTH THREADSDocument3 pagesMachinery's Handbook 28 Edition - WHITWORTH THREADSPatricia Carolina LimaNo ratings yet

- Screws SpecificationDocument4 pagesScrews SpecificationwozuirenNo ratings yet

- Pricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmDocument6 pagesPricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmasriNo ratings yet

- British Standard Whitworth - Wikipedia, The Free EncyclopediaDocument2 pagesBritish Standard Whitworth - Wikipedia, The Free EncyclopediaIvan DuncanNo ratings yet

- Blank Diameter Before Rolling ThreadDocument2 pagesBlank Diameter Before Rolling ThreadQA LAB ISMNo ratings yet

- Linde All Parts NumbersDocument1,944 pagesLinde All Parts NumbersEMRE ARSLAN100% (1)

- Rdca Rdce: Racc. Di Controllo ' UNF / MetricoDocument1 pageRdca Rdce: Racc. Di Controllo ' UNF / MetricoMichael AkhramovichNo ratings yet

- BSP - BSPT Thread Chart - British MetricsDocument1 pageBSP - BSPT Thread Chart - British MetricsvandanaNo ratings yet

- DORMER Product Selector: Tool Recommendation Cutting DataDocument1 pageDORMER Product Selector: Tool Recommendation Cutting DataskidamdnevnoNo ratings yet

- Fastener Weight & Count ChartDocument12 pagesFastener Weight & Count Chartsudarshan pugaliaNo ratings yet

- Power Screw ReportDocument15 pagesPower Screw ReportTanvesh PatilNo ratings yet

- Hex BoltsDocument13 pagesHex BoltsSandeep SNo ratings yet

- Screw Thread TerminologyDocument7 pagesScrew Thread TerminologyAmin SalahNo ratings yet

- Socket Set Screw TypesDocument1 pageSocket Set Screw TypestylerstearnsNo ratings yet

- Juki AMS-210A PGM-1Document52 pagesJuki AMS-210A PGM-1Marco MatosNo ratings yet

- Dimensions of Metric Threads According ISO 724Document12 pagesDimensions of Metric Threads According ISO 724Guillermo GuzmánNo ratings yet

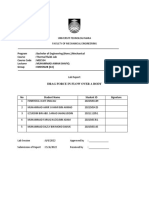

Bolts and Power Screws - Long

Bolts and Power Screws - Long

Uploaded by

Ameeh TorionOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolts and Power Screws - Long

Bolts and Power Screws - Long

Uploaded by

Ameeh TorionCopyright:

Available Formats

Bolts and Power Screws Machine Design 2

are needed or where vibration is present.

Bolts

major diameter

mean / pitch diameter

crest minor diameter

A bolt is a metal rod with a head on one end,

often hexagonal and a screw thread at the other to take a root

nut. (A stud is a rod threaded on both ends.) The purpose

of a bolt is to clamp two or more parts together if the pitch

parts require easy dismantling. The clamping load stret-

ches or elongates the bolt, the load is obtained by twisting

the nut until the bolt has elongated almost to the elastic thread

limit. If the nut does not loosen, this bolt tension remains angle, 2

as a preload or the clamping force.

diameter for

flanks stress area

Types of Bolts

machine bolt stud bolt Forms of Threads

eye bolt U bolt

stove bolt cap screw

set screw V-thread

h = 0.866 P

Bolt Nomenclature Sellers screw thread

h = 0.6403 P

Hexagonal Head Bolt

Whitworth thread

head, usu. hexagonal

30 h = 0.6403 P

grip radius Sellers square thread

length h = 0.4375 P

shank or unit

runout

thread 29° Acme thread

length threaded section h = 0.5 P

Buttress thread

h = 0.75 P

fine thread

nut

60° V-thread

washer

The square, the Acme and the buttress threads

Stud bolt cylinder head are used for power screws, being more efficient than the

60-degree Sellers thread. The square thread has the

cylinder block highest efficiency but is comparatively costly to make, and

coarse thread adjustment for wear is difficult. The Acme thread is not so

costly, and adjustment for wear can be accomplished by

using nuts split lengthwise; hence it is used for power

drives where there must be little or no backlash, such as

Designation of Bolts feed screws and lead screws of machine tools. Its

efficiency is less than that of the square thread. When the

Unified threads are specified by stating the power transmission is in one direction only, the buttress

nominal major diameter, the number of threads per inch, thread is used, the flat driving side retaining the high

and the thread series. efficiency of the square thread, and the sloping side

1/8" – 40 UNC permitting adjustment by means of a split nut.

Metric threads are specified by writing the

nominal major diameter in mm and pitch in mm, in that

Definition of Terms

order

M12 x 1.75 crest – top surface of connecting the two sides (flanks) of

the thread

depth of thread – the distance between the root and the

Types of Threads crest of a thread measured perpendicular to the

axis of the bolt

UNC (Unified National Coarse) is for general use grip – of a bolt connection is the total thickness of the

UNF (Unified National Fine) is frequently used in clamped material including the washers if there are

automotive and aircraft work and where fine adjustment is any

required. lead – the distance the nut moves parallel to the screw

UNEF (Unified National Extra Fine) is used in axis when the nut is given one turn. For a single

aeronautical equipment and where very fine adjustment is threaded screw, the lead is the same as the pitch.

required. left-hand thread – a screw thread that requires counter-

clockwise rotation to tighten.

The fine thread is used where greater strength is major diameter – the outside or largest diameter of a

required at the root of the threads, but the coarse thread screw thread. Also called the nominal diameter.

is desirable where the material around a tapped hole is the minor diameter – the smallest diameter of a screw

weaker. The fine thread is desirable for fastenings requir- thread and is commonly called the root diameter.

ing fine adjustments or where vibration is present. The multiple-threaded product – one having two or more

extra fine thread is suitable for tough, strong materials threads cut beside each other. A double-

and is used in thin light sections where fine adjustments threaded screw has a lead equal to twice the

1 Patrick D. Sta. Maria / August 15, 2017

Bolts and Power Screws Machine Design 2

pitch, a triple-threaded screw has a lead equal

to three times the pitch.

pitch – the distance between adjacent thread forms

measured parallel to the thread axis. It is also the

reciprocal of the number of threads per inch in the

English system.

pitch diameter – the mean of the major and minor

Power Screws

diameters. It is an imaginary diameter that passes

through the thread at the point where the width of

the groove and the threads are equal, also known The screw is an inclined plane wrapped around a

as the mean diameter cylinder in such a way that the height of the plane is

pre-tension/bolt pre-load – the clamping force of the parallel to the axis of the cylinder. If the screw is formed

bolt. It is produced by twisting the nut, thus on the internal surface of a hollow cylinder, it is called a

stretching the bolt. nut. When force is applied to raise a weight or overcome

proof load – the maximum load (force) a bolt can with- resistance by means of a screw and nut, either the screw

stand without acquiring a permanent set. or the nut may be fixed, the other being moveable. The

proof strength – the quotient of the proof load and the force is generally applied at the end of a wrench or lever

tensile stress area arm, or at the circumference of a wheel.

All threads are made according to the right hand rule

unless otherwise noted. Power screws are screws that are used to move

right-hand thread – a screw thread that requires clock- weights and machine parts. They provide a means of

wise rotation to tighten. obtaining a large mechanical advantage in such applica-

root – bottom surface connecting the two sides of the tions as screw jacks, clamps and presses. Depending on

thread the application, power screw uses either the square

size – the nominal major diameter of the screw thread, when higher efficiency is required or buttress

stress area – the area of an imaginary circle whose thread, when adjustment of the nut to prevent backlash is

diameter is the mean of the pitch and minor necessary.

diameters. This area is used for the purpose of

computing the tensile strength. Helix angle, x

stud bolt – a bolt having thread on both ends

The helix angle is related to the lead and the

Note – Many tensile tests of threaded rods have mean diameter by the equation

shown that an unthreaded rod having a diameter equal to

the mean of the pitch diameter and minor diameter will L L

tan x= Eq. 1

have the same tensile strength as the threaded rod. The π Dm

area of this unthreaded rod is called the tensile stress Dm

area of the threaded rod.

Dm – mean diameter of the screw

Tabulated data on threads for nominal size, Dm = D – h

threads per inch, minor diameter and stress area. Dm = d + h

L – lead, m

Table 6-1 p. 130 Doughtie and Vallance x – helix angle, degrees

Table AT14 Faires

Lead is the distance the screw advances in one

turn.

Bolt Formula

Dm L = pitch for single-threaded screw

Mean Diameter L = 2P for double-threaded screw

1

Dm= 2 ( D +d ) d Linear velocity is the distance the screw moves

D in its axis as it is rotated

Diameter of the Stress Area

Linear velocity = (rotational speed)(lead)

1

Ds= 2 ( Dm+d ) Ds W

DO

d – inside diameter, m thread

D – outside diameter, m d

Dm – mean diameter, m

Ds – diameter for stress area Dm x

Pitch

Bolt Deformation Dm

FL SL

δ= δ=

AE E

δ – deformation/elongation, m

A – stress area, m2 DC collar

E – modulus of elasticity

30 Mpsi, 206.84 GPa for steel

28 Mpsi, 193.05 GPa for wrought iron

F – clamping force, N Force Required to Raise the Load

L – length of bolt, m

N

R 2 N2 f 2

R

x

FR = R sin (φ + x)

W = R cos (φ + x)

x FR

dividing FR by W

FR / W = tan (φ + x) f

W

FR = W tan (φ + x)

Breaking down the tangent part

2 Patrick D. Sta. Maria / August 15, 2017

Bolts and Power Screws Machine Design 2

tan ϕ+ tan x

tan (ϕ+ x )= using tan x = L / πDm

[ ]

1−tan ϕ tan x

cos φ L

where tan φ = f / N = μ μ+

WD m π Dm

μ+tan x T F=

tan ( ϕ+ x )= 2 μ L

1−μ tan x cos φ−

W ( μ+tan x ) π Dm

F R= Eq. 2

1−μ tan x

Force Required to Lower the Load

T F =W

2 [

Dm πμ Dm +cos φ L

π D m cos φ−μ L ]

N R N R Torque required in lowering the load

2

R N f 2 2

x

f

x

T F =W [

Dm μ−cos φ tan x

2 cos φ+μ tan x ] Eq. 5

[ ]

x

FL Dm πμ D m −cos φ L

T F =W

2 π Dm cos φ+ μ L

W

where : Dm = D – h

FL = R sin (φ – x) or : Dm = d + h

W = R cos (φ – x)

FL = W tan (φ – x) Φ – half of thread angle

tan ϕ−tan x μ – coefficient of thread friction

tan (ϕ−x )=

1+tan ϕ tan x d – root diameter of the screw, m

W ( μ−tan x ) D – outer diameter, m

F L= Eq. 3 Dm – mean diameter, m

1+μ tan x L – lead, m

x – helix angle of the screw W – axial force carried by the screw, N

φ – angle of the resultant force of the friction TF – torque required to overcome friction on the

and the normal force screw thread

μ – coefficient of thread friction

FL – force required to lower the load, N The computed torque required to lower the load

FR – force to raise the load, N may either be positive or negative. If the torque is posi-

W – axial force carried by the screw, N tive, work must be done to lower the load. If the torque is

negative, specifically, the quantity (μ – cos ϕ tan x), the

To calculate the torque required to raise or lower axial load alone will cause rotation. In this case, the screw

a load, the above equations for the force are multiplied by is said to be overhauling.

the mean radius (0.5 Dm) of the screw.

Thread Angles and Height

A self-locking power screw is obtained whenever Type angle, Φ cos Φ h

the coefficient of thread friction is equal to or greater than acme 14.5° 0.9681 0.5 P

the tangent of the helix angle. square 0° 1.0000 7/16 P

v-thread 30° 0.8660 0.866 P

μ ≥ tan x

Assuming that the force diagram above for

Collar Friction

lowering the axial load is drawn to scale, the screw is self-

locking if R is found to the right of the line of action of W. In computing the total torque in power screw

If R is found to the left of W, the load will lower itself application, collar friction must be taken into considera-

without the application of any force. Power screws used to tion. When the screw is loaded axially, a thrust or collar

lower the load must be self locking. bearing must be employed between the rotating and

stationary members in order to carry the axial component.

When R is found to be on the left of the line of

action of W (as shown below), the equation for FL is TC = 1/2 W μCDC – Eq. 6

becomes DC = 1/2 (D + d) – Eq. 7

W ( tan x−μ)

F L= μC – coefficient of friction on collar

1+μ tan x

which is positive if μ is less than tan x. This is the case d – inside diameter of collar

where the load will lower itself because the value of μ – D – outside diameter of collar

tan x is negative contrary to the requirement of a self- DC – mean diameter of collar

locking screw as stated above. W – axial force carried by the screw

TC – torque required to overcome collar friction

R

N R

N

x Total Torque

FL x In power screw applications where both thread

and collar friction are involved, the external torque is

f

x found by adding the collar torque to the appropriate

equation for thread torque depending on the type of screw

W thread.

T = TF + TC

Thread Torques

Sample Thread Equations

When a torque is applied to the nut by means of a

lever, a gear or any other turning mechanism, the screw American Standard Thread (V thread)

will move forward L units for one revolution of the nut. cos (30°) = 0.8660

raising the load

Torque required in raising the load

T F =W [

D m μ+ cos φ tan x

] Eq. 4

a. T =W

F [

Dm μ+ 0. 8660 tan x

2 0 . 8660−μ tan x

+W

2]

μ C DC

2 cos φ−μ tan x

3 Patrick D. Sta. Maria / August 15, 2017

Bolts and Power Screws Machine Design 2

lowering the load

b. T F =W

[

D m μ−0 .8660 tan x

2 0 . 8660+μ tan x

+W

μ C DC

2 ] Problems

1. A V-thread with a pitch of 3 mm has an outer diam-

ACME Thread cos (14.5°) = 0.9681 eter of 18 mm. It is used as a power screw in con-

raising the load junction with a collar having an outside diameter of

[ ]

D m μ+0. 9681 tan x μ C DC 40 mm and an inside diameter of 20 mm. Find the

c. T F =W +W torque required to raise a load of 400 kg if the

2 0 . 9681−μ tan x 2 coefficient of friction is 0.3 for both the thread and

lowering the load the collar.

d. T F =W

[

Dm μ−0 . 9681 tan x

2 0 . 9681+μ tan x

+W

μC D C

2 ] W = (400 kg)(9.81 N/kg)

– dimensions of the screw

W = 3924 N

h = 0.866 P = (0.866)(3 mm) h = 2.60 mm

trapezoidal Metric Thread cos (15°) = 0.9659 L=P L = 3 mm

raising the load d = D – 2h = 18 – (2)(2.60) d = 12.80 mm

[ ]

D m μ+ 0. 9659 tan x μ C DC Dm = (0.5)(18 + 12.80) Dm = 15.4 mm

e. T F =W +W cos ϕ = cos 30° for V-thread cos ϕ = 0.866

2 0 . 9659−μ tan x 2

lowering the load tan x = L = 3 mm tan x = 0.062

[

Dm μ−0 . 9659 tan x μC D C

]

π Dm (π)(15.4 mm) x = 3.548°

f. T F =W +W – torque for friction

2 cos

square thread 0 . 9659+μ

(0°) = 1tan x 2 Tf = WDm μ + cos ϕ tan x

raising the load 2 cos ϕ – μ tan x

[ ]

Dm μ+(1 )(tan x ) μ D Tf = (3924 N)(15.4 mm) 0.3 + (0.866)(0.062)

g. T =W

F +W C C 2 0.866 – (0.3)(0.062)

2 1−μ tan x 2 Tf = 12.611 N-m

lowering the load – collar friction

[ ]

D μ−(1)( tan x ) μ D Dc = (0.5)(40 + 20) Dc = 30 mm

h. T F =W m +W C C Tc = 0.5 W μCDC

2 1+μ tan x 2 Tc = (0.5)(3924 N)(0.3)(30 mm) Tc = 17.658 N-m

– total friction

Power of a Power Screw T = 12.611 N-m + 17.658 N-m T = 30.269 N-m

– screw efficiency

Input to the screw Pi = 2π Tf e = WL = (3924 N)(3 mm)

Output of the screw Po = WV 2π T (2)(π)(30.269 N-m) e = 6.1897 %

W – force carried, N e = 0.5W Dm tan x / T

V – vertical velocity of the weight, m/s e = (0.5)(3924 N)(15.4 mm)(0.062)

30.27 N-m e = 6.1887 %

– using tan x = 0.062 and cos ϕ = 0.866

Efficiency of the Screw Thread e= (tan x)(cos ϕ – μ tan x)

cos ϕ tan x + μ + μC DC (cos ϕ – μ tan x)

Efficiency is the ratio of the useful work to the Dm

input work. e= (0.062)[0.866 – (0.3)(0.062)]

work output

efficiency= (0.866)(0.062) + 0.3

work input + [(0.3)(30)/15.40](0.866 – (0.3)(0.062)]

The efficiency of a screw thread is the ratio of the e =6.1889

torque required to raise the load without friction to the

torque required when friction is considered. For a screw,

the general formula is

WL WV 2. A triple-threaded square power screw with a root

e= or e= – Eq. 8 & 9 diameter of 50 mm and a pitch of 12 mm is used in

2 πT 2 π Tf

conjunction with a collar with an outer diameter of

For a screw with a given type of thread, the 100 mm and an inner diameter of 60 mm. Find the

formula is derived as follows. From force needed to raise a 15-kN load if the operating

WL

and L force is applied at a radius of 0.8 m. The coefficient

TT = tan x=

2π π Dm of friction is 0.2 for both the thread and the collar.

the torque required to lift a load on a screw with 100%

efficiency is – dimensions of the screw

TT = (1/2) WDm tan x h = 7/16 P = (7/16)(12 mm) h = 5.25 mm

L = 3P = (3)(12 mm) L = 36 mm

Considering friction, both in the screw thread and D = d + 2h = 50 + (2)(5.25) D = 60.50 mm

collar, the torque is given by Dm = d + h = 50 + 5.25 Dm = 55.25 mm

[ ]

D m cosφ tan x + μ DC cos ϕ = cos 0° square thread cos ϕ = 1

T =W +Wμ C tan x = L = 36 mm tan x = 0.2074

2 cosφ−μ tan x 2 π Dm (π)(55.25 mm) x = 11.717°

Efficiency, therefore, is the ratio T/TF: – torque for thread friction

Dm

W tan x Tf = WDm μ + cos ϕ tan x

T 2 2 cos ϕ – μ tan x

=

TF D m cos φ tan x+ μ μ C DC Tf = (15 kN)(55.25 mm) 0.2 + (1)(0.2074)

W +W

2 cos φ−μ tan x 2 2 1 – (0.2)(0.2074)

tan x Tf = 176.122 N-m

e= – another solution

cos φ tan x + μ μ C D C – Eq. 10

+ Tf = WDm πμ Dm + cos ϕ L

cos φ−μ tan x Dm 2 πDm cos ϕ – μ L

Tf = (414.375 N-m) (0.2 π)(55.25 mm) + (1)(36 mm)

(π)(55.25 mm)(1) – (0.2)(36 mm)

Tf = 176.125 N-m

4 Patrick D. Sta. Maria / August 15, 2017

Bolts and Power Screws Machine Design 2

radius of collar to be 45 mm and a coefficient of

– collar friction thread friction of 0.15, determine the weight to be

Dc = (0.5)(100 + 60) Dc = 80 mm raised and the efficiency of the screw. Use a double-

Tc = 0.5 W μCDC threaded rod.

Tc = (0.5)(15 kN)(0.2)(80 mm) Tc = 120 N-m

– total friction

T = 176.122 N-m + 120 N-m T = 296.122 N-m 6. A square-threaded screw has an efficiency of 65%

– force required when raising a load. The coefficient of thread friction

F = T = 296.122 N-m is 0.15 while collar friction is negligible. The pitch dia-

r 0.8 m F = 370.153 N meter of the screw is 70 mm. When lowering a load,

– screw efficiency a uniform velocity is maintained by a brake mounted

e = WL = (15 kN)(36 mm) on a screw. If the load is 90 kN, what torque must be

2π T (2)(π)(296.122 N-m) e = 29.02 % exerted by the brake?

e = 0.5W Dm tan x / T

e = (0.5)(15 kN)(55.25 mm)(0.2074)

296.122 N-m e = 29.02 % 7. Find the power and the rpm required in lifting 18 kN

(~1.83 MT) vertically at a rate of 50 mm/s using a

60-mm (OD) ACME threaded power screw. The screw

3. A single square-threaded power screw is to raise a is to be double-threaded with a pitch of 15 mm. The

load of 100 kN. The screw has a major diameter of friction radius of the collar is to be 50 mm and the

36 mm and a pitch of 6 mm. The coefficient of thread coefficient of friction are 0.10 for the threads and

and collar friction are 0.13 and 0.10 respectively. If 0.15 for the collar.

the collar frictional diameter is 90 mm and the screw

rotates once every second, find the efficiency of the

screw and the power to operate it.

4. A sluice gate weighing 50,000 kg is to be raised and

lowered using two acme-threaded power screws (h =

0.5p, ϕ = 14.5°). The screws are to be double-

threaded with a pitch of 24 mm and an outside dia-

meter of 80 mm. A collar with a mean diameter of

120 mm is used to carry the load on each screw.

Friction on the thread and collar are 0.14 and 0.05

respectively. What is the required torque on each

screw to raise the gate? If the gates are to be raised

and lowered at the rate of 0.01 m/s, at what rate

should the screws be rotated? What is the efficiency

of the screws?

– dimensions of the screw

h = 0.5 P = (0.5)(24 mm) h = 12 mm

L = 2P = (2)(24 mm) L = 48 mm

Dm = D – h = 80 – 12 Dm = 68 mm

cos ϕ = cos 14.5° acme thread cos ϕ = 0.9681

tan x = L = 48 mm tan x = 0.2247

π Dm (π)(68 mm) x = 12.663°

– force on each screw

W = (25,000 kg)(9.81 N/kg) W = 245.25 kN

– torque for thread friction

Tf = WDm μ + cos ϕ tan x

2 cos ϕ – μ tan x

Tf = (245.25 kN)(68 mm) 0.14 + (0.9681)(0.2247)

2 0.9681 – (0.14)(0.2247)

Tf = 3182.946 N-m

– total friction

Tc = 0.5 W μCDC

Tc = (0.5)(245.25 kN)(0.05)(120 mm)

Tc = 735.75 N-m

T = 3182.946 + 735.75 T = 3918.696 N-m

– rpm required to raise the gate

N = (10 mm/s)(60 s/min)

48 mm/rev N = 12.5 rpm

– efficiency of the screw

e = WL = (245.25 kN)(48 mm)

2π T (2π)(3918.696 N-m) e = 47.811 %

e = 0.5W Dm tan x / T

e = (0.5)(245.25 kN)(68 mm)(0.2247)

3918.696 N-m e = 47.813 %

– using power required by the screw

Pin = (2π)(3918.696 N-m)(12.5/60 r/s)

Pin = 5129.561 W

– and the power output of the screw

Pout = (245.26 kN)(0.01 m/s) Pout = 2452.5 W

e = 2452.5/5129.561 e = 47.811 %

5. A square thread screw of 50 mm outside diameter is

used to raise a load. The nut makes one turn per cm

of axial travel. A force of 50 kg is applied at the end

of a 1-m wrench used on a nut. Assuming a mean

5 Patrick D. Sta. Maria / August 15, 2017

You might also like

- Propeller and Propfan: NoiseDocument64 pagesPropeller and Propfan: NoiseWouterr GNo ratings yet

- Versaworks ManualDocument36 pagesVersaworks ManualMartinNo ratings yet

- GPRP Pro Setup and Tuning Guide PDFDocument46 pagesGPRP Pro Setup and Tuning Guide PDFmohnaserNo ratings yet

- EMF Assignment1Document5 pagesEMF Assignment1Ahtasham ArshadNo ratings yet

- Budgeting Exercise 03Document7 pagesBudgeting Exercise 03ERIK ACEVEDO ESCOBEDONo ratings yet

- Instructions For Paper Submission of Form FDA 2541eDocument41 pagesInstructions For Paper Submission of Form FDA 2541eVân Nguyễn Trương TuyếtNo ratings yet

- Block Port v1Document14 pagesBlock Port v1Ariel OneCHEENo ratings yet

- Example of Spot Speed StudyDocument9 pagesExample of Spot Speed StudySivaruban FrancisNo ratings yet

- ROVHYDocument77 pagesROVHYXyriz Paz EstrelladoNo ratings yet

- Tilak Slides PDFDocument72 pagesTilak Slides PDFDarsh MenonNo ratings yet

- Linear Actuator-ThomsonDocument168 pagesLinear Actuator-ThomsonANTON NEAGUNo ratings yet

- OptistructDocument85 pagesOptistructSahithyananda ShashidharNo ratings yet

- Small Scale Wind Tunnel Testing of Model PropellersDocument10 pagesSmall Scale Wind Tunnel Testing of Model PropellersClaus WehmannNo ratings yet

- Effective Bulk Modulus PHD Thesis PDFDocument177 pagesEffective Bulk Modulus PHD Thesis PDFDizzixxNo ratings yet

- Computational Modelling For Cavitation and Tip Vortex FlowsDocument115 pagesComputational Modelling For Cavitation and Tip Vortex FlowsQianZHNo ratings yet

- NECS 0202T-0612T Technical BulletinDocument42 pagesNECS 0202T-0612T Technical BulletinVictor AANo ratings yet

- DissertationDocument82 pagesDissertationCoCoNo ratings yet

- DACO Occupational Safety ManualDocument47 pagesDACO Occupational Safety Manualabdullah shafeiNo ratings yet

- Icar Institute ProfileDocument214 pagesIcar Institute ProfilerakeshalleNo ratings yet

- Updated List of Approved ART Clinics04082021Document72 pagesUpdated List of Approved ART Clinics04082021ChandanNo ratings yet

- Asaan Movers Thesis 7.0Document65 pagesAsaan Movers Thesis 7.0Qasim KhanNo ratings yet

- Optimizing Gear Ratio Selection For Lap Performance: Vehicle ModelsDocument9 pagesOptimizing Gear Ratio Selection For Lap Performance: Vehicle ModelsRITESH RATHORENo ratings yet

- Camd Manual18me36a FinalDocument44 pagesCamd Manual18me36a FinalDANISH ME-18-40No ratings yet

- Unit 1 - IntroductionDocument33 pagesUnit 1 - IntroductionRavi KantNo ratings yet

- RPP 2021 - Project Guidelines and Work PackagesDocument25 pagesRPP 2021 - Project Guidelines and Work PackagespintuNo ratings yet

- 1 s2.0 S0029801822002840 MainDocument13 pages1 s2.0 S0029801822002840 Main刘五六No ratings yet

- RADIOSS 2017 Tutorials and ExamplesDocument947 pagesRADIOSS 2017 Tutorials and ExamplesRanjit PatilNo ratings yet

- Grammar - Reported SpeechDocument18 pagesGrammar - Reported SpeechArpithaNo ratings yet

- Alex 123 EditedDocument90 pagesAlex 123 EditedabeNo ratings yet

- DR Ganesh Patil Medical StatisticsDocument77 pagesDR Ganesh Patil Medical StatisticsKaushal PatelNo ratings yet

- Hindustan TimesDocument20 pagesHindustan TimesRavindra Varma PvsNo ratings yet

- John ResearchDocument109 pagesJohn ResearchJo NipseyNo ratings yet

- Biochemistry Summary NotesDocument98 pagesBiochemistry Summary NotesPatricia EspirituNo ratings yet

- Bài tập tự động hóa sản xuất - 0001-0001Document1 pageBài tập tự động hóa sản xuất - 0001-0001Minh NhậtNo ratings yet

- Design Final ProjectDocument41 pagesDesign Final ProjectmagnifcoNo ratings yet

- WAVE Tutorial 001Document46 pagesWAVE Tutorial 001Premkumarr SanthanammNo ratings yet

- A Review On Planning, Configurations, Modeling and Optimization Techniques of Hybrid Renewable Energy Systems For Off Grid ApplicationsDocument21 pagesA Review On Planning, Configurations, Modeling and Optimization Techniques of Hybrid Renewable Energy Systems For Off Grid Applicationsel_ruso__83100% (1)

- Optimal Baffle DesignDocument16 pagesOptimal Baffle DesignJustine HauptNo ratings yet

- CS2252 NotesDocument196 pagesCS2252 NotesANBALAGHI DaddyNo ratings yet

- Nara Bassinet Maintenance ManualDocument46 pagesNara Bassinet Maintenance ManualAnonymous KiraNo ratings yet

- ROBOTICS. Application Manual PROFINET Controller - DeviceDocument88 pagesROBOTICS. Application Manual PROFINET Controller - DevicebNo ratings yet

- Lecture 7Document12 pagesLecture 7MohamedNo ratings yet

- Technical Specifications: Hydraulic Mining ShovelDocument10 pagesTechnical Specifications: Hydraulic Mining ShovelOrso OsvaldNo ratings yet

- DURBIN MEDICAL SUPPLY CATALOGUE Consumables and General SuppliesDocument22 pagesDURBIN MEDICAL SUPPLY CATALOGUE Consumables and General SuppliesAlexander Kwaitota100% (1)

- Novak Thesis 2019Document132 pagesNovak Thesis 2019Hossein MalekinejadNo ratings yet

- Digital-Alternate ChannelDocument146 pagesDigital-Alternate ChannelBhaskar GarimellaNo ratings yet

- Military TechDocument15 pagesMilitary TechAbel TayeNo ratings yet

- Jeecs 20 3 0310021Document16 pagesJeecs 20 3 0310021rosca raulNo ratings yet

- ECSS E 30part5.1a (2april2002) PDFDocument72 pagesECSS E 30part5.1a (2april2002) PDFAndreeNo ratings yet

- Bearing LifetimeDocument164 pagesBearing LifetimeOscar Orlando CuervoNo ratings yet

- Andersson-Valves Contribution To System DampingDocument25 pagesAndersson-Valves Contribution To System Dampingsivaraman jaganathanNo ratings yet

- Drag Force in Flow Over A Body Full ReportDocument25 pagesDrag Force in Flow Over A Body Full Reportfaruq haziqNo ratings yet

- Material Drive Control Systems For Wheel LoadersDocument20 pagesMaterial Drive Control Systems For Wheel LoadersJerson T. Altovar100% (1)

- DFM SK DFM DFM I Operation ManualDocument105 pagesDFM SK DFM DFM I Operation ManualBrion Bara IndonesiaNo ratings yet

- Infineon EPS User ManualDocument42 pagesInfineon EPS User Manualacmilan4eva1899No ratings yet

- Main Ngoài Ngáng DceDocument16 pagesMain Ngoài Ngáng DceCao LanNo ratings yet

- API 650 Manhole Torque ValuesDocument2 pagesAPI 650 Manhole Torque ValuesJadon TheophilusNo ratings yet

- Automobile ModuleiiDocument96 pagesAutomobile ModuleiinameNo ratings yet

- Eme PDFDocument7 pagesEme PDFprathaNo ratings yet

- Bolts (Screws) and Nuts: External Thread Internal ThreadDocument8 pagesBolts (Screws) and Nuts: External Thread Internal ThreadLanugan, Jenkhen B.No ratings yet

- TORION - Progress Report #1Document5 pagesTORION - Progress Report #1Ameeh TorionNo ratings yet

- ConEngg TorionDocument1 pageConEngg TorionAmeeh TorionNo ratings yet

- Quiz I - PumpsDocument1 pageQuiz I - PumpsAmeeh TorionNo ratings yet

- Quiz 2Document1 pageQuiz 2Ameeh TorionNo ratings yet

- Lesson 2 - Principles of ThermodynamicsDocument10 pagesLesson 2 - Principles of ThermodynamicsAmeeh TorionNo ratings yet

- ConeggDocument1 pageConeggAmeeh TorionNo ratings yet

- Vacuum Cooling For The Food IndustryDocument11 pagesVacuum Cooling For The Food IndustryAmeeh TorionNo ratings yet

- Shaft Design LongDocument5 pagesShaft Design LongAmeeh TorionNo ratings yet

- RA 115350 MECHANICAL ENGINEER Rosales Pangasinan 8 2022 With RemindersDocument24 pagesRA 115350 MECHANICAL ENGINEER Rosales Pangasinan 8 2022 With RemindersAmeeh TorionNo ratings yet

- Bonus Rules and CalcuDocument7 pagesBonus Rules and CalcuAmeeh TorionNo ratings yet

- Improvement of The Vacuum Cooling System For Biodiesel ProductionDocument7 pagesImprovement of The Vacuum Cooling System For Biodiesel ProductionAmeeh TorionNo ratings yet

- Friction Clutches - LongDocument4 pagesFriction Clutches - LongAmeeh TorionNo ratings yet

- Constants and ConversionsDocument32 pagesConstants and ConversionsAmeeh TorionNo ratings yet

- Brake Design - LongDocument3 pagesBrake Design - LongAmeeh TorionNo ratings yet

- Leaf Spring - LongDocument2 pagesLeaf Spring - LongAmeeh TorionNo ratings yet

- Synthes ScrewsDocument4 pagesSynthes ScrewsviolentmidnightNo ratings yet

- Manual Thread Cutting - Course - Technique For Manual Working of Materials. Trainees' Handbook of Lessons - 7Document7 pagesManual Thread Cutting - Course - Technique For Manual Working of Materials. Trainees' Handbook of Lessons - 7Henrique MarquesNo ratings yet

- US Wall Chart REV 06 2011Document2 pagesUS Wall Chart REV 06 20111DB7Li51Q2cZMNo ratings yet

- Valve Assy, Control, P - N Yy30v00036f1Document3 pagesValve Assy, Control, P - N Yy30v00036f1刘奇雄No ratings yet

- Meritor TP9613P Wheel Stud ID ChartDocument40 pagesMeritor TP9613P Wheel Stud ID ChartScottNo ratings yet

- FAIDocument14 pagesFAIalejandroruiz020697No ratings yet

- The Car Tools Vocabulary (I)Document6 pagesThe Car Tools Vocabulary (I)Abdi AvalosNo ratings yet

- Tapping Procedures: MACH 112: Cutting Tools & MeasurementDocument14 pagesTapping Procedures: MACH 112: Cutting Tools & MeasurementG. Dancer GhNo ratings yet

- Maryland Metrics - Thread Data ChartsDocument3 pagesMaryland Metrics - Thread Data ChartsbalaNo ratings yet

- Fastbind EliteXT SPDocument16 pagesFastbind EliteXT SPLidograf Used Printing MachinesNo ratings yet

- Whitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)Document2 pagesWhitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)aldoNo ratings yet

- Catalogo de Equipos de Medicion de Roscas 2Document27 pagesCatalogo de Equipos de Medicion de Roscas 2HERNANDO CASTILLONo ratings yet

- All in One MC 50 (2023)Document98 pagesAll in One MC 50 (2023)YashuNo ratings yet

- Metric Thread Size Chart: Product TableDocument5 pagesMetric Thread Size Chart: Product TableAan KurniawanNo ratings yet

- Machinery's Handbook 28 Edition - WHITWORTH THREADSDocument3 pagesMachinery's Handbook 28 Edition - WHITWORTH THREADSPatricia Carolina LimaNo ratings yet

- Screws SpecificationDocument4 pagesScrews SpecificationwozuirenNo ratings yet

- Pricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmDocument6 pagesPricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmasriNo ratings yet

- British Standard Whitworth - Wikipedia, The Free EncyclopediaDocument2 pagesBritish Standard Whitworth - Wikipedia, The Free EncyclopediaIvan DuncanNo ratings yet

- Blank Diameter Before Rolling ThreadDocument2 pagesBlank Diameter Before Rolling ThreadQA LAB ISMNo ratings yet

- Linde All Parts NumbersDocument1,944 pagesLinde All Parts NumbersEMRE ARSLAN100% (1)

- Rdca Rdce: Racc. Di Controllo ' UNF / MetricoDocument1 pageRdca Rdce: Racc. Di Controllo ' UNF / MetricoMichael AkhramovichNo ratings yet

- BSP - BSPT Thread Chart - British MetricsDocument1 pageBSP - BSPT Thread Chart - British MetricsvandanaNo ratings yet

- DORMER Product Selector: Tool Recommendation Cutting DataDocument1 pageDORMER Product Selector: Tool Recommendation Cutting DataskidamdnevnoNo ratings yet

- Fastener Weight & Count ChartDocument12 pagesFastener Weight & Count Chartsudarshan pugaliaNo ratings yet

- Power Screw ReportDocument15 pagesPower Screw ReportTanvesh PatilNo ratings yet

- Hex BoltsDocument13 pagesHex BoltsSandeep SNo ratings yet

- Screw Thread TerminologyDocument7 pagesScrew Thread TerminologyAmin SalahNo ratings yet

- Socket Set Screw TypesDocument1 pageSocket Set Screw TypestylerstearnsNo ratings yet

- Juki AMS-210A PGM-1Document52 pagesJuki AMS-210A PGM-1Marco MatosNo ratings yet

- Dimensions of Metric Threads According ISO 724Document12 pagesDimensions of Metric Threads According ISO 724Guillermo GuzmánNo ratings yet