Professional Documents

Culture Documents

pc20tk 1 44 22

pc20tk 1 44 22

Uploaded by

Ryan LeeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pc20tk 1 44 22

pc20tk 1 44 22

Uploaded by

Ryan LeeCopyright:

Available Formats

[4] Assembling

4-1 Soldering

Soldering is important work in assembling the multimeter. Incomplete soldering of parts can cause

a problem by causing the multimeter to fail to operate or malfunction during use. Solder is alloy

with a low melting point, which uses lead and tin as main ingredients to electrically and

mechanically connect metal to metal (a component to a component). Solder wire is solder alloy

formed into wire, which includes flux to ensure and facilitate successful soldering. Flux reduces and

removes oxides on the metal surface to be soldered and improves the affinity between solder and

metal. Precautionary instructions on the soldering work are given below:

1. Remove foreign matter and rust on the surface of the metal to be soldered, by using cloth or

abrasive paper.

2. Control the temperature of the soldering iron.

Use the following criteria to determine whether the temperature of the tip is appropriate:

• Too high temperature: The tip is blackened with oxidization in several minutes and cannot be

coated with solder.

• Too low temperature: Solder melts too slowly and the soldering tip becomes sharp-pointed or

dull-colored.

To control the temperature of a soldering iron that has no automatic temperature control, use a

voltage regulator or change the length of the exposed tip of the soldering iron. In controlling the

temperature with the length of the tip, longer length of the exposed portion decreases the

temperature, while shorter one increases the temperature.

3. If the tip of a soldering iron is dirty or coated with excessive solder, soldering cannot be

performed properly. Use wet cloth or the like to wipe off foreign matter and then carry out

soldering.

4. If the tip is difficult to coat with solder, apply preliminary solder to the tip to ensure efficient

soldering.

Memo: Soldering is work that is done to joint metal to metal by applying solder to the part to be

soldered. Hold the soldering iron tip on the metal surface, wait for the temperature of

the surface to become high enough to melt solder, and then apply solder. This will result

in successful soldering. In other words, feed solder a little later than making the

soldering iron tip contact with the metal surface.

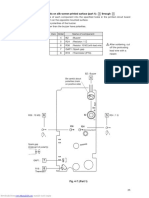

4-2 Soldering procedure

Successful soldering results in forming a crest with a glossy surface.

1. Component with lead wire

1 Soldering

2 3 4 5

iron tip

Lead wire

Substrate

Component

Heat Melt solder by 2-3 Separate solder Wait for solder Separate the

mm in length to spread soldering iron tip

1 second 1 second

Fig. 4-1

20

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Shu/Shi/Shv Dishwasher Troubleshooting Tips: 5551 Mcfadden Avenue Huntington Beach, California 92649Document40 pagesShu/Shi/Shv Dishwasher Troubleshooting Tips: 5551 Mcfadden Avenue Huntington Beach, California 92649Keith Drake100% (3)

- Soldering TutorialDocument15 pagesSoldering Tutorialyrikki100% (1)

- 43LJ5000Document40 pages43LJ5000atomo333No ratings yet

- Through-Hole Soldering - Learn - Sparkfun PDFDocument15 pagesThrough-Hole Soldering - Learn - Sparkfun PDFpolikarpaNo ratings yet

- Presentation Topic:: Soldering and BrazingDocument27 pagesPresentation Topic:: Soldering and BrazingSarath ChandraNo ratings yet

- LA02b - Soldering TechniqueDocument24 pagesLA02b - Soldering TechniqueFairolizwan AbdullahNo ratings yet

- Experiment No. 5: 1. SolderingDocument4 pagesExperiment No. 5: 1. SolderingArun kumar rouniyarNo ratings yet

- Manuale Saldatura WellerDocument0 pagesManuale Saldatura WellerTorero CamomilloNo ratings yet

- SolderingDesoldering 2Document34 pagesSolderingDesoldering 2delfino santosNo ratings yet

- Soldering & De-Soldering: Digital ElectronicsDocument17 pagesSoldering & De-Soldering: Digital ElectronicsMichael Conan MaglaqueNo ratings yet

- Hand Solder Training PDFDocument52 pagesHand Solder Training PDFFatema ChoudhuryNo ratings yet

- Solder Hand Solder Training PDFDocument52 pagesSolder Hand Solder Training PDFftafedeNo ratings yet

- Department of EducationDocument6 pagesDepartment of EducationJay BustamanteNo ratings yet

- Soldering DesolderingDocument17 pagesSoldering Desolderingdelfino santosNo ratings yet

- SOLDERING AND BRAZING Presentation #1Document24 pagesSOLDERING AND BRAZING Presentation #1hastavprantoNo ratings yet

- Joining of MetalsDocument25 pagesJoining of MetalsSaba SaqerNo ratings yet

- 10 LAS WEEk4Document4 pages10 LAS WEEk4Jenelyn RusianaNo ratings yet

- 9) Soldering WeldingDocument23 pages9) Soldering WeldingArchanaNo ratings yet

- Experiment No 4Document3 pagesExperiment No 4M IRFANNo ratings yet

- Soldering NotesDocument7 pagesSoldering NotesAlfred Galea100% (1)

- Group 2 Cpe479Document35 pagesGroup 2 Cpe479Azike valentineNo ratings yet

- WeldingDocument10 pagesWeldingbrownicon38No ratings yet

- Workshop PresentationDocument11 pagesWorkshop Presentationaadityaray2004No ratings yet

- SolderingDocument15 pagesSolderingAnonymous Zx7EG1PaNo ratings yet

- Eme Mod2@Azdocuments - inDocument31 pagesEme Mod2@Azdocuments - inPratham BalikaiNo ratings yet

- Soldering and Brazing PDFDocument4 pagesSoldering and Brazing PDFnaresh naikNo ratings yet

- BrazingDocument5 pagesBrazingmeghrajkadamNo ratings yet

- Week No 3Document6 pagesWeek No 3surajit biswasNo ratings yet

- Assemble Information SheetDocument18 pagesAssemble Information SheetLeon AtsilegnaveNo ratings yet

- Basic Mechanical - Engineering-Soldering Brazing and WeldingDocument10 pagesBasic Mechanical - Engineering-Soldering Brazing and WeldingRavichandran GNo ratings yet

- Welding Class 1Document73 pagesWelding Class 1omkardashetwarNo ratings yet

- BME Joining ProcessesDocument11 pagesBME Joining ProcessesalysonmicheaalaNo ratings yet

- Welding DefectDocument33 pagesWelding DefectabdoNo ratings yet

- Soldering, Brazing & WeldingDocument52 pagesSoldering, Brazing & WeldingChandrakantha K100% (1)

- Elements of Mechanical Engineering-CompliedDocument10 pagesElements of Mechanical Engineering-CompliedzingadayNo ratings yet

- Learning ObjectivesDocument19 pagesLearning Objectivesfred gallardoNo ratings yet

- What Is SolderingDocument11 pagesWhat Is SolderingRanuj HazarikaNo ratings yet

- Soldering, Brazing and Welding in DentistryDocument36 pagesSoldering, Brazing and Welding in DentistryAmniAzmiNo ratings yet

- 7.15a - Welding, Brazing, Soldering and BondingDocument22 pages7.15a - Welding, Brazing, Soldering and BondingAslam AwanNo ratings yet

- Soldering March IntakeDocument49 pagesSoldering March IntakeoriverbmwasotemwasoteNo ratings yet

- Weld DefectsDocument9 pagesWeld DefectsshankarNo ratings yet

- Soldering Basic GuideDocument6 pagesSoldering Basic GuidechchuanNo ratings yet

- Welding Technology: By: Engr. Elmer B. Dollera, MSMEDocument31 pagesWelding Technology: By: Engr. Elmer B. Dollera, MSMEReuven SioseNo ratings yet

- PCB FabricationDocument3 pagesPCB FabricationAnzari AsNo ratings yet

- How To Solder 0902eDocument26 pagesHow To Solder 0902ebehzadNo ratings yet

- Soldering: What Is The Purpose of Soldering in Electronics?Document54 pagesSoldering: What Is The Purpose of Soldering in Electronics?John Jairo Ayop TadenaNo ratings yet

- Modul CO2 - 2.5Document62 pagesModul CO2 - 2.5icyblaze azriyNo ratings yet

- Experiment 5 (Soldering)Document9 pagesExperiment 5 (Soldering)laibazafar1111No ratings yet

- Chapter 2 - Soldering TechniqueDocument19 pagesChapter 2 - Soldering Techniquefaiz_84100% (1)

- Weld DefectsDocument5 pagesWeld DefectsMark Joseph PagutaNo ratings yet

- Brazing & Soldering: by Ashrav GuptaDocument22 pagesBrazing & Soldering: by Ashrav GuptaAshrav GuptaNo ratings yet

- 7.2 Soldering: Sngce Ece DeptDocument5 pages7.2 Soldering: Sngce Ece DeptSai KiranNo ratings yet

- Fabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringDocument18 pagesFabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringSatish HSNo ratings yet

- Welding Class 2Document22 pagesWelding Class 2omkardashetwarNo ratings yet

- Welding Defect in GTAWDocument19 pagesWelding Defect in GTAWMuhammad Ghiyats100% (1)

- Chapter 8 SolderingDocument19 pagesChapter 8 Solderingarkarminkhant734No ratings yet

- Unit 6 Soldering and BrazingDocument4 pagesUnit 6 Soldering and BrazingRohitNo ratings yet

- MXR Phase 90 Script Pedal ModDocument14 pagesMXR Phase 90 Script Pedal ModInfoMecanicaTaller contactoNo ratings yet

- Mod 7 Book 8 Sheet Metal Work PipelinesDocument71 pagesMod 7 Book 8 Sheet Metal Work Pipelinesranjit prasadNo ratings yet

- Presentasi SMAW 2Document59 pagesPresentasi SMAW 2Surya Lesmana100% (1)

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- pc20tk 1 44 31Document1 pagepc20tk 1 44 31Ryan LeeNo ratings yet

- pc20tk 1 44 30Document1 pagepc20tk 1 44 30Ryan LeeNo ratings yet

- THP SL eDocument2 pagesTHP SL eRyan LeeNo ratings yet

- Goldhofer: Main FeaturesDocument1 pageGoldhofer: Main FeaturesRyan LeeNo ratings yet

- DropdeckDocument2 pagesDropdeckRyan LeeNo ratings yet

- Goldhofer: Main FeaturesDocument1 pageGoldhofer: Main FeaturesRyan LeeNo ratings yet

- Goldhofer: Main FeaturesDocument1 pageGoldhofer: Main FeaturesRyan LeeNo ratings yet

- pc20tk 1 44 25Document1 pagepc20tk 1 44 25Ryan LeeNo ratings yet

- pc20tk 1 44 33Document1 pagepc20tk 1 44 33Ryan LeeNo ratings yet

- pc20tk 1 44 29Document1 pagepc20tk 1 44 29Ryan LeeNo ratings yet

- pc20tk 1 44 28Document1 pagepc20tk 1 44 28Ryan LeeNo ratings yet

- pc20tk 1 44 27Document1 pagepc20tk 1 44 27Ryan LeeNo ratings yet

- pc20tk 1 44 24Document1 pagepc20tk 1 44 24Ryan LeeNo ratings yet

- pc20tk 1 44 15Document1 pagepc20tk 1 44 15Ryan LeeNo ratings yet

- pc20tk 1 44 26Document1 pagepc20tk 1 44 26Ryan LeeNo ratings yet

- pc20tk 1 44 20Document1 pagepc20tk 1 44 20Ryan LeeNo ratings yet

- pc20tk 1 44 23Document1 pagepc20tk 1 44 23Ryan LeeNo ratings yet

- pc20tk 1 44 21Document1 pagepc20tk 1 44 21Ryan LeeNo ratings yet

- pc20tk 1 44 17Document1 pagepc20tk 1 44 17Ryan LeeNo ratings yet

- pc20tk 1 44 18Document1 pagepc20tk 1 44 18Ryan LeeNo ratings yet

- pc20tk 1 44 16Document1 pagepc20tk 1 44 16Ryan LeeNo ratings yet

- pc20tk 1 44 19Document1 pagepc20tk 1 44 19Ryan LeeNo ratings yet

- pc20tk 1 44 14Document1 pagepc20tk 1 44 14Ryan LeeNo ratings yet

- pc20tk 1 44 8Document1 pagepc20tk 1 44 8Ryan LeeNo ratings yet

- pc20tk 1 44 11Document1 pagepc20tk 1 44 11Ryan LeeNo ratings yet

- pc20tk 1 44 12Document1 pagepc20tk 1 44 12Ryan LeeNo ratings yet

- pc20tk 1 44 10Document1 pagepc20tk 1 44 10Ryan LeeNo ratings yet

- pc20tk 1 44 9Document1 pagepc20tk 1 44 9Ryan LeeNo ratings yet

- pc20tk 1 44 13Document1 pagepc20tk 1 44 13Ryan LeeNo ratings yet

- pc20tk 1 44 6Document1 pagepc20tk 1 44 6Ryan LeeNo ratings yet

- Pana Bežični Manujal kx-tcd150FXDocument77 pagesPana Bežični Manujal kx-tcd150FXi4004No ratings yet

- LG TFT-LCD Color Monitor Flatron l1550s-Sn, l1550s-BnDocument29 pagesLG TFT-LCD Color Monitor Flatron l1550s-Sn, l1550s-BnIanmax Adja DehNo ratings yet

- Freund Product BroschDocument24 pagesFreund Product Broscheternal_harpyNo ratings yet

- Toshiba Rd-xv48dtkb SMDocument124 pagesToshiba Rd-xv48dtkb SMmarshall tmNo ratings yet

- Service Manual: Digital Video Camera RecorderDocument478 pagesService Manual: Digital Video Camera RecorderDanNo ratings yet

- Sony CFD-G700CP-G770CP-G-770CPKDocument70 pagesSony CFD-G700CP-G770CP-G-770CPKvideoson100% (1)

- Actual CostDocument51 pagesActual CostanshscribdNo ratings yet

- Experiment 5 SolderingDocument15 pagesExperiment 5 SolderingmtariqanwarNo ratings yet

- Marshall AS100DDocument2 pagesMarshall AS100DBarry StoveNo ratings yet

- E Cat Weller 1Document74 pagesE Cat Weller 1elfrichNo ratings yet

- Philips Bdp-7500b2 SMDocument55 pagesPhilips Bdp-7500b2 SMJose Koc GongoraNo ratings yet

- Chapter 2 - Soldering Techniques PDFDocument21 pagesChapter 2 - Soldering Techniques PDFfaiz_84No ratings yet

- DVD Daewoo Dm-k40Document44 pagesDVD Daewoo Dm-k40Fernando Guamán SimbañaNo ratings yet

- NASA Student Handbook For Hand SolderingDocument125 pagesNASA Student Handbook For Hand SolderingmuratifagaNo ratings yet

- Electrician SEM4 TT PDFDocument260 pagesElectrician SEM4 TT PDFSonul JohnNo ratings yet

- Philips Manual For BillDocument116 pagesPhilips Manual For BilltvshopNo ratings yet

- LG 26lc51 26lc51a - 26lc7r - 26lc7r-Za-Chassis Lp78a ServicemanualDocument38 pagesLG 26lc51 26lc51a - 26lc7r - 26lc7r-Za-Chassis Lp78a ServicemanualC.Rama MurthhyNo ratings yet

- Tool ShopDocument6 pagesTool ShopJiwithe NidahaseNo ratings yet

- E Hakko General PDFDocument97 pagesE Hakko General PDFSilver SelwayneNo ratings yet

- 1.laptop Technician ToolDocument3 pages1.laptop Technician ToolKarthickNo ratings yet

- Final Work Shop Practice IDocument36 pagesFinal Work Shop Practice IAbrhaNo ratings yet

- Manual SONY W55Document58 pagesManual SONY W55Alejandro SebaNo ratings yet

- 32PFL3508 F4Document42 pages32PFL3508 F4memedelarosa100% (1)

- LCD TV: Service ManualDocument30 pagesLCD TV: Service ManualSureshNo ratings yet

- FUNAI Manual de Servicio 39FL753P - 10 (A33T1EP) - External - v1Document44 pagesFUNAI Manual de Servicio 39FL753P - 10 (A33T1EP) - External - v1Pony_37100% (1)

- SCC - Electonics - Q4M2Weeks3-4 - PASSED NO AKDocument18 pagesSCC - Electonics - Q4M2Weeks3-4 - PASSED NO AKLyle Isaac L. IllagaNo ratings yet

- Toshiba D-r160-Sb DVD Video RecorderDocument77 pagesToshiba D-r160-Sb DVD Video RecorderIulian_DNo ratings yet