Professional Documents

Culture Documents

Vautid100 Engl

Vautid100 Engl

Uploaded by

Ramona CrangasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vautid100 Engl

Vautid100 Engl

Uploaded by

Ramona CrangasCopyright:

Available Formats

VAUTID-100

Abras ion Im pact

Tubular Wire and Welding Rod

Hardfacing material for

high abrasion and moderate Corros ion Tem perature

temperatures VAUTID-Material

Characteristics

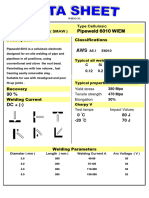

Specification: Tubular wire electrode DIN EN 14700 T Fe 15 g

Welding rod DIN EN 14700 E Fe 15 g

Material type: High-chrome-high-carbon hard alloy on Fe-basis.

Typical material analysis (DIN EN ISO 6847) [%]:

C: 4,5 – Cr: 28 – Fe: Balance

Weld deposit characteristics: VAUTID-100 produces a wear-resistant, austenitic, primary carbide-

containing weld deposit. It is very resistant on abrasion. The material

cannot be flame cut, offers good resistance to scaling and cannot be

machined. The weld deposit exhibits cracks.

Weld deposit properties: Hardness: 1st layer on S235 JRG2: 56-60 HRC

2nd layer on S235 JRG2: 58-62 HRC

Pure welding deposit

(DIN 32525-4): 60-63 HRC

Recommended applications: Recommended particularly for the hardfacing of parts subjected to

strong abrasion and average shock stress, e.g. screws, dredging bucket

front edges, sieves, stirrer blades, sand slingers, top coats on dredger

teeth and crushing rolls.

The application temperatures should not exceed 350°C.

Standard sizes: Tubular wires: Diameters: 1,6 / 2,0 / 2,4 / 2,8 / 3,2 mm

Packing: Mandrels 12,5 kg

Reels 25 kg

Drums 250 kg

Welding rods: Diameters: 3,25 / 4,0 / 5,0 / 6,0 mm

Packing: 5 kg packages

________________________________________________________________________________________

Welding instructions for tubular wires: Welding instructions for welding rods:

VAUTID-100 is welded without inert gas on the VAUTID-100 welding rods can be welded with

+pole (a.c. possible). Weave technique is usual. d.c. on the +pole but also with a.c. The height of

The arc should be held as short as possible and the hardfacing should be limited to 10 mm. It is

the thickness of hard-surfacing deposits should be not necessary to re-dry the electrodes prior to

limited to 10 mm. Preheating decreases the welding.

generation of stress cracking on the hard-facing.

Ø mm Current Voltage (V) Stick out Ø mm Current (A)

3,25 100-120

(A) (mm)

4,0 120-160

1,2 100-220 18-22 20-30 5,0 170-210

1,6 150-270 24-27 20-40 6,0 210-250

2,0 180-300 25-28 25-40

2,4 230-350 26-29 25-50 VAUTID -100 welding rods are high-performance

2,8 260-420 27-29 30-55 electrodes with a deposition rate of 200%.

3,2 290-470 28-30 30-55

Welding positions (EN ISO 6947): PA, PB

VAUTID GmbH

73744 Ostfildern-Ruit P.O.Box 4110 phone +49 711/4404-0 fax +49 711/442039

http://www.vautid.de e-mail: vautid@vautid.de

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Spec Section 05-05-19 For Post-Installed Concrete Anchors Specification Text ASSET DOC LOC 1614384Document8 pagesSpec Section 05-05-19 For Post-Installed Concrete Anchors Specification Text ASSET DOC LOC 1614384Marcus de AssisNo ratings yet

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Vautid 100, Engl 041016Document1 pageVautid 100, Engl 041016Maria TzagarakiNo ratings yet

- VAUTID ASW 145 Engl 041016Document1 pageVAUTID ASW 145 Engl 041016maiquelernNo ratings yet

- UTP AF 7565-Rev1Document1 pageUTP AF 7565-Rev1VIRPOPNo ratings yet

- Utp Af A7Document1 pageUtp Af A7VIRPOPNo ratings yet

- Hardface StaincarbwDocument1 pageHardface StaincarbwMarcos VieroNo ratings yet

- Corwire Katalog YiceDocument54 pagesCorwire Katalog YiceAlexandar Marinkovic100% (1)

- Din 8555Document1 pageDin 8555Kara WhiteNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Supercito E: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageSupercito E: MMA Electrodes C-MN and Low-Alloy Steelsantonio111aNo ratings yet

- Stud Welding Catalogue PDFDocument42 pagesStud Welding Catalogue PDFRajan SteeveNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Pipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionDocument1 pagePipeweld 6010 WIEM E 6010: Type Cellulosic Shield Metal Arc Weld (SMAW) Classifications DescriptionagrinjoshNo ratings yet

- Sus904l 158Document1 pageSus904l 158rinthusNo ratings yet

- Hardface NM oDocument1 pageHardface NM ojohndupNo ratings yet

- Vautid 100Document4 pagesVautid 100emad sabriNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- 70cuni TigDocument3 pages70cuni TigGiannhs SeitaridhsNo ratings yet

- 56 GBDocument1 page56 GBJonathan DiazNo ratings yet

- Coremax H43Document1 pageCoremax H43LIM hoon boonNo ratings yet

- Tencord KB (E 42 4 Z B 42 h5)Document1 pageTencord KB (E 42 4 Z B 42 h5)brunizzaNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Hardface HC oDocument1 pageHardface HC ojohndupNo ratings yet

- Hardface Hc-ODocument1 pageHardface Hc-OTirath TmsNo ratings yet

- Chromecore-430-G Er430Document1 pageChromecore-430-G Er430peymanNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Fincord DB: MMA Electrodes C-MN and Low-Alloy SteelsDocument1 pageFincord DB: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Hardface BN oDocument1 pageHardface BN ol.raickNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- Lastek 90 Ceweld - Croni 29-9 S - 2013-06-27Document1 pageLastek 90 Ceweld - Croni 29-9 S - 2013-06-27Niksa ZekicNo ratings yet

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Document3 pagesDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kNo ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- 1564 Fox Ev 85 ElettrodoDocument1 page1564 Fox Ev 85 ElettrodoAminNo ratings yet

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Document2 pagesUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNo ratings yet

- Welding Wire - MTC - MIG 133Document1 pageWelding Wire - MTC - MIG 133Ranjeet BhureNo ratings yet

- S 23820 ENG Sanicro 60Document2 pagesS 23820 ENG Sanicro 60Koshy JohnNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- LINCOLN Nicromo 60-16Document2 pagesLINCOLN Nicromo 60-16AbdülHak ÖZkaraNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- UTP - UF - DUR600 Rev1Document1 pageUTP - UF - DUR600 Rev1VIRPOPNo ratings yet

- JQ - Yj501-1-Products E71t1 Tianjing FcawDocument5 pagesJQ - Yj501-1-Products E71t1 Tianjing FcawDiego PabonNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Katalogas enDocument20 pagesKatalogas enEman AdelNo ratings yet

- CHW 50C6Document1 pageCHW 50C6scribdsonbaNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- Askaynak - As B-248Document1 pageAskaynak - As B-248Faraj KhalikovNo ratings yet

- Avesta 2205 - MIGDocument1 pageAvesta 2205 - MIGgonzomapsNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- Fisorg-005-0004-R02 - General Terms and Conditions of Purchase For EquipmentDocument22 pagesFisorg-005-0004-R02 - General Terms and Conditions of Purchase For EquipmentRamona CrangasNo ratings yet

- Pages From BPVC - IX-2021Document2 pagesPages From BPVC - IX-2021Ramona CrangasNo ratings yet

- Product Certificate Welding Wire-ModelDocument1 pageProduct Certificate Welding Wire-ModelRamona CrangasNo ratings yet

- Welding Equipment - Annex 6 - DIN 18800Document1 pageWelding Equipment - Annex 6 - DIN 18800Ramona CrangasNo ratings yet

- Schede Acciai Antiusura IngDocument1 pageSchede Acciai Antiusura IngRamona CrangasNo ratings yet

- Vdocument - in - Hanking Molore Smelter Plant Project Lisbonrev1Document25 pagesVdocument - in - Hanking Molore Smelter Plant Project Lisbonrev1Aman EgaNo ratings yet

- Practical Workbook MY-303: Foundry: Principles, Methods & PracticeDocument32 pagesPractical Workbook MY-303: Foundry: Principles, Methods & Practicethodeti babuNo ratings yet

- 132 KV Grid StationDocument14 pages132 KV Grid StationWaqas AhmedNo ratings yet

- FusosDocument49 pagesFusosBruno PaulinoNo ratings yet

- Lost Foam CastingDocument31 pagesLost Foam CastingokicirdarNo ratings yet

- Catalog SoDocument48 pagesCatalog SooichiNo ratings yet

- Presentation On GrindingDocument36 pagesPresentation On GrindingPragyan Agrawal100% (3)

- Atv DVWK A 281 e LibreDocument25 pagesAtv DVWK A 281 e LibrerafapoNo ratings yet

- Types: Piston Rings Cylinder Liners/finned Cylinders AssemblyDocument3 pagesTypes: Piston Rings Cylinder Liners/finned Cylinders Assemblyeng_ebrahim_20000% (1)

- RS Pro Surface Roughness Comparator Composite Set: DatasheetDocument2 pagesRS Pro Surface Roughness Comparator Composite Set: Datasheetcyber service10No ratings yet

- A Review of The Production of Ferromanganese in Blast FurnaceDocument28 pagesA Review of The Production of Ferromanganese in Blast FurnaceJorge MadiasNo ratings yet

- Pengolahan Limbah Cair Industri TahuDocument6 pagesPengolahan Limbah Cair Industri TahuDenni RachmawanNo ratings yet

- Datasheet For Steel Grades Mould Steel 1.4869: 1.4869 Standard NumberDocument2 pagesDatasheet For Steel Grades Mould Steel 1.4869: 1.4869 Standard NumberManoj SNo ratings yet

- Biogas 1Document5 pagesBiogas 1NiegleNo ratings yet

- J-DMS: CHS168.3 (DIA 114.3 X 4.78) CHS114.3 (DIA 219.1 X 8.18) CHS219.1 (DIA 273 X 9.27) CHS273.0Document1 pageJ-DMS: CHS168.3 (DIA 114.3 X 4.78) CHS114.3 (DIA 219.1 X 8.18) CHS219.1 (DIA 273 X 9.27) CHS273.0Mary DenizeNo ratings yet

- TP - Hot Gas - Extrusion - Hot Wedge - CPL - WeldingDocument3 pagesTP - Hot Gas - Extrusion - Hot Wedge - CPL - Weldingmasdipuro simbolonNo ratings yet

- Astm E-1417-PtDocument11 pagesAstm E-1417-PtRamadhan AdityaNo ratings yet

- Crank Case Left Top and Bottom Side FacingDocument24 pagesCrank Case Left Top and Bottom Side FacingBilal AjmalNo ratings yet

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument6 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServicePaulo GalvãoNo ratings yet

- Vimp Theory of Metal Cutting 2Document100 pagesVimp Theory of Metal Cutting 2Harsh PawarNo ratings yet

- Specifications For Painting WorksDocument2 pagesSpecifications For Painting WorksvinodNo ratings yet

- Observaciones Instucciones de Montaje RingmotorDocument2 pagesObservaciones Instucciones de Montaje RingmotorNoname_user989No ratings yet

- (DS - P - 40 - 07-13 Rev. 1A - 07-13) Parker Domnick Hunter Bag FiltersDocument2 pages(DS - P - 40 - 07-13 Rev. 1A - 07-13) Parker Domnick Hunter Bag FiltersRyelfi SessimNo ratings yet

- Food Preparation EquipmentDocument17 pagesFood Preparation EquipmentsnabilNo ratings yet

- Mobil Pegasus 805Document2 pagesMobil Pegasus 805ali zaenal abidinNo ratings yet

- Cameron: 2-1/163.000 and 5.000 FL GA TE VAL VESDocument1 pageCameron: 2-1/163.000 and 5.000 FL GA TE VAL VESElinton SarmientoNo ratings yet

- Varieties and Applications 1: 1.general Steel Materials 3.aluminum Alloy MaterialsDocument1 pageVarieties and Applications 1: 1.general Steel Materials 3.aluminum Alloy MaterialsHari KiranNo ratings yet

- Wide-Lite Effex Series Area Light Brochure 1996Document16 pagesWide-Lite Effex Series Area Light Brochure 1996Alan Masters100% (1)

- CH 1 MPTDocument28 pagesCH 1 MPTmolla biyadgieNo ratings yet