Professional Documents

Culture Documents

Test Oil Compressor #4067 (06-12-22)

Test Oil Compressor #4067 (06-12-22)

Uploaded by

albertoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Oil Compressor #4067 (06-12-22)

Test Oil Compressor #4067 (06-12-22)

Uploaded by

albertoCopyright:

Available Formats

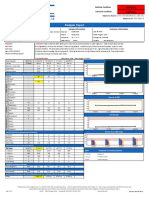

Machine Condition:

NORMAL

Lubricant Condition:

CRITICAL

Inseco

Analysis Report

Lube Type: SULLUBE Serial No.: 201310180016 ATTN: Laika Gonzalez

Compressor MFG: SULLAIR Asset No: 4067 Five Star

Compressor Model: 5510 AC Report: 12/05/2022 Analyst: MMM (8185/120/4)

Problems: ***High Viscosity 40C ***High Water Content ***Excessive Particle Customer Notes:

Count

The viscosity (44.8 cSt) is higher than expected for SULLAIR-SULLUBE and considered abnormal. The viscosity specification for this lubricant is 39 cSt. Typical

causes for higher than expected viscosity are: wrong lubricant indicated, contamination with another product and lubricant degradation. The particle count for

this compressor exceeds the limit (21/18/15) and is considered abnormal. Check for sources of particulate ingression first before changing filters. The level of

water contamination 2.8696% is excessive and considered abnormal. Some sources of water contamination in compressors are: running compressor at a light

load for an extended period, ingression from external sources, cooling system issues.

For questions concerning this report, contact your local authorized Sullair distributor or Sullair service at 1-888-785-5247.

Date Sampled 10/31/22 2/14/22 Acid Number

Lab No Reference 4149545 3483548 1.00

Lube Hours 3342 3670 0.90

0.80

Compressor Hours 23488 20682 0.70

pH (DOW Method) * 0.60

0.50

pH 7.50 7.23 6.67

0.40

Viscosity (Reported in centistokes) ASTM D 445 Mod 0.30

Viscosity @ 40C 38.1 44.8 44.1 0.20

10/31/2022 2/14/2022

Acid Number D974 Mod.

pH

Acid Number 0.06 0.32 0.27

FTIR JOAP Method (Indexing Numbers) IWI-110 7.60

7.20

Oxidation 146 99 111 6.80

P E Alcohol 47 162 158 6.40

6.00

Antiwear 66 48 46

5.60

Other Fluids 323 223 228 5.20

Water Content (a)-ASTM D6304C (b)-IWI-134* (c)-Crackle (d)-IWI-135* (e)-IWI-370* 4.80

4.40

Water % Neg (c) 2.8696 (a) 0.5946 (a) 10/31/2022 2/14/2022

Spectroscopic Analysis (Reported in ppm) ASTM D5185 Mod Viscosity @ 40C

Iron 0 0 5

48.00

Copper 0 2 46 46.00

Lead 0 0 3 44.00

Wear Metals

42.00

Aluminum 0 0 0 40.00

38.00

Tin 0 2 0

36.00

Nickel 0 0 0 34.00

32.00

Chromium 0 0 0 30.00

10/31/2022 2/14/2022

Titanium 0 0 0

Calcium 1 34 127 PC >6 Micron

Magnesium 0 2 4

100,000.00

Additives

Phosphorus 3 12 68

80,000.00

Zinc 0 21 119

60,000.00

Barium 745 325 227

40,000.00

Molybdenum 0 0 0

Silicon 8 1 5 20,000.00

Contam.

Boron 0 16 6 0.00

10/31/2022 2/14/2022

Sodium 2 54 56

Potassium 0 9 0

Particle Count (Reported in particles per ml) ISO 4406.99

ISO CODE 21/18/15 27/24/20 22/21/17

>4 Micron 20000 999999 39853

>6 Micron 2500 99999 15499

>14 Micron 320 9999 1182

>50 Micron 0 99 51

>100 Micron 0 9 3

This test is accredited under the laboratory’s ISO/IEC 17025 accreditation issued by the ANSI-ANAB National Accreditation Board. Refer to certificate and scope of accreditation L2221. (e)

-Estimated sample date. (*) - Not in scope of accreditation. Sullair assumes sole responsibility for the application of and reliance upon results and recommendations reported by Eurofins TestOil,

whose obligation is limited to good faith performance. Samples tested as received.

Page 1 of 1 Eurofins TestOil - 20338 Progress Drive - Strongsville, OH 44149 Lab No. 4149545

You might also like

- ASM-HEMT GaN RF Extraction Demo GuideDocument58 pagesASM-HEMT GaN RF Extraction Demo GuiderexNo ratings yet

- DCT (Dual Clutch Transmission) SystemDocument72 pagesDCT (Dual Clutch Transmission) Systemwilder0l0pez100% (4)

- C++ MCQDocument23 pagesC++ MCQVishal ManeNo ratings yet

- Year 11 Maths Ext 1 2019 Task 1Document9 pagesYear 11 Maths Ext 1 2019 Task 1bailey. sNo ratings yet

- Analyst: Sumico Lube Ici PolyesterDocument4 pagesAnalyst: Sumico Lube Ici PolyesterMalik AbbasNo ratings yet

- Oil Analysis Test Report: Physio-Chemical Properties GraphDocument2 pagesOil Analysis Test Report: Physio-Chemical Properties Graphsachinborkar10094No ratings yet

- Benzyna 4 T Max v2Document1 pageBenzyna 4 T Max v2iflix iflixNo ratings yet

- Untitled 1Document2 pagesUntitled 1sachinborkar10094No ratings yet

- Program Analisa Pelumas Engine Generator SetDocument1 pageProgram Analisa Pelumas Engine Generator SetRio Si MarioNo ratings yet

- Pat - Ide Fan BearingDocument2 pagesPat - Ide Fan BearingJohn Choquemaque MendozaNo ratings yet

- Micro Analysis Report PDFDocument1 pageMicro Analysis Report PDFChalil FachroniNo ratings yet

- Account: Prd/Bombas Address:: L23 Kubota Z482-B-ACP-1 NADocument1 pageAccount: Prd/Bombas Address:: L23 Kubota Z482-B-ACP-1 NABrayan MejiaNo ratings yet

- Marine Test (T2P02347)Document2 pagesMarine Test (T2P02347)jgmanaure3105No ratings yet

- Performance Data: Section: Date: December 2008Document26 pagesPerformance Data: Section: Date: December 2008cesar moraNo ratings yet

- JAYANTI BARUNA-25 - Apr - 2024 - 10 - 05 - 39-100042854Document10 pagesJAYANTI BARUNA-25 - Apr - 2024 - 10 - 05 - 39-100042854BoyNo ratings yet

- Understanding ISO Codes Appearance of Water in Oil: Viscosity Grading SystemsDocument1 pageUnderstanding ISO Codes Appearance of Water in Oil: Viscosity Grading Systemsjuanmanuel_4615958No ratings yet

- C56 FDDocument198 pagesC56 FDneomar BaptistaNo ratings yet

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument11 pagesOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- Oil Analysis Test Report: Physio-Chemical Properties GraphDocument61 pagesOil Analysis Test Report: Physio-Chemical Properties Graphsachinborkar10094No ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- ردول ديكس D236 CU100 P80 P100C (120-130) C15 C18 930 966F 966F2 140G 14G 14H 14M 14M-3 doosan300 966H 972HDocument1 pageردول ديكس D236 CU100 P80 P100C (120-130) C15 C18 930 966F 966F2 140G 14G 14H 14M 14M-3 doosan300 966H 972HMohamed SaiedNo ratings yet

- MCR BW219D-4 With BF6M2012CDocument1 pageMCR BW219D-4 With BF6M2012CKe HalimunNo ratings yet

- DecaneDocument2 pagesDecaneNivasNo ratings yet

- Test Report & Inspection CertificateDocument1 pageTest Report & Inspection CertificateAji HatmantoNo ratings yet

- Pg84234 All PDFDocument49 pagesPg84234 All PDFfaisalnadimNo ratings yet

- Bouri Crude Oil1Document24 pagesBouri Crude Oil1زينب فرجNo ratings yet

- PDS-G500 (ENG) - 220330-임형진 책임님Document2 pagesPDS-G500 (ENG) - 220330-임형진 책임님Jorge NarvaezNo ratings yet

- PDS Poweroil Turbo AWDocument2 pagesPDS Poweroil Turbo AWNitant MahindruNo ratings yet

- D11200ADocument4 pagesD11200AmahendrandsNo ratings yet

- Vehicle Identification: Notes Specified Value Measured ValueDocument5 pagesVehicle Identification: Notes Specified Value Measured ValueПан ТелемонNo ratings yet

- Boilers: Apparel Unit # 01Document1 pageBoilers: Apparel Unit # 01Naveed Ul Qamar MughalNo ratings yet

- A11627SE-04 - CVDS Rev C Technical Specification 840GDocument2 pagesA11627SE-04 - CVDS Rev C Technical Specification 840GMichael Adu-boahenNo ratings yet

- Estandar Disolucion LevoDocument5 pagesEstandar Disolucion LevoBrendapaez3No ratings yet

- Turbonycoil 3570 Sae 60: Piston Aircraft Engine Lubricating OilDocument1 pageTurbonycoil 3570 Sae 60: Piston Aircraft Engine Lubricating OilMahdi Khanfir HachenniNo ratings yet

- Duct AcDocument4 pagesDuct Acjoelaloshius1212No ratings yet

- Resultados - Aceite - Gloria IllapuDocument3 pagesResultados - Aceite - Gloria IllapuDavid Chapoñan PascoNo ratings yet

- A11627SE-08 - CVDS Rev B Technical Specification 840GDocument2 pagesA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenNo ratings yet

- G3516 Engine Test SheetDocument1 pageG3516 Engine Test SheetEdisson SanabriaNo ratings yet

- Pump Selector Program: 2.30.038 / 22.04.25 / F20.05.04 Date: 5/2/2022 2:10:35 PM Created By: Jaime Ocampo CustomerDocument6 pagesPump Selector Program: 2.30.038 / 22.04.25 / F20.05.04 Date: 5/2/2022 2:10:35 PM Created By: Jaime Ocampo CustomerJaime Ocampo SalgadoNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

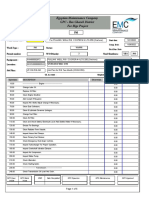

- Emc PM Form (Rigs)Document6 pagesEmc PM Form (Rigs)AmirNo ratings yet

- PDS-HD 3000 (Eng) - 220418Document2 pagesPDS-HD 3000 (Eng) - 220418Jorge NarvaezNo ratings yet

- Qa3 MCR BW211D-40 (5402)Document1 pageQa3 MCR BW211D-40 (5402)nanda adisNo ratings yet

- VROV4-digitCare 8929188061655176 SCHEDULEDocument2 pagesVROV4-digitCare 8929188061655176 SCHEDULEAJAY RAJPUTNo ratings yet

- TESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveDocument32 pagesTESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveAnonymous v7XdaQuNo ratings yet

- Plus 50 IIProduct Specification SheetDocument4 pagesPlus 50 IIProduct Specification SheetRIZKY FIQRINo ratings yet

- Compact Catalog: Monoblock Directional Control ValvesDocument12 pagesCompact Catalog: Monoblock Directional Control ValvesTAHRI BELGACEMNo ratings yet

- BT Oil Lab - Hpu - 09-10.06.2022Document1 pageBT Oil Lab - Hpu - 09-10.06.2022Faizhal ROGNo ratings yet

- Toyota 2LDocument7 pagesToyota 2LjefriNo ratings yet

- Attention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Document2 pagesAttention-Port Jacking Gearbox-Leg Chord 2-4-09-11-2020Sanju laaNo ratings yet

- Full Synthetic Motor OilDocument1 pageFull Synthetic Motor OilfghdNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Test Record Smi Tower V6178Document3 pagesTest Record Smi Tower V6178Rangga SetaNo ratings yet

- MCR PC200-8Document7 pagesMCR PC200-8FaridNo ratings yet

- Inspection Certificate: Fevziçakmak Mah. 10801 Sok. No:1B Karatay/KONYA +90 332 502 86 53Document1 pageInspection Certificate: Fevziçakmak Mah. 10801 Sok. No:1B Karatay/KONYA +90 332 502 86 53Murat CelikNo ratings yet

- HydraulicDocument2 pagesHydraulicQuy CocanhNo ratings yet

- Sample SummaryDocument2 pagesSample Summarydoniindarto1987No ratings yet

- DPC 38 ADocument12 pagesDPC 38 ATAHRI BELGACEMNo ratings yet

- Test Certificate-ER347-lot 563092-75344Document1 pageTest Certificate-ER347-lot 563092-75344Mohammad HassanNo ratings yet

- Indian RailwaysDocument23 pagesIndian RailwaysRAYNo ratings yet

- 2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Document185 pages2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Clash with HBNo ratings yet

- Drum Turbin Oil Tellus S2 MX 46Document1 pageDrum Turbin Oil Tellus S2 MX 46lettoyNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3.5 out of 5 stars3.5/5 (5)

- 01 Identifying Challenges of Construction Industry in IndiaDocument15 pages01 Identifying Challenges of Construction Industry in IndiaPranav100% (1)

- Module 8-c Sugar Manufacturing Process - Clarification Steps and CrystalisationDocument29 pagesModule 8-c Sugar Manufacturing Process - Clarification Steps and CrystalisationDaudNo ratings yet

- Personality DisordersDocument35 pagesPersonality DisordersEsraRamosNo ratings yet

- Week 3 MilDocument30 pagesWeek 3 MilBenilda Pensica SevillaNo ratings yet

- 14.handbook For Password ScreenDocument14 pages14.handbook For Password Screensunanda94No ratings yet

- FinGAT Financial Graph Attention Networks For Recommending Top-KK Profitable StocksDocument13 pagesFinGAT Financial Graph Attention Networks For Recommending Top-KK Profitable StocksSivaramakrishnan KanagarajNo ratings yet

- Ontrac Wire Mesh Cable Tray System: Product Data SheetDocument6 pagesOntrac Wire Mesh Cable Tray System: Product Data SheetHugo Americo Condori BustamanteNo ratings yet

- Hydrological Cycle - An Overview - ScienceDirect TopicsDocument3 pagesHydrological Cycle - An Overview - ScienceDirect TopicsAshis MingalaNo ratings yet

- Dali SymbolsDocument2 pagesDali SymbolskalamiNo ratings yet

- 7-3 IP Board Part (SMPS Part) : 7 Block DiagramsDocument8 pages7-3 IP Board Part (SMPS Part) : 7 Block DiagramsSonu KumarNo ratings yet

- Presentation On BEAMEX MC5 CalibratorDocument29 pagesPresentation On BEAMEX MC5 Calibratoranu prakashNo ratings yet

- 97050228-06 - Piezosteril 6 - Piezolight 6 - ENDocument9 pages97050228-06 - Piezosteril 6 - Piezolight 6 - ENRamona HarbuzNo ratings yet

- Softening-Point-Test OmedDocument12 pagesSoftening-Point-Test OmedOmar BokhareNo ratings yet

- Operating Systems Design and Implementation: Third Edition Andrew S. Tanenbaum Albert S. WoodhullDocument33 pagesOperating Systems Design and Implementation: Third Edition Andrew S. Tanenbaum Albert S. Woodhullbhammack-1No ratings yet

- TEMPLATE FOR REFLECTION Day 2Document2 pagesTEMPLATE FOR REFLECTION Day 2Noel BandaNo ratings yet

- PRC New ShowDocument31 pagesPRC New ShowxyxyquazNo ratings yet

- MTCP ETN Server EDocument3 pagesMTCP ETN Server EcardonPTNo ratings yet

- Properties of SteamDocument7 pagesProperties of SteamRavichandran GNo ratings yet

- Salman Baloch ExperienceDocument3 pagesSalman Baloch ExperienceEngr Salman BalochNo ratings yet

- 1 T - Pemeliharaan Dan Perbaikan Mesin PascapanenDocument22 pages1 T - Pemeliharaan Dan Perbaikan Mesin PascapanenDIAN AL-MUNAWAR ZUHRINo ratings yet

- S8 Diagnostic Table of SpecificationsDocument3 pagesS8 Diagnostic Table of SpecificationsNanette MoradoNo ratings yet

- Usman Najam Introduction of Research ScholarDocument10 pagesUsman Najam Introduction of Research ScholarUsmanNo ratings yet

- Me2026 Ucmp Unit 1Document32 pagesMe2026 Ucmp Unit 1velavansuNo ratings yet

- 14342a PDFDocument600 pages14342a PDFD RAVINDRANNo ratings yet

- 9.18 Hvac Guide: Chapter 9 - Design GuidesDocument25 pages9.18 Hvac Guide: Chapter 9 - Design Guidessolarstuff100% (1)

- Saida KhanDocument3 pagesSaida Khankhan786shabnamNo ratings yet

- Editor - Juan A. Martinez-Velasco - Transient Analysis of Power Systems - A Practical Approach (2020, John Wiley & Sons) - Libgen - LiDocument610 pagesEditor - Juan A. Martinez-Velasco - Transient Analysis of Power Systems - A Practical Approach (2020, John Wiley & Sons) - Libgen - LiDDdivyaNo ratings yet