Professional Documents

Culture Documents

Revised Drawing For 630Kg From Suzhou LG Elevator Co., Ltd.

Revised Drawing For 630Kg From Suzhou LG Elevator Co., Ltd.

Uploaded by

leekodak0 ratings0% found this document useful (0 votes)

15 views1 page1. The power supply and earthing wire for the main circuit breaker and controller should be installed near the top floor controller.

2. The main power supply should be 3-phase 380V AC, 50Hz power, with a single phase 220V AC power supply also provided.

3. The elevator shaft should be vertically plumb with a maximum deflection of 25mm for shafts under 30m and 50mm for shafts over 60m.

Original Description:

shop drawing elevator

Original Title

Revised drawing for 630Kg from Suzhou LG Elevator Co., Ltd.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The power supply and earthing wire for the main circuit breaker and controller should be installed near the top floor controller.

2. The main power supply should be 3-phase 380V AC, 50Hz power, with a single phase 220V AC power supply also provided.

3. The elevator shaft should be vertically plumb with a maximum deflection of 25mm for shafts under 30m and 50mm for shafts over 60m.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views1 pageRevised Drawing For 630Kg From Suzhou LG Elevator Co., Ltd.

Revised Drawing For 630Kg From Suzhou LG Elevator Co., Ltd.

Uploaded by

leekodak1. The power supply and earthing wire for the main circuit breaker and controller should be installed near the top floor controller.

2. The main power supply should be 3-phase 380V AC, 50Hz power, with a single phase 220V AC power supply also provided.

3. The elevator shaft should be vertically plumb with a maximum deflection of 25mm for shafts under 30m and 50mm for shafts over 60m.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

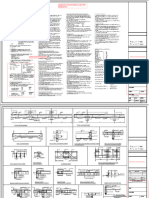

1.

POWER SUPPLY TO MAIN CIRCUIT BREAKER PER

ELEVATOR TO BE NEAR TO THE CONTROLLER ON TOP

FLOOR. AND ONE EARTHING WIRE TO BE SET NEAR TO

THE CONTROLLER TOO, THE SECTION OF EARTHING

,THE WIRE FROM GROUND TO

MACHINE ROOM SHOULD BE INSULATED.

2. MAIN POWER SUPPLY TO BE 3PHASE AC380V, 50HZ,

AC220V.

3. THE SHAFT TO BE OF GOOD VERTICALITY, THE SHAFT

SIZE INDICATED IN PLANE SHALL BE MIN. AVAILABLE

NET SIZE, VERTICAL DEFLECTION RANGE: 0

+25mm(SHAFT HEIGHT<30M), 0

SHAFT HEIGHT 60M), 0 +50mm(60M<SHAFT

4. PIT GROUND SHALL BE WATER-PROOF AND SMOOTH.

5. A POWER SOCKET (2P+ PE) SHALL BE SET IN THE PIT.

6. THERE SHALL BE CONCRETE BEAMS IN SHAFT WALL

WITH INTERVAL 2000MM (UNLESS THE INTERVAL HAS

SPECIAL REQUIREMENT IN CONTRACT), BEAM HEIGHT

SHALL MIN. 300MM, THE LOWEST BEAM SHOULD BE

700MM ABOVE THE PIT GROUND, THE HIGHEST BEAM

SHOULD BE 300MM BELOW THE SHAFT TOP SLAB.

7. THE DECORATION FOR LANDING DOOR ENTRANCE AND

OTHER RESERVED HOLES SHOULD BE DONE AFTER

ELEVATOR INSTALLATION COMPLETION.

8. IF THE SPACE UNDER PIT IS ACCESSABLE FOR PEOPLE,

THE PIT GROUND SHALL BE ABLE TO BEAR 5000N/M

LOAD, AND BUFFER SUPPORT SHALL BE SOLID

COLUMN EXTEND TO THE GROUND.

9. WHEN TWO ADJACENT LANDING DOOR SILL DISTANCE IS

ABOVE 11M, SAFETY EXIT TO BE SET ON THE SHAFT

WALL IN MIDDLE. AND THE EXIT DOOR SHALL COMPLY

WITH EN81.

10. CABLE FROM GUARDS' ROOM TO SHAFT PIT TO BE SET

BY OTHERS.

11. ON TOP OF CONTROLLER, PERMANENT LIGHT TO BE

SET, AND ILLUMINATION NOT SMALLER THAN 200LX.

12. SHAFT CONCRETE WALL TO BE SOUND, COMPRESSION

STRENGTH NOT BE LOWER THAN 30MPA, WALL

THICKNESS NOT BE SMALLER THAN 150MM.

Client Signature Supply Signature

Date Date

LG- Rise

You might also like

- Electro Mecanica, TypeVD-GSMI 34.5kV Vacuum Breaker & Grounding Breaker - (INTERLOCKED)Document18 pagesElectro Mecanica, TypeVD-GSMI 34.5kV Vacuum Breaker & Grounding Breaker - (INTERLOCKED)Dean BartlettNo ratings yet

- ZXONE 9700 Hardware 250PDocument250 pagesZXONE 9700 Hardware 250PhammadNo ratings yet

- 6-Methodologyfor Plum ConcreteDocument4 pages6-Methodologyfor Plum ConcreteMani Kanta100% (4)

- BP344 BookletDocument17 pagesBP344 BookletKenneth CachoNo ratings yet

- ELECTRICALDocument1 pageELECTRICALronulfo fabulaNo ratings yet

- Install-Multi FSDocument4 pagesInstall-Multi FSislaydownsNo ratings yet

- Schedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyDocument1 pageSchedule of Loads: To Service Entrance 2WIRE, 1 PHASE, 230V, 60 HZ FrequencyVincent FilomenaNo ratings yet

- GAD PA-22063 (REV2) NS1# (2022.12.19) 1350-Model HOSPITAL DE CHEPO FOSODocument4 pagesGAD PA-22063 (REV2) NS1# (2022.12.19) 1350-Model HOSPITAL DE CHEPO FOSOFlorencio SandovalNo ratings yet

- SampleDocument9 pagesSampleumeimasohail.engNo ratings yet

- CHIMNEY/COWL - 1000mm Above Highest Pitch To Comply With NBR Part V V1-4Document1 pageCHIMNEY/COWL - 1000mm Above Highest Pitch To Comply With NBR Part V V1-4anzaniNo ratings yet

- Sediment Fence 2Document1 pageSediment Fence 2Wing MacNo ratings yet

- Stone Masonry WallDocument1 pageStone Masonry WallHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- General NotesDocument1 pageGeneral Notesktguillermo777No ratings yet

- Shed Sample JobDocument14 pagesShed Sample Jobarchdesign.ouniNo ratings yet

- Symbol: Jjam Mall (5 Storey Mall)Document1 pageSymbol: Jjam Mall (5 Storey Mall)john benedict orbeNo ratings yet

- Ee9al Ee5d Pedro Dalino PDF File 1Document11 pagesEe9al Ee5d Pedro Dalino PDF File 1jenixson tamondongNo ratings yet

- El ElectricalDocument1 pageEl Electricaljoseph arao-araoNo ratings yet

- Cariño Structural (A3)Document7 pagesCariño Structural (A3)Alvin DeliroNo ratings yet

- Lighting & Convenience Outlet Layout: General NotesDocument1 pageLighting & Convenience Outlet Layout: General NotesJayvee Latosa Dividina100% (1)

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- BT4 4Document1 pageBT4 4JasNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- Jurucita ConsultantDocument1 pageJurucita ConsultantHong Jin YaoNo ratings yet

- Electrical PlanDocument6 pagesElectrical PlanEJ CaneteNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- General NotesDocument1 pageGeneral NotesMuhammad Idrees KhanNo ratings yet

- Ac-036261-001 5312022 2Document1 pageAc-036261-001 5312022 2JAWAHAR TNo ratings yet

- Ac 036261 001 - 05312022Document1 pageAc 036261 001 - 05312022JAWAHAR TNo ratings yet

- General NotesDocument1 pageGeneral NotesKarenNikz GuillermoNo ratings yet

- IRC 93 - 1985 Layout Page of Road Traffic SignalsDocument1 pageIRC 93 - 1985 Layout Page of Road Traffic Signalsanon_965040886No ratings yet

- Cuaton E1Document1 pageCuaton E1zaccNo ratings yet

- Technical SpecificationDocument1 pageTechnical SpecificationRavi ShrivastavNo ratings yet

- Dar Dec 6Document1 pageDar Dec 6vjh8bkmhqhNo ratings yet

- Electrical ReviisedDocument12 pagesElectrical ReviisedEarl Darenz ZamoraNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- Precast Compound Wall - 14.02.2023 - CommentedDocument1 pagePrecast Compound Wall - 14.02.2023 - CommentedSumanNo ratings yet

- Presentation 1Document4 pagesPresentation 1mohdnurasyraafNo ratings yet

- Sevilleja Final E1Document1 pageSevilleja Final E1Renvil PedernalNo ratings yet

- P301 - Chain Link FenceDocument1 pageP301 - Chain Link FencesarthibhavsarNo ratings yet

- E6 Electrical SamplesDocument1 pageE6 Electrical Samplesgeneveve colasitoNo ratings yet

- Construction Notes:: General MasonryDocument1 pageConstruction Notes:: General MasonryJohn And ThenaNo ratings yet

- 16 Bridget Place, Kellyville Goodhew CDC Application WP WP Cover SheetDocument4 pages16 Bridget Place, Kellyville Goodhew CDC Application WP WP Cover SheetEmon RayNo ratings yet

- A20X30 - TW Filinvest Pixie AUG - 23 - 2022V2013-E1Document1 pageA20X30 - TW Filinvest Pixie AUG - 23 - 2022V2013-E1Smart Lte SuperlagNo ratings yet

- Caadlawon Christon Rey BOARDING HOUSEDocument7 pagesCaadlawon Christon Rey BOARDING HOUSEGabriel SosobanNo ratings yet

- General Notes: Legends: Riser Diagram:: Service EntranceDocument1 pageGeneral Notes: Legends: Riser Diagram:: Service EntranceJonard Meregildo100% (1)

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- General Notes Mounting Heights: Proposed Two (2) - Storey Residence Jason L. Herreria E-1/E-4Document1 pageGeneral Notes Mounting Heights: Proposed Two (2) - Storey Residence Jason L. Herreria E-1/E-4GigiNo ratings yet

- 1) General Notes:: Karthikeyan AssociatesDocument12 pages1) General Notes:: Karthikeyan AssociatesSLV GROUPNo ratings yet

- This Site: General Notes/ SpecificationsDocument1 pageThis Site: General Notes/ SpecificationsDonita AcuinNo ratings yet

- Jak1 Aur El DWG A 0 0002 (C)Document1 pageJak1 Aur El DWG A 0 0002 (C)Budi HahnNo ratings yet

- General Notes:: LegendDocument1 pageGeneral Notes:: LegendMItchNo ratings yet

- 2012 ct2Document2 pages2012 ct2Anonymous BoP7nnBNo ratings yet

- Locatio Map A: Symbols DescriptionDocument1 pageLocatio Map A: Symbols DescriptionAlsean Soriano DetubioNo ratings yet

- Refresher Module 54 - (GH-7) - Geotechnical and HydraulicsDocument2 pagesRefresher Module 54 - (GH-7) - Geotechnical and HydraulicsJoenem AbenojaNo ratings yet

- Past Board QuestionsDocument5 pagesPast Board QuestionsFrank Carlo HayagNo ratings yet

- 100 Bed Hospital Okpala StructuralDocument83 pages100 Bed Hospital Okpala StructuralEngr Josh ChisimdiNo ratings yet

- Khuthi Munarini - A4Document1 pageKhuthi Munarini - A4anzaniNo ratings yet

- DSS - Layout.Without - TX AP-2023.07.06Document1 pageDSS - Layout.Without - TX AP-2023.07.06sundareee96No ratings yet

- DXB-478-STR - Drawing CommentsDocument19 pagesDXB-478-STR - Drawing Commentsdubai eyeNo ratings yet

- Excitation and GeneratorDocument74 pagesExcitation and GeneratorRam Singh100% (1)

- 33KV GisDocument214 pages33KV GisCEPCO karthikNo ratings yet

- Instructor Engr. Muhammad YaseenDocument33 pagesInstructor Engr. Muhammad Yaseenbedilu77No ratings yet

- START UP Last Edit GabDocument9 pagesSTART UP Last Edit GabAlpha CapacitorNo ratings yet

- LV10 042022 en 202206151024289669Document1,216 pagesLV10 042022 en 202206151024289669Shahrear SultanNo ratings yet

- Segase Villa 1# Electrical #B.o.qDocument5 pagesSegase Villa 1# Electrical #B.o.qAhmed KhattabNo ratings yet

- Isolation Power Systems by Bender PDFDocument52 pagesIsolation Power Systems by Bender PDFShailesh ChettyNo ratings yet

- Memo Plus (MP 9300-0.9) 10-20KDocument32 pagesMemo Plus (MP 9300-0.9) 10-20KAbdelwhab ElsaftyNo ratings yet

- 1SDC001007D0202-sn1250sace AbbDocument128 pages1SDC001007D0202-sn1250sace AbbUmberPenza100% (1)

- Seccionadoras de M.TDocument72 pagesSeccionadoras de M.TFernando SantanaNo ratings yet

- Fmeg0202 Daily Checklist TransformerDocument2 pagesFmeg0202 Daily Checklist Transformertoni panjiNo ratings yet

- Neutral Grounding High VoltageDocument2 pagesNeutral Grounding High VoltageABDUL GHAFOORNo ratings yet

- Ferraz Fuse Catalogue PDFDocument2 pagesFerraz Fuse Catalogue PDFShariNo ratings yet

- 11KV Network Manual - V.0Document232 pages11KV Network Manual - V.0Shaharyar Waliullah0% (1)

- L3-PPD - Turbine Selection - Unit 1Document25 pagesL3-PPD - Turbine Selection - Unit 1Amrit PandeyNo ratings yet

- Unit 3Document100 pagesUnit 3Mukesh 2004No ratings yet

- CPS22400Document3 pagesCPS22400alexander3233No ratings yet

- Isometer Ir470ly - D00119 - D - XxenDocument6 pagesIsometer Ir470ly - D00119 - D - Xxenguillen j-cNo ratings yet

- Complete Report On DTL ppk2Document40 pagesComplete Report On DTL ppk2अक्षय कल्यानNo ratings yet

- Curvas de Disparo QODocument16 pagesCurvas de Disparo QOIvanNo ratings yet

- Transformer ProtectionDocument116 pagesTransformer ProtectionRobert Lopez100% (5)

- Liebert Ita2 MBC Quick Start Guide PDFDocument12 pagesLiebert Ita2 MBC Quick Start Guide PDFCarlos PalmaNo ratings yet

- Insulation Monitor DAP IM 230VDocument2 pagesInsulation Monitor DAP IM 230VDerarghNo ratings yet

- Fault Location Identification in Smart Distribution Networks With Distributed GenerationDocument7 pagesFault Location Identification in Smart Distribution Networks With Distributed GenerationrupamandalNo ratings yet

- Laguna Gym Schedule of LoadDocument1 pageLaguna Gym Schedule of LoadjanmczealNo ratings yet

- SG2K-S/SG2K5-S/SG3K-S: Residential String InverterDocument2 pagesSG2K-S/SG2K5-S/SG3K-S: Residential String InverterThắng CòiNo ratings yet

- Catalogo Racing Masterpower PDFDocument74 pagesCatalogo Racing Masterpower PDFJuan Carlos Vera Moscoso100% (1)

- INDEX MechukaDocument3 pagesINDEX MechukaPritam SinghNo ratings yet

- PESCO Sakhi Chashma & Taru Jabba 132/11kV Gridstation ProjectDocument30 pagesPESCO Sakhi Chashma & Taru Jabba 132/11kV Gridstation ProjectTahirNo ratings yet