Professional Documents

Culture Documents

Metalcor 1.4562 Alloy 31

Metalcor 1.4562 Alloy 31

Uploaded by

Em JoeCopyright:

Available Formats

You might also like

- Theory of Flight PDFDocument58 pagesTheory of Flight PDFJC Burciaga100% (2)

- Thermodynamics Project: TOPIC: Fugacity of Pure SubstancesDocument6 pagesThermodynamics Project: TOPIC: Fugacity of Pure SubstancesRaman K. Bedi100% (1)

- Lab Report On Fitting LossDocument13 pagesLab Report On Fitting LossJyiou Yimushi100% (1)

- METACOLORDocument1 pageMETACOLORShariq KhanNo ratings yet

- CHBHCUYFVSDDocument1 pageCHBHCUYFVSDedrNo ratings yet

- Metalcor 1.4410 Alloy 2507Document1 pageMetalcor 1.4410 Alloy 2507Ahmed GhonimNo ratings yet

- Metalcor 1.4828 Aisi 309Document1 pageMetalcor 1.4828 Aisi 309Avn PrasadNo ratings yet

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNo ratings yet

- Metalcor 1.4574 Alloy PH 157 MoDocument1 pageMetalcor 1.4574 Alloy PH 157 MonazgulNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Metalcor 1.4876 Alloy 800Document1 pageMetalcor 1.4876 Alloy 800tonicmiraNo ratings yet

- Metalcor 1.3917 Alloy 42Document1 pageMetalcor 1.3917 Alloy 42imtiyazNo ratings yet

- Metalcor 1.4571 Aisi 316 TiDocument1 pageMetalcor 1.4571 Aisi 316 TirezaNo ratings yet

- Metalcor 1.4742Document1 pageMetalcor 1.4742Pablo PerdomoNo ratings yet

- Hempel Alloy254SMO14547LongflatproductsHempel PDFDocument1 pageHempel Alloy254SMO14547LongflatproductsHempel PDFqualityNo ratings yet

- Metalcor Cual10fe3mn2Document1 pageMetalcor Cual10fe3mn2robertjob34No ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardschetanNo ratings yet

- 1.4841 Aisi 314Document1 page1.4841 Aisi 314Josevi Jiménez MerinoNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- Metalcor 1.4361 Alloy 1815Document1 pageMetalcor 1.4361 Alloy 1815Francisco SousalimaNo ratings yet

- Metalcor 1.4307 Aisi 304 LDocument1 pageMetalcor 1.4307 Aisi 304 LRanjith CrazyNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- Metalcor 1.4436 Aisi 316Document1 pageMetalcor 1.4436 Aisi 316Ahmed GhonimNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Material No.: EscriptionDocument2 pagesMaterial No.: EscriptionMd Omar FaruqueNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Fio Outershield 71e-HDocument2 pagesFio Outershield 71e-HJose NevesNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Metrode Supercore 2205P: Welding Consumables Stainless SteelDocument2 pagesMetrode Supercore 2205P: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- S-312.16 Ficha TecnicaDocument4 pagesS-312.16 Ficha TecnicaKATHERINE VIRGINIA AMARO CARRIONNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- PDS - Bohler Q 71 BC (C1)Document1 pagePDS - Bohler Q 71 BC (C1)RaviTeja BhamidiNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Datasheet Sanicro 60Document2 pagesDatasheet Sanicro 60Ismail JamaluddinNo ratings yet

- Weld 71 TDocument1 pageWeld 71 TGanesh HileNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- S 777MXXH 14Document7 pagesS 777MXXH 14amir bizhehNo ratings yet

- The US Particle Accelerator School Materials, Fabrication Techniques, and Joint DesignsDocument46 pagesThe US Particle Accelerator School Materials, Fabrication Techniques, and Joint Designsgangappa birajadarNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDDocument12 pagesS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- EN12073T19123L PC/Mi: - Chemical Composition of All-Weld MetalDocument1 pageEN12073T19123L PC/Mi: - Chemical Composition of All-Weld Metalmohamed AdelNo ratings yet

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDocument2 pagesProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- RTJ Flanges Dimensions ASME B 16.5Document6 pagesRTJ Flanges Dimensions ASME B 16.5Em JoeNo ratings yet

- Properties of Portland Cement Type V Mortar MixedDocument16 pagesProperties of Portland Cement Type V Mortar MixedEm JoeNo ratings yet

- N+F Present EnglishDocument22 pagesN+F Present EnglishEm JoeNo ratings yet

- AEDocument2 pagesAEEm JoeNo ratings yet

- Accutech - General Catalog DTD 030717Document4 pagesAccutech - General Catalog DTD 030717Em JoeNo ratings yet

- Geotechnical Engineering-1: Course Code - CE-221Document46 pagesGeotechnical Engineering-1: Course Code - CE-221Muhammad Umer Mughal100% (1)

- JR InterDocument4 pagesJR InterAswani Kumar67% (3)

- Flex Separation Systems, P-Separators 605615Document4 pagesFlex Separation Systems, P-Separators 605615ABID JAVED DAR0% (1)

- SDLG 2015 Product ManualDocument50 pagesSDLG 2015 Product Manualbjrock123No ratings yet

- Wiring Diagram ABS Hummer H3Document133 pagesWiring Diagram ABS Hummer H3Angga SaputraNo ratings yet

- 9702 s02 QP 4Document16 pages9702 s02 QP 4api-3706826100% (1)

- MAC FCC Paster 7-09Document2 pagesMAC FCC Paster 7-09Sameep GaikwadNo ratings yet

- Solar Collector DaikinDocument3 pagesSolar Collector DaikinMac NyandoroNo ratings yet

- SOLIDWORKS Premium 2016 x64 Edition - (Part1 - )Document1 pageSOLIDWORKS Premium 2016 x64 Edition - (Part1 - )dimas6setyawanNo ratings yet

- 2019 Audi A3 19Document414 pages2019 Audi A3 19zo andriamiarintsoaNo ratings yet

- Mounting Surfaces For The Master RailDocument4 pagesMounting Surfaces For The Master RailsuhartoNo ratings yet

- Surface & Coatings Technology: SciencedirectDocument11 pagesSurface & Coatings Technology: SciencedirectkarenglzNo ratings yet

- Parts Book PC200-10M0 2021 FENC0064-00-MA4Document518 pagesParts Book PC200-10M0 2021 FENC0064-00-MA4Nur haniifah lam100% (1)

- AFT FathomDocument2 pagesAFT Fathomnelvar2005No ratings yet

- Drive PerformanceDocument47 pagesDrive PerformanceEduardo VicelisNo ratings yet

- Optimized Design For TSHDs Swell CompensatorDocument13 pagesOptimized Design For TSHDs Swell CompensatorTomasz FelknerNo ratings yet

- Toaz - Info Timber Design PRDocument13 pagesToaz - Info Timber Design PRJose Josua GaleraNo ratings yet

- Asm HandbookDocument1 pageAsm HandbookMansourjanNo ratings yet

- ACK (Abb)Document62 pagesACK (Abb)Tiyyagura RoofusreddyNo ratings yet

- Tender227 VOL II PDFDocument945 pagesTender227 VOL II PDFrasnowmah2012No ratings yet

- Service Transformer Sizing CalculationDocument23 pagesService Transformer Sizing CalculationSureshraja9977100% (2)

- Technical Specification Part 4 Phe Maitree 1517654301Document71 pagesTechnical Specification Part 4 Phe Maitree 1517654301saravananNo ratings yet

- 300 SA57 DRE90L4 ProductData en DEDocument1 page300 SA57 DRE90L4 ProductData en DEJielyn San MiguelNo ratings yet

- 5164-ENG-065 - IFU01 Bulkhead Specification PDFDocument17 pages5164-ENG-065 - IFU01 Bulkhead Specification PDFSAUGAT DUTTANo ratings yet

- On The Manufacture 01 Impellers For TurbocompressorsDocument16 pagesOn The Manufacture 01 Impellers For TurbocompressorsWillian Tavares de CarvalhoNo ratings yet

- Tuf Pneumatic Long Nose Hog Ring Gun Sc77xeDocument5 pagesTuf Pneumatic Long Nose Hog Ring Gun Sc77xearturoNo ratings yet

- ANSI Standard Pipe ChartDocument4 pagesANSI Standard Pipe ChartccemilovaNo ratings yet

Metalcor 1.4562 Alloy 31

Metalcor 1.4562 Alloy 31

Uploaded by

Em JoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metalcor 1.4562 Alloy 31

Metalcor 1.4562 Alloy 31

Uploaded by

Em JoeCopyright:

Available Formats

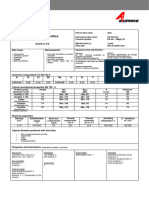

1.

4562 ALLOY 31

Brand name Nicrofer® 3127 hMo

Trade name Alloy 31

Standards

Material No. EN Designation UNS Alloy

1.4562 X1NiCrMoCu32-28-7 N08031 31

Description 1.4563 / Alloy 31 is an iron-nickel-chromium-molybdenum alloy with a nitrogen addition.

Special properties Outstanding resistance to corrosion of halide media. Outstanding resistance to sulphuric acid, even highly

concentrated. Outstanding resistance to corrosion and erosion-corrosion in phosphoric acid media. Excellent

resistance to localized corrosion.

Chemical Composition

C Si Mn P S

% ≤% ≤% ≤% ≤%

≤ 0.015 0.30 2.00 0.02 0.01

Cr Mo Ni N Cu

% % % % %

26.0-28.0 6.00-7.00 30.0-32.0 0.15-0.25 1.00-1.40

Mechanical Properties

Hardness HB 30 0.2% Yield strength Rp Tensile strength Rm Elongation A5 Modulus of elasticity

20°C ≤ HB ≥ N/mm² N/mm² ≥% kN/mm²

220 275 ≥ 650 40 198

Physical Properties 20°C

Density Specific heat capacity Thermal conductivity Electrical resistivity

g/cm³ J/kg K W/m K Ω mm²/m

8 450 11.7 1.03

Suitable welding 1.4562; 2.4607; 2.4609

filler materials

Application Chemical industry, offshore

Available forms for 1.4562 Forged / cast Finished part

/ ALLOY 31 Sheets/Plates Bars Tubes/Pipes Fittings

parts (drawing)

© Metalcor GmbH | Heidhauser Str. 89a | D-45239 Essen | Germany

Tel. +49 (201) 310 77 52 | Fax +49 (201) 310 77 47 | info@metalcor.de | www.metalcor.de

All data is without guarantee for correctness/completeness and serves only for consultation. The data sheets do not constitute a legal contract.

A liability for any data as well as the result in processing and application is excluded.

You might also like

- Theory of Flight PDFDocument58 pagesTheory of Flight PDFJC Burciaga100% (2)

- Thermodynamics Project: TOPIC: Fugacity of Pure SubstancesDocument6 pagesThermodynamics Project: TOPIC: Fugacity of Pure SubstancesRaman K. Bedi100% (1)

- Lab Report On Fitting LossDocument13 pagesLab Report On Fitting LossJyiou Yimushi100% (1)

- METACOLORDocument1 pageMETACOLORShariq KhanNo ratings yet

- CHBHCUYFVSDDocument1 pageCHBHCUYFVSDedrNo ratings yet

- Metalcor 1.4410 Alloy 2507Document1 pageMetalcor 1.4410 Alloy 2507Ahmed GhonimNo ratings yet

- Metalcor 1.4828 Aisi 309Document1 pageMetalcor 1.4828 Aisi 309Avn PrasadNo ratings yet

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNo ratings yet

- Metalcor 1.4574 Alloy PH 157 MoDocument1 pageMetalcor 1.4574 Alloy PH 157 MonazgulNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Metalcor 1.4876 Alloy 800Document1 pageMetalcor 1.4876 Alloy 800tonicmiraNo ratings yet

- Metalcor 1.3917 Alloy 42Document1 pageMetalcor 1.3917 Alloy 42imtiyazNo ratings yet

- Metalcor 1.4571 Aisi 316 TiDocument1 pageMetalcor 1.4571 Aisi 316 TirezaNo ratings yet

- Metalcor 1.4742Document1 pageMetalcor 1.4742Pablo PerdomoNo ratings yet

- Hempel Alloy254SMO14547LongflatproductsHempel PDFDocument1 pageHempel Alloy254SMO14547LongflatproductsHempel PDFqualityNo ratings yet

- Metalcor Cual10fe3mn2Document1 pageMetalcor Cual10fe3mn2robertjob34No ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Label StandardschetanNo ratings yet

- 1.4841 Aisi 314Document1 page1.4841 Aisi 314Josevi Jiménez MerinoNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNo ratings yet

- Metalcor 1.4361 Alloy 1815Document1 pageMetalcor 1.4361 Alloy 1815Francisco SousalimaNo ratings yet

- Metalcor 1.4307 Aisi 304 LDocument1 pageMetalcor 1.4307 Aisi 304 LRanjith CrazyNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- Metalcor 1.4436 Aisi 316Document1 pageMetalcor 1.4436 Aisi 316Ahmed GhonimNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Material No.: EscriptionDocument2 pagesMaterial No.: EscriptionMd Omar FaruqueNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Fio Outershield 71e-HDocument2 pagesFio Outershield 71e-HJose NevesNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Metrode Supercore 2205P: Welding Consumables Stainless SteelDocument2 pagesMetrode Supercore 2205P: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- S-312.16 Ficha TecnicaDocument4 pagesS-312.16 Ficha TecnicaKATHERINE VIRGINIA AMARO CARRIONNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- item11-LNT NiCroMo 59.23Document1 pageitem11-LNT NiCroMo 59.23VVan TanNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- PDS - Bohler Q 71 BC (C1)Document1 pagePDS - Bohler Q 71 BC (C1)RaviTeja BhamidiNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Datasheet Sanicro 60Document2 pagesDatasheet Sanicro 60Ismail JamaluddinNo ratings yet

- Weld 71 TDocument1 pageWeld 71 TGanesh HileNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Afrox MIG/TIG 904L: Welding Consumables Stainless SteelDocument5 pagesAfrox MIG/TIG 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- S 777MXXH 14Document7 pagesS 777MXXH 14amir bizhehNo ratings yet

- The US Particle Accelerator School Materials, Fabrication Techniques, and Joint DesignsDocument46 pagesThe US Particle Accelerator School Materials, Fabrication Techniques, and Joint Designsgangappa birajadarNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDDocument12 pagesS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- EN12073T19123L PC/Mi: - Chemical Composition of All-Weld MetalDocument1 pageEN12073T19123L PC/Mi: - Chemical Composition of All-Weld Metalmohamed AdelNo ratings yet

- Product Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryDocument2 pagesProduct Data Sheet OK 48.60: E 'Manual Metal-Arc Welding' ESAB-MÓR KFT HungaryCristina CoceasuNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- RTJ Flanges Dimensions ASME B 16.5Document6 pagesRTJ Flanges Dimensions ASME B 16.5Em JoeNo ratings yet

- Properties of Portland Cement Type V Mortar MixedDocument16 pagesProperties of Portland Cement Type V Mortar MixedEm JoeNo ratings yet

- N+F Present EnglishDocument22 pagesN+F Present EnglishEm JoeNo ratings yet

- AEDocument2 pagesAEEm JoeNo ratings yet

- Accutech - General Catalog DTD 030717Document4 pagesAccutech - General Catalog DTD 030717Em JoeNo ratings yet

- Geotechnical Engineering-1: Course Code - CE-221Document46 pagesGeotechnical Engineering-1: Course Code - CE-221Muhammad Umer Mughal100% (1)

- JR InterDocument4 pagesJR InterAswani Kumar67% (3)

- Flex Separation Systems, P-Separators 605615Document4 pagesFlex Separation Systems, P-Separators 605615ABID JAVED DAR0% (1)

- SDLG 2015 Product ManualDocument50 pagesSDLG 2015 Product Manualbjrock123No ratings yet

- Wiring Diagram ABS Hummer H3Document133 pagesWiring Diagram ABS Hummer H3Angga SaputraNo ratings yet

- 9702 s02 QP 4Document16 pages9702 s02 QP 4api-3706826100% (1)

- MAC FCC Paster 7-09Document2 pagesMAC FCC Paster 7-09Sameep GaikwadNo ratings yet

- Solar Collector DaikinDocument3 pagesSolar Collector DaikinMac NyandoroNo ratings yet

- SOLIDWORKS Premium 2016 x64 Edition - (Part1 - )Document1 pageSOLIDWORKS Premium 2016 x64 Edition - (Part1 - )dimas6setyawanNo ratings yet

- 2019 Audi A3 19Document414 pages2019 Audi A3 19zo andriamiarintsoaNo ratings yet

- Mounting Surfaces For The Master RailDocument4 pagesMounting Surfaces For The Master RailsuhartoNo ratings yet

- Surface & Coatings Technology: SciencedirectDocument11 pagesSurface & Coatings Technology: SciencedirectkarenglzNo ratings yet

- Parts Book PC200-10M0 2021 FENC0064-00-MA4Document518 pagesParts Book PC200-10M0 2021 FENC0064-00-MA4Nur haniifah lam100% (1)

- AFT FathomDocument2 pagesAFT Fathomnelvar2005No ratings yet

- Drive PerformanceDocument47 pagesDrive PerformanceEduardo VicelisNo ratings yet

- Optimized Design For TSHDs Swell CompensatorDocument13 pagesOptimized Design For TSHDs Swell CompensatorTomasz FelknerNo ratings yet

- Toaz - Info Timber Design PRDocument13 pagesToaz - Info Timber Design PRJose Josua GaleraNo ratings yet

- Asm HandbookDocument1 pageAsm HandbookMansourjanNo ratings yet

- ACK (Abb)Document62 pagesACK (Abb)Tiyyagura RoofusreddyNo ratings yet

- Tender227 VOL II PDFDocument945 pagesTender227 VOL II PDFrasnowmah2012No ratings yet

- Service Transformer Sizing CalculationDocument23 pagesService Transformer Sizing CalculationSureshraja9977100% (2)

- Technical Specification Part 4 Phe Maitree 1517654301Document71 pagesTechnical Specification Part 4 Phe Maitree 1517654301saravananNo ratings yet

- 300 SA57 DRE90L4 ProductData en DEDocument1 page300 SA57 DRE90L4 ProductData en DEJielyn San MiguelNo ratings yet

- 5164-ENG-065 - IFU01 Bulkhead Specification PDFDocument17 pages5164-ENG-065 - IFU01 Bulkhead Specification PDFSAUGAT DUTTANo ratings yet

- On The Manufacture 01 Impellers For TurbocompressorsDocument16 pagesOn The Manufacture 01 Impellers For TurbocompressorsWillian Tavares de CarvalhoNo ratings yet

- Tuf Pneumatic Long Nose Hog Ring Gun Sc77xeDocument5 pagesTuf Pneumatic Long Nose Hog Ring Gun Sc77xearturoNo ratings yet

- ANSI Standard Pipe ChartDocument4 pagesANSI Standard Pipe ChartccemilovaNo ratings yet