Professional Documents

Culture Documents

A-2.2-21-17-03 - Asphalt Plant

A-2.2-21-17-03 - Asphalt Plant

Uploaded by

Nisanth ThulasidasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A-2.2-21-17-03 - Asphalt Plant

A-2.2-21-17-03 - Asphalt Plant

Uploaded by

Nisanth ThulasidasCopyright:

Available Formats

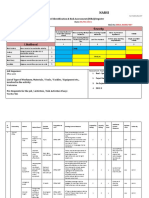

SAFETY CHECK-LIST FOR ASPHALT PLANT A-2.

2-21-17-03

Machine Sl. No.: Month:

Site: Date

Sl. Activity Frequency Action, if 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

No. not OK

1 Check for any abnormal noise and vibration Daily Correct

2 Check all the fasteners & Locks Daily Correct

3 Check all the electrical components Daily Correct

4 Verify all the instructions and safety labels/components in place Daily Provide

5 Check for any foreign material from the steps,handholds and operator's cabin Daily Clean

6 Check all safety device Daily Repair/

Replace

7 Check the plant for externally perceptible damage and defects Each shift Correct

Repair/

8 Check all limit switches Daily

Replace

9 Check area under the discharge chute Daily Repair/

Replace

10 Check the direction of rotation of all the motors Weekly Ensure

11 Inspect the chain drives Daily Replace

12 List of authorized operators and emergency contact numbers displayed in the cabin Daily Provide

13 Check pneumatic lines for any leakage. Daily Repair/

Replace

14 Check the safety guard of the conveyor,pulleys, belts and drive mechanisms Daily replace

15 Check all safety guards Daily replace

16 Check all the storage bins for proper supports Weekly Ensure

17 Check the guide rollers,bearings Weekly Replace

18 Check all the foundation bolts Monthly tighten

19 Check emergency stop switch Daily Replace

20 Check for insulation of cables. Installing Provide

21 Check the first aid kit avaliability in plant Weekly Ensure

22 Check for suitable fire extinguisher avaliable in the cabin and near burner Weekly Provide

23 Check function valves,cylinders,drives,mixers,pumps,dampers, wear plates & screens. Weekly Replace

24 Check hoses,pipes,couplings Weekly Replace

25 Check the Health condition of the operator Daily Ensure

26 Check the marking of traffic line pattern in the plant Weekly Ensure

27 Check the flame safety device Daily Ensure

Check for any Leaks in oil heating lines and steam lines or jacketing on the binder Repair/

28 Each shift

distribution lines Replace

29 Check for safety sign boards in each area of the plant. Daily Provide

30 Check the dust collector and its components Weekly Ensure

31 Check

the accuracy of opening and closing of the weigh hopper,

Weekly Correct

discharge gate, binder valve, and the pugmill discharge gate

Clean/

32 Check the bag house / dust bags Weekly

Replace

Repair/

33 Check the door locks Weekly

Replace

34 Check for proper calibration Monthly Ensure

35 Provide safety training to the operator as well as maintenance team Weekly Provide

Sign. Of the Operator/Technician - Done Daily

Signature of the Engineer - P&M - Checked Daily

Signature of the Safety Engineer - Verified Daily

Safety Instructions on the Asphalt plant:

1 Operation and Maintenance Personnel have read and understand all safety instructions 7 Never allow anyone to stand/move in between the plant/rotating parts,conveyors while plant is working.

2 Before starting/actuating the machine/plant,make sure that nobody is endangered by starting machine/plant. 8 while transporting transport lock should be properly mounted.

3 While carrying out maintenance activity/repair work,plant must be safeguarded against unexpected switching - on. 9 Donot allow any unathorised persons to operate the asphalt plant.

4 Lightning arrester should be provided to the plant. 10 Reduced visibility in work traffic is a prime cause of accidents.Donot operate the plant in poor visibility.

5 Always wear PPE's while working. 11 Plant workers are not allowed to work on cold bins while the plant is in operation.

6 Good housekeeping is essential for plant safety. 12 No one may walk or stand on the aggregates in the bins or on the bunkers over the feeder gate openings.

Special safety instruction for the manpower working in the plant:

1 When handling heated binder, chemical goggles or a face-shield are required. 5 Covered or protected ladders or stairways to provide safe access to all parts of the plant are required to be provided.

2 All shirt collars are required to be worn closed and cuffs buttoned at the wrist. 6 All stairs and platforms are required to have secure handrails.

3 Gloves

with gauntlets that extend up the arm are required to be worn loosely so the Technician may flip them off easily if

7 The

Technician is required to exercise extreme care when climbing around the screen deck, inspecting the

covered with hot binder. screens and hot bins, or collecting hot bin samples.

4 Pants without cuffs are required to be extended over boot tops. 8 All workers around the plant are required to always wear a hard hat when not under cover.

You might also like

- ACMV Maintenance Check ListDocument7 pagesACMV Maintenance Check ListHtet Linn Aung100% (2)

- Academic3 PDFDocument216 pagesAcademic3 PDFAnthony AguirreNo ratings yet

- A-2.2-21-17-04 - Batching PlantDocument1 pageA-2.2-21-17-04 - Batching PlantNisanth ThulasidasNo ratings yet

- A-2.2-21-17-02 - Asphalt PaverDocument1 pageA-2.2-21-17-02 - Asphalt PaverNisanth ThulasidasNo ratings yet

- A 2.2!21!17 05 Bitumen SprayerDocument1 pageA 2.2!21!17 05 Bitumen SprayerNisanth ThulasidasNo ratings yet

- A 2.2!21!17 06 Dewatering PumpDocument1 pageA 2.2!21!17 06 Dewatering PumpNisanth ThulasidasNo ratings yet

- A-2.2-21-17-08 - Mixer MachineDocument1 pageA-2.2-21-17-08 - Mixer MachineNisanth ThulasidasNo ratings yet

- Filler MachineDocument4 pagesFiller Machinenarendra kushwahaNo ratings yet

- FM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectionDocument2 pagesFM-OHS-1700-30 Pre Use Daily Weekly G20 Crane InspectiondavidburkepsNo ratings yet

- Preventive Sheet 13-02-2023Document15 pagesPreventive Sheet 13-02-2023Vishal MehtreNo ratings yet

- RT Inspection & Lubrication Service Log 242-00Document46 pagesRT Inspection & Lubrication Service Log 242-00hananmeliani79No ratings yet

- M Plan June For Unit # 2 Turbine, Main Inlet Valve and Automatic ST Control PanelDocument1 pageM Plan June For Unit # 2 Turbine, Main Inlet Valve and Automatic ST Control PanelUZARERWA Jean d'AmourNo ratings yet

- A-2.2-21-17-09 - Monoblock PumpDocument1 pageA-2.2-21-17-09 - Monoblock PumpNisanth ThulasidasNo ratings yet

- M Plan June For Unit # 1 Turbine, Main Inlet Valve and Automatic ST Control PanelDocument1 pageM Plan June For Unit # 1 Turbine, Main Inlet Valve and Automatic ST Control PanelUZARERWA Jean d'AmourNo ratings yet

- O&M Guidelines NPDocument6 pagesO&M Guidelines NPPaldexNo ratings yet

- Fencing Light PPMDocument1 pageFencing Light PPMzwarrior333No ratings yet

- Maintenance Checklist Shekar AugerDocument1 pageMaintenance Checklist Shekar Augershamsheer ikramNo ratings yet

- Generator PMDocument1 pageGenerator PMimanfarNo ratings yet

- Top Drive Maintenance Plan20210925Document4 pagesTop Drive Maintenance Plan20210925Franklin Silva100% (1)

- Drum Roller ChecklistDocument2 pagesDrum Roller ChecklistDAOUMY YOUNESSNo ratings yet

- Landrover Freelander 2 Maintenance ScheduleDocument2 pagesLandrover Freelander 2 Maintenance Schedulevincent_devine777dNo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- 06 - Maintenance ChecklistDocument4 pages06 - Maintenance ChecklistYuri FaroNo ratings yet

- Stručni Test Engleskog JezikaDocument3 pagesStručni Test Engleskog JezikadjukalNo ratings yet

- Maintenance Checklist Feed AugerDocument2 pagesMaintenance Checklist Feed Augershamsheer ikramNo ratings yet

- Ots 60af2Document104 pagesOts 60af2adamNo ratings yet

- SEW Line Machine Checksheet DDocument7 pagesSEW Line Machine Checksheet DMURALIDHRANo ratings yet

- FP PDW 002 - 02Document2 pagesFP PDW 002 - 02orisNo ratings yet

- Technical Health DCCMDocument25 pagesTechnical Health DCCMibsamengistu29No ratings yet

- A 2.2!21!17 07 Induction MotorDocument1 pageA 2.2!21!17 07 Induction MotorNisanth ThulasidasNo ratings yet

- MAINTENANCE AND REPAIR MANUAL. Carendo. For Internal Use Only!Document34 pagesMAINTENANCE AND REPAIR MANUAL. Carendo. For Internal Use Only!Casey FriendNo ratings yet

- CPA Mobile Cranes Wheeled Daily Checks TemplateDocument1 pageCPA Mobile Cranes Wheeled Daily Checks Templateaalaamostafa23No ratings yet

- Maintenance InstructionsDocument3 pagesMaintenance InstructionsNavnath GawasNo ratings yet

- PM 04-MinDocument2 pagesPM 04-MinUsman HassanNo ratings yet

- Toyota Reach Truck PM Check SheetDocument2 pagesToyota Reach Truck PM Check Sheetharshavardhan100% (1)

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Compressor Maintenance LogDocument1 pageCompressor Maintenance Logsohel rana100% (1)

- ML B 1900d b19dmm9 1Document8 pagesML B 1900d b19dmm9 1ramzi30No ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- ML B 1900d b19dmm10Document3 pagesML B 1900d b19dmm10ramzi30No ratings yet

- V30ZMUDocument26 pagesV30ZMUmanuelsaenzNo ratings yet

- Datex Ohmeda Modulus II With 7Document31 pagesDatex Ohmeda Modulus II With 7Eng. Edelson MartinsNo ratings yet

- Calavar Condor 446q8 Operators Maintenance and Part ManualDocument20 pagesCalavar Condor 446q8 Operators Maintenance and Part ManualMichelle100% (62)

- Ims-Om-Cl-001-R00 AcdbDocument1 pageIms-Om-Cl-001-R00 AcdbVeerendra YduvanshiNo ratings yet

- AIP Preventive Mainteanace Week 3 March 31-2023 Inspection ReportDocument24 pagesAIP Preventive Mainteanace Week 3 March 31-2023 Inspection Reportyibelta abebeNo ratings yet

- Manual TX EngDocument61 pagesManual TX EngPreeth jayasinghe100% (1)

- Preventive Maintenance Checklist: SymbolDocument1 pagePreventive Maintenance Checklist: SymbolMohd AliminNo ratings yet

- Weekly Maintenance Schedule and Checklist CompressorDocument4 pagesWeekly Maintenance Schedule and Checklist CompressorNaqqash SajidNo ratings yet

- PM - Work Order Operation No: 50.1 (MAG) January February March April May June JulyDocument6 pagesPM - Work Order Operation No: 50.1 (MAG) January February March April May June JulyvishalNo ratings yet

- Field Quality Plan: BusbarsDocument3 pagesField Quality Plan: BusbarsSourav RanaNo ratings yet

- BOOK 09 - MaintananceDocument15 pagesBOOK 09 - MaintananceShau WilliamNo ratings yet

- Preventive, Performance MonitoringDocument3 pagesPreventive, Performance Monitoringhasmirah salehNo ratings yet

- S1 Maintenance DetailsDocument6 pagesS1 Maintenance DetailsHemanthNo ratings yet

- CPAD-CPADM-Heatless-Dryer-Manual1 - Dew Point Demand Control SystemDocument24 pagesCPAD-CPADM-Heatless-Dryer-Manual1 - Dew Point Demand Control SystemMuhammad ImranNo ratings yet

- ARDO Amelie3 - 1 ServiceInstructions - en 08 - 2011Document97 pagesARDO Amelie3 - 1 ServiceInstructions - en 08 - 2011Moas GabrounNo ratings yet

- Washer Repair Manual AshlandDocument84 pagesWasher Repair Manual AshlandDavid Loney100% (1)

- Preventive Checklist For Process EquipmentDocument9 pagesPreventive Checklist For Process EquipmentVishal MehtreNo ratings yet

- Installation, Operation & MaintenanceDocument38 pagesInstallation, Operation & MaintenanceFRANCISCO JAVIER PARAISO VUYOVICHNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Maintenance-Log-Mud PumpDocument4 pagesMaintenance-Log-Mud PumpSarah RavikumarNo ratings yet

- A-2.2-21-17-08 - Mixer MachineDocument1 pageA-2.2-21-17-08 - Mixer MachineNisanth ThulasidasNo ratings yet

- A 2.2!21!17 05 Bitumen SprayerDocument1 pageA 2.2!21!17 05 Bitumen SprayerNisanth ThulasidasNo ratings yet

- A 2.2!21!17 06 Dewatering PumpDocument1 pageA 2.2!21!17 06 Dewatering PumpNisanth ThulasidasNo ratings yet

- A-2.2-21-17-09 - Monoblock PumpDocument1 pageA-2.2-21-17-09 - Monoblock PumpNisanth ThulasidasNo ratings yet

- A-2.2-21-17-01 - Bentonite MixerDocument1 pageA-2.2-21-17-01 - Bentonite MixerNisanth ThulasidasNo ratings yet

- A-2.2-21-17-02 - Asphalt PaverDocument1 pageA-2.2-21-17-02 - Asphalt PaverNisanth ThulasidasNo ratings yet

- A-2.2!21!46-05 - Complete Demobilization of ProjectDocument2 pagesA-2.2!21!46-05 - Complete Demobilization of ProjectNisanth ThulasidasNo ratings yet

- A-2.2-21-17-04 - Batching PlantDocument1 pageA-2.2-21-17-04 - Batching PlantNisanth ThulasidasNo ratings yet

- AFCONS-O-2.2-21-46 - Preparation of HSE PlanDocument6 pagesAFCONS-O-2.2-21-46 - Preparation of HSE PlanNisanth ThulasidasNo ratings yet

- A-2.2-21-46-03 - EHS WalkdownDocument1 pageA-2.2-21-46-03 - EHS WalkdownNisanth ThulasidasNo ratings yet

- A-2.2-21-46-02 - Tool Box TalkDocument2 pagesA-2.2-21-46-02 - Tool Box TalkNisanth ThulasidasNo ratings yet

- 08 - Block WorkDocument16 pages08 - Block WorkNisanth ThulasidasNo ratings yet

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

- Waterproofing WorkDocument10 pagesWaterproofing WorkNisanth ThulasidasNo ratings yet

- Painting WorkDocument8 pagesPainting WorkNisanth Thulasidas100% (1)

- A-2.2-21-46-01 - Sample HSE PlanDocument31 pagesA-2.2-21-46-01 - Sample HSE PlanNisanth ThulasidasNo ratings yet

- Use of Power ToolsDocument3 pagesUse of Power ToolsNisanth ThulasidasNo ratings yet

- Disinfection at SiteDocument8 pagesDisinfection at SiteNisanth ThulasidasNo ratings yet

- A-2.2-21-46-06 - Meeting Attendance Sheet.Document1 pageA-2.2-21-46-06 - Meeting Attendance Sheet.Nisanth ThulasidasNo ratings yet

- Demolition WorkDocument4 pagesDemolition WorkNisanth ThulasidasNo ratings yet

- HIRA NARSI Workmen ColonyDocument2 pagesHIRA NARSI Workmen ColonyNisanth ThulasidasNo ratings yet

- Manual Material HandlingDocument9 pagesManual Material HandlingNisanth ThulasidasNo ratings yet

- Civil WorkDocument10 pagesCivil WorkNisanth ThulasidasNo ratings yet

- Roles& ResponsibilityDocument1 pageRoles& ResponsibilityNisanth ThulasidasNo ratings yet

- Carpentry WorkDocument10 pagesCarpentry WorkNisanth ThulasidasNo ratings yet

- HIRA BLR 17 034 Operation of Hand ToolsDocument3 pagesHIRA BLR 17 034 Operation of Hand ToolsNisanth ThulasidasNo ratings yet

- COVID-19 Risk Assesment FinalDocument4 pagesCOVID-19 Risk Assesment FinalNisanth ThulasidasNo ratings yet

- HIRA NARSI Office AreaDocument3 pagesHIRA NARSI Office AreaNisanth ThulasidasNo ratings yet

- Alcohol & Drug PolicyDocument1 pageAlcohol & Drug PolicyNisanth ThulasidasNo ratings yet

- HIRA BLR 17 029 Operation of Portable ToolsDocument3 pagesHIRA BLR 17 029 Operation of Portable ToolsNisanth ThulasidasNo ratings yet

- Glp1ra SteatohepatitisDocument16 pagesGlp1ra Steatohepatitislakshminivas PingaliNo ratings yet

- LAKAS NG MANGGAGAWANG MAKABAYAN (LAKAS), vs. MARCELO ENTERPRISESDocument6 pagesLAKAS NG MANGGAGAWANG MAKABAYAN (LAKAS), vs. MARCELO ENTERPRISESRudith ann QuiachonNo ratings yet

- Maruti Suzuki India Limited (Msil)Document7 pagesMaruti Suzuki India Limited (Msil)KARUN RAJ K MBA IB 2018-20No ratings yet

- Credit Risk Management-City BankDocument69 pagesCredit Risk Management-City BankGobinda saha100% (1)

- Pe 3 First QuizDocument1 pagePe 3 First QuizLoremer Delos Santos LiboonNo ratings yet

- Annotated BibliographyDocument4 pagesAnnotated BibliographysarinarwNo ratings yet

- Envision 2014 Article 3Document9 pagesEnvision 2014 Article 3Kartik KNo ratings yet

- Reminiscences of Madame Sidney PrattenDocument121 pagesReminiscences of Madame Sidney PrattenjavisatrianiNo ratings yet

- AC3103 Seminar 19: Biosensors International Group (BIG) Valuation and Impairment Testing of IntangiblesDocument39 pagesAC3103 Seminar 19: Biosensors International Group (BIG) Valuation and Impairment Testing of IntangiblesTanisha GuptaNo ratings yet

- Songs To Practice Advent SG Masses 2013Document4 pagesSongs To Practice Advent SG Masses 2013Ronaldo BulanNo ratings yet

- Sub Module 13.1 Theory of FlightDocument56 pagesSub Module 13.1 Theory of FlightteacherNo ratings yet

- Microwave: LAB ReportDocument14 pagesMicrowave: LAB Reportmakhzom alshhumiNo ratings yet

- pt2730 Usaeng Usr LW6057001 A PDFDocument88 pagespt2730 Usaeng Usr LW6057001 A PDFSR DTNo ratings yet

- Dat AssDocument19 pagesDat AssMa k Kk60% (15)

- Name: - Date: - Grade and Section: - Score: - Formative AssessmentDocument7 pagesName: - Date: - Grade and Section: - Score: - Formative AssessmentLey F. FajutaganaNo ratings yet

- English Rough Draft 1Document4 pagesEnglish Rough Draft 1api-463048454No ratings yet

- 01 Diabetes Mellitus Type2Document39 pages01 Diabetes Mellitus Type2Che HaniffNo ratings yet

- Thesis Statement Cafeteria FoodDocument7 pagesThesis Statement Cafeteria Foodafbwszvft100% (1)

- Modern Science and Vedic Science: by David Frawley (Vamadeva Shastri)Document8 pagesModern Science and Vedic Science: by David Frawley (Vamadeva Shastri)swami1423No ratings yet

- Annual Report 2006 07Document191 pagesAnnual Report 2006 07Ritu AgarawalNo ratings yet

- Scientific Method Test Study Guide2Document4 pagesScientific Method Test Study Guide2Gabriel TaylorNo ratings yet

- Once Upon The Time in America - Google Search PDFDocument1 pageOnce Upon The Time in America - Google Search PDFDiana KarchavaNo ratings yet

- Gastech2008 Macdonald MaguireDocument6 pagesGastech2008 Macdonald Maguire463990305No ratings yet

- Christmas DollDocument20 pagesChristmas Dollcraftycow62No ratings yet

- A Study On Adoption of Digital Payment Through Mobile Payment Application With Reference To Gujarat StateDocument6 pagesA Study On Adoption of Digital Payment Through Mobile Payment Application With Reference To Gujarat StateEditor IJTSRDNo ratings yet

- Transforming An Urban Corridor: Bus Rapid Transit Along Lake StreetDocument40 pagesTransforming An Urban Corridor: Bus Rapid Transit Along Lake StreetRia NathNo ratings yet

- DLL - Mathematics 5 - Q1 - W5Document10 pagesDLL - Mathematics 5 - Q1 - W5aleeza ROXASNo ratings yet

- Gligoric - I Play Against Pieces (2003) PDFDocument144 pagesGligoric - I Play Against Pieces (2003) PDFArdelean Lorela100% (3)

- Procedure For FTR SettlementDocument3 pagesProcedure For FTR SettlementSaranya SundaresanNo ratings yet