Professional Documents

Culture Documents

VV Reductora Pilotada Forbes FMPRV41

VV Reductora Pilotada Forbes FMPRV41

Uploaded by

cristian villegasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VV Reductora Pilotada Forbes FMPRV41

VV Reductora Pilotada Forbes FMPRV41

Uploaded by

cristian villegasCopyright:

Available Formats

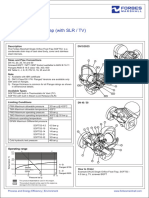

FMPRV41

Forbes Marshall Pilot Operated Pressure Reducing Valve

Description A

The Forbes Marshall Pilot Operated Pressure Reducing Valve,

FMPRV41 is a SG iron pressure reducing valve (pilot operated)

suitable for steam or compressed air.

Sizes and End Connections

DN 15, 20, 25, 40 and 50

Screwed: BSPT / NPT / BSP for DN 15, 20, 25, 40 and 50

Flanged: BS 10 table “F/H”, PN10, PN 16, Class 150, Class 125

L

for DN 40 and 50

DN15 FMPRV41 LC (low capacity) versions available

D1

D

Limiting Conditions M

PMO-Maximum operating pressure 17 bar g

TMO-Maximum operating temperature 232°C

Cold hydraulic test pressure 34 bar g E

Spring range 0.3 to 17 bar g

Pressure Sensing Pipe B

The FMPRV41 controls the pressure by sensing the downstream FMPRV41 sCREWED

pressure through a pressure sending pipe taken to the union (item

L ) or through the internal sensing pipe (item M). Fitting of the

external pressure sensing pipe is described in the user manual

supplied with the valve.

Note: Capacity is reduced and there is a possibility of hunting if

an external pressure sensing pipe is not fitted. A1

Operating Range:

232 D

A B

Temperature °C

200

150

Steam F

100 saturation

curve T

50

G C E

0 5 10 15 17 20

D1

D

Pressure bar g

The product must not be used in this region.

Dimensions (approx.) in mm FMPRV41 (Steam)

Size (DN) A A1 B D D1(Air) E T Wt. E

15 160 .... 180 409 358 129 .... 13kg

15 LC 160 .... 180 409 358 129 .... 13kg

20 160 .... 180 409 358 129 .... 13kg

25 180 .... 203 432 381 178 .... 14kg

40 212 212 251 450 414 149 22 30kg B

50NB 232 232 251 480 414 173 25 32kg FMPRV41 fLANGED

Energy Conservation | Environment | Process Efficiency www.forbesmarshall.com

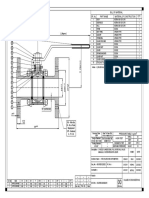

Materials FMPRV41 sTEAM

No Part Material Standard

1 Adjustments screw Carbon Steel IS1367 Gr14

2 Adjustment lock nut SS Type 304

3 Spring housing SG iron EN-JS1025 DIN EN 1563

4 Top spring pad C-20 IS2062

5 Pressure adjustment SS Type 302 IS4454 Part IV Gr.1

Spring

6 Bottom spring pad SS Type 304 ASTM A276

7 Spring housing

Securing nut Carbon Steel ASTM A 194 Gr. 2H

Securing studs Carbon Steel BS970 EN9

DN 15-32 M10x95mm

DN 40, 50 M12x95mm

8 Pilot diaphragms SS Type 304 ASTM A240

9 Pilot valve chamber SG iron EN-JS1025 DIN En1563

10 Pilot valve plunger SS Type 304

11 Pilot valve seat with Stainless Steel BS 970 431 S29

integral seal +PTFE

12 Pilot valve ball Stainless Steel AISI 420

13 Pilot valve Spring Stainless Steel BS 2057 302 S26

14 Pilot Valve clip Stainless Steel ASTM A240 Type 301

15 Pilot filter cap gasket Stainless Steel BS 1449-304-S16

16 Pilot filter cap Stainless Steel ASTM A743Gr. CA 40

17 Pilot filter element Bronze

18 Internal strainer Stainless Steel ASTM A240 Type 304

19 Body gasket SS forced

exfoliated graphite

20 Main valve return Stainless Steel BS 2056 302 S26

spring

21 Main valve Stainless Steel ASTM A276 Type 420

22 Main valve seat Stainless Steel ASTM A276 Type 420

23 Balance pipe Stainless Steel ASTM A213

assembly Type 304

24 Main Valve body SG iron EN JS1025 DIN EN 1563

25 Lower diaphragm SG iron EN JS1025 DIN EN 163

chamber

26 Lower diaphragm

chamber

Securing nuts Carbon steel ASTM A 194 Gr. 2H

Securing Bolts Carbon steel ASTM A 193 B7

DN 15 - 25 M12x50mm

DN 40, 50 M12x50mm

27 Main diaphragm pad SS Type 304 ASTM A240

28 Lower diaphragm pad SS Type 304 ASTM A276

29 Pushrod SS Type 431

30 Lock nut SS Type 316

31 Control pipe assembly SS Type 304 ASTM A213

32 Name plate Stainless Steel

Note : Item 10,11,12,13 and 14 are shown on the exploded view,

as they are hidden by the pilot filter on the main illustration.

Steam Capacity Chart

Note pressure line. A perpendicular dropped from this point gives the

The capacities quoted below are based on valves fitted with an capacities of all FMPRV41 sizes under these conditions.

external pressure sensing pipe. Reliance on the internal

pressure sensing pipe will mean that capacities may be Superheated steam

reduced. In the case of low downstream pressure this reduction Because of the higher specific volume of superheated steam a

could be up to 30% of the valve capacity. correction factor must be applied to the figure obtained from the

chart above. For 55°C of superheat the factor is 0.95 and for

How to Use the Chart 100°C of superheat the factor is 0.9.

Using the example given for saturated steam, the DN40 valve

Saturated Steam would pass 1150X0.95=1092kg/hr. if the steam had 55°C

A valve is required to pass 600kg/h reducing from 6 bar g to 4 superheat. It is still big enough to pass the required load of

bar g. Find the point at which the curved 6 bar g upstream 600kg/hr.

pressure line crosses the horizontal 4 bar g downstream

FMPRV41 Steam Version

Downstream pressure bar g (Steam)

Upstream pressure bar g (Steam)

How to Use the Chart Compressed Air Capacity Chart

Capacities are given in cubic decimeters of free air per second

3

(dm /s). The use of the capacity chart can be best explained by

an example.

3

Required, a valve to pass 100dm /s of free air reducing from 12

bar g to 8 bar g.

Downstream pressure bar g

Find the point at which the curved 12 bar g upstream pressure

line crosses the horizontal 8 bar g downstream pressure line. A

perpendicular dropped from this point shows that, a DN15 valve

3

will pass approximately 120 dm /s under these conditions and is

the correct valve size to choose.

KV Values

The Kv values are full capacities and should be used for safety

valve sizing purpose only.

SIZE DN 15LC DN15 DN20 DN25 DN40 DN50

Upstream pressure bar g

KV 1 2.8 5.5 8.1 17 28

For conversion Cv (UK)=Kv x 0.963

Cv (US)=Kv x 1.156

FMPRV41 Air Version

How to Order

1 no. Forbes Marshall Pilot Operated Pressure Reducing Valve,

DN 40 FMPRV41 having a 0.2-17 bar g spring and flanged BS10

table “F/H” connections.

Installation note

The pilot operated pressure reducing valve should be installed in

a horizontal pipeline, protected by a strainer and a separator, with

the direction of flow as indicated by the arrow on the valve body.

Safety Information, Installation and Maintenance

For full details see the user manual supplied with the product.

Spare Parts

For spares refer user manual.

Opp 106th Milestone B-85, Phase II, Chakan Indl Area A-34/35, MIDC H Block

Bombay Poona Road Sawardari, Chakan, Tal. Khed Pimpri, Pune - 411 018. INDIA.

Kasarwadi, Pune - 411 034. INDIA Dist. Pune - 410 501. INDIA Tel : 91(0)20-27442020, 39851199

Forbes Marshall Tel : 91(0)20-27145595, 39858555 Tel : 91(0)2135-393400 Fax : 91(0)20-27442040

Krohne Marshall Fax : 91(0)20-27147413 CIN No.: U28996PN1985PTC037806

Forbes Marshall Arca Email : seg@forbesmarshall.com, ccmidc@forbesmarshall.com www.forbesmarshall.com

Codel International © All rights reserved. Any reproduction or distribution in part or as a whole without written permission of Forbes Marshall Pvt Ltd, its associate companies

Forbes Solar or its subsidiaries (“FM Group”) is prohibited.

Forbes Vyncke Information, designs or specifications in this document are subject to change without notice. Responsibility for suitability, selection, installation, use,

operation or maintenance of the product(s) rests solely with the purchaser and/or user. The contents of this document are presented for informational

Forbes Marshall Steam Systems purposes only. FM Group disclaims liabilities or losses that may be incurred as a consequence of the use of this information.

DOC# FMSS/0317/TIS-FMPRV41-O/R1

You might also like

- Stephan UMSK-24 - Manual (EN)Document111 pagesStephan UMSK-24 - Manual (EN)cristian villegasNo ratings yet

- Hmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Document81 pagesHmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Krunal Shaj100% (1)

- Advanced Engineering Fluid Mechanics - K. Muralidhar and G. BiswasDocument20 pagesAdvanced Engineering Fluid Mechanics - K. Muralidhar and G. BiswasAli Adnan100% (1)

- Rate Analysis For NasikDocument59 pagesRate Analysis For NasikAHMED SOHELNo ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- Ptfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-ADocument4 pagesPtfe-Lined Butterfly Valve T 214-A Ptfe-Lined Butterfly Valve T 214-AFernando Ortiz De La CruzNo ratings yet

- Air Trap RL1090 - RL1290Document2 pagesAir Trap RL1090 - RL1290satphoenixNo ratings yet

- EBRODocument4 pagesEBROramNo ratings yet

- Double Check Valve DC: Technical DataDocument2 pagesDouble Check Valve DC: Technical DataAthanasoulis KostasNo ratings yet

- DP 23Document4 pagesDP 23american_guy10No ratings yet

- 5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300Document3 pages5 11 e s25s Centrifugal Humidity Separator pn16 pn40 dn15 300sabasthianNo ratings yet

- Technical Sheet FT47Document7 pagesTechnical Sheet FT47Malik DaniyalNo ratings yet

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Document1 page1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamNo ratings yet

- Ball Valves: DIN Full Bore, Floa! NG Ball, 2-Piece BodyDocument12 pagesBall Valves: DIN Full Bore, Floa! NG Ball, 2-Piece BodyErcan YilmazNo ratings yet

- Lug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-ADocument4 pagesLug Type Butterfly Valve Z 414-A Lug Type Butterfly Valve Z 414-AFernando Ortiz De La CruzNo ratings yet

- VAL Team: Humidity Separators SF251/S PN 16 and PN 40Document2 pagesVAL Team: Humidity Separators SF251/S PN 16 and PN 40peyman mahinsaNo ratings yet

- 11.8a Ghibson GB015Document2 pages11.8a Ghibson GB015Shah Rizal AbidNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- (31000 - 31200) Series: Butterfly Valve Wafer TypeDocument9 pages(31000 - 31200) Series: Butterfly Valve Wafer TypefotopredicNo ratings yet

- Sta-F: Balancing Valves September 1985Document8 pagesSta-F: Balancing Valves September 1985ThanhNo ratings yet

- Spirax Sarco Fig 33Document2 pagesSpirax Sarco Fig 33Jacobus CalvelageNo ratings yet

- Volute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261Document20 pagesVolute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261safwan azizNo ratings yet

- Una25 PK Ps - enDocument1 pageUna25 PK Ps - enhamid vahedil larijaniNo ratings yet

- Eliminador de AireDocument4 pagesEliminador de AiresusansueNo ratings yet

- 3 80 e pv25g Pneumatic On Off Valves dn15 100Document4 pages3 80 e pv25g Pneumatic On Off Valves dn15 100Layton DfcNo ratings yet

- SOFT53Document4 pagesSOFT53govind rajNo ratings yet

- 558-dbl 810304 04 rk41 enDocument2 pages558-dbl 810304 04 rk41 enHideki MojicaNo ratings yet

- Manual Balancing 130seriesDocument16 pagesManual Balancing 130seriesa_salehiNo ratings yet

- Catalogo Asca Valvula RetencaoDocument2 pagesCatalogo Asca Valvula RetencaoMaurício Duarte de AndradeNo ratings yet

- Double Check Valve DCDocument2 pagesDouble Check Valve DCJOHNNo ratings yet

- DP27T and DP27TE Pilot Operated Pressure Temperature Control Valves With SG Iron BodiesDocument12 pagesDP27T and DP27TE Pilot Operated Pressure Temperature Control Valves With SG Iron BodiesDiegoNo ratings yet

- 2700ARDocument2 pages2700ARJulio GodinezNo ratings yet

- Klinger Ball Valve KHCDocument4 pagesKlinger Ball Valve KHCFood andfoodNo ratings yet

- Wafer Type Process Valve T 211-C Wafer Type Process Valve T 211-CDocument4 pagesWafer Type Process Valve T 211-C Wafer Type Process Valve T 211-CSamy PradoNo ratings yet

- ALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignDocument16 pagesALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignHamza AbdelhamidNo ratings yet

- 2700ADDocument2 pages2700ADJulio GodinezNo ratings yet

- 9900 Series DatasheetDocument3 pages9900 Series DatasheetHans HongNo ratings yet

- FRLM With Internal AutodrainDocument3 pagesFRLM With Internal AutodrainBiswanath LenkaNo ratings yet

- Robinet Clapa Fluture Wafer Centric - DuyarDocument3 pagesRobinet Clapa Fluture Wafer Centric - DuyarRebecca TerryNo ratings yet

- VFDH PRSH enDocument3 pagesVFDH PRSH enOmar JarwanNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- Lede Butterfly PDFDocument1 pageLede Butterfly PDFMuliawan TjandraNo ratings yet

- Steam Pressure Reducing ValveDocument2 pagesSteam Pressure Reducing ValveFilipe FilipeNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- C2..QFL-.. R2..FL-.. Datasheet En-GbDocument4 pagesC2..QFL-.. R2..FL-.. Datasheet En-GbROGER CHNo ratings yet

- TLV SJ3FXDocument2 pagesTLV SJ3FXÁlvaro Martínez FernándezNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- DPF Modification InstructionsDocument13 pagesDPF Modification InstructionsWidlak KocełakNo ratings yet

- 3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enDocument6 pages3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enQuyết Bạch ĐìnhNo ratings yet

- "ADCATROL" TDS Blowdown Control Valves VPC SeriesDocument3 pages"ADCATROL" TDS Blowdown Control Valves VPC SeriesMuzakir Al ZakirNo ratings yet

- Double Flanged Butterfly Valve F012-A Double Flanged Butterfly Valve F012-ADocument4 pagesDouble Flanged Butterfly Valve F012-A Double Flanged Butterfly Valve F012-ANguyen Quang NamNo ratings yet

- Double Flanged Butterfly Valve F012-A Double Flanged Butterfly Valve F012-ADocument4 pagesDouble Flanged Butterfly Valve F012-A Double Flanged Butterfly Valve F012-AAndré LutzNo ratings yet

- Pressure Reducing Valve - Irrigation (LFN45B) & Water Supply (W-M115)Document6 pagesPressure Reducing Valve - Irrigation (LFN45B) & Water Supply (W-M115)AHMAD ISLAHINo ratings yet

- Pressure Reducing Valve: PED 2014/68/UEDocument2 pagesPressure Reducing Valve: PED 2014/68/UEFaisal ImranNo ratings yet

- HTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulDocument8 pagesHTTP WWW - Documentation.emer... Bulletins 0029en VSFL BulRktBatamNo ratings yet

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocument5 pages2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNo ratings yet

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongNo ratings yet

- Wafer Type Butterfly Valve Z 011-A ThermDocument4 pagesWafer Type Butterfly Valve Z 011-A ThermJOHNNo ratings yet

- DP27, DP27E, DP27G, DP27GY, DP27R & DP27Y Pilot Operated Pressure Reducing Valves With SG Iron BodiesDocument14 pagesDP27, DP27E, DP27G, DP27GY, DP27R & DP27Y Pilot Operated Pressure Reducing Valves With SG Iron BodiesPocola AdrianNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- ES - Model LFN45BDocument2 pagesES - Model LFN45BSANRAJ TECHNONo ratings yet

- DBL 810708 01 BK15 en PDFDocument2 pagesDBL 810708 01 BK15 en PDFMedian Ari WidodoNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Spence Type E Main DocsDocument2 pagesSpence Type E Main Docscristian villegasNo ratings yet

- 400 Series ManualDocument2 pages400 Series Manualcristian villegasNo ratings yet

- T301WFPDocument1 pageT301WFPcristian villegasNo ratings yet

- Trampa Flotador Ayvaz SK-51Document1 pageTrampa Flotador Ayvaz SK-51cristian villegasNo ratings yet

- Ficha #2 Cono Duplex 2205 o Inox Rasai, IndiaDocument4 pagesFicha #2 Cono Duplex 2205 o Inox Rasai, Indiacristian villegasNo ratings yet

- Marathon SeriesDocument184 pagesMarathon Seriescristian villegasNo ratings yet

- Ecoline SCC - 7362.13.01-EN Type Series BookletDocument10 pagesEcoline SCC - 7362.13.01-EN Type Series Bookletcristian villegasNo ratings yet

- Technical Data Burnercontrol Bc300: 1 Rast5 Plug-In Connector 2 Rast2.5 Plug-In Connection ForDocument6 pagesTechnical Data Burnercontrol Bc300: 1 Rast5 Plug-In Connector 2 Rast2.5 Plug-In Connection Forcristian villegasNo ratings yet

- A588807 0 Centrifugal Pump PDF FreeDocument1 pageA588807 0 Centrifugal Pump PDF Freecristian villegasNo ratings yet

- Manual LDZX KB KbsDocument20 pagesManual LDZX KB Kbscristian villegasNo ratings yet

- Multicalor 700.1 MD Multicalor 800.1 MD Multicalor 1000.1 MD Multicalor 1200.1 MDDocument24 pagesMulticalor 700.1 MD Multicalor 800.1 MD Multicalor 1000.1 MD Multicalor 1200.1 MDcristian villegasNo ratings yet

- Mechanical Seal CatalogDocument172 pagesMechanical Seal Catalogcristian villegasNo ratings yet

- Renewable and Sustainable Energy Reviews: M.S. Gu Ney, K. KaygusuzDocument9 pagesRenewable and Sustainable Energy Reviews: M.S. Gu Ney, K. Kaygusuzcristian villegasNo ratings yet

- Providing Sustainable Energy Solutions Worldwide: Installation-And Maintenance InstructionDocument20 pagesProviding Sustainable Energy Solutions Worldwide: Installation-And Maintenance Instructioncristian villegasNo ratings yet

- FBR FGP 1000MDocument1 pageFBR FGP 1000Mcristian villegasNo ratings yet

- 750/m-El - FGP 1000/m-El - FGP 1300/m-El - FGP 1500/m-El - FGP 1800/m-ElDocument4 pages750/m-El - FGP 1000/m-El - FGP 1300/m-El - FGP 1500/m-El - FGP 1800/m-Elcristian villegasNo ratings yet

- Performance Characterization and Placement of A Marine Hydrokine - 2015 - ApplieDocument13 pagesPerformance Characterization and Placement of A Marine Hydrokine - 2015 - Appliecristian villegasNo ratings yet

- Ecoflam Technical SpecificationDocument62 pagesEcoflam Technical Specificationcristian villegasNo ratings yet

- Self-Priming Liquid Ring Pumps: With Double Anti-Seize Frontal InsertsDocument4 pagesSelf-Priming Liquid Ring Pumps: With Double Anti-Seize Frontal Insertscristian villegasNo ratings yet

- Renewable and Sustainable Energy Reviews: Nicholas D. Laws, Brenden P. EppsDocument15 pagesRenewable and Sustainable Energy Reviews: Nicholas D. Laws, Brenden P. Eppscristian villegasNo ratings yet

- Status of Micro Hydrokinetic River Technology in - 2014 - Renewable and SustainDocument9 pagesStatus of Micro Hydrokinetic River Technology in - 2014 - Renewable and Sustaincristian villegasNo ratings yet

- Power and Thrust Measurements of Marine Current Turbines Under Various Hydrodynamic Ow Conditions in A Cavitation Tunnel and A Towing TankDocument20 pagesPower and Thrust Measurements of Marine Current Turbines Under Various Hydrodynamic Ow Conditions in A Cavitation Tunnel and A Towing Tankcristian villegasNo ratings yet

- 1082.21.b Body Boiler TH.V 1250 1.250.000kcal.h 1.453 KW Quemadores Chile S.P.ADocument13 pages1082.21.b Body Boiler TH.V 1250 1.250.000kcal.h 1.453 KW Quemadores Chile S.P.Acristian villegasNo ratings yet

- Renewable Energy: W.C. Schleicher, J.D. Riglin, A. OztekinDocument8 pagesRenewable Energy: W.C. Schleicher, J.D. Riglin, A. Oztekincristian villegasNo ratings yet

- Ultragas (125-1000) : Technical Information Installation InstructionsDocument68 pagesUltragas (125-1000) : Technical Information Installation Instructionscristian villegasNo ratings yet

- Quemadores Bentone DIESEL GLP GNDocument15 pagesQuemadores Bentone DIESEL GLP GNcristian villegasNo ratings yet

- Class 150 Bronze Gate ValvesDocument1 pageClass 150 Bronze Gate Valvescristian villegasNo ratings yet

- Working PressureDocument11 pagesWorking Pressureshojaee1063No ratings yet

- Flange Carbon Steel ANSI CatalogDocument4 pagesFlange Carbon Steel ANSI CatalogKhonlong TangNo ratings yet

- Appendix 2-1.ep11422 - h-16 PDFDocument15 pagesAppendix 2-1.ep11422 - h-16 PDFbsnegi111No ratings yet

- M30120B-531-002F - R1 - Domestic Water Service System PDFDocument17 pagesM30120B-531-002F - R1 - Domestic Water Service System PDFirfanNo ratings yet

- Upvc Class D MpiDocument102 pagesUpvc Class D MpijovindhaNo ratings yet

- ATA-18 - Material PRs - Acid Section 10.02.18Document11 pagesATA-18 - Material PRs - Acid Section 10.02.18gullipalli srinivasa raoNo ratings yet

- Class 13834Document10 pagesClass 13834adewunmi olufemiNo ratings yet

- Bill of Quantities For Mall Total Plumbing Works Unit Qty SECTION - 1.00 A) Sanitary Fixtures and Fittings 24Document20 pagesBill of Quantities For Mall Total Plumbing Works Unit Qty SECTION - 1.00 A) Sanitary Fixtures and Fittings 24Santosh ShahNo ratings yet

- Aeroquip Part IndexDocument9 pagesAeroquip Part IndexSetyohdWNo ratings yet

- 02250176-181 (r05) enDocument118 pages02250176-181 (r05) enMiguel Angel Martinez DominguezNo ratings yet

- Filter: Saudi Arabian Oil CompanyDocument1 pageFilter: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Hydraulic Valves, Actuators and Accessories: 24 MarksDocument95 pagesHydraulic Valves, Actuators and Accessories: 24 MarksLAliNo ratings yet

- Endex Traditional End Feed SolutionsDocument60 pagesEndex Traditional End Feed Solutionsghetto_bmx_boyNo ratings yet

- X-Mas Tree 4-1/16'' X 3-1/8'', 5K, - 20 To 250°F, H S: Type Approval / Design Verification ReviewDocument1 pageX-Mas Tree 4-1/16'' X 3-1/8'', 5K, - 20 To 250°F, H S: Type Approval / Design Verification ReviewFernando OlaveoNo ratings yet

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDocument1 pageGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoNo ratings yet

- Seal-Lok O-Ring Face Seal Tube FittingsDocument34 pagesSeal-Lok O-Ring Face Seal Tube Fittingsarmin_kunosic9871No ratings yet

- Water Supply Fixture Units - I - WSFU - I - PDFDocument5 pagesWater Supply Fixture Units - I - WSFU - I - PDFEmir KarNo ratings yet

- CTC-2019-0038 Rev. 0Document1 pageCTC-2019-0038 Rev. 0Rafeek AliNo ratings yet

- Marley ValveDocument4 pagesMarley ValveM Fadli AzhariNo ratings yet

- Bill of Material Part Name SR. No. Material of Construction QtyDocument1 pageBill of Material Part Name SR. No. Material of Construction QtyHardik SuchakNo ratings yet

- M & e Design BriefDocument18 pagesM & e Design BriefFarhan Ariff Zaiton100% (2)

- Pipe GuideDocument48 pagesPipe GuideaaNo ratings yet

- Vendor List of PlumbingDocument1 pageVendor List of PlumbingBDAYA CompanyNo ratings yet

- 3-Way High Pressure Ball Valves: Carbon SteelDocument5 pages3-Way High Pressure Ball Valves: Carbon Steel劉功暹No ratings yet

- Defects in Building:: A) Structural DefectDocument12 pagesDefects in Building:: A) Structural DefectkalimNo ratings yet

- Retractable QuillDocument1 pageRetractable QuillimtiyazNo ratings yet

- MODULE 5 Alternativebuildingmaterials PDFDocument28 pagesMODULE 5 Alternativebuildingmaterials PDFPreethi SrinivasNo ratings yet