Professional Documents

Culture Documents

GNHS Smaw 2ND Quarter

GNHS Smaw 2ND Quarter

Uploaded by

Jymaer GeromoCopyright:

Available Formats

You might also like

- Question On CSWIP 3.2Document7 pagesQuestion On CSWIP 3.2mushruff89% (9)

- Böhler Welding CalcDocument2 pagesBöhler Welding CalcMOHAN0% (1)

- 4.1 Written TestDocument11 pages4.1 Written TestTvet Acn100% (2)

- Sample Written Test & Answer KeyDocument5 pagesSample Written Test & Answer KeyAlberto T. ToledoNo ratings yet

- Sample Written Test & Answer KeyDocument5 pagesSample Written Test & Answer KeyAlberto T. Toledo100% (1)

- Meaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orDocument10 pagesMeaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orLianne Sanchez75% (4)

- Welding Questions PDFDocument42 pagesWelding Questions PDFA. ΒρατσισταNo ratings yet

- Welding - Test Paper No.1Document4 pagesWelding - Test Paper No.1Ghulam AhmadNo ratings yet

- Flash Butt Welding of RailsDocument4 pagesFlash Butt Welding of RailsNagarajesh NaraparajuNo ratings yet

- 2nd Summative Test Smaw 8Document3 pages2nd Summative Test Smaw 8Krizzie Jade Cailing100% (2)

- A Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65Document5 pagesA Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65tuanNo ratings yet

- Math 11 2nd GradingDocument4 pagesMath 11 2nd GradingJymaer GeromoNo ratings yet

- 1st - Q - Exam - Grade 9 - Smaw - 25Document4 pages1st - Q - Exam - Grade 9 - Smaw - 25Jurie FernandezNo ratings yet

- SMAW NC I Set C - 50 ItemsDocument9 pagesSMAW NC I Set C - 50 Itemslouie gerasmiaNo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa Aquitan100% (1)

- 2nd Quarter Exam Smaw - Doc For PRINTDocument5 pages2nd Quarter Exam Smaw - Doc For PRINTSabas Quijada100% (3)

- SMAW NC I Set B - 50 ItemsDocument9 pagesSMAW NC I Set B - 50 Itemslouie gerasmia100% (1)

- Hooghly Engineering & Technology College: Question BankDocument18 pagesHooghly Engineering & Technology College: Question BankChayan PaulNo ratings yet

- Mcqs WeldingDocument5 pagesMcqs WeldingBabar Ali100% (3)

- Mastery Test Lesson 2 Metal Works 2Document6 pagesMastery Test Lesson 2 Metal Works 2Jessie MirandaNo ratings yet

- Workshop Technology PDFDocument48 pagesWorkshop Technology PDFilamparithiNo ratings yet

- Smaw 8 Second SummativeDocument3 pagesSmaw 8 Second SummativeJOHN REY VIDALNo ratings yet

- Cswip 3.2 Q&aDocument3 pagesCswip 3.2 Q&aMoses_Jakkala100% (3)

- Workshop ObjectivesDocument8 pagesWorkshop ObjectivesMansaf AbroNo ratings yet

- Ecet - Welding, Forging and Foundry1Document13 pagesEcet - Welding, Forging and Foundry1GENESIS ENGINEERS ACADEMYNo ratings yet

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- Test No 4ccDocument4 pagesTest No 4ccSalman GhaffarNo ratings yet

- MIDTERM-smaw ExamDocument6 pagesMIDTERM-smaw ExamRamramramManmanmanNo ratings yet

- Smaw 9 Summative Test Q1Document2 pagesSmaw 9 Summative Test Q1Jose Intraboy Arais Tabugoc Jr.No ratings yet

- HATDOGDocument3 pagesHATDOGMa Jamil SablaonNo ratings yet

- SMAWDocument2 pagesSMAWNarpie Jay DelubioNo ratings yet

- Cswip QuestionsDocument31 pagesCswip Questionsanandu vjNo ratings yet

- SMAW 1st Periodical ExamDocument3 pagesSMAW 1st Periodical ExamIrish Melody Dela FuertaNo ratings yet

- M CHOICE in Ra Để Mang Ve NhaDocument102 pagesM CHOICE in Ra Để Mang Ve NhaDinh Quang NhamNo ratings yet

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNo ratings yet

- Pre Test SMAW NC I 1Document6 pagesPre Test SMAW NC I 1Gaudencio BoniceliNo ratings yet

- Welding Q1 With AnsDocument12 pagesWelding Q1 With AnsAhmed HaridiNo ratings yet

- All ElementsDocument392 pagesAll ElementsWilliam Bataluna100% (2)

- Question Paper Welder Set 2Document22 pagesQuestion Paper Welder Set 2Devraj VermaNo ratings yet

- 3RD QTR Exam Grade 11-PearlDocument4 pages3RD QTR Exam Grade 11-PearlemmabentonioNo ratings yet

- CSWIP Sample QuestionsDocument31 pagesCSWIP Sample QuestionsNeo80% (5)

- General 5Document3 pagesGeneral 5Sobia KalsoomNo ratings yet

- Cswip QA/answerDocument6 pagesCswip QA/answerJoseph PeterNo ratings yet

- MD ElementsDocument13 pagesMD ElementsJosue RicaldeNo ratings yet

- 02 WeldingDocument11 pages02 WeldingLucky BoatNo ratings yet

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocument100 pagesCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNo ratings yet

- Comprehensive Evaluation 01, 2013Document14 pagesComprehensive Evaluation 01, 2013Zain Sani ButtNo ratings yet

- Welding Questions 1Document26 pagesWelding Questions 1dselvakuuNo ratings yet

- Elements of Machine DesignDocument18 pagesElements of Machine DesignDexter Frank Virtucio CalderonNo ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- SmawDocument2 pagesSmawEL JEAH MOSQUEDANo ratings yet

- Welding QuestionsDocument40 pagesWelding Questionssaba100% (1)

- Quiz For Lesson 9 (Metal Craft)Document5 pagesQuiz For Lesson 9 (Metal Craft)Bondoc John JustinNo ratings yet

- Module 1 Essentials of WeldingDocument22 pagesModule 1 Essentials of WeldingMARCOE ALONZO ACAIN100% (2)

- Smaw NC Ii Pre TestDocument22 pagesSmaw NC Ii Pre TestOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCNo ratings yet

- General 6Document4 pagesGeneral 6Solomon AttaNo ratings yet

- Exams For SMAWDocument7 pagesExams For SMAWRuddy SuicoNo ratings yet

- Welding Inspection Q and Ans.Document20 pagesWelding Inspection Q and Ans.Ashwani Dogra100% (2)

- Engineering Materials ExaminationDocument6 pagesEngineering Materials ExaminationRay-Ray Carino AraoNo ratings yet

- 3rd Quarter Exam For SMAWDocument3 pages3rd Quarter Exam For SMAWalvin madahan100% (1)

- Question 1Document27 pagesQuestion 1Rammer PakpahanNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Accomplishment Report Brigada 2022-2023Document2 pagesAccomplishment Report Brigada 2022-2023Jymaer GeromoNo ratings yet

- A New Normal The Critical Role of Assessment in Online Learning - CertificatesDocument2 pagesA New Normal The Critical Role of Assessment in Online Learning - CertificatesJymaer GeromoNo ratings yet

- Action Plan GulayanDocument3 pagesAction Plan GulayanJymaer Geromo100% (1)

- Smaw Tle 9 Q4 W1-8Document6 pagesSmaw Tle 9 Q4 W1-8Jymaer GeromoNo ratings yet

- MARY JANE GEROMO - Assessment 5Document2 pagesMARY JANE GEROMO - Assessment 5Jymaer GeromoNo ratings yet

- Solicitation LetterDocument1 pageSolicitation LetterJymaer GeromoNo ratings yet

- BE Form 7 SCHOOL ACCOMPLISHMENT REPORT 1Document8 pagesBE Form 7 SCHOOL ACCOMPLISHMENT REPORT 1Jymaer GeromoNo ratings yet

- Matrial and EquipmentDocument2 pagesMatrial and EquipmentJymaer GeromoNo ratings yet

- Jay 23Document19 pagesJay 23Jymaer GeromoNo ratings yet

- AUR FormDocument1 pageAUR FormJymaer GeromoNo ratings yet

- Math 11 2nd GradingDocument4 pagesMath 11 2nd GradingJymaer GeromoNo ratings yet

- Smaw EXAMDocument4 pagesSmaw EXAMJymaer GeromoNo ratings yet

- Letter of Intent For NTTCDocument1 pageLetter of Intent For NTTCJymaer GeromoNo ratings yet

- Carpentry 10-2nd-GradingDocument4 pagesCarpentry 10-2nd-GradingJymaer GeromoNo ratings yet

- Parental Consent Boy ScoutsDocument1 pageParental Consent Boy ScoutsJymaer GeromoNo ratings yet

- Lesson Plan SMAW 12Document8 pagesLesson Plan SMAW 12Jymaer GeromoNo ratings yet

- QuizDocument4 pagesQuizJymaer GeromoNo ratings yet

- PolytechnicDocument3 pagesPolytechnicJymaer GeromoNo ratings yet

- Be Form 1 Physical Facilities and Maintenance Needs Assessment FormDocument2 pagesBe Form 1 Physical Facilities and Maintenance Needs Assessment FormJymaer GeromoNo ratings yet

- 15 Intro To Arc WeldingDocument8 pages15 Intro To Arc WeldingJymaer GeromoNo ratings yet

- Be Form 7 School Accomplishment Report 1Document9 pagesBe Form 7 School Accomplishment Report 1Jymaer GeromoNo ratings yet

- Cover Page BrigadaDocument1 pageCover Page BrigadaJymaer GeromoNo ratings yet

- GSP MatrixDocument2 pagesGSP MatrixJymaer GeromoNo ratings yet

- CBLM Fabricating FormworksDocument33 pagesCBLM Fabricating FormworksJymaer GeromoNo ratings yet

- TLE 9 1st Quarter Exam With Answer Key PDFDocument3 pagesTLE 9 1st Quarter Exam With Answer Key PDFJymaer GeromoNo ratings yet

- Be Form 3 Resource Mobilization Form 1Document2 pagesBe Form 3 Resource Mobilization Form 1Jymaer GeromoNo ratings yet

- Tle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Document9 pagesTle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Jymaer GeromoNo ratings yet

- Be Form 6 Daily Accomplishment ReportDocument1 pageBe Form 6 Daily Accomplishment ReportJymaer Geromo100% (1)

- Chapter 7 ConnectionDocument140 pagesChapter 7 Connectionalafkhair tradingNo ratings yet

- SS EN 1993-1-8-2010 (2016) - PreviewDocument13 pagesSS EN 1993-1-8-2010 (2016) - PreviewPatrick100% (1)

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILONo ratings yet

- Plastic Welding Using Kamweld S Durable WeldersDocument33 pagesPlastic Welding Using Kamweld S Durable WeldersFaiz SabianNo ratings yet

- Welding ProcedureDocument11 pagesWelding ProcedureAziz RanaNo ratings yet

- Danfoss EconomozerDocument12 pagesDanfoss EconomozerDusan CajicNo ratings yet

- File 20210119 102344 Ketcau Han 3.06Document66 pagesFile 20210119 102344 Ketcau Han 3.06Nguyễn Văn NguyệnNo ratings yet

- Steel Design Rules For BracketsDocument70 pagesSteel Design Rules For BracketsJIA MANo ratings yet

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Full Price List For Specimens-2019-INRDocument3 pagesFull Price List For Specimens-2019-INRmanojNo ratings yet

- Asme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesDocument69 pagesAsme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesnitinNo ratings yet

- Welding SymbolsDocument8 pagesWelding SymbolsSantosh Kumar100% (1)

- F WeldDocument4 pagesF Weldshantanu chowdhuryNo ratings yet

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsNo ratings yet

- MSS-SP-97 (2006)Document15 pagesMSS-SP-97 (2006)Rahul MehtaNo ratings yet

- ISO 15614-1 Englisch PDFDocument1 pageISO 15614-1 Englisch PDFashrafNo ratings yet

- 9201 Spec Barred TeeDocument23 pages9201 Spec Barred TeeSoumya KumarNo ratings yet

- ISO 9606-5 2000 Qualification Testing of Welders-Fusion Welding Part 5 Titanium and Titanium Alloys, Zirconium and Zirconium AlloysDocument26 pagesISO 9606-5 2000 Qualification Testing of Welders-Fusion Welding Part 5 Titanium and Titanium Alloys, Zirconium and Zirconium AlloysJames Hurtado100% (1)

- What Does MSS Mean in Piping Industry List of MSS Standards PDFDocument6 pagesWhat Does MSS Mean in Piping Industry List of MSS Standards PDFVKT TiwariNo ratings yet

- WeldToolkit Documentation V212.1Document91 pagesWeldToolkit Documentation V212.1sekhar730No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Welding Calculations: Return To Main Menu BasicsDocument27 pagesWelding Calculations: Return To Main Menu BasicsBarry LibertyNo ratings yet

- Butt WeldingDocument4 pagesButt Weldinghatman1929No ratings yet

- As 2885.2-2007 Pipelines - Gas and Liquid Petroleum WeldingDocument11 pagesAs 2885.2-2007 Pipelines - Gas and Liquid Petroleum WeldingSAI Global - APAC100% (2)

- Is - 816Document30 pagesIs - 816mmkatta100% (1)

- Magnetic Particle Generic ProcedureDocument19 pagesMagnetic Particle Generic ProcedureAbdullah AnsariNo ratings yet

GNHS Smaw 2ND Quarter

GNHS Smaw 2ND Quarter

Uploaded by

Jymaer GeromoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GNHS Smaw 2ND Quarter

GNHS Smaw 2ND Quarter

Uploaded by

Jymaer GeromoCopyright:

Available Formats

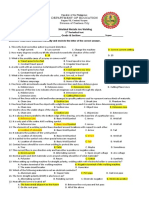

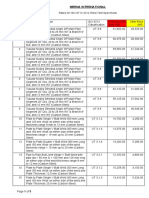

REPUBLIC OF THE PHILIPPINES

Department of Education

REGION XI

Schools Division of Digos City

GOMA NATIONAL HIGH SCHOOL

School ID: 301906

Sitio Napan, Brgy.Goma, Digos City

2nd Quarterly exam

Name:________________________________ Date:______________

Grade and section:___________________ Score:_____________

Choose the correct answer from the series given for every item.

Write the letter only.

1. is a method of joining two metals by applying heat to

melt and fuse them, producing a coalescence of materials

with or without the use of filler metal.

a. Fushion welding c. Gmaw

b. . welding d. Oxy-acetylene process

2. is a metal rod coated with a special substance called flux,

which determines the nature of the electrode. During

welding it is melted to fill up joints in the base metal.

a. Bare electrode c. flux

b. Flux coated electrode d. electrode angle

3. a filler metal electrode used in arc welding, consisting of a

metal wire with no coating on its surface.

a. Bare electrode c. coated

b. Coated electrode d. electrode coated

4. is a fusible material or gas used to dissolve and/or

prevent the formation of oxides, nitrides or other

undesirable inclusions formed in welding.

a. Weldment c. weld bead

b. Face of the weld d. flux

5. The metal that is to be welded or worked.

a. Core metal c. metallic

b. Parent or base metal d. circle metal

6. an assembly or structure whose component parts are joined by

welding.

a. Weld bead c. weld face

b. Weld ment d. weld root

7. it is a deposit of filler metal from a single welding pass.

a. Weld bead c. weld face

b. Weld ment d. weld root

8. a type of weld bead with appreciable transverse oscillation

or side to side movement.

a. Figure of 8 c. linear motion

b. Cresent motion d. stringer bead motion

9. expose surface of the weld.

a. Face of a Weld c. ripple

b. Crater d. pass

10. it is an angle from the electrode which is perpendicular to

the base metal.

a. arc length c. type of electrode

b. electrode angle d. arc angle

.11 What method in striking an arc is recommended for the

beginners?

a. Tapping method

b. Scratching method

c. Any of these

d. None of the above

12. In the symbol E-6013; letter “E” stands for:

a.Electric

b.Energy

c.Electrode

d.None of the above

13. Eyes can be protected during welding operations by using:

a. Gloves

b. Leggings

c. Goggles

d. Apron

14. It is done by touching the electrode to the base metal like

scratching a match.

a. Tapping Method

b. Scratching Method

c. All of these

d. None of there

15. It is done by moving the electrode downward until it

steps to the base metal and then bringing the electrode

up slightly to form an arc.

a. Taping Method

b. Scratching Method

c. All of these

16. None of these The coating of electrode is sometimes called:

a. Flux

b. Shield

c. Covering

d. All of these

17. The electrode which has no coating is called:

a. Shielded

b. Bare

c. Dusted

d. Dipped

18. The symbol E-6013;60 means

a. Welding Position

b. Tensile Strength

c. Power Supply

d. Flux Coating

19. The third digit in the symbol E-6013; 1 stands for

a. Welding Position

b. Tensile Strength

c. Power Supply

d. Flux Coating

20. The diameter of the electrode to be used in welding operation

depends upon the:

a. Thickness of the Base Metal

b. Welding Position

c. Type of Base Metal

d. None of these

21. . Tack welds are simply short sections of weld beads measured?

.

a. 1/4” to ½” c. ½” to !/4”

b. 1” to 2 “ d. 3/8” to 5/8”

22. Type of tack weld measured at about ¼” up to ½” length.

It is used fir up temporarily the two pieces of heavy metal being

joined.

a. Permanent Tacking c. Semi-permanent Tacking

b.Bridge Tacking d. Semi Tacking

23. When two plates are joint, the following gap must be

considered in performing tack welding?

a. 8 mm c. 4 mm

b. 3 mm d. 2 cm

24. What method of weld tacking usiusesiffeners or backing

plate to keep both plates aligned?

a. Permanent Tacking c. Semi-permanent Tacking

b. Bridge Tacking d. Semi Tacking

25. A tack weld done only in a very short bead. It is used to

fit up temporarily the two light pieces of metal to be joined.

a. Permanent Tacking c. Semi-permanent Tacking

b. Bridge Tacking d. Semi Tacking

26. It is the area where filler metal intersects the base metal

opposite face.

a. Weld toe c. Weld root

b. Weld leg d. Weld face

27.It is the surface of the base metal that melts during welding.

a. Fusion welding c. Fusion face

b. Weld root d. Weld Toe

28. It is the shortest distance from the face of a

fillet weld to the weld root aft welding.

a. Actual Throat c. Theoretical Throat

b. Effective Throat d. Weld Toe

29. It is the work angle used for thin metal welded to

thick metal plate fillet weld.

a. 40 degrees c. 45 degree

b. 55 degrees d. 60 degree

30. A fillet weld is a weld type in the cross-sectional shape of

a. Square c. Circle

b. Rectangle d. Triangle

31. What is the correct root gap between two plates?

a. a. 1.0mm c. 3.2mm

b. b. 4.0mm d. 5.0mm

32. What electrode number used

to weld on root pass?

a. 6011 c. 6013

b. b. 7018 d. 7024

33. What electrode number is

used to weld on the hot pass?

a. 6010 c.6012

b. 7018 d. 6011

34. What is the ideal arc length of electrode to the base metal?

a. 4.2mm c. 2.0mm

b. 1.2mm d. 3.2mm

35. What is the angle at which a bevel is cut?

a. Bevel c. Right angle

b. Bevel angle d. groove angle

36. Why is a surfacing weld different from the other weld types?

a. Because it does not join to distinct parts, but instead adds only

filler metal to a surface.

b. Because the heat is concentrated in a small region for greatest

efficiency and minimum metallurgical damage.

c. reconditioning temperatures for electrodes are higher than the

storage temperature, which helps eliminate excess moisture

d. welding arc, they release shielding gas to protect the molten

weld pool from atmospheric impurities.

37. Groove welds are most closely associated with which one of the

following joint types:

a . butt, b.corner, c. edge, d. lap, e. tee

38. A fillet weld can be used to join which of the following joint types

a. butt, b. corner, c. edge, d. lap, e. tee

39. Prepare sketches showing how the part edges would be prepared

and aligned with each other and also showing the weld cross section for the

following welds:

a.square groove weld, both sides, for butt weld and

b.single fillet weld for a lap joint.

c. single fillet weld for tee joint;

d. double U-groove weld for a butt weld.

40. A heat source can transfer 3500 J/sec to a metal part surface.

The heated area is circular, and theheat intensity decreases as the radius

increases, as follows: 70% of the heat is concentrated in acircular area that

is 3.75 mm in diameter. Is the resulting power density enough to melt

metal?

a.225 W

b.224W

c. 222 W

d. 283 W

Answer key:

1. B 21.C

2. B 22.C

3. A 23.C

4. D 24.B

5. B 25.C

6. B 26.C

7. A 27.C

8. D 28.A

9. A 29.C

10.B 30.D

11. B 31.C

12. C 32.A

13. C 33.B

14. B 34.D

15.A 35.B

16.D 36.A

17.B 37.A

18.B 38.B

19.A 39. A

20. A 40. C

You might also like

- Question On CSWIP 3.2Document7 pagesQuestion On CSWIP 3.2mushruff89% (9)

- Böhler Welding CalcDocument2 pagesBöhler Welding CalcMOHAN0% (1)

- 4.1 Written TestDocument11 pages4.1 Written TestTvet Acn100% (2)

- Sample Written Test & Answer KeyDocument5 pagesSample Written Test & Answer KeyAlberto T. ToledoNo ratings yet

- Sample Written Test & Answer KeyDocument5 pagesSample Written Test & Answer KeyAlberto T. Toledo100% (1)

- Meaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orDocument10 pagesMeaning: Heat - Affected-Zone (HAZ) Is The Area of Base Material, Either A Metal orLianne Sanchez75% (4)

- Welding Questions PDFDocument42 pagesWelding Questions PDFA. ΒρατσισταNo ratings yet

- Welding - Test Paper No.1Document4 pagesWelding - Test Paper No.1Ghulam AhmadNo ratings yet

- Flash Butt Welding of RailsDocument4 pagesFlash Butt Welding of RailsNagarajesh NaraparajuNo ratings yet

- 2nd Summative Test Smaw 8Document3 pages2nd Summative Test Smaw 8Krizzie Jade Cailing100% (2)

- A Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65Document5 pagesA Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65tuanNo ratings yet

- Math 11 2nd GradingDocument4 pagesMath 11 2nd GradingJymaer GeromoNo ratings yet

- 1st - Q - Exam - Grade 9 - Smaw - 25Document4 pages1st - Q - Exam - Grade 9 - Smaw - 25Jurie FernandezNo ratings yet

- SMAW NC I Set C - 50 ItemsDocument9 pagesSMAW NC I Set C - 50 Itemslouie gerasmiaNo ratings yet

- Shielded Metal Arc Welding NC Ii 3 Final ExaminationDocument2 pagesShielded Metal Arc Welding NC Ii 3 Final ExaminationJessa Aquitan100% (1)

- 2nd Quarter Exam Smaw - Doc For PRINTDocument5 pages2nd Quarter Exam Smaw - Doc For PRINTSabas Quijada100% (3)

- SMAW NC I Set B - 50 ItemsDocument9 pagesSMAW NC I Set B - 50 Itemslouie gerasmia100% (1)

- Hooghly Engineering & Technology College: Question BankDocument18 pagesHooghly Engineering & Technology College: Question BankChayan PaulNo ratings yet

- Mcqs WeldingDocument5 pagesMcqs WeldingBabar Ali100% (3)

- Mastery Test Lesson 2 Metal Works 2Document6 pagesMastery Test Lesson 2 Metal Works 2Jessie MirandaNo ratings yet

- Workshop Technology PDFDocument48 pagesWorkshop Technology PDFilamparithiNo ratings yet

- Smaw 8 Second SummativeDocument3 pagesSmaw 8 Second SummativeJOHN REY VIDALNo ratings yet

- Cswip 3.2 Q&aDocument3 pagesCswip 3.2 Q&aMoses_Jakkala100% (3)

- Workshop ObjectivesDocument8 pagesWorkshop ObjectivesMansaf AbroNo ratings yet

- Ecet - Welding, Forging and Foundry1Document13 pagesEcet - Welding, Forging and Foundry1GENESIS ENGINEERS ACADEMYNo ratings yet

- Wa0084Document33 pagesWa0084miteshNo ratings yet

- Test No 4ccDocument4 pagesTest No 4ccSalman GhaffarNo ratings yet

- MIDTERM-smaw ExamDocument6 pagesMIDTERM-smaw ExamRamramramManmanmanNo ratings yet

- Smaw 9 Summative Test Q1Document2 pagesSmaw 9 Summative Test Q1Jose Intraboy Arais Tabugoc Jr.No ratings yet

- HATDOGDocument3 pagesHATDOGMa Jamil SablaonNo ratings yet

- SMAWDocument2 pagesSMAWNarpie Jay DelubioNo ratings yet

- Cswip QuestionsDocument31 pagesCswip Questionsanandu vjNo ratings yet

- SMAW 1st Periodical ExamDocument3 pagesSMAW 1st Periodical ExamIrish Melody Dela FuertaNo ratings yet

- M CHOICE in Ra Để Mang Ve NhaDocument102 pagesM CHOICE in Ra Để Mang Ve NhaDinh Quang NhamNo ratings yet

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNo ratings yet

- Pre Test SMAW NC I 1Document6 pagesPre Test SMAW NC I 1Gaudencio BoniceliNo ratings yet

- Welding Q1 With AnsDocument12 pagesWelding Q1 With AnsAhmed HaridiNo ratings yet

- All ElementsDocument392 pagesAll ElementsWilliam Bataluna100% (2)

- Question Paper Welder Set 2Document22 pagesQuestion Paper Welder Set 2Devraj VermaNo ratings yet

- 3RD QTR Exam Grade 11-PearlDocument4 pages3RD QTR Exam Grade 11-PearlemmabentonioNo ratings yet

- CSWIP Sample QuestionsDocument31 pagesCSWIP Sample QuestionsNeo80% (5)

- General 5Document3 pagesGeneral 5Sobia KalsoomNo ratings yet

- Cswip QA/answerDocument6 pagesCswip QA/answerJoseph PeterNo ratings yet

- MD ElementsDocument13 pagesMD ElementsJosue RicaldeNo ratings yet

- 02 WeldingDocument11 pages02 WeldingLucky BoatNo ratings yet

- Cut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackDocument100 pagesCut Pieces: From Flat Plates, Strips and Coil Stock. A. Shearing B. Bend Allowance C. Forming Dies D. Spring BackJade DigNo ratings yet

- Comprehensive Evaluation 01, 2013Document14 pagesComprehensive Evaluation 01, 2013Zain Sani ButtNo ratings yet

- Welding Questions 1Document26 pagesWelding Questions 1dselvakuuNo ratings yet

- Elements of Machine DesignDocument18 pagesElements of Machine DesignDexter Frank Virtucio CalderonNo ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- SmawDocument2 pagesSmawEL JEAH MOSQUEDANo ratings yet

- Welding QuestionsDocument40 pagesWelding Questionssaba100% (1)

- Quiz For Lesson 9 (Metal Craft)Document5 pagesQuiz For Lesson 9 (Metal Craft)Bondoc John JustinNo ratings yet

- Module 1 Essentials of WeldingDocument22 pagesModule 1 Essentials of WeldingMARCOE ALONZO ACAIN100% (2)

- Smaw NC Ii Pre TestDocument22 pagesSmaw NC Ii Pre TestOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCNo ratings yet

- General 6Document4 pagesGeneral 6Solomon AttaNo ratings yet

- Exams For SMAWDocument7 pagesExams For SMAWRuddy SuicoNo ratings yet

- Welding Inspection Q and Ans.Document20 pagesWelding Inspection Q and Ans.Ashwani Dogra100% (2)

- Engineering Materials ExaminationDocument6 pagesEngineering Materials ExaminationRay-Ray Carino AraoNo ratings yet

- 3rd Quarter Exam For SMAWDocument3 pages3rd Quarter Exam For SMAWalvin madahan100% (1)

- Question 1Document27 pagesQuestion 1Rammer PakpahanNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Accomplishment Report Brigada 2022-2023Document2 pagesAccomplishment Report Brigada 2022-2023Jymaer GeromoNo ratings yet

- A New Normal The Critical Role of Assessment in Online Learning - CertificatesDocument2 pagesA New Normal The Critical Role of Assessment in Online Learning - CertificatesJymaer GeromoNo ratings yet

- Action Plan GulayanDocument3 pagesAction Plan GulayanJymaer Geromo100% (1)

- Smaw Tle 9 Q4 W1-8Document6 pagesSmaw Tle 9 Q4 W1-8Jymaer GeromoNo ratings yet

- MARY JANE GEROMO - Assessment 5Document2 pagesMARY JANE GEROMO - Assessment 5Jymaer GeromoNo ratings yet

- Solicitation LetterDocument1 pageSolicitation LetterJymaer GeromoNo ratings yet

- BE Form 7 SCHOOL ACCOMPLISHMENT REPORT 1Document8 pagesBE Form 7 SCHOOL ACCOMPLISHMENT REPORT 1Jymaer GeromoNo ratings yet

- Matrial and EquipmentDocument2 pagesMatrial and EquipmentJymaer GeromoNo ratings yet

- Jay 23Document19 pagesJay 23Jymaer GeromoNo ratings yet

- AUR FormDocument1 pageAUR FormJymaer GeromoNo ratings yet

- Math 11 2nd GradingDocument4 pagesMath 11 2nd GradingJymaer GeromoNo ratings yet

- Smaw EXAMDocument4 pagesSmaw EXAMJymaer GeromoNo ratings yet

- Letter of Intent For NTTCDocument1 pageLetter of Intent For NTTCJymaer GeromoNo ratings yet

- Carpentry 10-2nd-GradingDocument4 pagesCarpentry 10-2nd-GradingJymaer GeromoNo ratings yet

- Parental Consent Boy ScoutsDocument1 pageParental Consent Boy ScoutsJymaer GeromoNo ratings yet

- Lesson Plan SMAW 12Document8 pagesLesson Plan SMAW 12Jymaer GeromoNo ratings yet

- QuizDocument4 pagesQuizJymaer GeromoNo ratings yet

- PolytechnicDocument3 pagesPolytechnicJymaer GeromoNo ratings yet

- Be Form 1 Physical Facilities and Maintenance Needs Assessment FormDocument2 pagesBe Form 1 Physical Facilities and Maintenance Needs Assessment FormJymaer GeromoNo ratings yet

- 15 Intro To Arc WeldingDocument8 pages15 Intro To Arc WeldingJymaer GeromoNo ratings yet

- Be Form 7 School Accomplishment Report 1Document9 pagesBe Form 7 School Accomplishment Report 1Jymaer GeromoNo ratings yet

- Cover Page BrigadaDocument1 pageCover Page BrigadaJymaer GeromoNo ratings yet

- GSP MatrixDocument2 pagesGSP MatrixJymaer GeromoNo ratings yet

- CBLM Fabricating FormworksDocument33 pagesCBLM Fabricating FormworksJymaer GeromoNo ratings yet

- TLE 9 1st Quarter Exam With Answer Key PDFDocument3 pagesTLE 9 1st Quarter Exam With Answer Key PDFJymaer GeromoNo ratings yet

- Be Form 3 Resource Mobilization Form 1Document2 pagesBe Form 3 Resource Mobilization Form 1Jymaer GeromoNo ratings yet

- Tle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Document9 pagesTle - Iaaw11Fw-Ia-Iij-3: K To 12 TVL Track Industrial Arts - Shielded Metal Arc Welding Curriculum Guide December 2013Jymaer GeromoNo ratings yet

- Be Form 6 Daily Accomplishment ReportDocument1 pageBe Form 6 Daily Accomplishment ReportJymaer Geromo100% (1)

- Chapter 7 ConnectionDocument140 pagesChapter 7 Connectionalafkhair tradingNo ratings yet

- SS EN 1993-1-8-2010 (2016) - PreviewDocument13 pagesSS EN 1993-1-8-2010 (2016) - PreviewPatrick100% (1)

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILONo ratings yet

- Plastic Welding Using Kamweld S Durable WeldersDocument33 pagesPlastic Welding Using Kamweld S Durable WeldersFaiz SabianNo ratings yet

- Welding ProcedureDocument11 pagesWelding ProcedureAziz RanaNo ratings yet

- Danfoss EconomozerDocument12 pagesDanfoss EconomozerDusan CajicNo ratings yet

- File 20210119 102344 Ketcau Han 3.06Document66 pagesFile 20210119 102344 Ketcau Han 3.06Nguyễn Văn NguyệnNo ratings yet

- Steel Design Rules For BracketsDocument70 pagesSteel Design Rules For BracketsJIA MANo ratings yet

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Full Price List For Specimens-2019-INRDocument3 pagesFull Price List For Specimens-2019-INRmanojNo ratings yet

- Asme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesDocument69 pagesAsme b16 9 b16 11 Elbow Pipe Fittings Dimensions SizesnitinNo ratings yet

- Welding SymbolsDocument8 pagesWelding SymbolsSantosh Kumar100% (1)

- F WeldDocument4 pagesF Weldshantanu chowdhuryNo ratings yet

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsNo ratings yet

- MSS-SP-97 (2006)Document15 pagesMSS-SP-97 (2006)Rahul MehtaNo ratings yet

- ISO 15614-1 Englisch PDFDocument1 pageISO 15614-1 Englisch PDFashrafNo ratings yet

- 9201 Spec Barred TeeDocument23 pages9201 Spec Barred TeeSoumya KumarNo ratings yet

- ISO 9606-5 2000 Qualification Testing of Welders-Fusion Welding Part 5 Titanium and Titanium Alloys, Zirconium and Zirconium AlloysDocument26 pagesISO 9606-5 2000 Qualification Testing of Welders-Fusion Welding Part 5 Titanium and Titanium Alloys, Zirconium and Zirconium AlloysJames Hurtado100% (1)

- What Does MSS Mean in Piping Industry List of MSS Standards PDFDocument6 pagesWhat Does MSS Mean in Piping Industry List of MSS Standards PDFVKT TiwariNo ratings yet

- WeldToolkit Documentation V212.1Document91 pagesWeldToolkit Documentation V212.1sekhar730No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Welding Calculations: Return To Main Menu BasicsDocument27 pagesWelding Calculations: Return To Main Menu BasicsBarry LibertyNo ratings yet

- Butt WeldingDocument4 pagesButt Weldinghatman1929No ratings yet

- As 2885.2-2007 Pipelines - Gas and Liquid Petroleum WeldingDocument11 pagesAs 2885.2-2007 Pipelines - Gas and Liquid Petroleum WeldingSAI Global - APAC100% (2)

- Is - 816Document30 pagesIs - 816mmkatta100% (1)

- Magnetic Particle Generic ProcedureDocument19 pagesMagnetic Particle Generic ProcedureAbdullah AnsariNo ratings yet