Professional Documents

Culture Documents

Apcs 1B 1e Hem

Apcs 1B 1e Hem

Uploaded by

jinujoseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apcs 1B 1e Hem

Apcs 1B 1e Hem

Uploaded by

jinujoseCopyright:

Available Formats

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

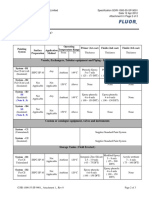

Manufacturer - Approved Saudi Aramco Data Sheet

APCS-1B/1E

Type of Coating : Epoxy Primer, with Zinc Phosphate

Manufacturer : Hempel Paints (Saudi Arabia) W.L.L.

Product Name : Hempadur HB Primer 17300

SAP M/N (SAMS S/N) : 1000194626 (09-612-362)

1. Storage

1.1 Shelf life, sheltered storage @ 35°C maximum : 2 years

2. Mixing

2.1 No. of Components : 2

2.1.1 Base : 17309

2.1.2 Hardener (Curing Agent) : 95010

2.2 Mixing Ratio (Base : Curing Agent) : 5:1 by volume

2.3 Thinner : Hempel’s 08450

SAP M/N (SAMS S/N) : 1000198445 (09-738-280)

2.4 Minimum-Maximum Thinning Requirements : up to 5%

2.5 Induction Time : Nil

2.6 Pot Life : 3 hours @ 25ºC

1 hours @ 40ºC

3. Application

3.1 Minimum-Maximum Allowable Substrate Temperature : 20-50°C

3.2 Minimum-Maximum Allowable Relative Humidity : 50 -85%

3.3 Typical Wet Film Thickness Per Coat : 135 microns

3.4 Typical Dry Film Thickness Per Coat : 75 microns

Page 174 of 428

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

Manufacturer - Approved Saudi Aramco Data Sheet

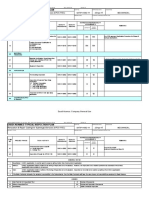

APCS-1B/1E - Hempadur HB Primer 17300 (Cont'd)

3.5 Theoretical Coverage @ 25 Micrometers : 22.4 m2/L

Dry Film Thickness

3.6 Minimum Number of Coats : 1

3.7 Applicable Substrate : Steel and other metal

3.8 Surface Preparation Requirements:

New steel: Abrasive blasting to Sa 2½. For temporary protection, if required, use a

suitable shop primer. All damage of shop primer and contamination from storage and

fabrication should be thoroughly cleaned prior to final painting. For repair and touch-up

use HEMPADUR HB PRIMER 17300.

Other metals and light alloys: Thorough degreasing and removal of any salty

contamination. Abrasive sweeping to create a suitable dense anchor profile.

Repair and maintenance: Remove oil and grease, etc. with suitable detergent. Remove

salt and other contaminants by (high pressure) fresh water cleaning. Clean damaged areas

thoroughly by power tool cleaning to St 3 (minor areas) or by abrasive blasting to min.

Sa 2, preferably to Sa 2½. Improved surface preparation will improve the performance of

HEMPADUR HB PRIMER 17300.Feather edges to sound intact areas. Dust off residues.

Touch up to full film thickness.

On pit-corroded surfaces, excessive amounts of salt residues may call for high pressure

water jetting, wet abrasive blasting, alternatively dry abrasive blasting, high pressure

fresh water hosing, drying, and finally, dry abrasive blasting again.

3.9 Drying Time at specified DFT

Substrate Recoat Interval To Handle To Service Full Cure

Temperature Minimum Maximum

10°C 10 days 60 days 6 hours

30°C 2½ hours 18 days 1½ hours

50°C 1 hour 7 days 1 hour

Page 175 of 428

Document Responsibility: Paints and Coatings Standards Committee SAES-H-101V

Issue Date: 16 October 2017

Next Planned Update: 16 October 2020 Approved Saudi Aramco Data Sheets - Paints and Coatings

Manufacturer - Approved Saudi Aramco Data Sheet

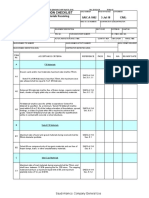

APCS-1B/1E - Hempadur HB Primer 17300 (Cont'd)

3.10 Recommended Application Equipment

Airless (A/L) Spray : Tip size: 0.021 inch

Conventional Spray : Tip Size: 0.021 inch

Brush : For stripe coating / touch-up only

4. Physical Properties

4.1 Volume Solids (ASTM D2697) : 54 to 58%

4.2 Product Weight (ASTM D1475) : 1.47 to 1.53 Kg/L

4.3 Viscosity (ASTM D562) : 75 to 80 KU

4.4 Flash Point (ASTM D93 or D56) : 26ºC

4.5 Approved Color/s : 21780 Yellow

4.6 Finish : Flat

Approval Date:

Replaces: December 22, 2004

Page 176 of 428

You might also like

- Complete MetalsmithDocument313 pagesComplete MetalsmithOana Bejan100% (17)

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDNo ratings yet

- Awwa M45Document6 pagesAwwa M45Rafael Ramirez0% (1)

- Building Handover Inspections ChecklistDocument7 pagesBuilding Handover Inspections ChecklistNisreen Abu-MahfouzNo ratings yet

- Painting and Coating For Fpso (New Construction) : Company Technical StandardDocument83 pagesPainting and Coating For Fpso (New Construction) : Company Technical StandardMohamed GhonaimNo ratings yet

- Basf MasterEmaco 8100 APDocument49 pagesBasf MasterEmaco 8100 APabdul majeedNo ratings yet

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- Painting System Guide No.: SSPC: The Society For Protective CoatingsDocument6 pagesPainting System Guide No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- ACQPA - Systems Certified in Im2 ANI PDFDocument1 pageACQPA - Systems Certified in Im2 ANI PDFANIBAL LOPEZNo ratings yet

- Peikko HFS Fixing SocketDocument4 pagesPeikko HFS Fixing SocketClaudioNo ratings yet

- Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17ADocument3 pagesManufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1D/11A/17AjinujoseNo ratings yet

- Manufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FDocument3 pagesManufacturer - Approved Saudi Aramco Data Sheet APCS-1A/1B/1C/1D/1E//1FjinujoseNo ratings yet

- Saes H 101V PDFDocument389 pagesSaes H 101V PDFQA QCNo ratings yet

- Apcs 17a 85710Document2 pagesApcs 17a 85710jojo_323No ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- Apcs 117Document12 pagesApcs 117Ilyas AhmedNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- 29006.eng - Cpi.std - Painting Systems SheetsDocument37 pages29006.eng - Cpi.std - Painting Systems SheetsMatteoNo ratings yet

- Barcoill Hardness Test PDFDocument2 pagesBarcoill Hardness Test PDFProkopNo ratings yet

- Coating Systems Norsok-Brochure - 0820Document12 pagesCoating Systems Norsok-Brochure - 0820Mameddurdy OrazalievNo ratings yet

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27No ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Oxsilan Presentation PDFDocument41 pagesOxsilan Presentation PDFHưng TrầnNo ratings yet

- Antox 71 E Pickling Paste PDFDocument2 pagesAntox 71 E Pickling Paste PDFasaasd100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Panel Test ReportDocument9 pagesPanel Test ReportLong Bui VietNo ratings yet

- A Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 04 of 05)Document5 pagesA Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 04 of 05)Adam Michael Green100% (1)

- Ep-Gis 18-013Document27 pagesEp-Gis 18-013GorakhNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- KOC-P-002 Part 2-R6-23-08-2015Document49 pagesKOC-P-002 Part 2-R6-23-08-2015Hari KrishnanNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Materials System SpecificationDocument8 pagesMaterials System SpecificationAjeetKumarNo ratings yet

- Majnoon CPF 2 Project: Vendor Document Review SheetDocument25 pagesMajnoon CPF 2 Project: Vendor Document Review SheetMassimo FumarolaNo ratings yet

- Training Cert Catalog 2020 Web-4Document64 pagesTraining Cert Catalog 2020 Web-4Ali RazaNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Gs Ep Cor 772 Rev02 2019Document67 pagesGs Ep Cor 772 Rev02 2019Alioune CamaraNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Field Applied Internal Coatings & Repairs SAIC-H-2057Document3 pagesSaudi Aramco Inspection Checklist: Review Procedure - Field Applied Internal Coatings & Repairs SAIC-H-2057Allan LindoNo ratings yet

- Hempadur Mastic 45880-45881Document3 pagesHempadur Mastic 45880-45881David HoffmanNo ratings yet

- Saudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbUzair AhmadNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Tes H 107 02 R0 PDFDocument31 pagesTes H 107 02 R0 PDFUmair QayyumNo ratings yet

- Hempel Curing Agent 98021 MsdsDocument10 pagesHempel Curing Agent 98021 MsdsM.FAIZAN ARSHADNo ratings yet

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeAbu Anas M.SalaheldinNo ratings yet

- AS 3894-5 Method 5 Surface-ProfileDocument6 pagesAS 3894-5 Method 5 Surface-Profilejonathan nachiroNo ratings yet

- P8AHEM4800Document14 pagesP8AHEM4800MarcoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)Document4 pagesSaudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)nadeem shaikhNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- 167ACT01-0000-PA-GS-0169 - 0 PaintingDocument21 pages167ACT01-0000-PA-GS-0169 - 0 PaintingSutiknoNo ratings yet

- 09 SAMSS 089 (Final Draft - 2018)Document28 pages09 SAMSS 089 (Final Draft - 2018)lhanx2No ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Document12 pagesSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNo ratings yet

- Epilux 219: Product DescriptionDocument2 pagesEpilux 219: Product DescriptionMoin AltafNo ratings yet

- DWST-MTHL-QP007 Painting ProcedureDocument31 pagesDWST-MTHL-QP007 Painting ProcedureDeepak UpadhayayNo ratings yet

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDocument2 pagesHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerNo ratings yet

- KOC-P-004 Part 4Document38 pagesKOC-P-004 Part 4Hari KrishnanNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- PDS Technofoam PT 01 - HFC-1Document2 pagesPDS Technofoam PT 01 - HFC-1Ahmed Fouda100% (1)

- Gen 00 104265 Qa 6050 00514 0000 03 PDFDocument11 pagesGen 00 104265 Qa 6050 00514 0000 03 PDFchandana kumarNo ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Hempel Apcs113aDocument6 pagesHempel Apcs113aNoman AhmedNo ratings yet

- Saes H 101VDocument83 pagesSaes H 101Vacolombel100% (2)

- Sigma 1DDocument8 pagesSigma 1Dyogeshkumar121998No ratings yet

- Carpentry and Joinery Material Prices in Addis AbabaDocument2 pagesCarpentry and Joinery Material Prices in Addis AbabaAmos KormeNo ratings yet

- Computation Sheet For BuildingDocument27 pagesComputation Sheet For BuildingNiko ChavezNo ratings yet

- RVT Tower Packings 150319Document8 pagesRVT Tower Packings 150319Adriana HernandezNo ratings yet

- OSMI Orientation To Valves Part 1 Forging Vs Castings Ste1Document30 pagesOSMI Orientation To Valves Part 1 Forging Vs Castings Ste1MeoNo ratings yet

- Garmy BrochureDocument36 pagesGarmy Brochuremagmuthu.98No ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDocument4 pages147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNo ratings yet

- Anite WorkDocument4 pagesAnite WorkShenbagaraja PandianNo ratings yet

- High-Carbon Anti-Friction Bearing Steel: Standard Specification ForDocument4 pagesHigh-Carbon Anti-Friction Bearing Steel: Standard Specification Forsharon blushteinNo ratings yet

- PVC Vs Polyurethane A Tubing ComparisonDocument8 pagesPVC Vs Polyurethane A Tubing ComparisonAdnan SheikhNo ratings yet

- SAE J1392-2001 Stabilized 2017Document10 pagesSAE J1392-2001 Stabilized 2017ALEX MURPHYNo ratings yet

- INSEE EXTRA Product DescriptionDocument2 pagesINSEE EXTRA Product DescriptionYasndra AbeygunewardhaneNo ratings yet

- GSR (ROAD) 2015Document74 pagesGSR (ROAD) 2015Gautam RaiNo ratings yet

- Chapter 6 MORTAR (Compatibility Mode) PDFDocument14 pagesChapter 6 MORTAR (Compatibility Mode) PDFBerhanu Mengstu AlemayohNo ratings yet

- Interpretation: VIII-79-02Document1 pageInterpretation: VIII-79-02rtrajan_mech5408No ratings yet

- Techn Data PCM SmartBoard EDocument2 pagesTechn Data PCM SmartBoard EnandoprietoNo ratings yet

- Tube Steel E235Document2 pagesTube Steel E235Noe Eulalio Torres PadillaNo ratings yet

- PIP 1 - Guide To Specifying Pervious ConcreteDocument4 pagesPIP 1 - Guide To Specifying Pervious ConcretemirzaNo ratings yet

- S 1300 Pene Krete Product Data 347250Document3 pagesS 1300 Pene Krete Product Data 347250uocmogiandi_aNo ratings yet

- Bosch Dishwasher SHV46C13-SHX43CiiDocument50 pagesBosch Dishwasher SHV46C13-SHX43CiijmcaeroNo ratings yet

- 3 BQDocument322 pages3 BQJia Jin100% (1)

- 09 20 00 Gypsum Board Etc Ceiling PDFDocument8 pages09 20 00 Gypsum Board Etc Ceiling PDFKiran D AnvekarNo ratings yet

- Gerardo A. Pesigan: Work ExperienceDocument1 pageGerardo A. Pesigan: Work ExperienceKhalied NoynayNo ratings yet

- Electroplating: Table of Conten TsDocument4 pagesElectroplating: Table of Conten TsKhaledEl-MaghallawyNo ratings yet

- 4G70mm N2XBY Type Test ReportDocument1 page4G70mm N2XBY Type Test ReportB JoldzicNo ratings yet

- April 2014: Kumar Neeraj JhaDocument35 pagesApril 2014: Kumar Neeraj JhaNavarang R KobbeNo ratings yet